Composite polyamide material for large-thickness-tolerance precision injection molded part and injection molding method

A composite material and polyamide technology, applied in the coating and other directions, can solve the problems of warpage deformation, shrinkage rate difference, etc., and achieve the effect of reducing the shrinkage of the part, reducing the grain size and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

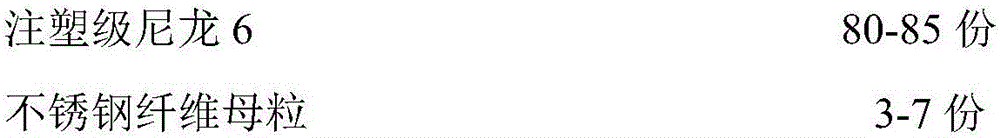

[0029] A kind of polyamide compound material that is used for precision injection molded parts with large thickness difference of the present invention, it is made up of the raw material of following weight part:

[0030]

[0031] Among them, the stainless steel fiber masterbatch is the stainless steel fiber masterbatch of Beijing Jinfubang Fiber Technology Co., Ltd.; the talc powder has a particle size of 1500 mesh; the dendritic rheology modifier is a polymer of 1-3 generations Amidoamine dendrimers; the anti-shrinkage agent is a commercially available plastic inorganic anti-shrinkage agent of Zhangjiagang Younuo Chemical Co., Ltd.

[0032] The polyamide composite is prepared as follows:

[0033] Step 1, prepare materials according to the ratio of raw materials

[0034] Step 2, put the materials prepared in step 1 into a high-speed mixer, stir evenly at a high speed, and discharge the materials at 45°C for later use.

[0035] Step 3, add the spare material into the twin...

Embodiment 2

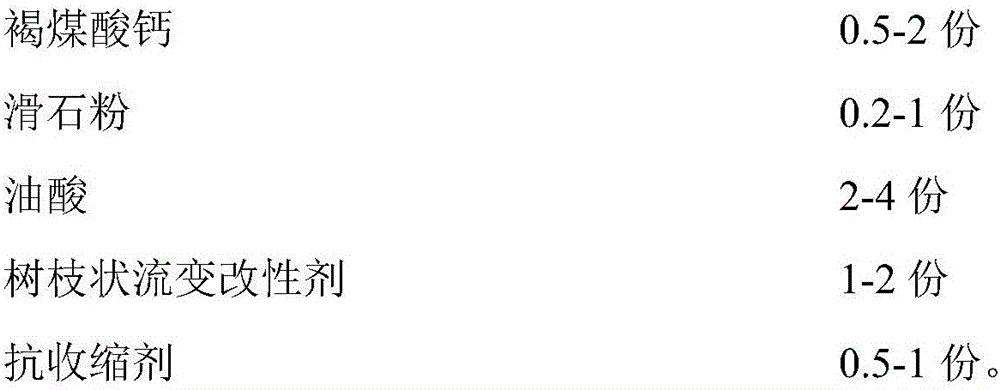

[0045] A kind of polyamide compound material that is used for precision injection molded parts with large thickness difference of the present invention, it is made up of the raw material of following weight part:

[0046]

[0047] Among them, the stainless steel fiber masterbatch is the stainless steel fiber masterbatch of Beijing Jinfubang Fiber Technology Co., Ltd.; the talc powder has a particle size of 1500 mesh; the dendritic rheology modifier is a polymer of 1-3 generations Amidoamine dendrimers; the anti-shrinkage agent is a commercially available plastic inorganic anti-shrinkage agent of Zhangjiagang Younuo Chemical Co., Ltd.

[0048] The preparation method of the polyamide composite material is the same as in Example 1, and the same method as in Example 1 is used to make precision injection molded parts with large thickness differences.

Embodiment 3

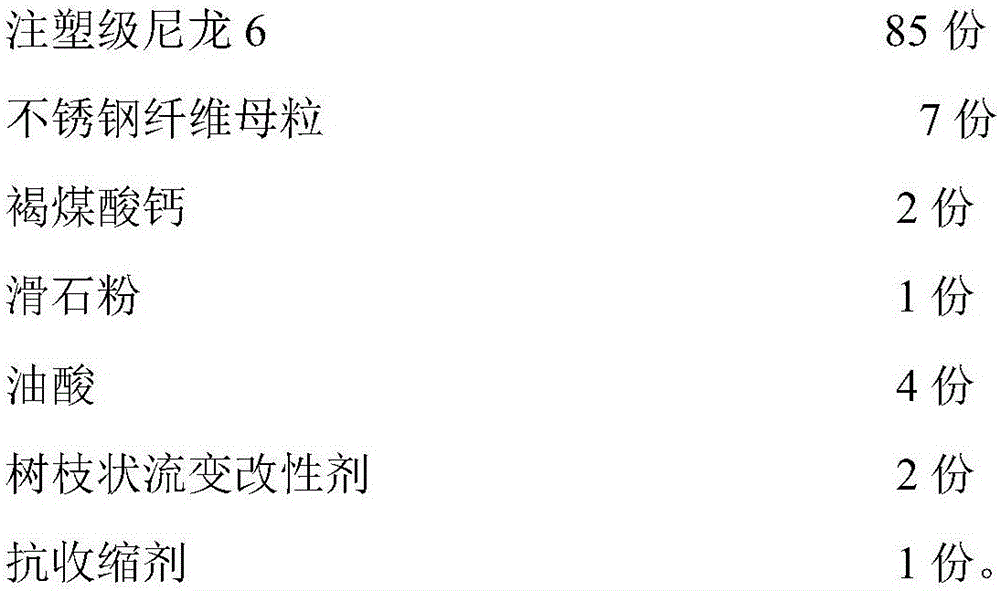

[0050] A kind of polyamide compound material that is used for precision injection molded parts with large thickness difference of the present invention, it is made up of the raw material of following weight part:

[0051]

[0052] Among them, the stainless steel fiber masterbatch is the stainless steel fiber masterbatch of Beijing Jinfubang Fiber Technology Co., Ltd.; the talc powder has a particle size of 1500 mesh; the dendritic rheology modifier is a polymer of 1-3 generations Amidoamine dendrimers; the anti-shrinkage agent is a commercially available plastic inorganic anti-shrinkage agent of Zhangjiagang Younuo Chemical Co., Ltd.

[0053] The preparation method of the polyamide composite material is the same as in Example 1, and the same method as in Example 1 is used to make precision injection molded parts with large thickness differences.

[0054] The precision injection molded parts with large thickness difference made in the above three embodiments use the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com