Method for preparing K418 nickel-based high temperature alloy charging turbine based on selective laser melting forming technology

A laser selective melting, nickel-based superalloy technology, applied in turbines, mechanical equipment, additive manufacturing, etc., can solve problems such as high cost, long cycle, and many defects, achieve rapid development and verification, avoid parts defects, and guarantee products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

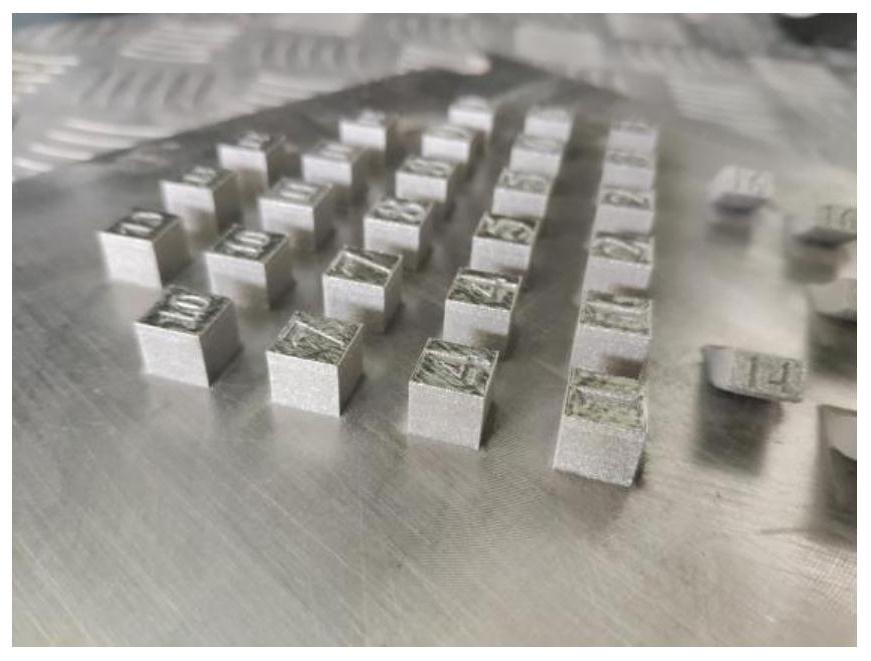

[0027] 1. Select the spherical K418 nickel-based superalloy powder with good powder fluidity and chemical composition that meets the requirements of the national standard as the raw material for laser selective melting and forming. Its specific composition is C: 0.08~0.16wt%, Cr: 11.50~13.50wt%, Mo: 3.8~4.80wt%, Al: 5.50~6.40wt%, Ti: 0.50~1.00wt%, Fe≤1.00wt%, Nb: 1.80~2.50wt%, B: 0.008~0.020wt%, Zr: 0.060~0.150wt%, Mn≤0.50wt%, Si≤0.50wt%, P≤0.015wt%, S≤0.010wt% and the balance Ni; its particle size distribution is: D10 is 24.57μm, D50 is 36.27μm, D90 is 49.22μm, which meets the requirements of laser selective melting powder particle size distribution; its bulk density is 4.47g / cm 3 , the tap density is 5.12g / cm 3 .

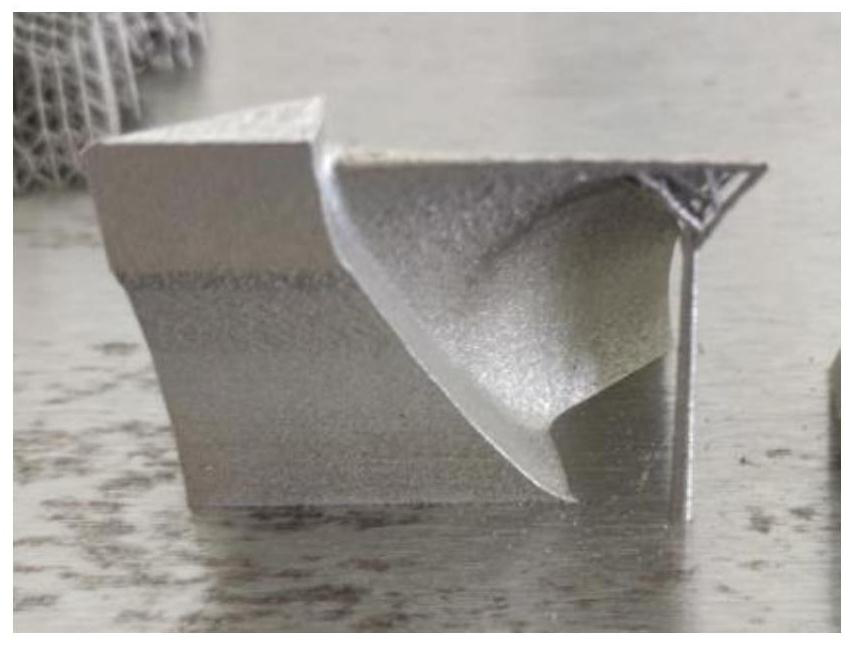

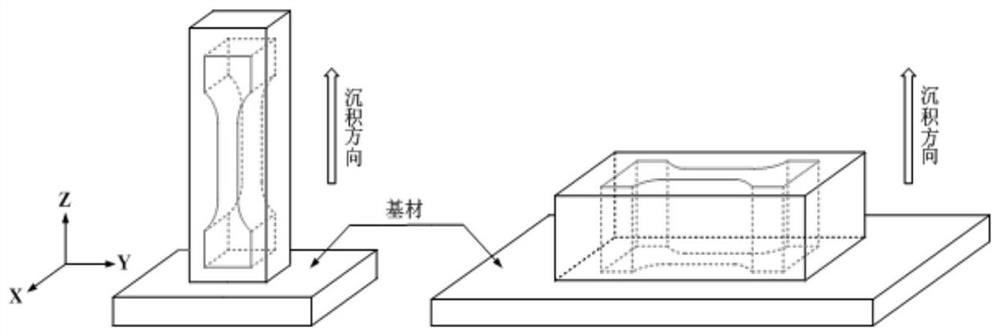

[0028] 2. Construct the model of the K418 turbocharger, import the turbocharger STL parts to the Magics RP interface, check and repair various model errors in the STL file, establish the FS271M virtual printing platform, place the parts, and design the basic sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com