Refrigeration mechanical diagnostic protection and control device

a technology of mechanical diagnostic and control device, which is applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of loss of lubricating oil, excessive high discharge temperature, and high cost of compressor failure, so as to increase system efficiency, reduce subcooling, and increase subcooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

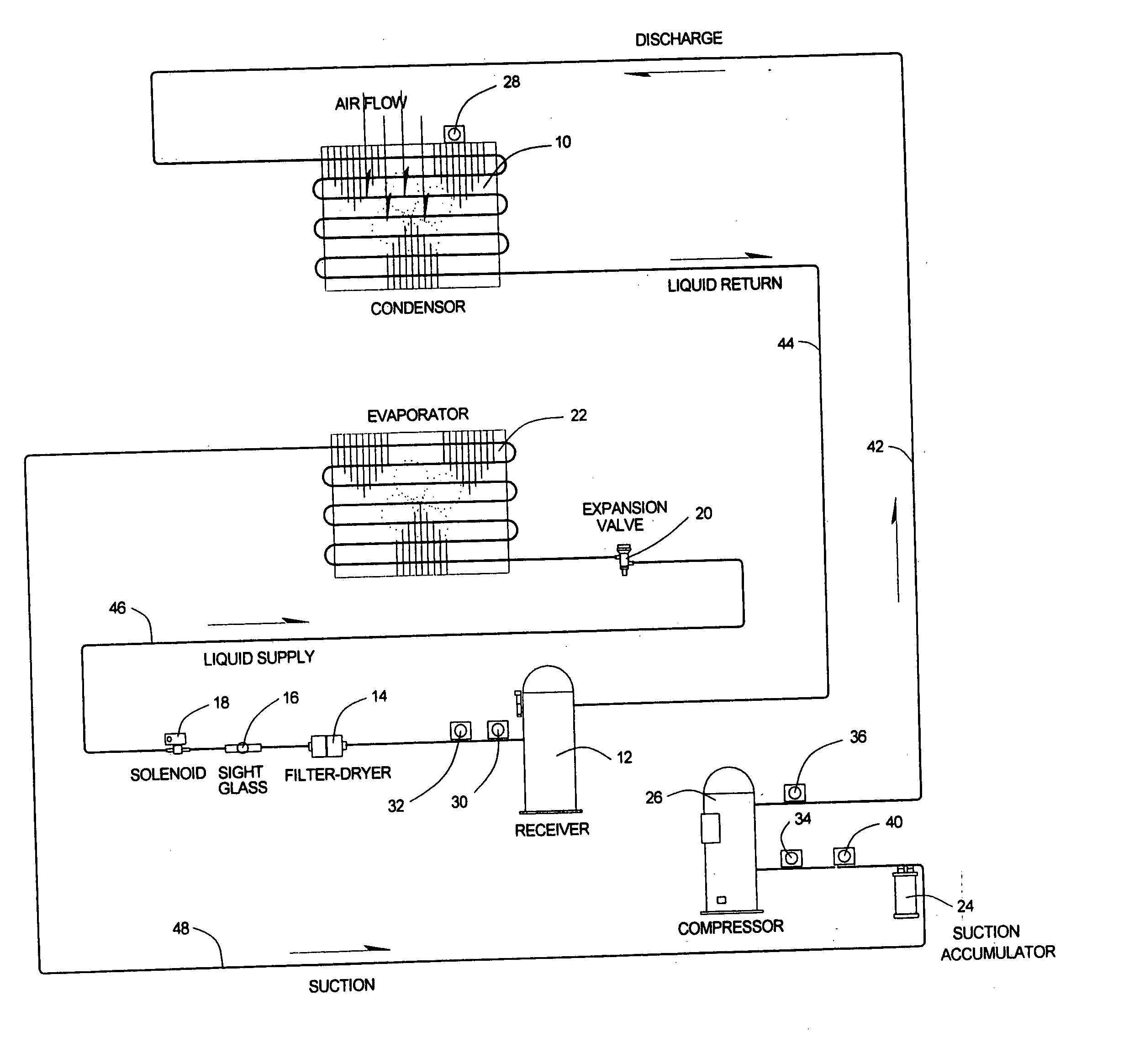

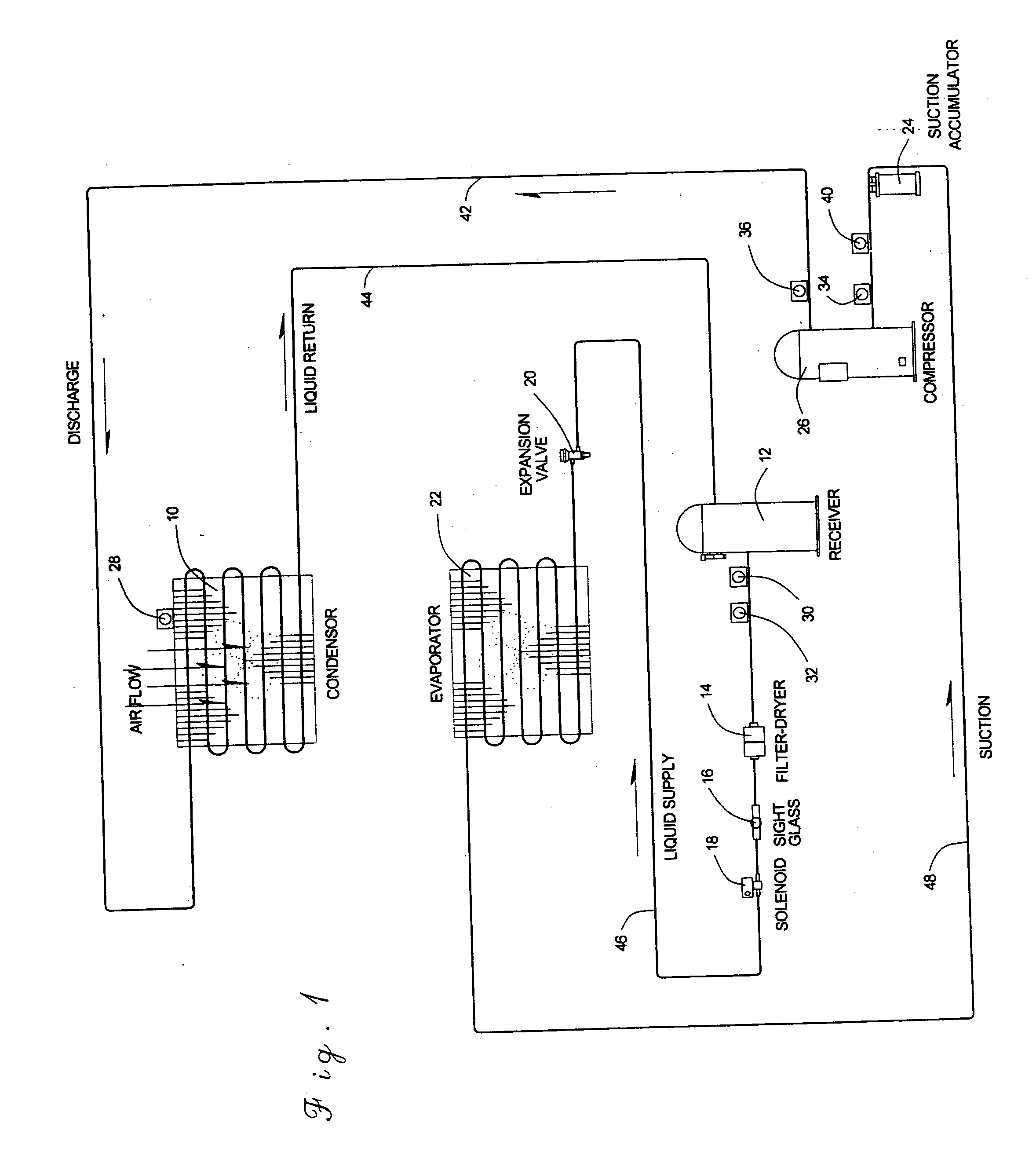

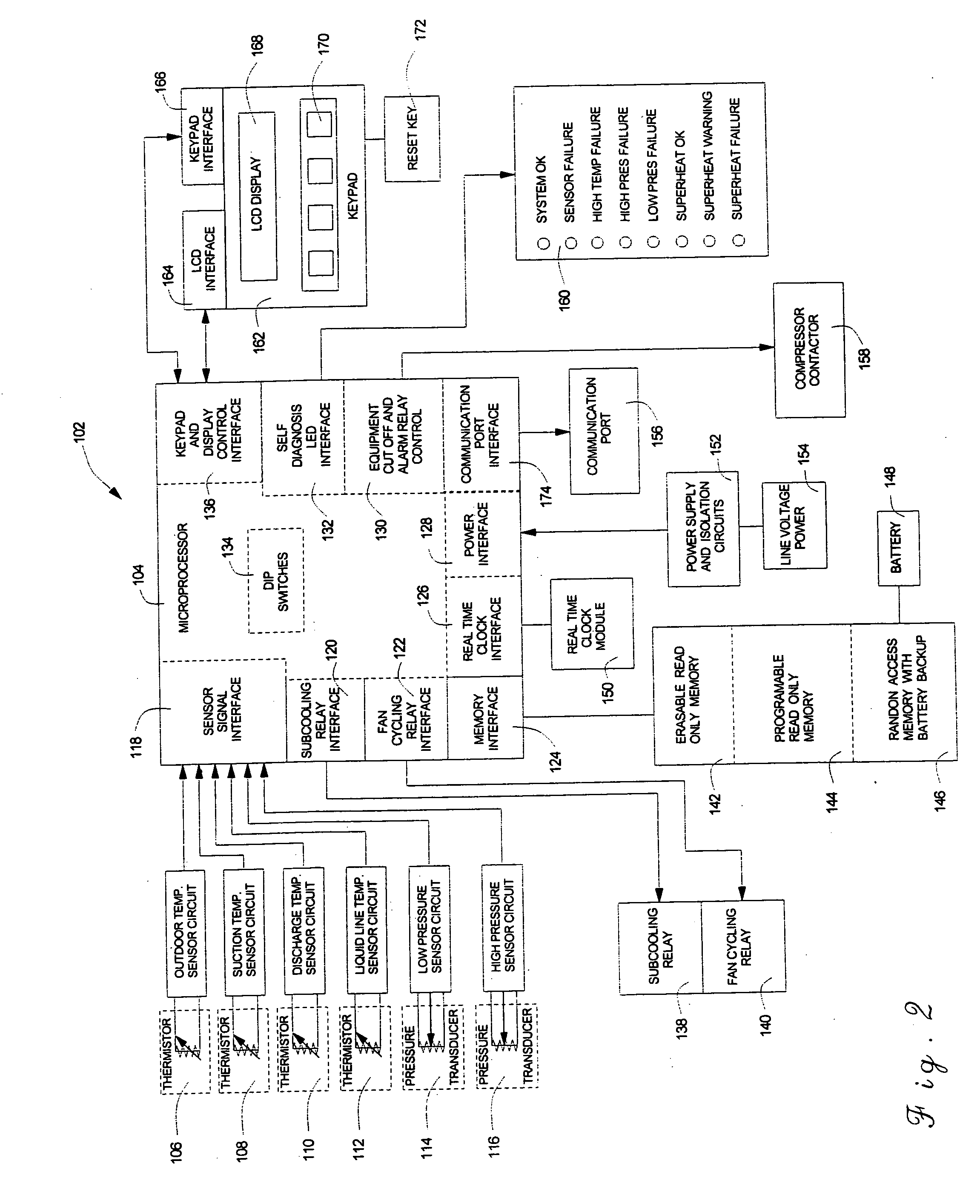

[0035] Referring in more particularity to the drawings, FIG. 1 illustrates a diagram of a standard refrigeration system which includes a compressor 26 driven by an electric motor in a conventional manner. The discharge side of the compressor 26 connects with a discharge line 42 which delivers the compressed refrigerant in a gaseous state to a condenser 10 or in some systems multiple condensers. Near the outlet of the compressor 26 a discharge temperature sensor 36 is connected with the discharge line 42. The gaseous refrigerant condenses into a liquid state in the condenser 10. Located at the inlet air side of the condenser 10 is an outdoor temperature sensor 28.

[0036] Exiting the condenser 10, the liquid refrigerant travels in the liquid line 44 to a receiver 12 which stores excess refrigerant during low load conditions.

[0037] Exiting the receiver 12 the refrigerant travels through the liquid line 46. Located on the supply line 46 near the exit of the receiver 12 are a high press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com