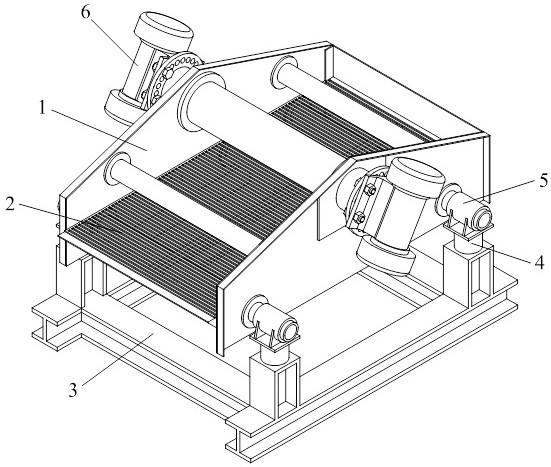

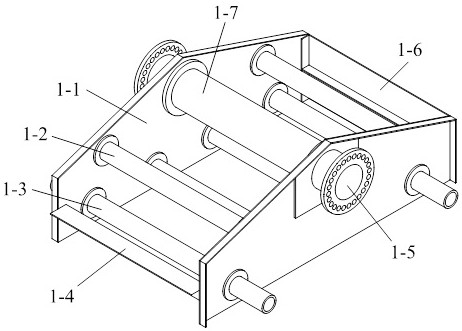

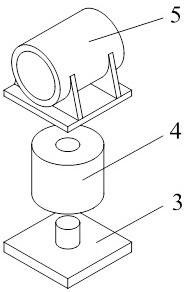

Linear vibrating screen with adjustable amplitude and vibration direction angle

A technology of linear vibrating sieve and vibration direction, which is applied to chemical instruments and methods, sieves, solid separation, etc. It can solve the problems of fixed amplitude and vibration direction angle, does not consider multiple working conditions, and increases production costs. The effects of small fluctuations in the over-resonance area, large adjustable range, and simple installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The application will be further described below in conjunction with the accompanying drawings. It should be noted that the orientation nouns that may be involved in the following paragraphs include but are not limited to "up, down, left, right, front, back", etc., and the orientations on which they are based They are all visual orientations shown in the accompanying drawings of the description, which should not and should not be regarded as limiting the scope of protection of the technical solution, and its purpose is only to facilitate those skilled in the art to better understand the description described in the description. technical solutions.

[0020] In the descriptions of the following paragraphs, unless otherwise clearly specified and limited, the terms "installation", "connection", "connection" and other similar expressions should be interpreted in a broad sense, for example, it can be a fixed connection or a detachable connection, Or integrally connected; it m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com