Manufacturing method of box dam ceramic substrate for ultraviolet LED packaging and product thereof

A technology of LED packaging and ceramic substrates, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve the problems of detachment of the dam and the ceramic substrate, the difference in expansion coefficient is too large, and the reliability of products is affected. It is convenient for mass production, the production method is simple, and it is conducive to the effect of wide popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

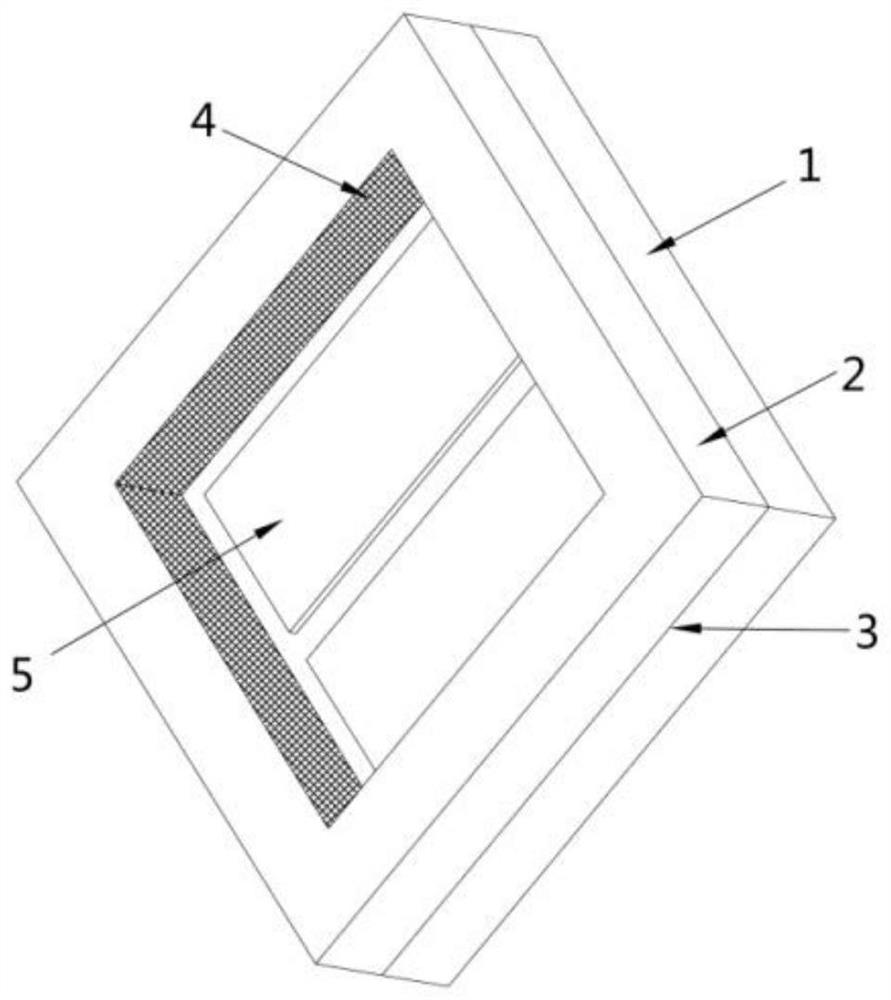

[0029] The present embodiment provides a method for manufacturing a dam ceramic substrate for ultraviolet LED packaging, which includes the following steps:

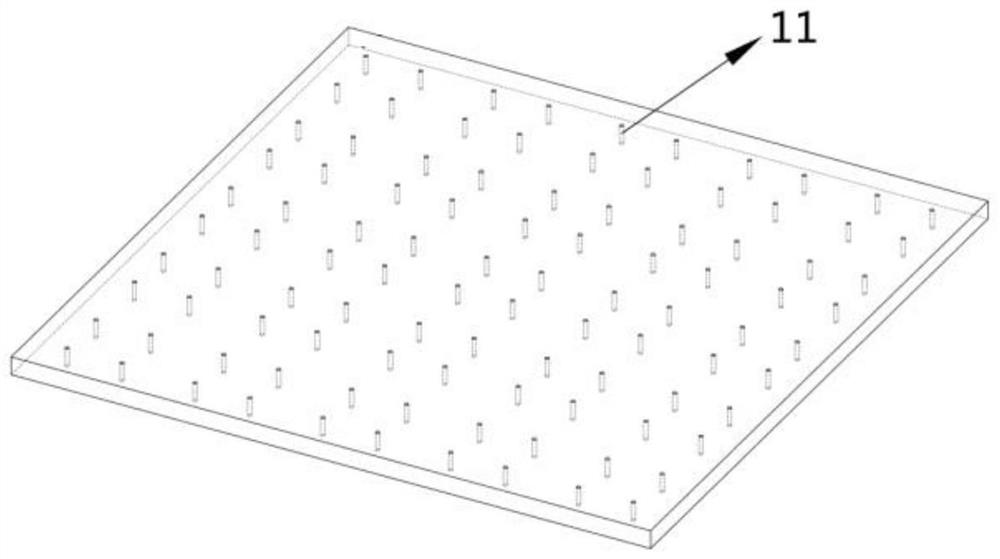

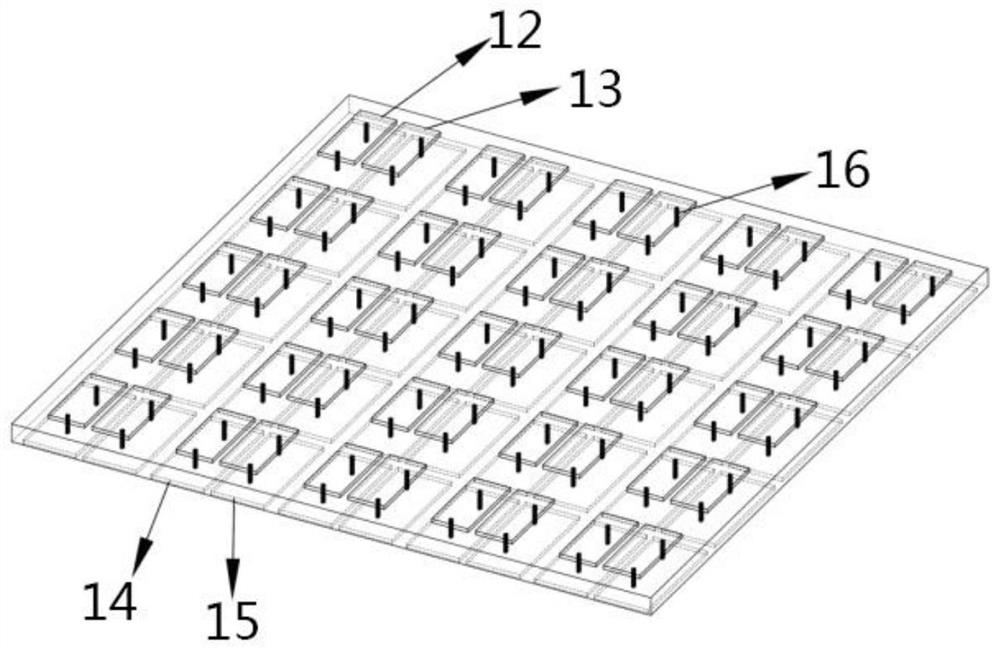

[0030] (1) preparing a ceramic substrate 1; the ceramic substrate 1 is made by a DPC process;

[0031] (2) Adopting glass, ceramics, glass ceramics, alumina ceramics or sapphire materials with a light wave transmittance exceeding 50% as the dam 2, the wavelength of the light wave being 700-12000nm;

[0032] (3) The dam 2 is placed on the ceramic substrate 1, and the contact surface 3 between the ceramic substrate 1 and the dam 2 is locally heated by a laser beam to form reliable welding; the laser beam operates at an average power greater than 3W. Lasers can be operated at any frequency and can be operated in quasi-continuous or continuous mode. In the discontinuous operation mode of the laser, the pulse width is 0.001~100ms;

[0033] (4) Obtain a dam ceramic substrate product used for ultraviolet LED packaging after c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com