Reflecting coating of double-glass assembly and preparation method of reflecting coating

A technology for component reflection and coating, applied in coating, photovoltaic power generation, etc., can solve the problem of low titanium dioxide content, and achieve the effects of good chemical stability, reduced production cost, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

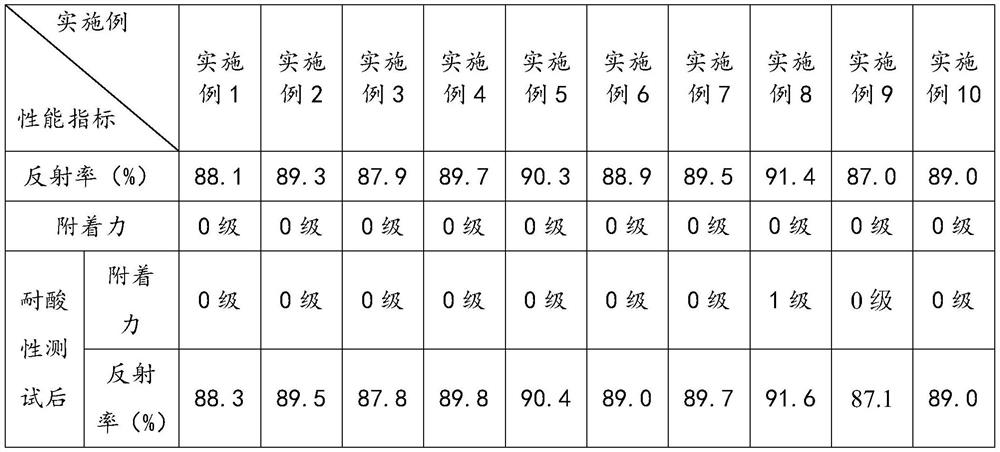

Examples

Embodiment

[0031] Embodiment: A composite reflective coating for a double-glass component, including a double-coating layer, the bottom layer is a high-content titanium dioxide layer, and the outer layer is a transparent glass glaze layer. The total thickness of the composite reflective coating is 33-45um, wherein the thickness of the bottom layer is 18-25um, and the thickness of the outer layer is 15-20um. The composition of the high-content titanium dioxide layer of the bottom layer includes mixed material and ink, and the mixed material includes 65-80 wt% of nano titanium dioxide and 20-35 wt% of basic glass glaze. The crystal form composition of nano titanium dioxide is 10-50wt% anatase crystal form, 50-90wt% rutile crystal form, and the average particle diameter of nano titanium dioxide is 50-500nm.

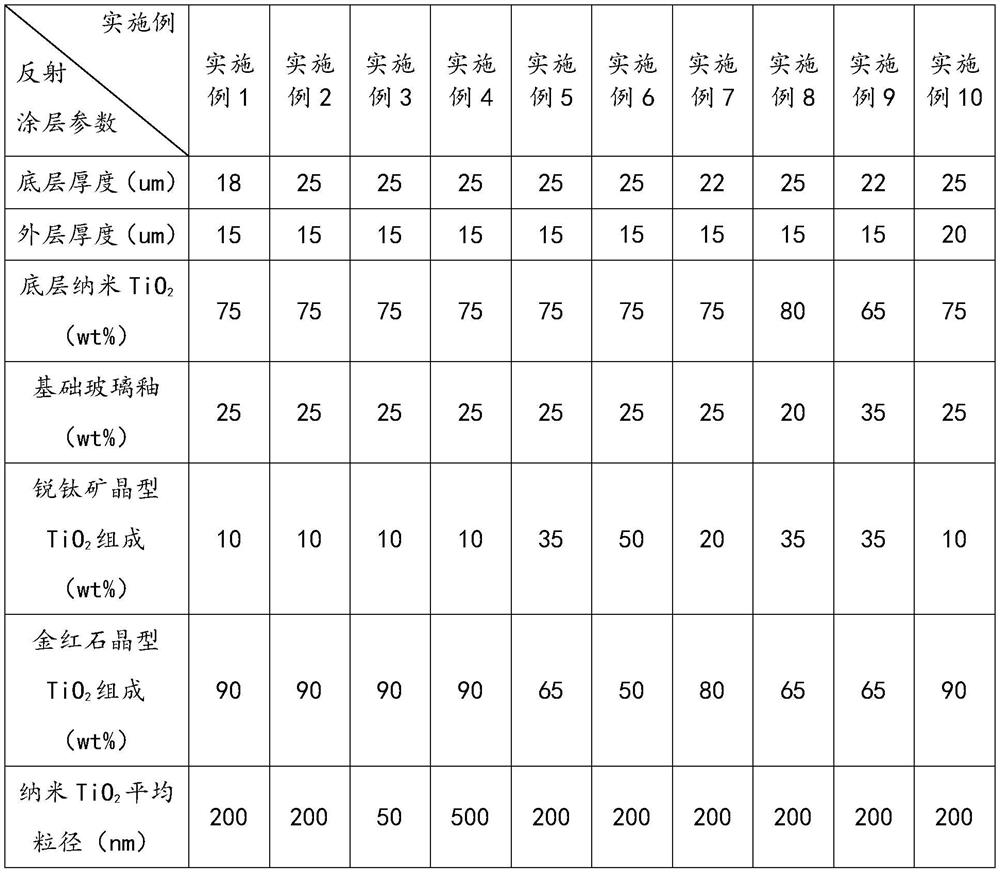

[0032] The present invention provides the compound reflective coating of 10 routine components, specifically as table 1:

[0033] Table 1

[0034]

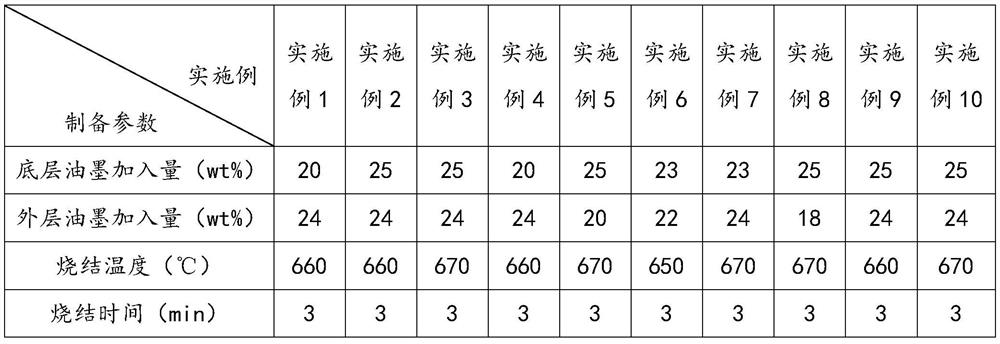

[0035] The preparation method ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com