Matt black glaze and sanitary ware and preparation method and application thereof

A technology of sanitary ware and black glaze, applied in the field of sanitary ware and its preparation, matte black glaze, to achieve the effect of good combination and matching expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of matte black glaze, used for the matte black glaze of any of the above-mentioned embodiments, is characterized in that, comprises the following steps:

[0038] Put lithium petalite, fused quartz, halloysite, calcined talc, barium carbonate, calcined zinc oxide, zirconium silicate, dolomite and calcite into the ball mill according to the proportion, add water and ball milling agent, and ball mill until the residue on the 325 mesh sieve is less than 0.05% Finally, add high-cobalt black pigment and continue ball milling, out of the ball, adjust the specific gravity to 1.60-1.90, and sieve to obtain matte black glaze.

[0039] A matte black sanitary ware, the surface of the sanitary ware is provided with a matte black glaze layer; the glaze layer is fired from the above matte black glaze.

[0040]General sanitary ware is mainly made of ceramics, glass fiber reinforced plastics, plastics, artificial marble (agate), stainless steel and other materials. ...

Embodiment A1

[0055] Preparation method of matte black glaze:

[0056] 1) Matte black glaze, its specific addition is shown in Table 1. Among them, the content of petalite K 2 O is 0.3%, Na 2 O content is 0.2%, SiO of fused silica 2 The aluminum content of halloysite is 99.5%, and the aluminum content of halloysite is 37.2%. The high-cobalt black pigment is fired at 1300°C, and the composition is CoO 30%, NiO 15%, Fe 2 o 3 40%, Cr 2 o 3 15%, and its 325-mesh sieve is 0%. Put all the raw materials except the high-cobalt black pigment into the ball mill according to the ratio, add water and 0.2% sodium carboxymethyl cellulose of the total amount of materials, and ball mill until the 325-mesh sieve is less than 0.05%, then add high-cobalt black color The material was continued to be ball-milled for 1 hour, the balls were taken out, the specific gravity was adjusted to 1.80, and the matte black glaze was obtained by passing through a 160-mesh sieve.

[0057] 2) On the pre-treated sani...

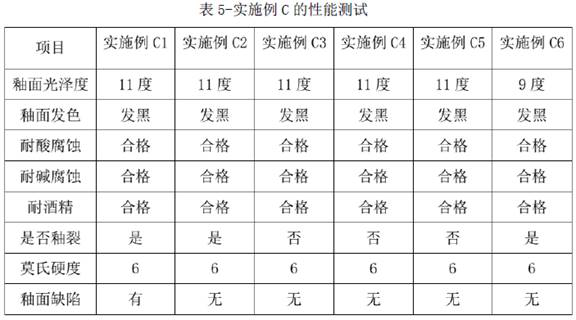

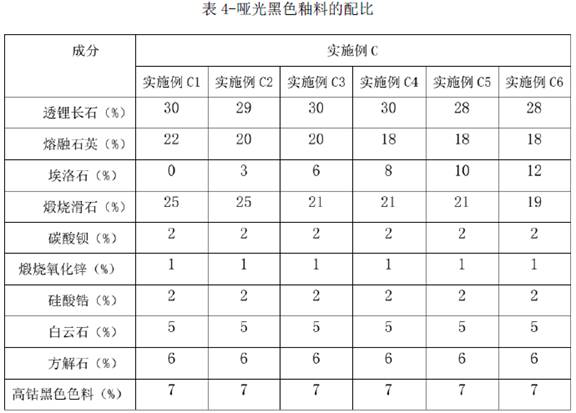

Embodiment B

[0065] Matte black glaze, its composition mass percentage is: Lithium feldspar 30%, fused quartz 20%, halloysite 6%, calcined talc 21%, barium carbonate 2%, calcined zinc oxide 1%, zirconium silicate 2% %, dolomite 5%, calcite 6% and high cobalt black pigment 7%. Among them, the content of petalite K 2 O is 0.3%, Na 2 O content is 0.2%, SiO of fused silica 2 The aluminum content of halloysite is 99.5%, the aluminum content of halloysite is 37.2%, and the high-cobalt black pigment is fired at 1300°C, and the composition is CoO 30%, NiO 15%, Fe 2 o 3 40%, Cr 2 o 3 15%, and its 325-mesh sieve is 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com