High-concentration organic wastewater wet oxidation treatment system and method

A technology of organic wastewater and wet oxidation, applied in the field of water treatment, can solve the problems of difficult to achieve direct discharge of organic wastewater, poor treatment effect of refractory substances, negative impact on the cost of exhaust gas treatment, etc., to reduce the risk of scaling and blockage, Convenient transportation and installation, and the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

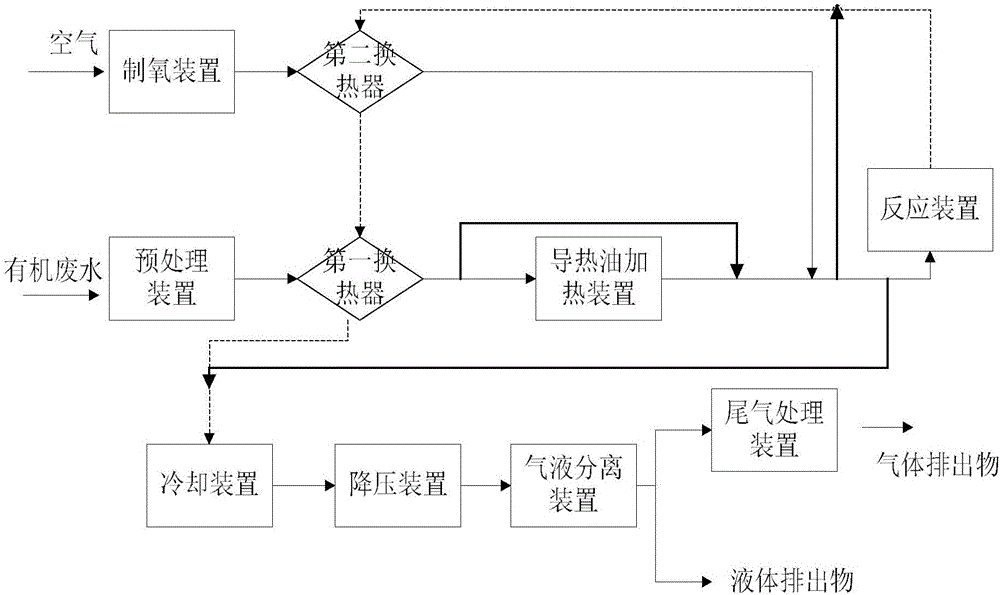

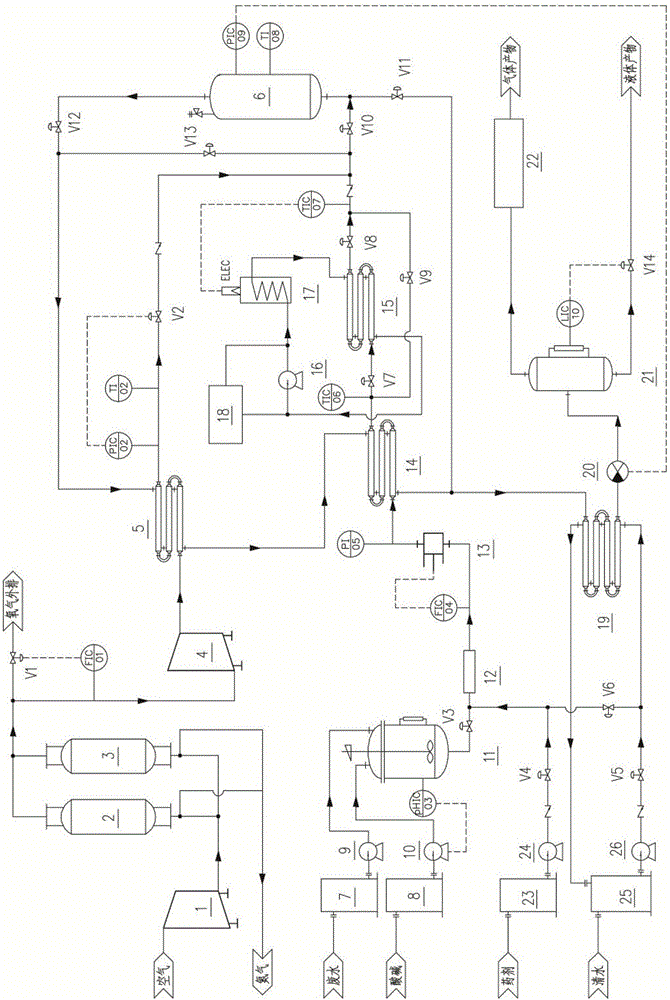

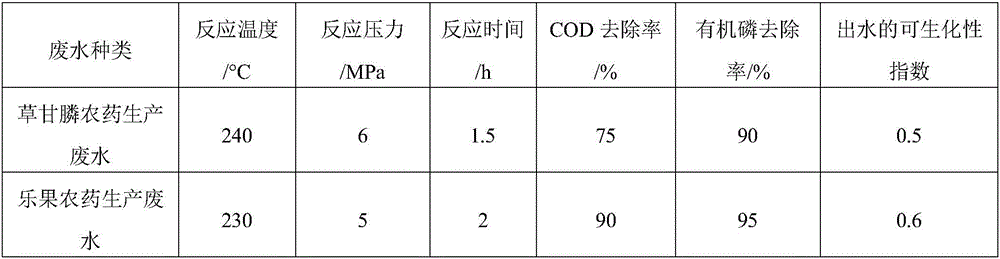

[0040] like figure 1 The shown wet oxidation treatment system for high-concentration organic wastewater includes a pretreatment device, a heat transfer oil heating device and a reaction device 6 connected in sequence through pipelines; A heat exchanger 14 is communicated through the inner pipe of the first heat exchanger 14; the inlet of the reaction device 6 is provided with a bypass for introducing oxygen, which is directly connected to the oxygen generator; the bypass for introducing oxygen is provided with a second heat exchange 5, the inlet of the oxygen generator and the reaction device 6 are communicated through the inner pipe of the second heat exchanger 5; the outlet of the reaction device 6 is connected to the outer pipe of the second heat exchanger 5 and the outer Pipe, cooling device, pressure reducing device 20, gas-liquid separation device 21 and exhaust gas treatment device 22. In addition, a bypass pipeline is provided between the inlet and outlet of the heat-...

Embodiment 2

[0052] Utilize the above-mentioned system to carry out the method for wet oxidation treatment of high-concentration organic wastewater:

[0053] When the system is running:

[0054] 1. The air is pressurized to 0.4-0.8MPa by the air compressor 1, and enters the first PSA oxygen generator tank 2 or the second PSA oxygen generator tank 3; wherein, the PSA oxygen generator tank is used for one use and one for preparation , when one oxygen generator is preparing high-purity oxygen, the other is discharging nitrogen for backup. High-purity oxygen with a purity of more than 90% can be produced through the first PSA oxygen generator 2 or the second PSA oxygen generator 3, and the opening of the valve V1 is automatically adjusted to control the oxygen flow into the system to reach the required set value The high-purity oxygen can be pressurized by the oxygen booster 4 to a reaction pressure of 5-12 MPa, and the pressurized high-purity oxygen enters the inner tube of the second heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com