Corrugated plate beam of single-side contact-free through flow way

A corrugated plate and non-contact technology, applied in the direction of fixed plate conduit components, heat exchange equipment, heat exchanger types, etc., can solve problems such as blockage of flow channels between plates, fouling and corrosion, and eliminate particle blockage and fouling , Solve the problem of clogging and scaling, and solve the problem of particle clogging and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

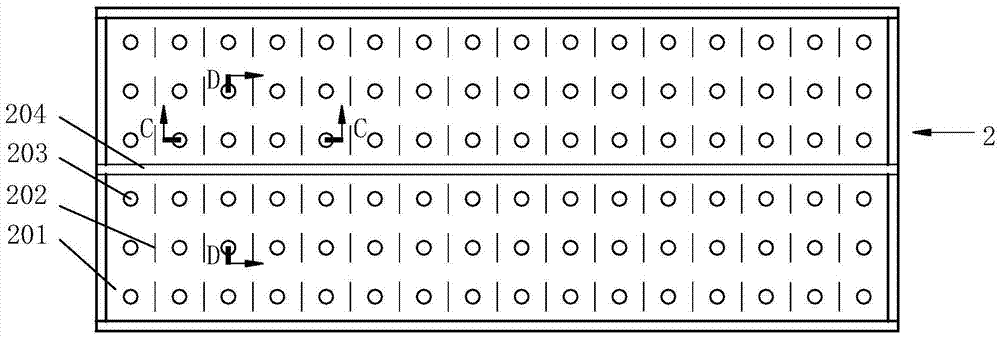

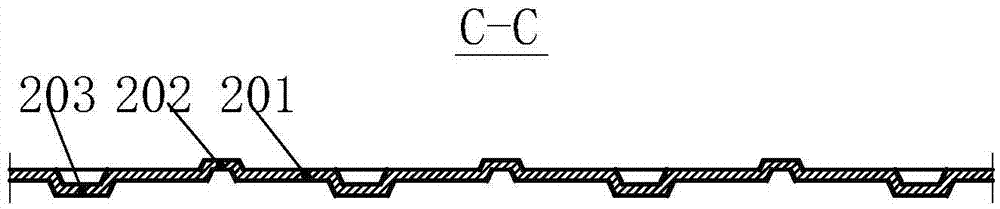

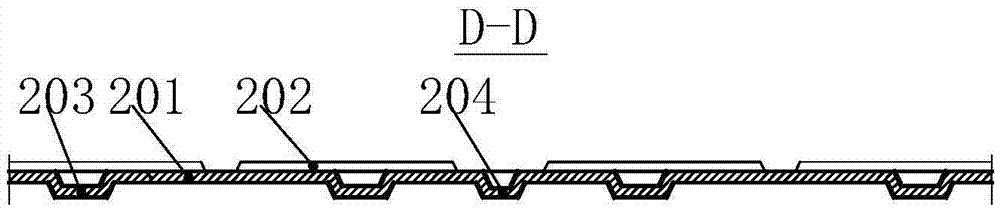

[0036] refer to figure 1 As shown, the plates 2 of the present invention include a main heat transfer surface 201 , flow-disturbing corrugations 202 , pressure-bearing corrugations 203 and split-range corrugations 204 . combine figure 2 and image 3 As shown, the spoiler corrugations 202 are convex corrugations relative to the main heat transfer surface 201 , and the pressure-bearing corrugations 203 and split-range corrugations 204 are concave corrugations relative to the main heat transfer surface.

[0037] refer to Figure 4 As shown, the corrugated plate pair 2 of the present invention is formed by buckling two plates, and the plates can be welded into a plate pair by bending around the plates, or there can be no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com