Efficient heat exchanger and application thereof

A heat exchanger, high-efficiency technology, applied in the direction of indirect heat exchanger, heat exchanger type, heat transfer modification, etc., can solve the problem of low heat exchange efficiency, low resistance, scale prevention, convenient maintenance and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

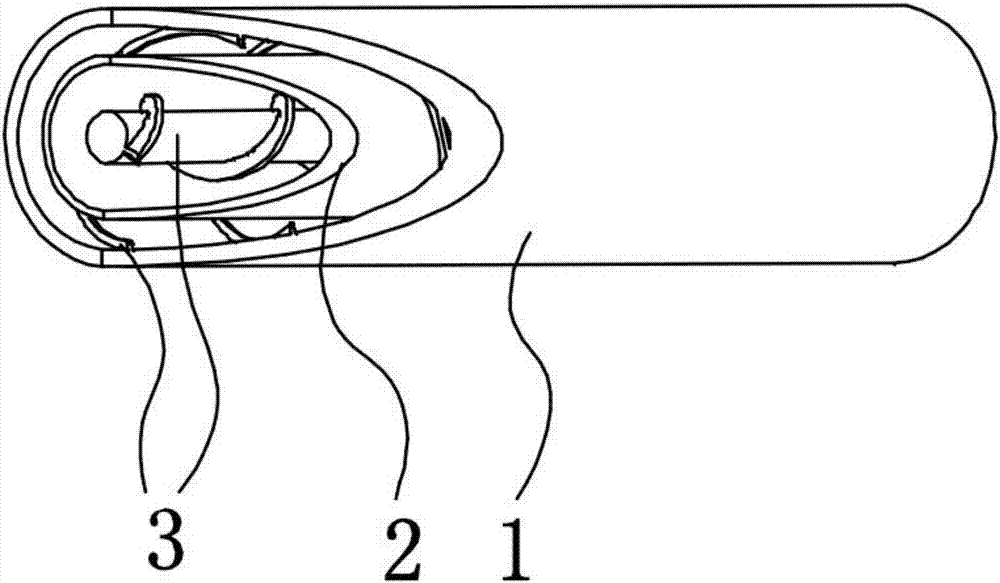

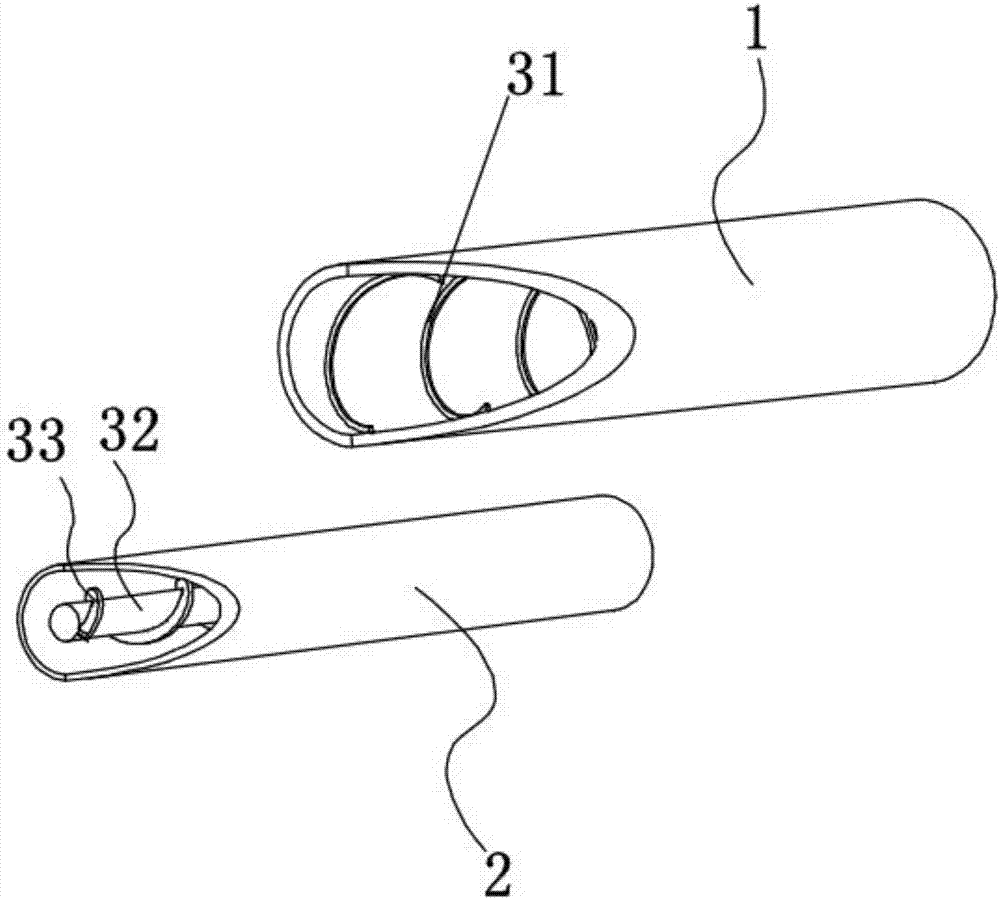

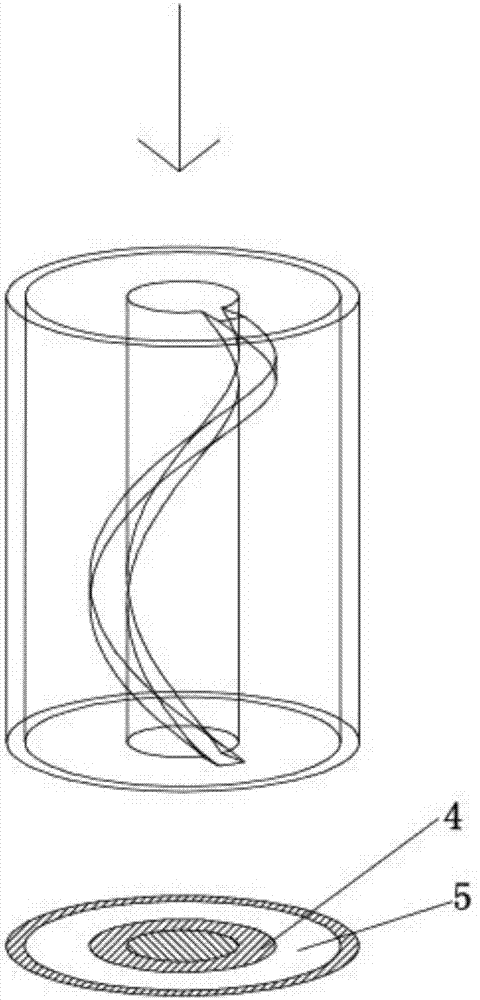

[0059] Such as figure 1 As shown in or 2, the high-efficiency heat exchanger of the present invention includes at least one set of heat exchange components arranged in the heat exchanger, and the heat exchange components include an outer tube 1 and an inner tube 2 arranged inside the outer tube 1, The inner pipe 2 and the inner pipe 2 and the outer pipe 1 are respectively provided with flow passages for the circulation of the medium, and the flow passages are equipped with a swirl field device 3 for causing the medium in the flow passage to generate a swirl flow. In the above-mentioned swirl field device 3, at least one swirl field device 3 generates swirl centrifugal force or swirl centripetal force on the medium in the flow channel directly acts on the heat exchange surface in the flow channel.

[0060] The high-efficiency heat exchanger described therein also includes the same cold and hot fluid inlets and outlets as the traditional heat exchanger, and the necessary auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com