Method for preventing ethylene device gasoline fractionating tower from scale formation and blockage

A technology for an ethylene plant and a fractionation tower is applied in the field of preventing the fouling and clogging of a gasoline fractionating tower of a steam cracking ethylene plant, and can solve the problems of reducing the content or concentration of unsaturated hydrocarbons, fouling and clogging of a gasoline fractionating tower, and not taking into account the large scale and the like. , to achieve the effect of increasing the processing capacity, saving production costs, eliminating scaling and clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

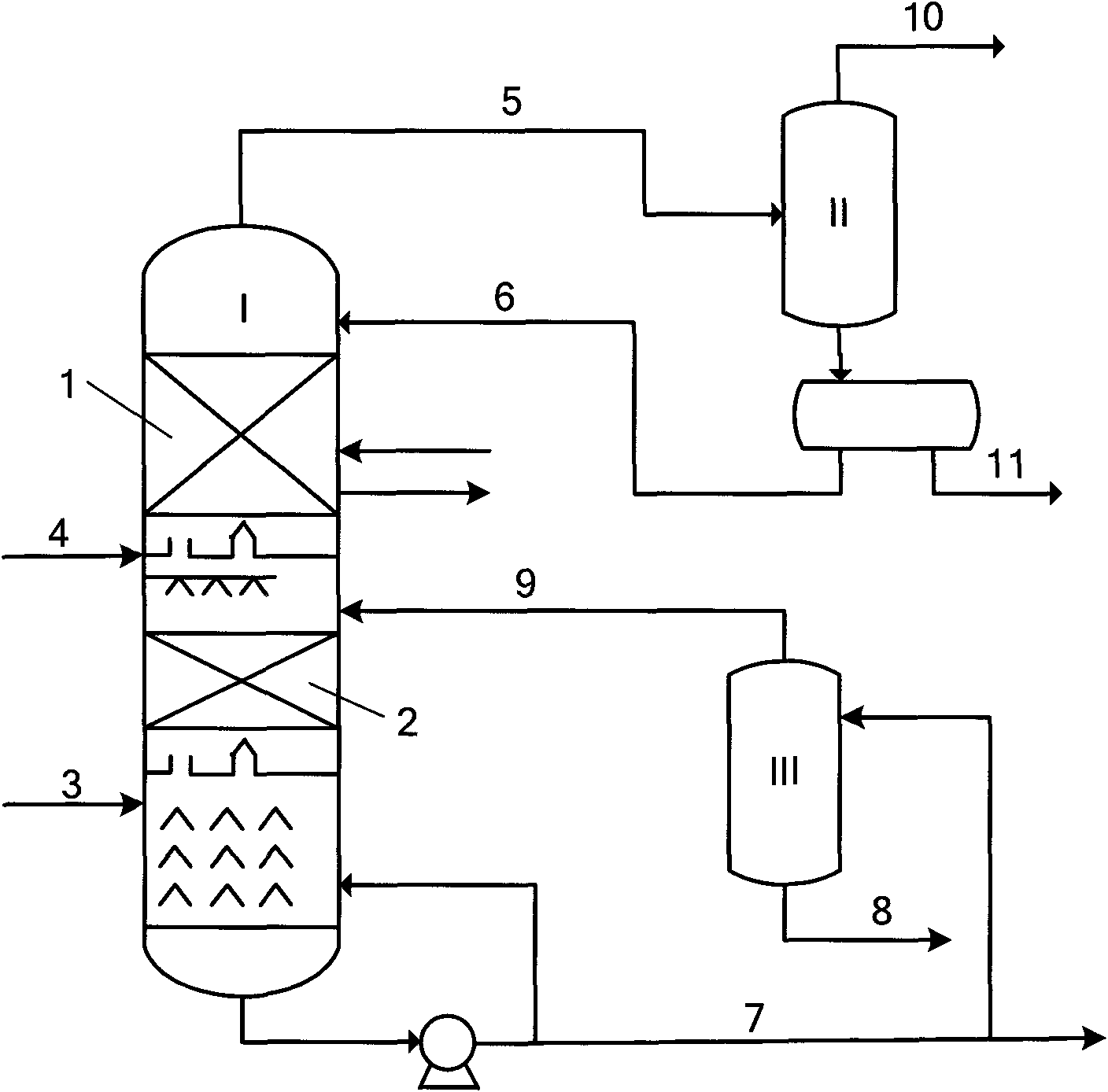

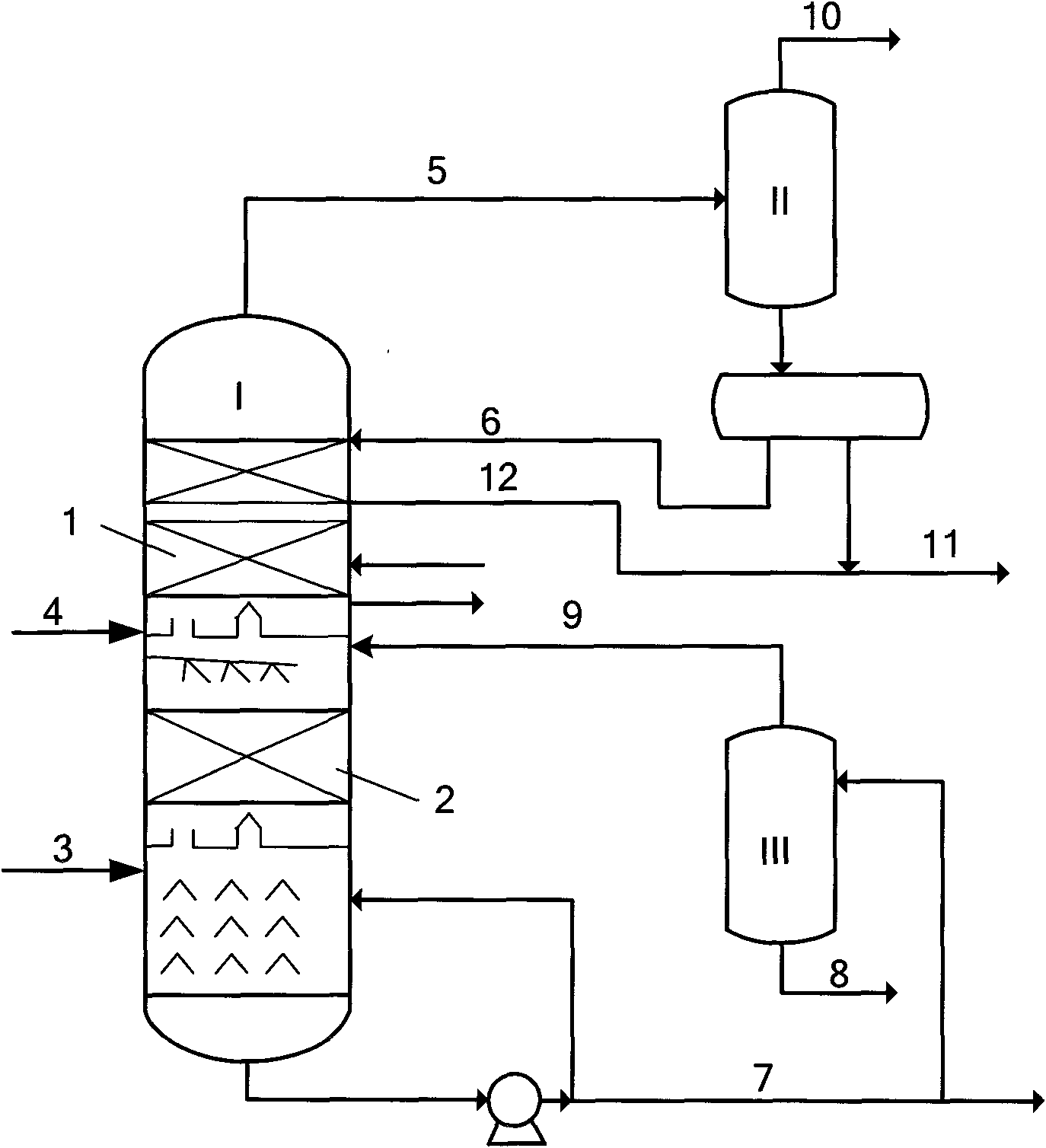

Method used

Image

Examples

Embodiment 1

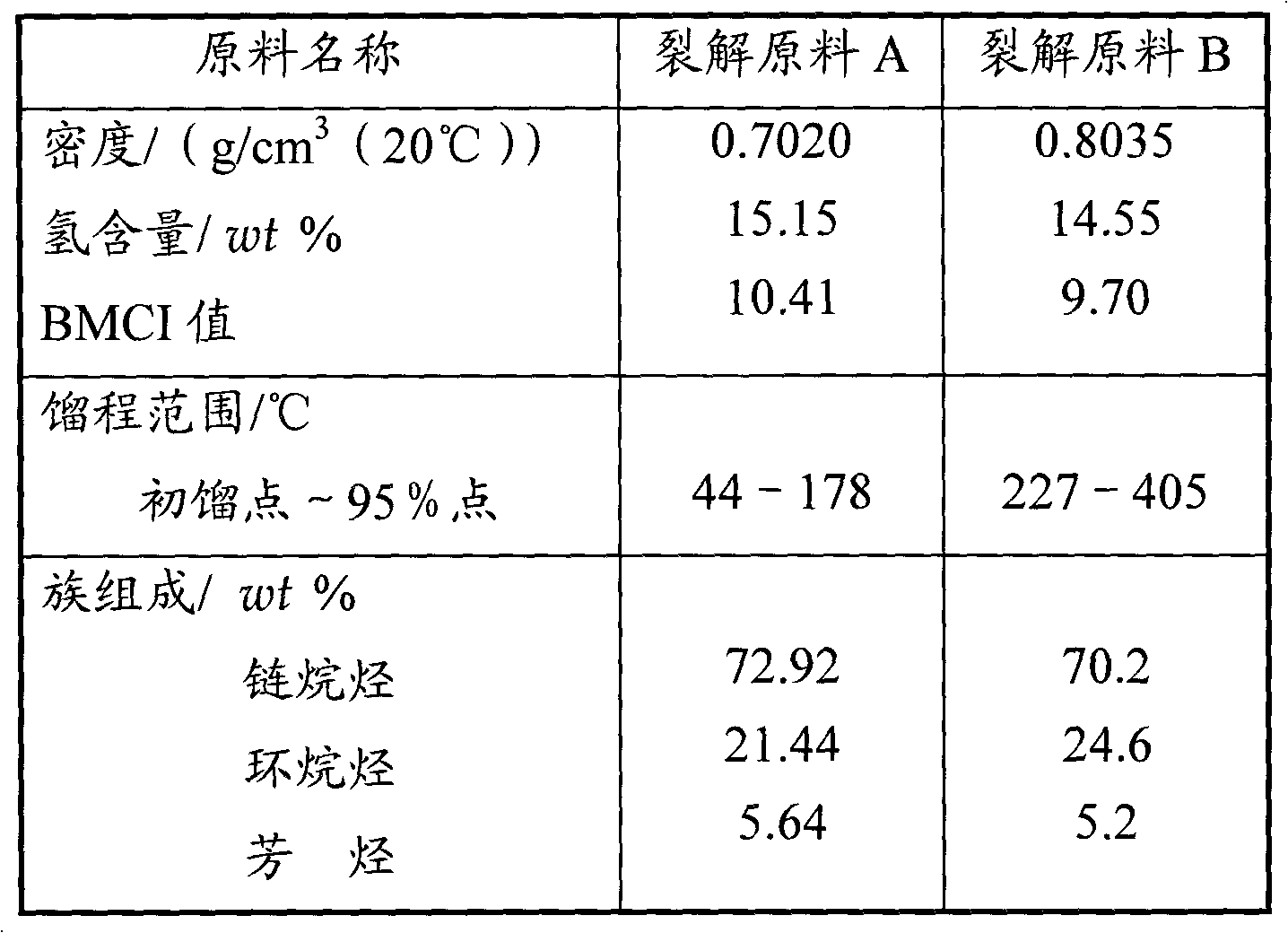

[0028]The test device and method were the same as those in Comparative Example 1. The full-run pyrolysis oil A was used alone as the feed to the simulated pyrolysis gasoline fractionator test device, and the pyrolysis gasoline distillation test was carried out under the operating conditions of the simulated gasoline fractionator to investigate the fouling of the packing in the tower. The difference is that the heavy fraction of pyrolysis gasoline is drawn out in the middle section of the fractionating tower, and the cut point is controlled at 130°C. Other operating conditions are as follows: distillation tower bottom temperature is 250°C, fractionation tower top temperature is 120°C, reflux ratio is 1:1.5, and the range of tower top reflux pyrolysis gasoline fraction is 48°C-130°C. After 96 hours of distillation test, use N 2 Carry out purging fractionation tower, take out the packing in fractionation tower and carry out weighing and analysis, test result is shown in Table 3. ...

Embodiment 2

[0030] The test device and method are the same as those in Comparative Example 1. The full-run pyrolysis oil A is used as the feed material of the simulated pyrolysis gasoline fractionation tower test device alone, and the pyrolysis gasoline distillation test is carried out under the operating conditions of the simulated gasoline fractionation tower to investigate the fouling of the packing in the tower. The same test device and test method as Comparative Example 1. The difference is that the heavy fraction of pyrolysis gasoline is extracted in the middle section of the fractionation tower, and the cut point is controlled at 160°C for distillation. Other operating conditions are as follows: distillation tower bottom temperature is 250°C, fractionation tower top temperature is 120°C, reflux ratio is 1:1, and the range of pyrolysis gasoline fraction refluxed at the top of the tower is 48°C-160°C. After 96 hours of distillation test, use N 2 Carry out purging fractionation tower...

Embodiment 3

[0034] The simulated pyrolysis gasoline fractionation tower test device is the same as that in Comparative Example 1, and the full-cut pyrolysis oil B is used alone as the feed material of the simulated pyrolysis gasoline fractionator test device, and the pyrolysis gasoline distillation test is carried out under the operating conditions of the simulated gasoline fractionator to investigate the fouling of the packing in the tower Situation, test method is the same as comparative example 1, and difference is that the pyrolysis gasoline heavy fraction is extracted in the fractionation tower middle section, and cut point is controlled at 140 ℃, and other operating conditions of distillation are: distillation tower bottom temperature is 250 ℃, fractionation tower top temperature is 120 °C, the reflux ratio is 1:1.6, and the range of the pyrolysis gasoline fraction returned at the top of the tower is 48 °C-140 °C. After 96 hours of distillation test, use N 2 Carry out purging fracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com