Wastewater recycling treatment process

A treatment process and wastewater recycling technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, ion-exchanged water/sewage treatment, etc., can solve problems such as low recovery rate, failure, pollution, etc. The effect of environment, stable operation and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

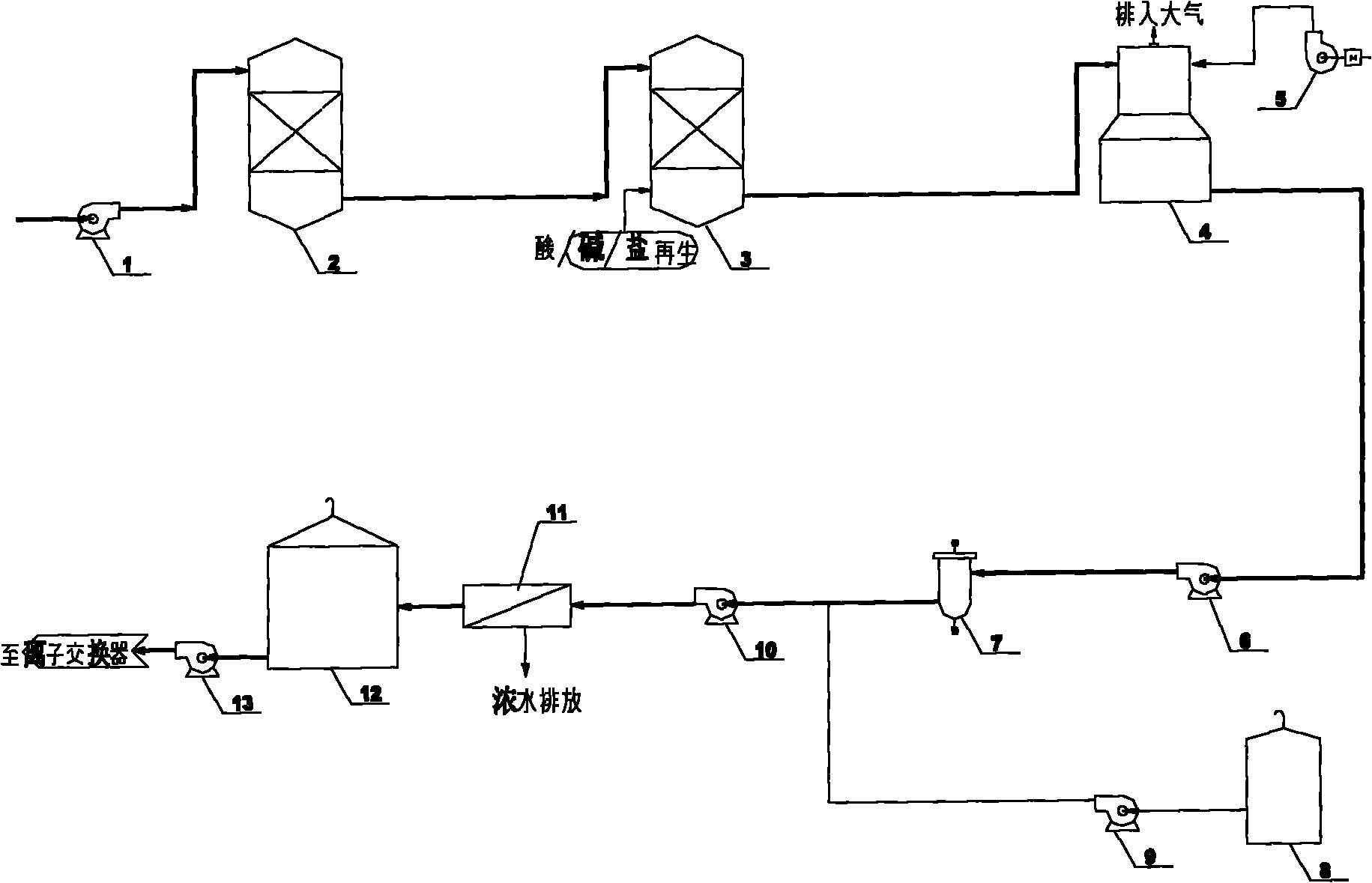

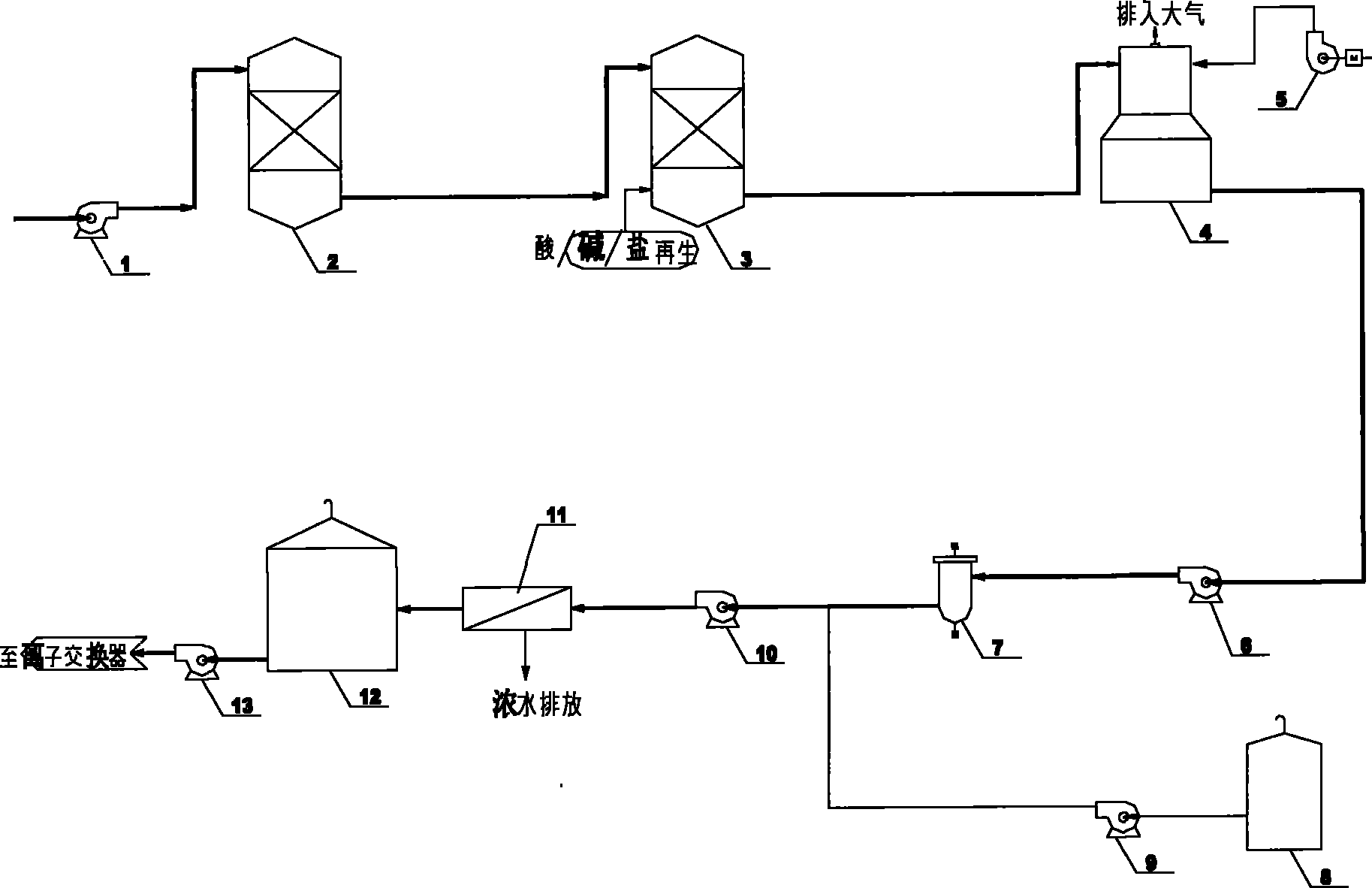

[0023] Such as figure 1 As shown, the raw water enters the filter 2 (which can be a media filter, microfiltration membrane or ultrafiltration membrane) under the action of the raw water pump 1, and the suspended matter and solid particles in the raw water are removed through the filter 2, and the filter The effluent water from 2 enters the ion exchanger 3. The ion exchanger (which can be hydrogen type or sodium-hydrogen series type) removes the calcium and magnesium ions in the raw water through ion exchange to remove the hardness in the water. At this time, the water is acidic and the ion The effluent from the exchanger 3 enters the decarbonization tower 4, and the CO in the raw water is blown off by the rotary fan 5 2 is removed, the alkalinity of the raw water is removed; the raw water from the decarbonization tower 4 enters the precision filter 7 under the action of the lift pump 6, and the precision filter 7 can trap particles larger than 5 microns, and the effluent of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com