Thermal power plant desulfurization wastewater resource utilization system and method with low reagent consumption

A technology for desulfurization wastewater and thermal power plants, which is applied in chemical instruments and methods, separation methods, gaseous effluent wastewater treatment, etc., and can solve problems such as fouling of the back-end membrane concentration system, increase of moisture content of flue gas, and increase of acid dew point , to achieve the effect of reducing resource consumption and environmental pollution, reducing energy consumption of system operation, and realizing concentration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

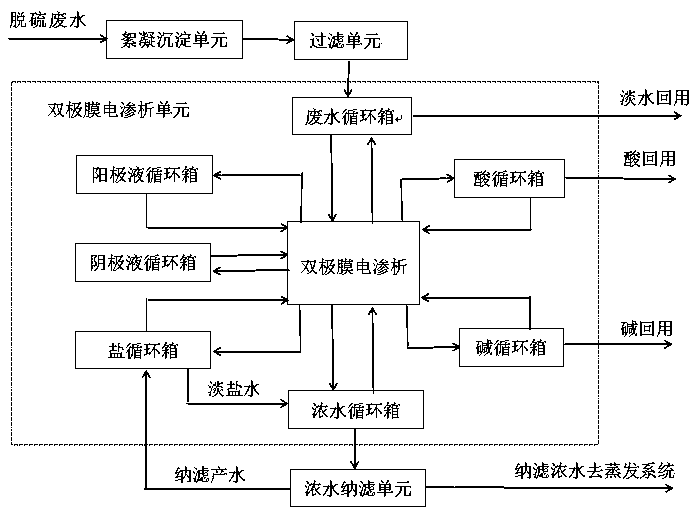

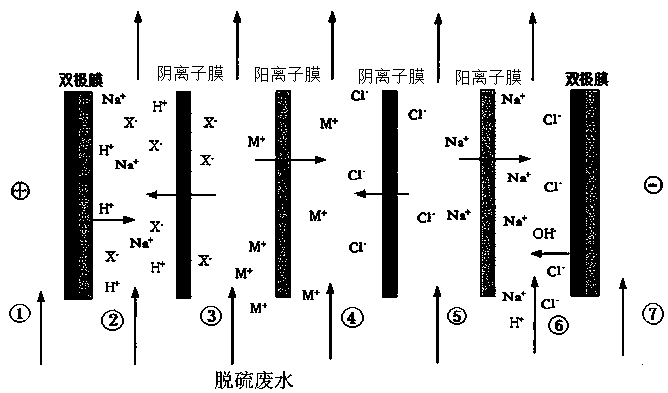

[0026] Such as Figure 1-2 Shown: a thermal power plant desulfurization wastewater resource utilization system with low reagent consumption of the present invention, including a flocculation sedimentation unit, a filtration unit, a bipolar membrane electrodialysis unit, and a concentrated water nanofiltration unit connected in series in sequence, the bipolar membrane The electrodialysis unit adopts a seven-chamber bipolar membrane electrodialysis unit, and the bipolar membrane electrodialysis unit is divided into seven different compartments by bipolar membranes, anion membranes, cationic membranes, anion membranes, cationic membranes, and bipolar membranes arranged in sequence. Each chamber is respectively connected with the anolyte circulation box, acid circulation box, desulfurization waste water circulation box, concentrated water circulation box, salt circulation box, alkali circulation box, catholyte circulation box, wherein the filter unit is connected to the desulfuriza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com