Preparation method of equal-thickness ultrafine grain TC4 titanium alloy plate

A technology for titanium alloy plates and titanium alloys, applied in the field of metallurgy, can solve the problems of incompleteness, deformation, cracking and welding, and difficulty in realizing fine-grained structure, so as to eliminate interfacial oxidation, improve interfacial bonding strength, and eliminate oxide scale and oil pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

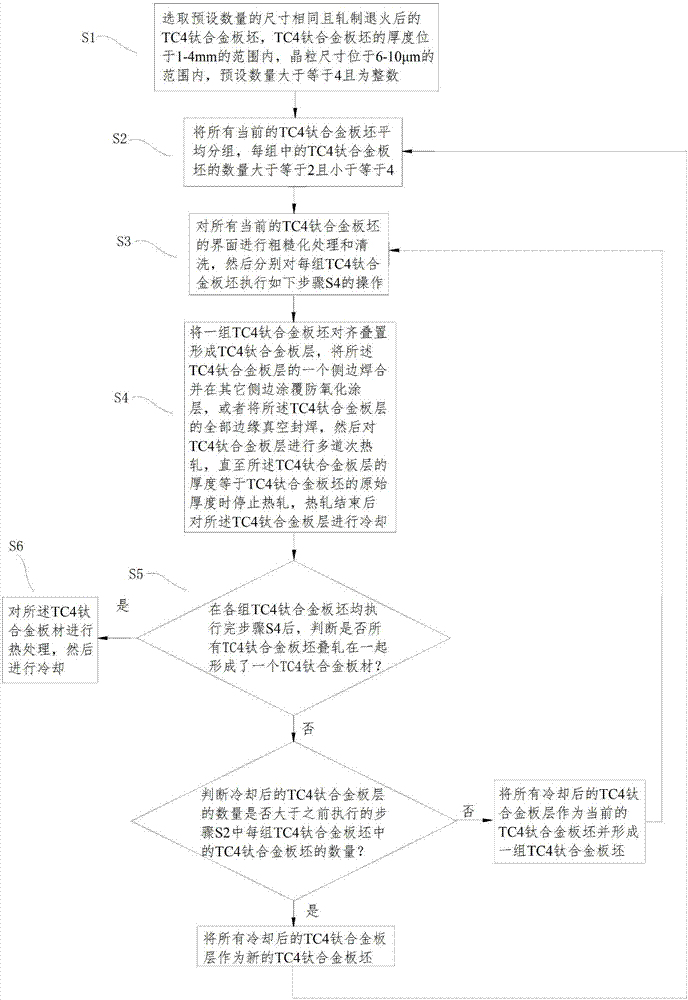

[0032] Provide a kind of preparation method of ultra-fine grain TC4 titanium alloy sheet material in the present embodiment, this preparation method comprises the following steps:

[0033] S1, select 16 TC4 titanium alloy slabs with the same size (that is, the length, width and thickness of each TC4 titanium alloy slab are the same) and rolled and annealed, the thickness of the TC4 titanium alloy slab is 1mm, and the grain The size lies in the range of 6-10 μm.

[0034] S2. Divide all current TC4 titanium alloy slabs into 4 groups on average, and the number of TC4 titanium alloy slabs in each group is 4 pieces.

[0035] S3. Grinding and cleaning the interface of all the current TC4 titanium alloy slabs ("interface" is the surface of the TC4 titanium alloy slab to be bonded with other slabs in the subsequent steps) with alcohol or acetone. After the grinding treatment and cleaning are completed, dry, and then perform the following step S4 for each group of TC4 titanium alloy s...

Embodiment 2

[0043] In this embodiment, the preparation method of the ultra-fine-grained TC4 titanium alloy plate with equal thickness of the present invention is repeated by changing some parameters of the first embodiment above. details as follows:

[0044] S1. Select 27 TC4 titanium alloy slabs of the same size after rolling and annealing. The thickness of the TC4 titanium alloy slabs is 2 mm, and the grain size is in the range of 6-10 μm.

[0045] S2. Divide all current TC4 titanium alloy slabs into 9 groups on average, and the number of TC4 titanium alloy slabs in each group is 3.

[0046] S3. Grinding the interfaces of all current TC4 titanium alloy slabs (27 in total) and cleaning the surface with alcohol or acetone. After the grinding and cleaning are completed, dry, and then perform the following step S4 for each group of TC4 titanium alloy slabs, that is, perform step S4 once for 9 groups of TC4 titanium alloy slabs;

[0047] S4, a group of TC4 titanium alloy slabs are aligned ...

Embodiment 3

[0060] In this embodiment, the preparation method of the ultra-fine-grained TC4 titanium alloy plate with equal thickness of the present invention is repeated by changing some parameters of the first embodiment above. details as follows:

[0061] S1. Select 32 TC4 titanium alloy slabs with the same size and after rolling and annealing. The thickness of the TC4 titanium alloy slabs is 4 mm, and the grain size is in the range of 6-10 μm.

[0062] S2. Divide all current TC4 titanium alloy slabs into 16 groups on average, and the number of TC4 titanium alloy slabs in each group is 2.

[0063] S3. Grinding the interface of all current TC4 titanium alloy slabs and cleaning the surface with alcohol or acetone. After the grinding treatment and cleaning are completed, dry, and then perform the following step S4 for each group of TC4 titanium alloy slabs, that is, perform step S4 once for 16 groups of TC4 titanium alloy slabs;

[0064] S4. Align and stack a group of TC4 titanium alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com