Patents

Literature

233results about How to "Improve flocculation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for treatment of sea red tides and fresh water bloom

InactiveCN1417136AReduce concentrationImprove flocculation efficiencySedimentation separationWater/sewage treatment using germicide/oligodynamic-processOctahedronSilicon oxygen

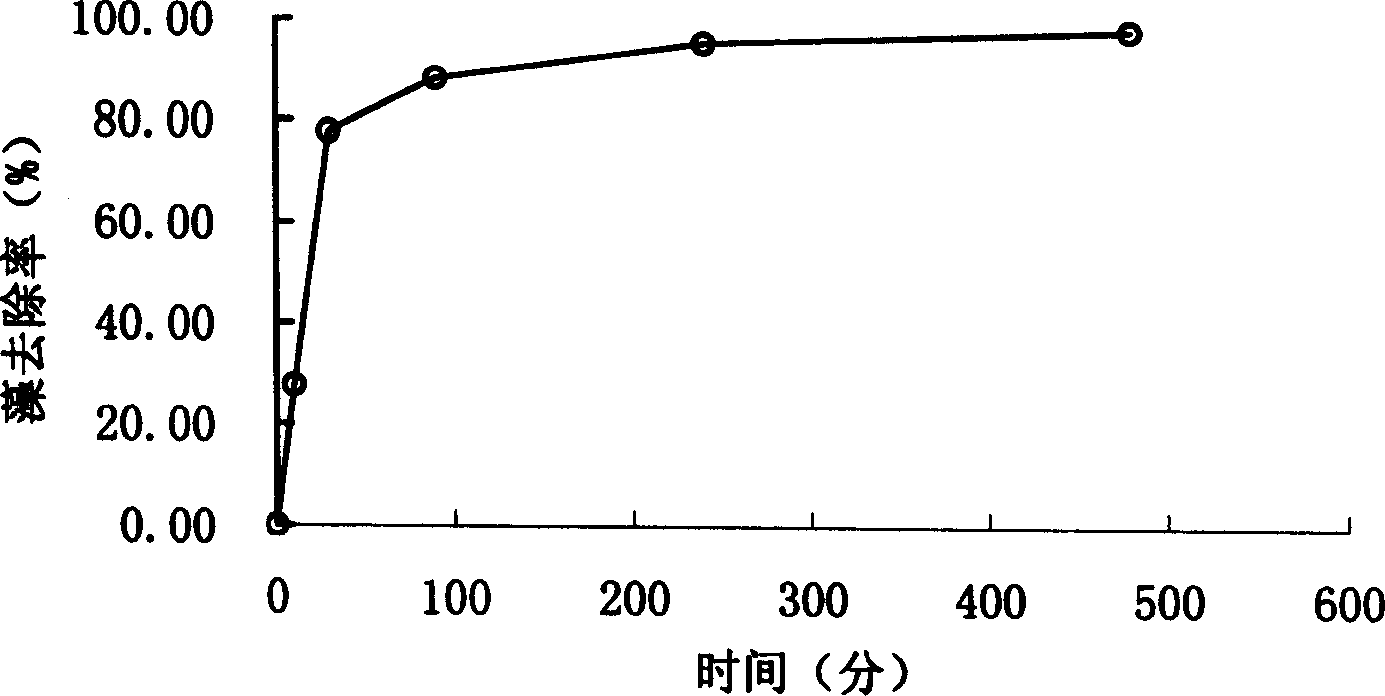

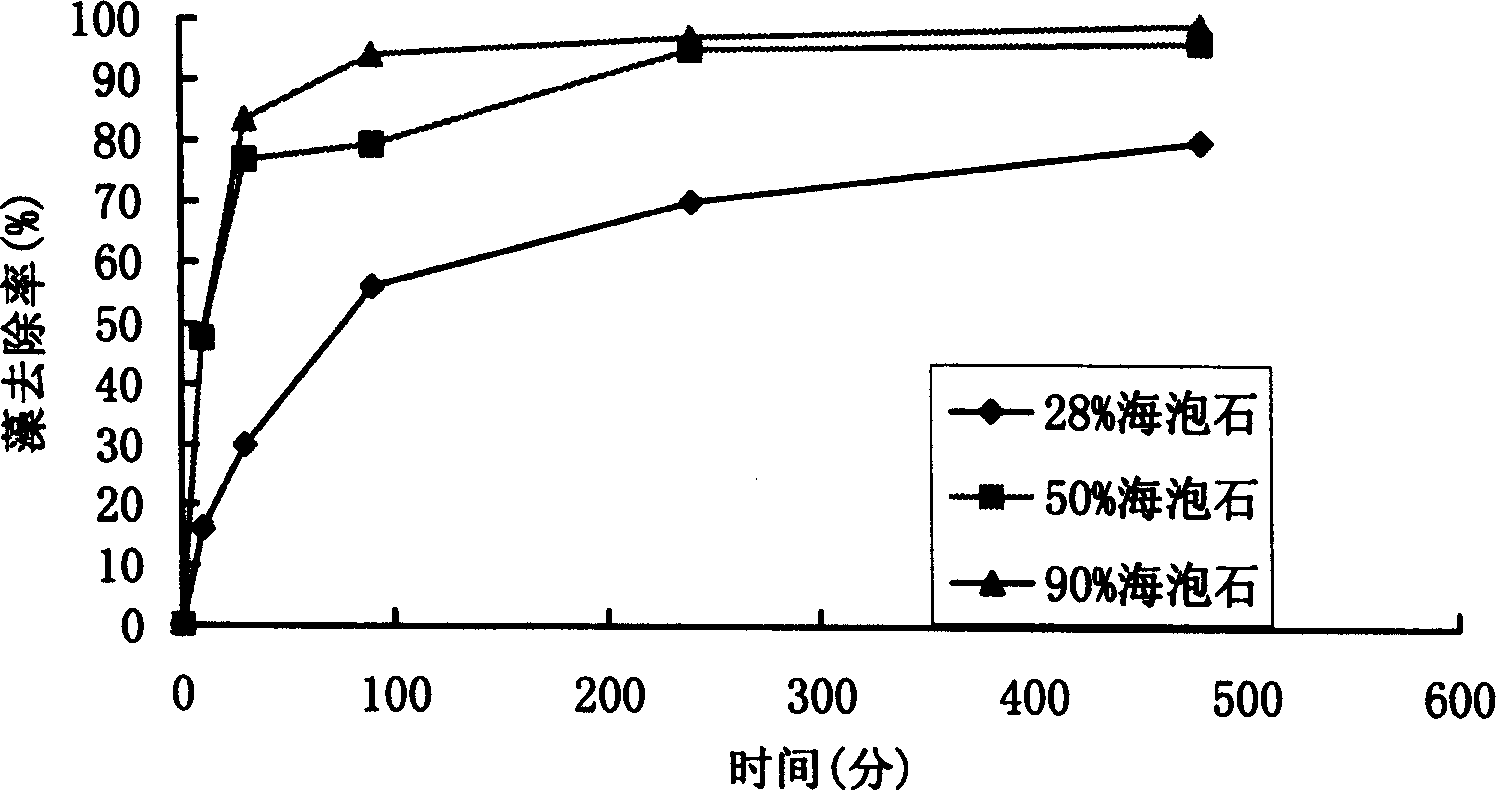

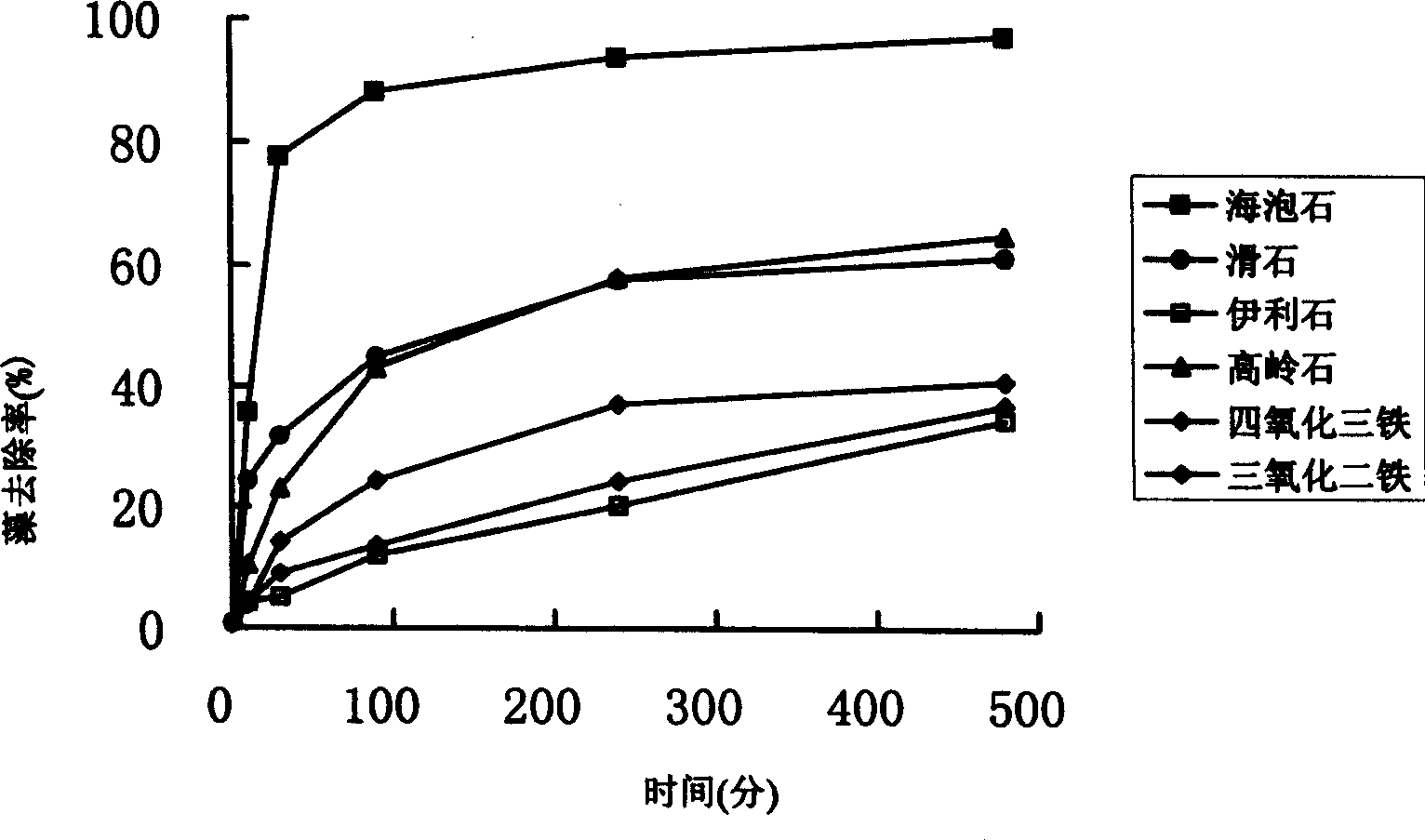

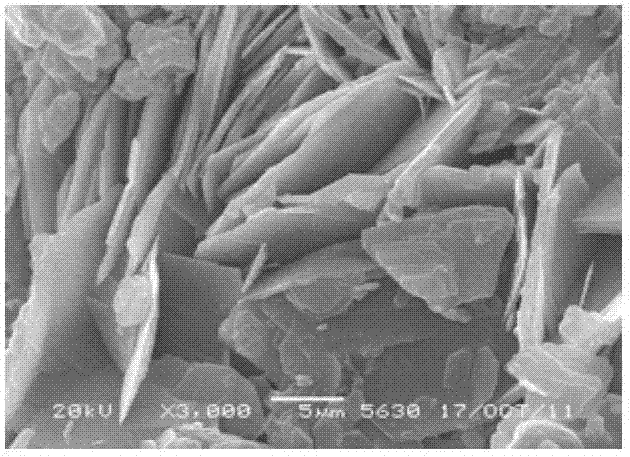

The present invention relates to a method of tackling sea red tides and fresh water bloom using clay as algae flocculant. The effective component of the flocculant is hydrated magnesio-silicate salt in the laminated structure including upper and lower silicon-oxygen tetrahedron layers and sandwiched magnesium-oxygen octahedron layer. The hydrated magnesio-silicate salt is easy to prepare, low in cost and high in algae flocculating elimination effect.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

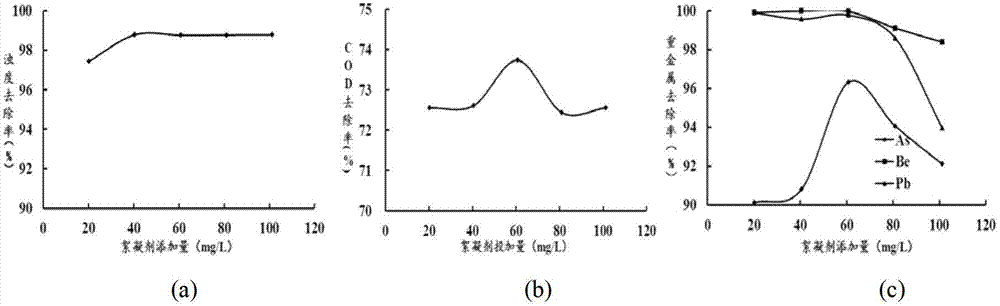

Efficient flocculent precipitate purification method for polymetallic ore benefication wastewater

ActiveCN102730885ASolve the poor effect of flocculation and sedimentationResolve separabilityMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationParticulatesPurification methods

The invention discloses an efficient flocculent precipitate purification method for polymetallic ore benefication wastewater. Specifically, the purification method comprises the steps of: neutralizing and regulating the pH value of benefication wastewater by adopting a little amount of alkaline materials; then sequentially feeding a proper amount of proper suitable flocculant for efficient flocculation and a little amount of efficient coagulant aids for fast precipitation; separating sludge from water through action of a partition wall, wherein the treated wastewater achieves primary standardof national Integrated wastewater discharge standard (GB8978-1996); through SV30 evaluation; settling for 5minutes to achieve 45-55mL of supernatant by volume; and settling for 15 minutes to achieve 70-80mL of supernatant by volume. The purification method can fully utilize the traditional benefication wastewater lime and sedimentation process, is simple in procedure, and can simultaneously remove suspended particulate matters, organic matters and heavy metal ions in wastewater, is high in flocculation efficiency and fast in sedimentation speed, and can better solve the purification problem of the low-concentration and high-tubidity polymetallic ore benefication wastewater of multiple heavy metals.

Owner:CENT SOUTH UNIV

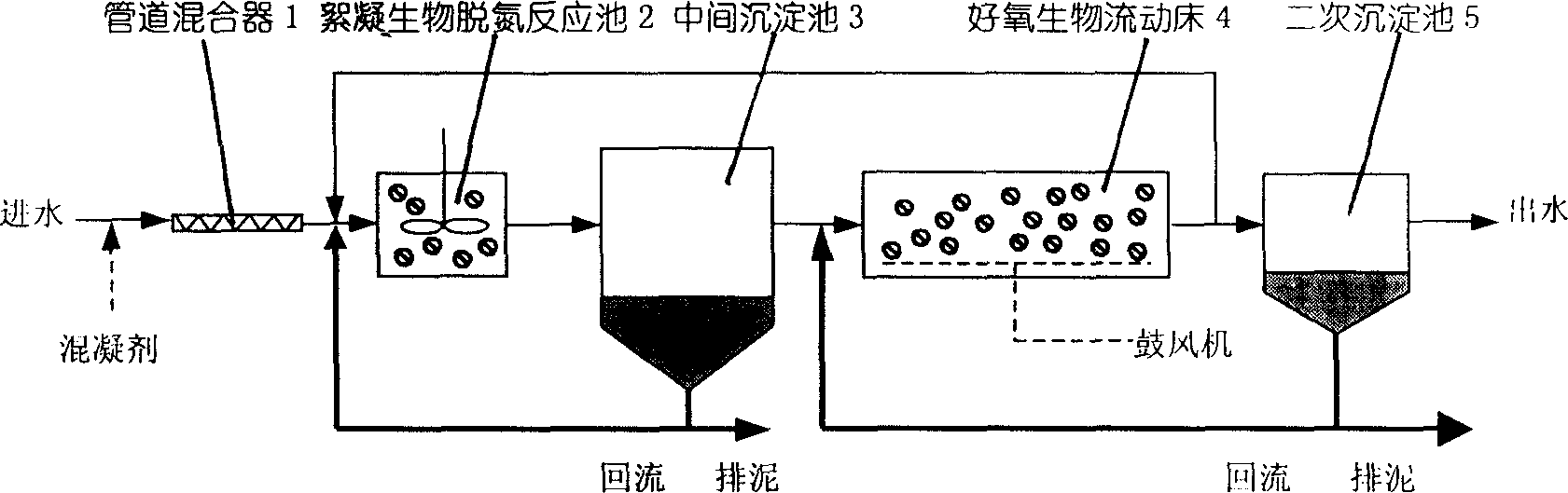

Integrated sewage treating process in flocculant biological flow bed

InactiveCN1740102ACompact processSimple craftTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFlocculationDenitrifying bacteria

The present invention belongs to the field of environment protecting technology, and is especially one kind of integrated sewage treating process in flocculant biological flow bed. The present invention integrates the first stage reinforcing technology and biological flow bed technology, and has flocculating biological denitrogenating reaction pond with thrown suspended stuffing for denitrifying bacteria to coagulate and grow on, and aerobic biological flow bed with outgoing water to flow back over the intermediate precipitation pond, to realize the chemical flocculation and denitrifying biological denitrogenating in the same reactor. The present invention realizes the organic combination of two said technologies, and has reduced building number, simple and compact technological process, and high sewage treating efficiency.

Owner:TONGJI UNIV

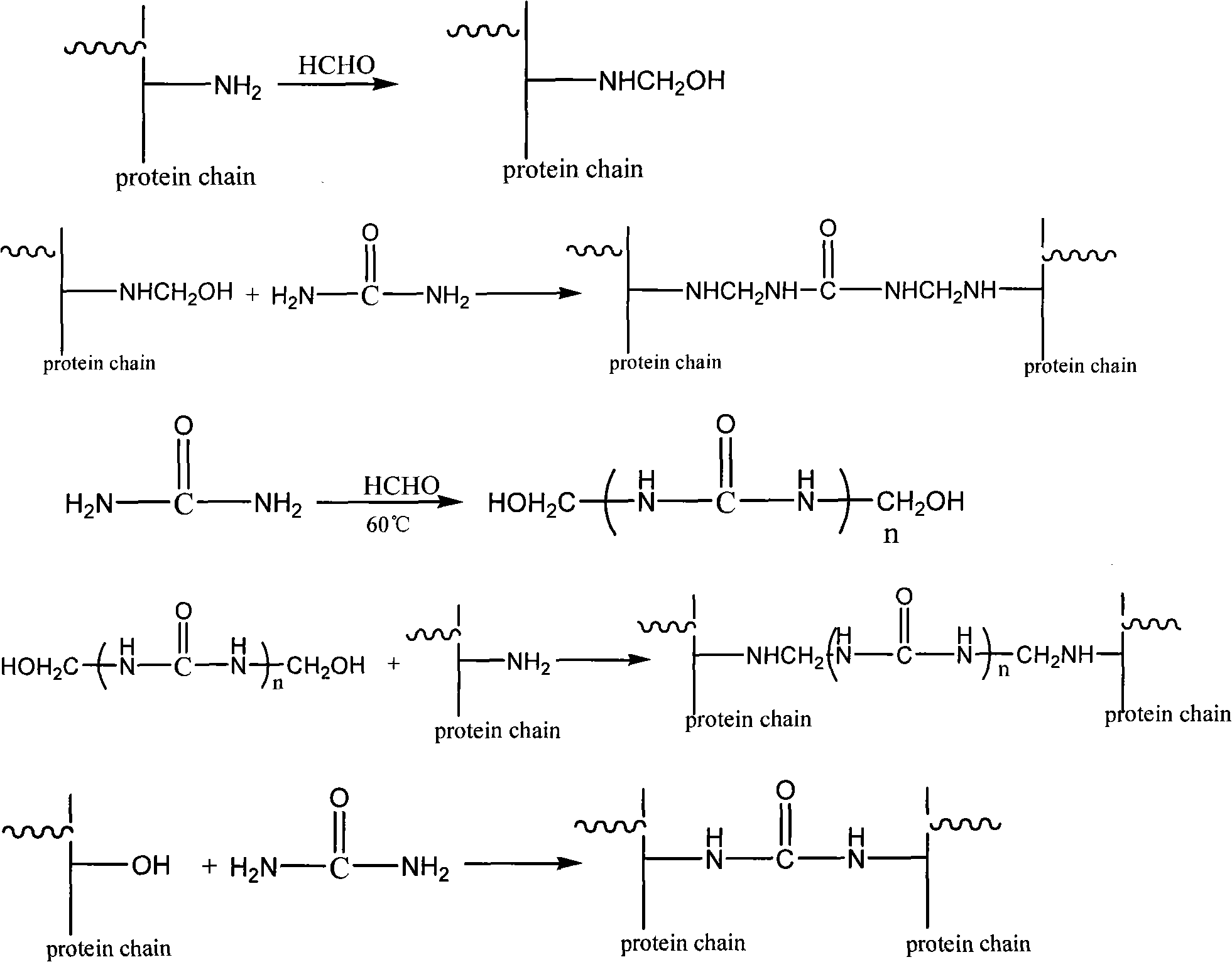

Protein flocculant for treating printing and dyeing wastewater

InactiveCN102115239AHigh decolorization rateReduce dosageWater/sewage treatment by flocculation/precipitationWater dischargeProtein molecules

The invention discloses a protein flocculant for treating printing and dyeing wastewater. The protein flocculant for treating the printing and dyeing wastewater is prepared from various animal protein powders originating from cheap waste animal pelts, hoofs, animal fur powders and bean pulps aiming at different groups in a protein molecule and a chemical modifier for reaction. The invention simultaneously provides a protein flocculant compound. The invention provides a simple and practicable method; and by utilizing the method, various dye waste waters discharged in printing and dyeing plants and dye production plants can be effectively treated, and the product cost is cheap.

Owner:中国中化股份有限公司 +1

Microalgae cell flocculating and harvesting technology

InactiveCN102604837ARaw materials are cheapLow priceUnicellular algaeMicroorganism based processesEthylene diamineFlocculation

The invention relates to a microalgae cell flocculating and harvesting technology, belonging to the technical field of energy microalgae. The technology is characterized in that chitosan, melamine or EDTA (ethylene diamine tetraacetic acid) and attapulgite are prepared into a flocculating agent; and CaCl2 is added as a flocculation aid to perform flocculating and harvesting of microalgae. The invention provides preparation of a flocculating agent and a flocculating and harvesting technology. The technology comprises the following steps of: drying the flocculating agent, grinding and sieving; adding the flocculating agent into the microalgae culture solution so that the concentration of the flocculating agent is 0.3-0.6g / L, and the concentration of the flocculation aid CaCl2 is 0.01-0.03g / L; adjusting the microalgae culture solution until the pH is 7-9; and stirring uniformly and standing for precipitation, wherein the flocculation degree can be more than 99%. For the flocculating technology provided by the invention, the raw materials are cheap; and the technology is safe and environment-friendly and convenient to operate, has high flocculation efficiency, and can be widely used for harvesting microalgae in the industrial production.

Owner:YANCHENG INST OF TECH

Single needle alga, as well as culture method and recovery method and application thereof

The invention relates to the technical field of microorganisms, and discloses single needle alga. The preservation number of the single needle alga is CGMCC No.8776, and the single needle alga is named single needle alga C29. The single needle alga is fast in growth speed and high in grease yield, and is an excellent bacterial strain of producing biodiesel. The invention also provides an open culture method of the single needle alga. By adopting the method, a specific culture medium is adopted to cultivate, and growth of the single needle alga C29 and accumulation of grease are facilitated. The invention also provides a recovery method of the single needle alga C29. The recovery method has nontoxicity, high flocculation efficiency and low recovery cost. The invention also provides an application of the single needle alga C29 in production of grease, especially production of biodiesel.

Owner:HAINAN UNIVERSITY

Method for preparing flocculating agent from paper mill sludge

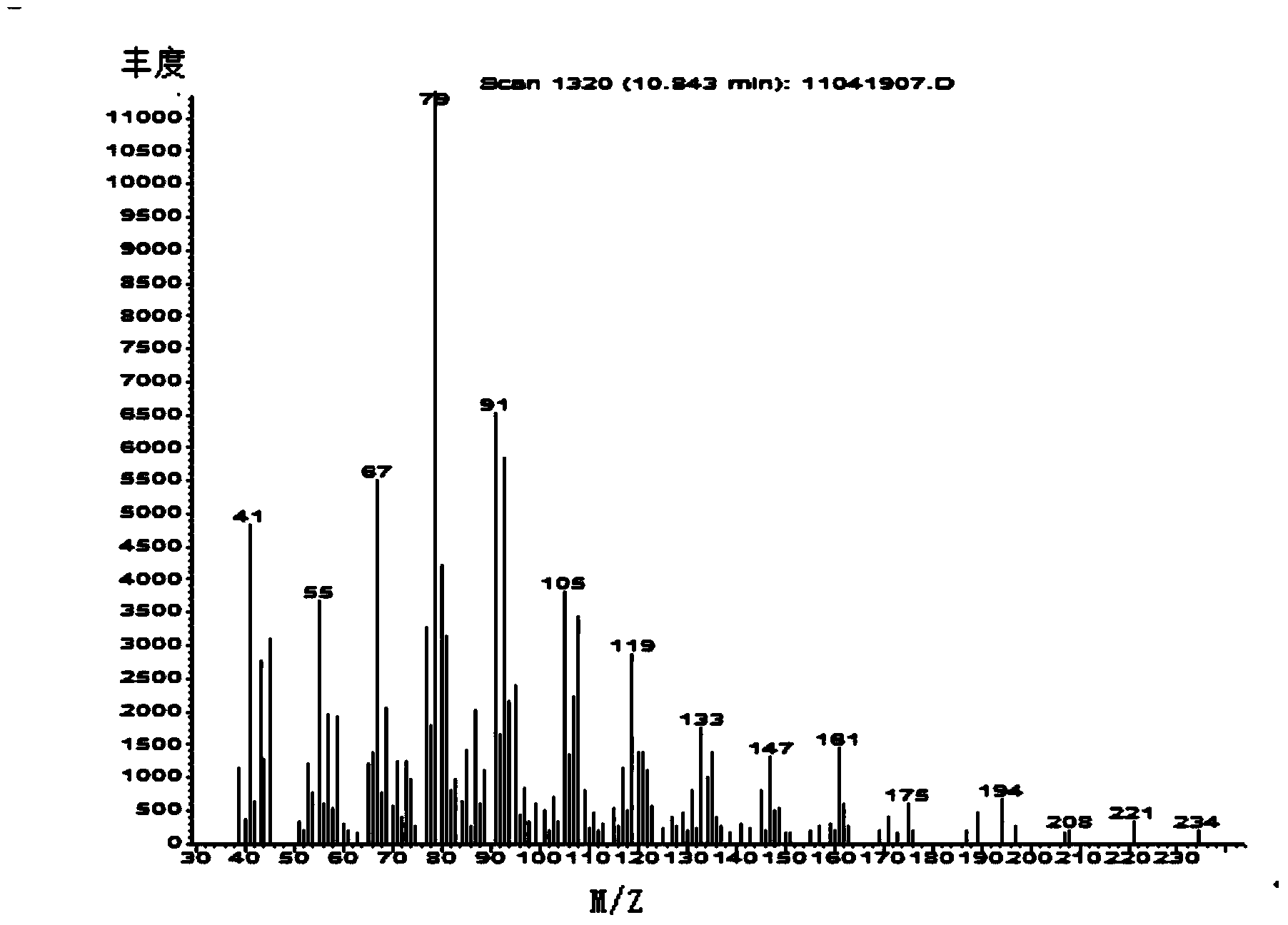

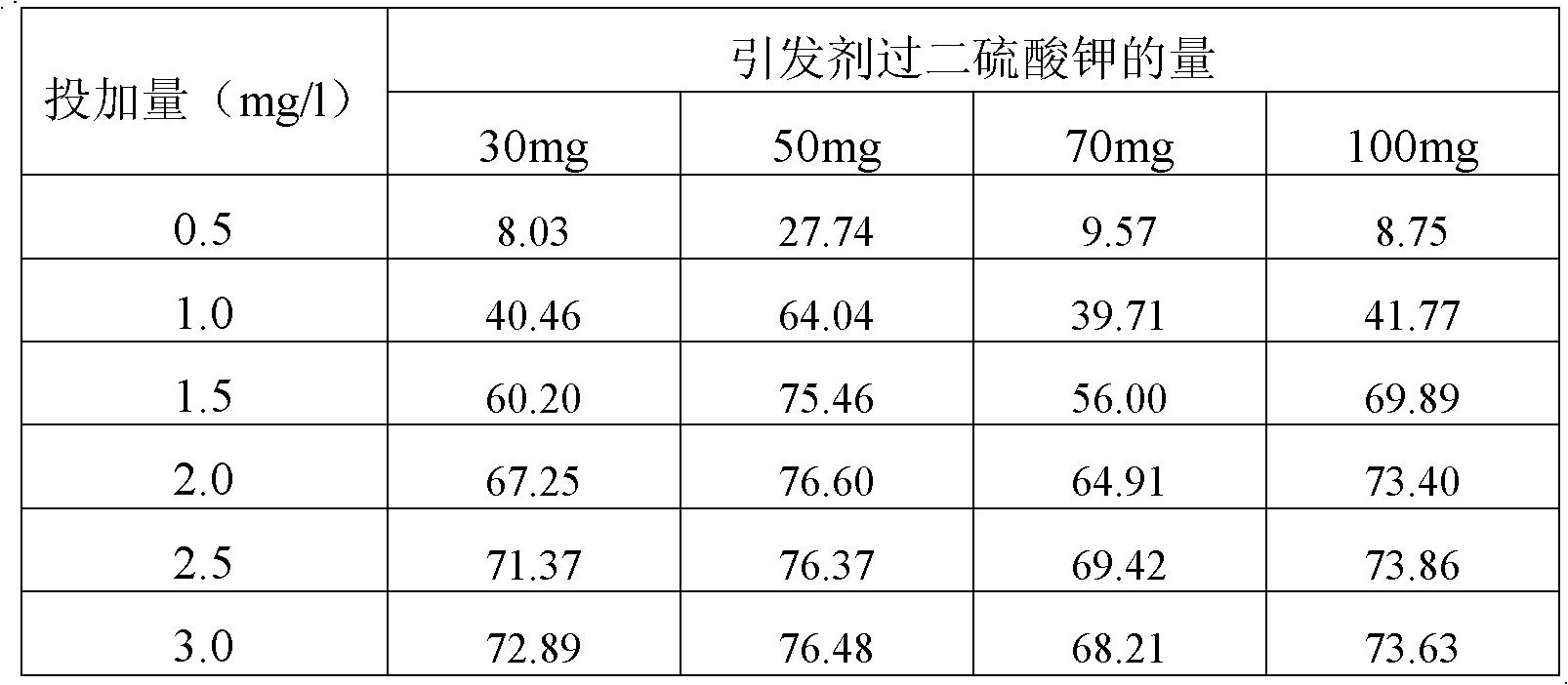

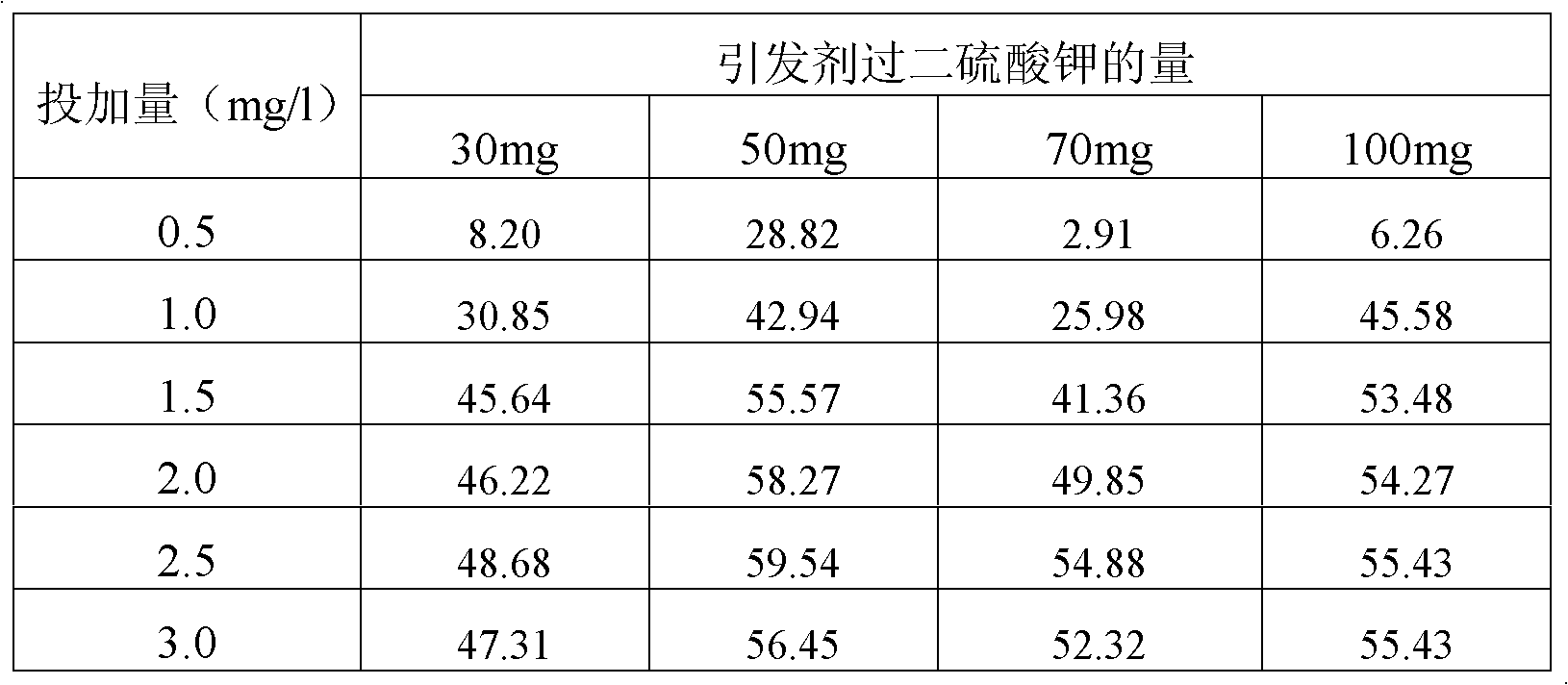

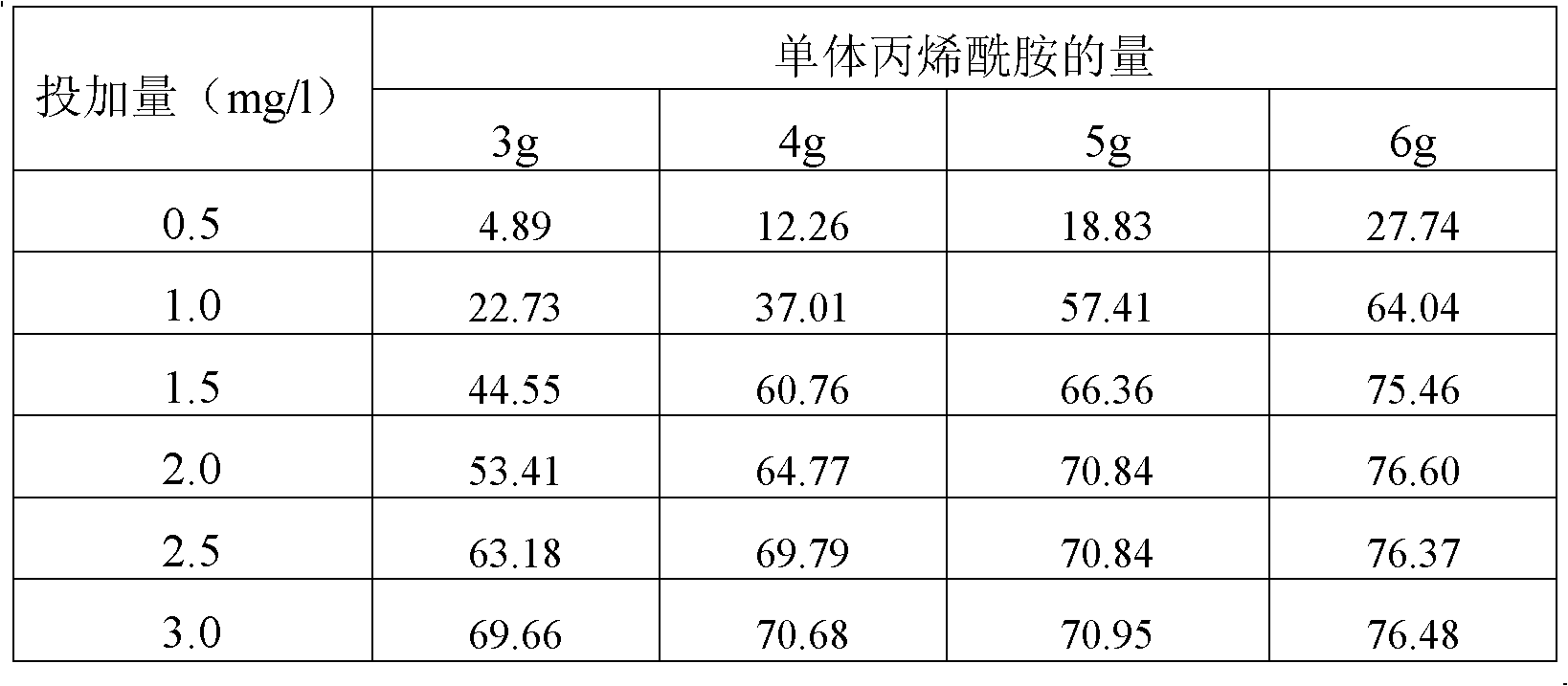

ActiveCN102583684AEase of mass productionLow costSludge treatmentWater/sewage treatment by flocculation/precipitationPotassium persulfateSlag

The invention relates to a method for preparing a flocculating agent from paper mill sludge. The method comprises the following steps: raw material is not purified, an alkali liquor is directly used for dissolving lignin, a supernatant is separated out, the PH value of the supernatant is regulated, after a reactor is heated to a certain temperature, potassium persulfate is added, nitrogen gas is filled, the stirring and the activating are performed for 15 minutes, and then acrylamide is added in the reactor, nitrogen gas is filled continuously, the stirring reaction is conducted, acetone is added to mix to separate out reaction products, the vacuum drawing and filtering is performed, and filtered slag is taken to conduct the vacuum drying to obtain the flocculating agent product. When theprepared flocculating agent is used for treating water samples, the adding quantity is 2 mg / l, the UV254 removal rate reaches about 70%, and the DOC removal rate reaches about 60%. The method provided by the invention has the advantages that the process is simple, the reaction condition is mild, the waste reuse is achieved and the use amount of the prepared flocculating agent is small through theindustrial production and appliance, the efficiency is high, and the cost of water treatment is low.

Owner:SHANDONG UNIV

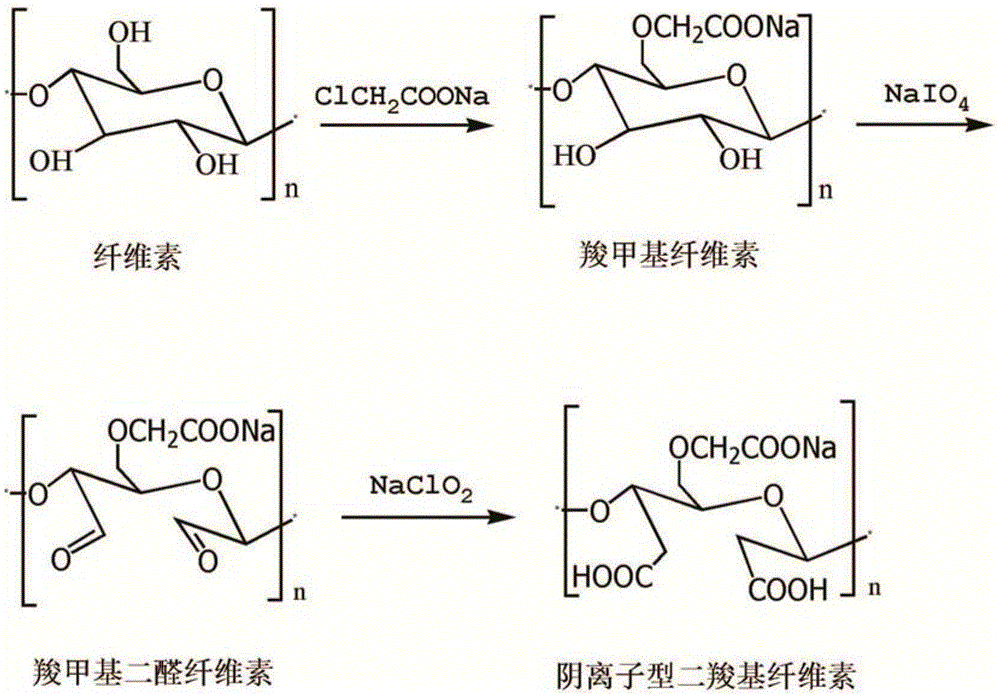

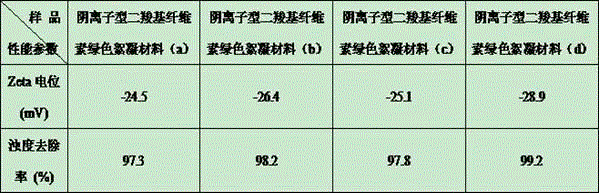

Preparation method for anionic dicarboxy cellulose green flocculation material

InactiveCN105111318AIncreased aldehyde contentEnhanced electronegativityWater/sewage treatment by flocculation/precipitationCarboxycelluloseMunicipal sewage

The invention discloses a preparation method for anionic dicarboxy cellulose green flocculation material. The method is characterized by comprising the following steps: dissolving cellulose through a sodium hydroxide and urea system, adding an anionic reagent, and generating anionic cellulose; and then preparing the anionic dicarboxy cellulose green flocculation material after two stages of oxidation. The method is simple in operation, the raw materials are easy to obtain, the production cost is low, and the method is easy for popularization and application. According to the material disclosed by the invention, chemically modified cellulose is used as a flocculation material, so that the utilization rate of cellulosic feedstocks is sufficiently improved; no poison or byproduct is generated, so that the flocculation efficiency of the existing flocculation cellulose-based material can be significantly improved, and the environmental pollution is reduced; and meanwhile, raw material dependence of traditional synthetic polymer flocculants on petroleum resources is greatly reduced, and the generated anionic dicarboxy cellulose green flocculation material is completely biodegradable and does not cause secondary pollution. The prepared anionic dicarboxy cellulose green flocculation material is widely applied in the flocculation process of papermaking waste water, dyeing waste water, chemical waste water and municipal sewage, and thus has significant environmental and social benefits.

Owner:ZHEJIANG SCI-TECH UNIV

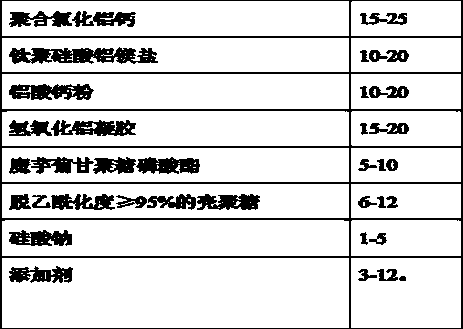

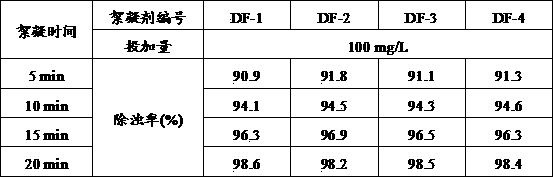

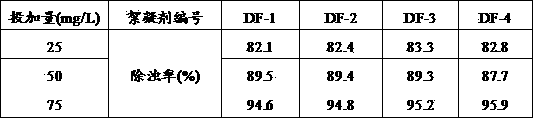

Multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and preparing method thereof

ActiveCN103420468AImprove flocculation efficiencyReduce dosageWater/sewage treatment by flocculation/precipitationPhosphateAluminium silicate

The invention relates to a multi-element composite flocculant for treating printing and dying wastewater and textile wastewater and a preparing method of the multi-element composite flocculant. The flocculant comprises polymeric aluminium, titanium polysilicic acid aluminium silicate, calcium aluminate powder, aluminium hydroxide gel, konjac glucomannan phosphate, chitosan, sodium silicate and an additive, wherein the deacetylation degree of the chitosan is larger than or equal to 95%. Through appropriate selection of components and proportion, the multi-element composite flocculant has the advantages of being high in flocculation efficiency, small in dosage, wide in temperature application range and pH application range and the like. The multi-element composite flocculant can be used for treatment and purification of the printing and dying wastewater and the textile wastewater and has wide industrialized application prospects and market values.

Owner:广州市豫泉净水材料有限公司

Microorganism flocculating agent and preparation method thereof

InactiveCN102311975AGreat application potentialImprove flocculation efficiencyMicroorganism based processesFermentationMicroorganismToxin

The invention provides a preparation method of a microorganism flocculating agent by utilizing novel microorganism flocculating agent producing bacteria, i.e., Galactomyces geotrichum in CGMCC (China General Microbiological Culture Collection Center) NO.2535 and a microorganism flocculating agent prepared by using the method. The preparation method of the microorganism flocculating agent by utilizing the microorganism flocculating agent producing bacteria is simple and easy and is short in fermenting time and low in production cost; the produced flocculating agent has a wide applicable scope, a small using amount but high flocculating efficiency; and the microorganism flocculating agent which is prepared by extracting has no toxin or harm and no secondary pollution, is biodegradable and suitable for large-scale spread and application, and has a wide application prospect.

Owner:BEIJING UNION UNIVERSITY

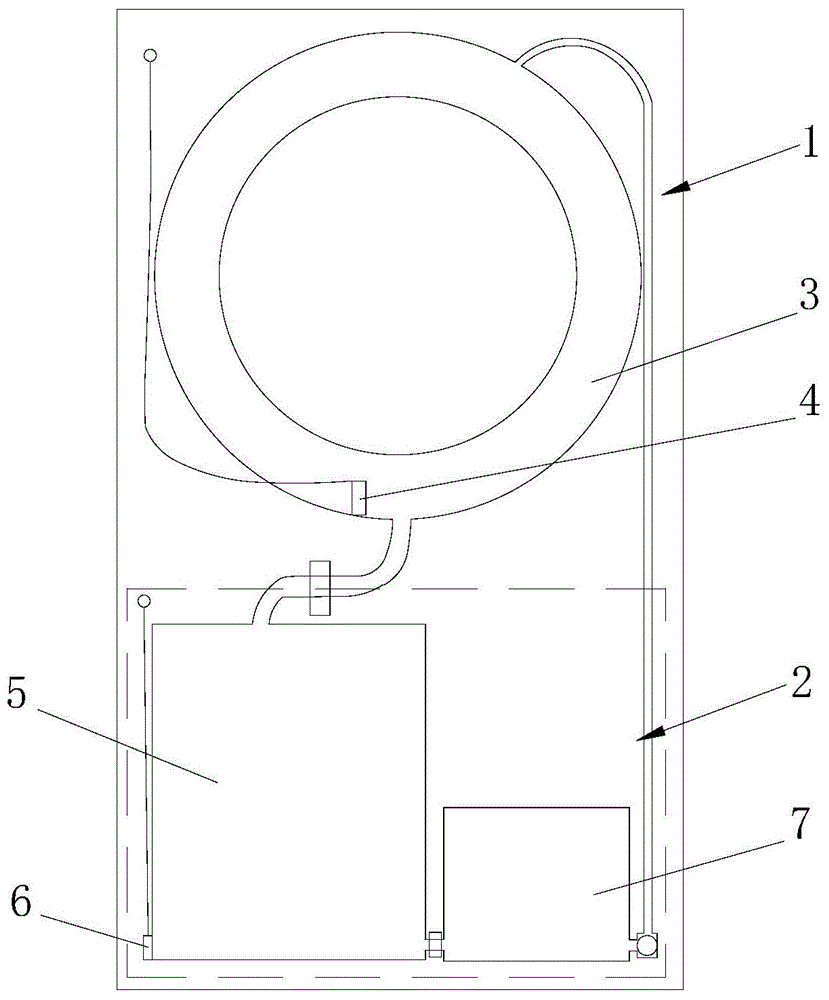

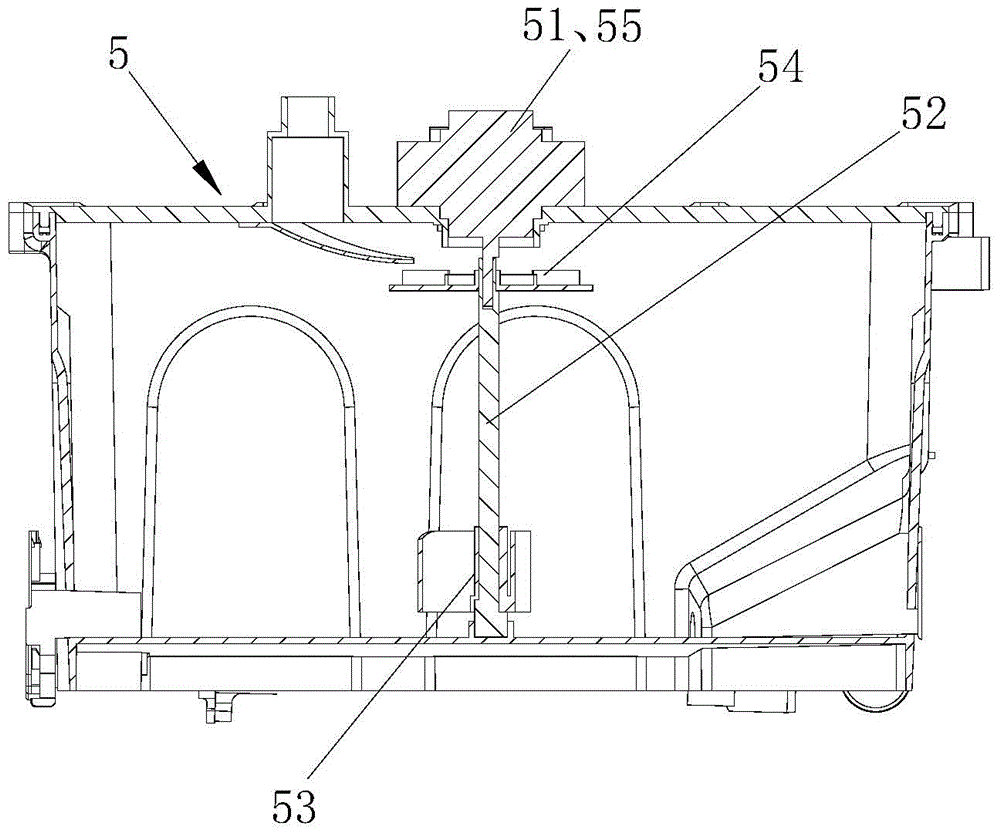

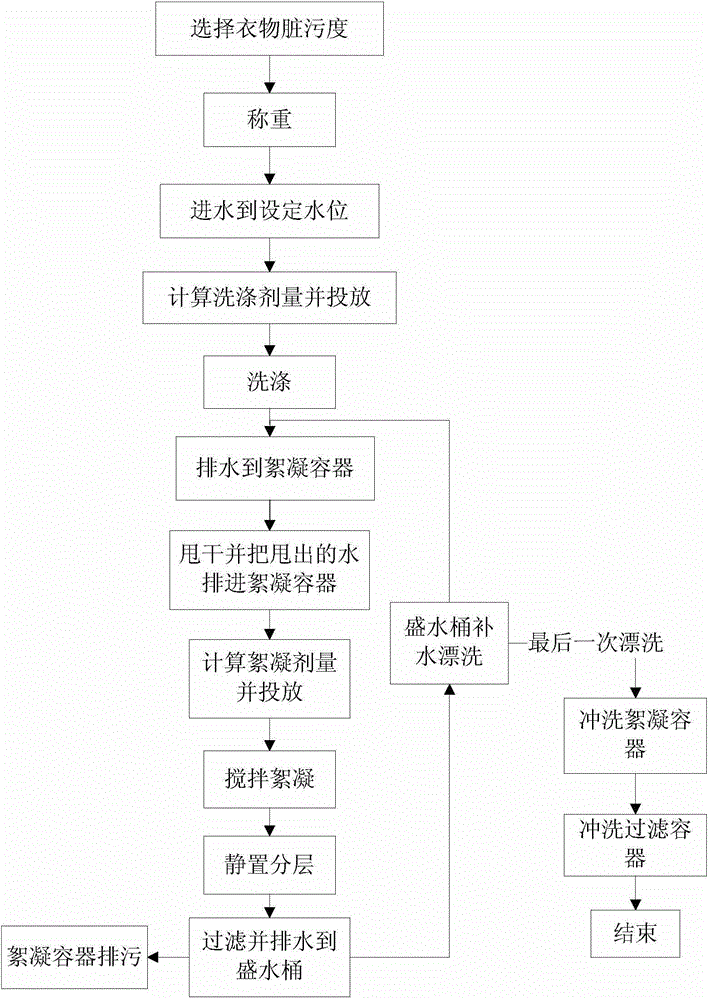

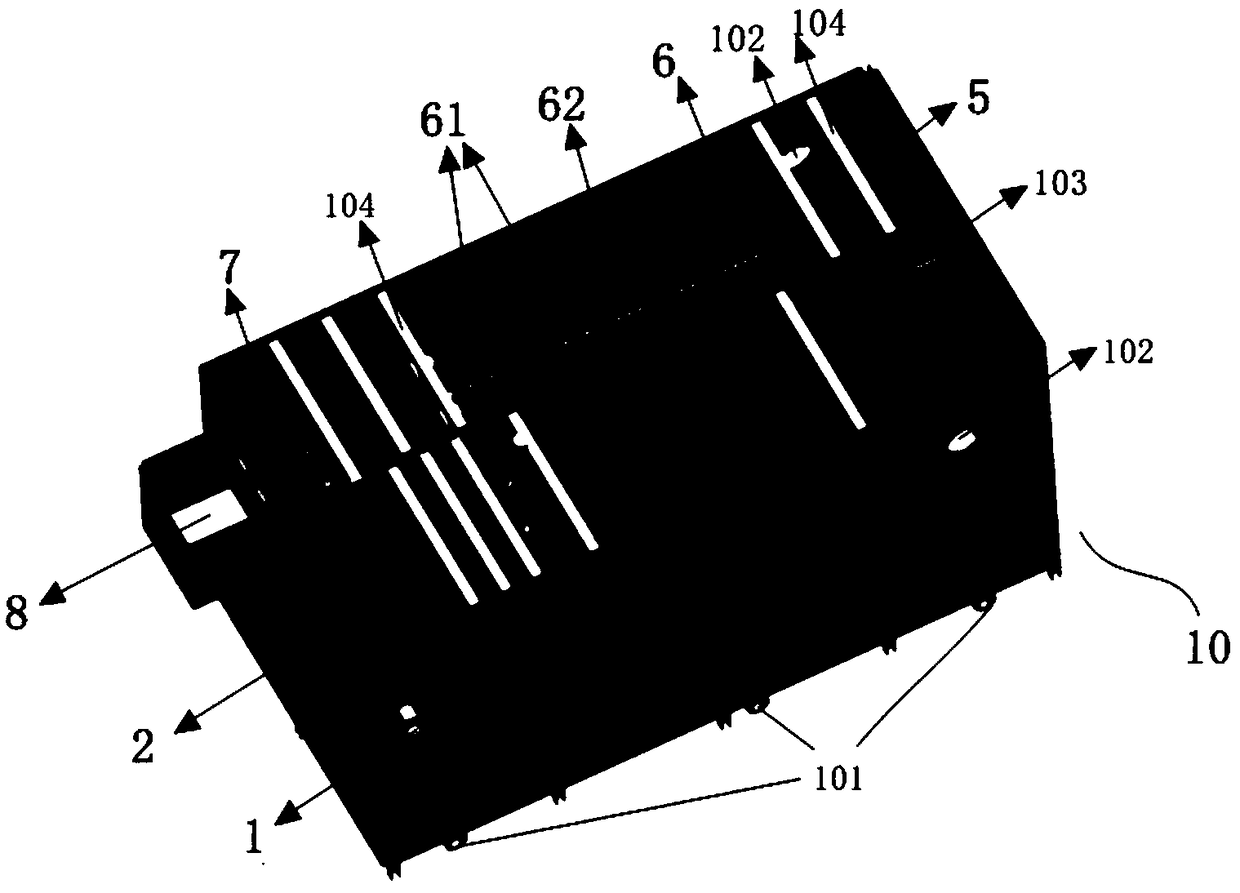

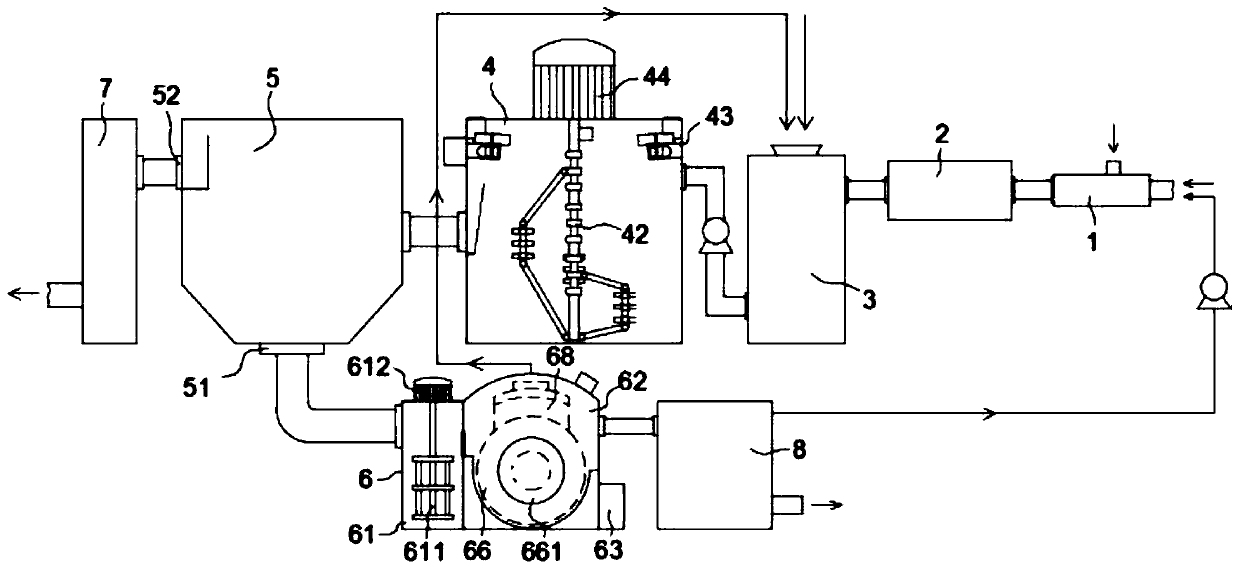

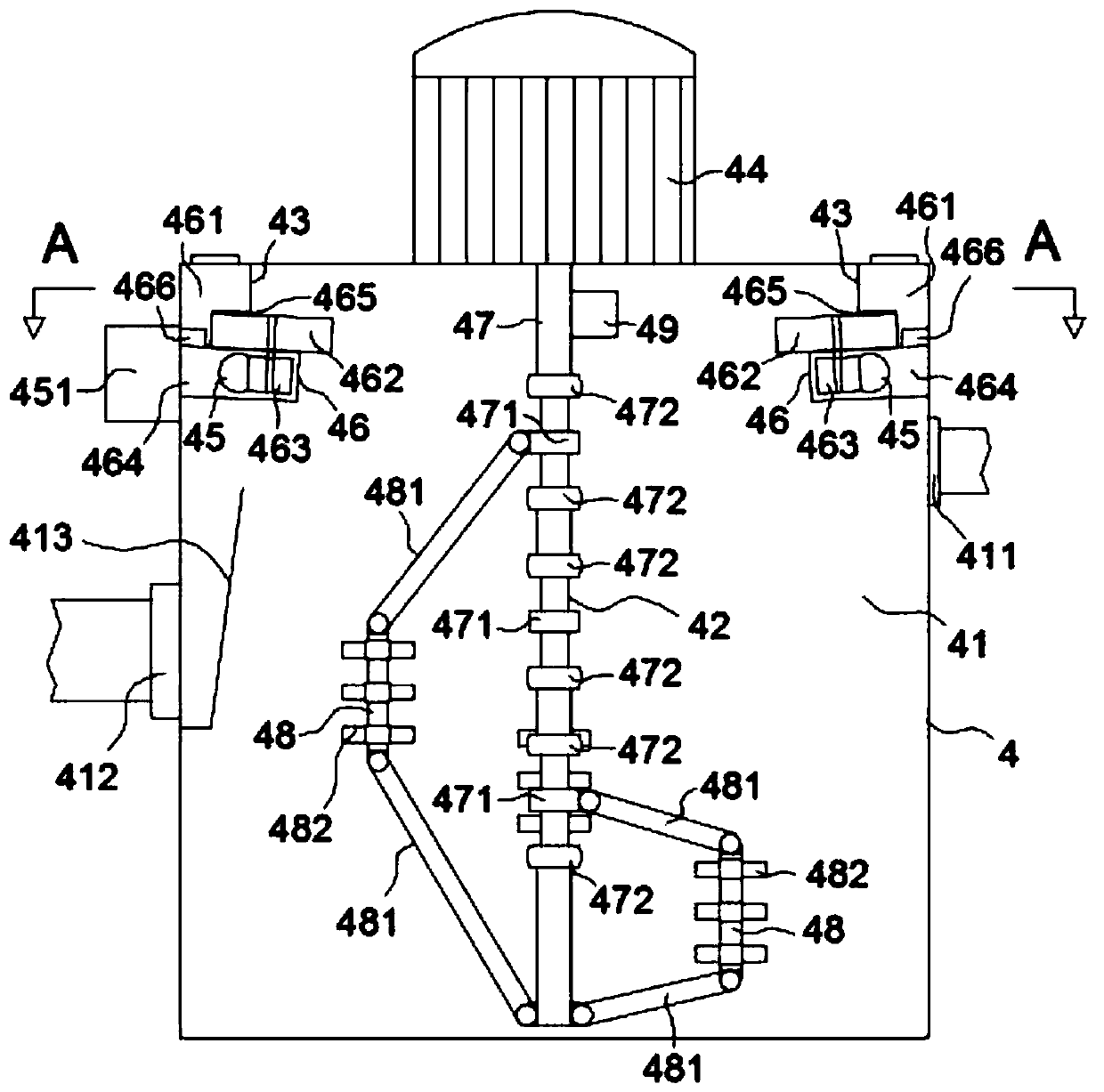

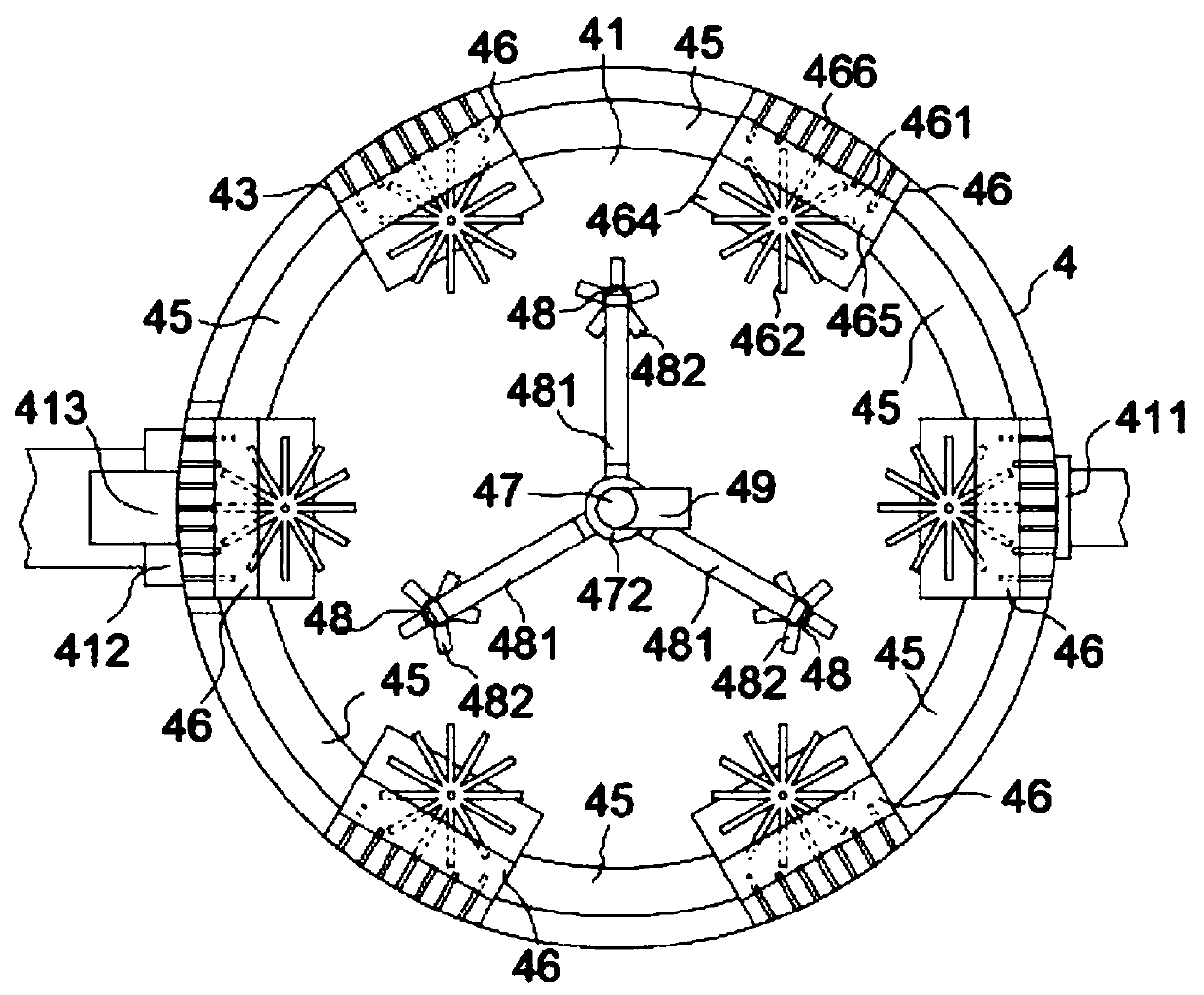

Washing machine water cycle treatment control method and washing machine

ActiveCN105088698AHigh degree of automationInnovative designOther washing machinesControl devices for washing apparatusFlocculationLaundry washing machine

Disclosed are a method for controlling water circulation and processing in a washing machine and a washing machine. The washing machine comprises a washing machine main body (1) and a water circulation and processing system (2). The water circulation and processing system (2) comprises a flocculation container (5) for flocculating the drained water from the washing machine main body (1), the flocculation container (5) being provided with a water level detection apparatus (4). After water is used by the washing machine for washing laundry, the water circulation and processing system (2) subjects the water to flocculation and then circulates same for re-use, and, according to the amount of detergent dosed, the amount of water intake for washing, and the amount of water processed in each flocculation, calculates the dose of flocculant needed for the water to be processed by the flocculation process this time. The dose of flocculant can be precisely calculated by measuring and calculating the amount of water intake for washing and the amount of water to be processed for each flocculation so as to ensure flocculation effects. Furthermore, by calculating the height of flocculation product after layer separation by means of the flocculant dose, using a water level measurement can entirely separate a clean water layer, such that more water joins the circulation for use, saving more water, and enabling flocculated matter to be prevented from mixing with the circulating clean water, improving flocculation efficiency.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

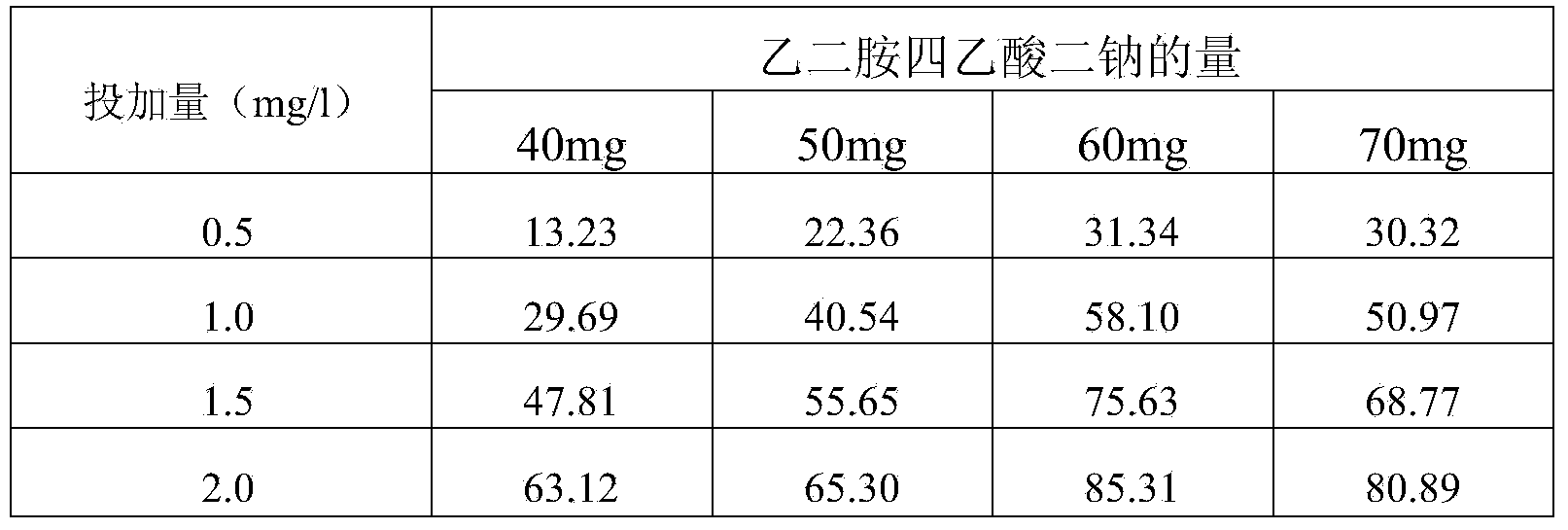

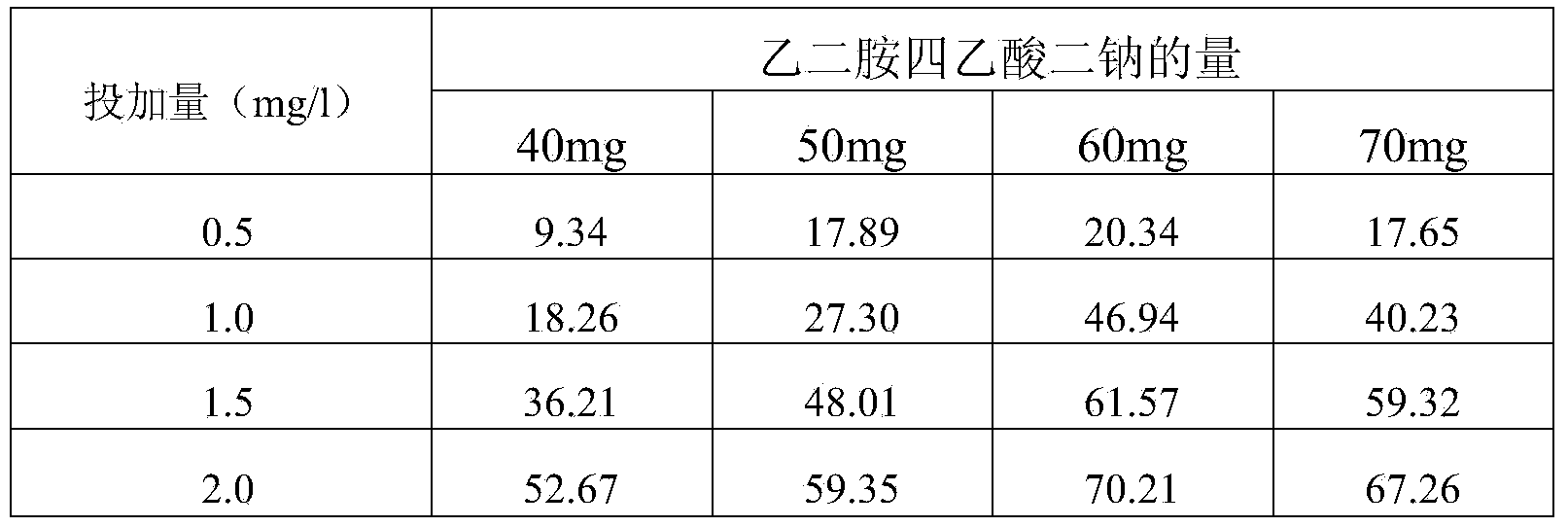

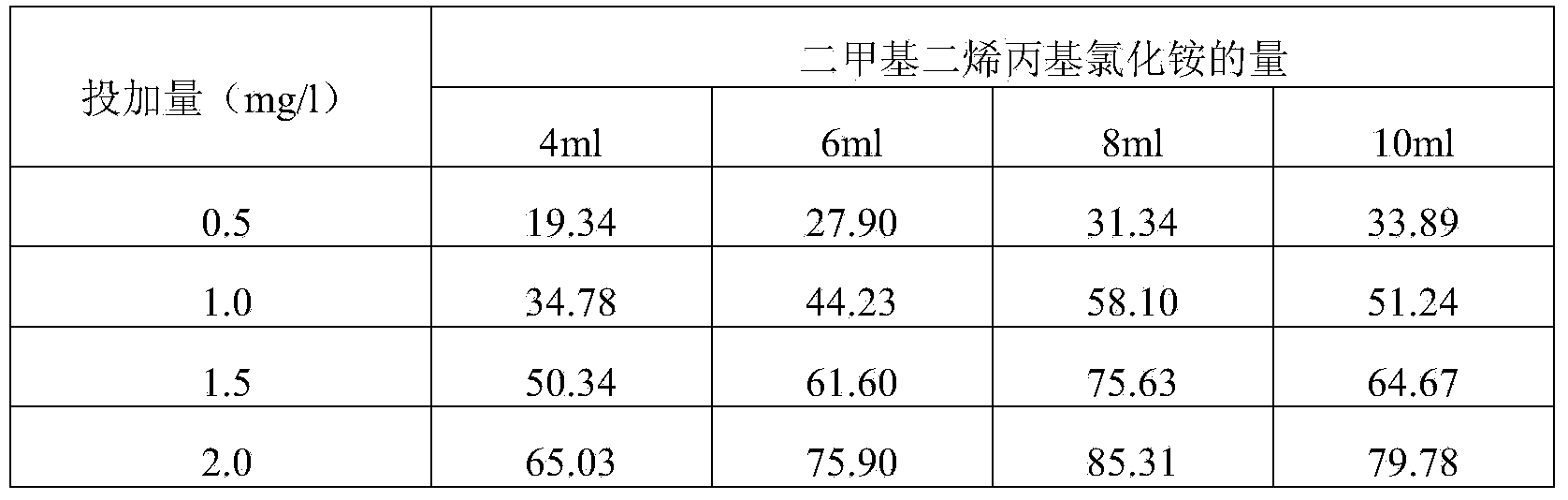

Method for preparing cationic organic flocculant by using paper-making sludge

ActiveCN103964557ATo achieve the effect of resource utilizationEmission reductionSludge treatmentWater/sewage treatment by flocculation/precipitationPeroxydisulfateSludge

The invention relates to a method for preparing a cationic organic flocculant by using paper-making sludge. The method comprises the following steps: directly dissolving a raw material by using an alkali liquid, centrifuging to separate supernate, adjusting the pH value of the solution, putting into a reactor, heating till a certain temperature, adding potassium peroxydisulfate and ethylenediamine tetraacetic acid, introducing nitrogen, stirring to activate for certain time, further adding acrylamide and a dimethyl diallyl ammonium chloride solution to the reactor, continuously introducing nitrogen, stirring for reaction, subsequently pouring into acetone to separate out a reaction product, and drying the filter residue in vacuum, thereby obtaining a flocculant product. When the prepared flocculant is used for treating a simulation water sample, the addition amount is 2mg / l, the UV254 removal rate is about 85%, and the DOC removal rate is about 70%. The method is simple in process, low in equipment requirement and beneficial for industrial production and application, not only is reuse of paper-making wastes achieved, but also the prepared flocculant product is environment-friendly, free of toxicity and high in efficiency, and the water treatment cost can be lowered.

Owner:SHANDONG UNIV

Preparation method and product of heavy metal ion absorption type composite flocculant

InactiveCN106745591AImprove flocculation efficiencyReduce dosageWater contaminantsWater/sewage treatment by flocculation/precipitationCross-linkAcid washing

The invention relates to a preparation method and product of a chitosan composite flocculant with the advantages that organic contaminants in water can be effectively removed; heavy metal ions such as nickel, chromium and lead in water can be adsorbed; the adsorption quantity on heavy metal ions is great; the adsorption efficiency is high. The product is prepared by using chitosan as raw materials, using glutaraldehyde as a cross-linking agent and using attapulgite subjected to water washing and acid washing treatment and tannin modification as a modifying agent. The adsorption removal rate of the composite flocculant product on the heavy metal ions such as low-concentration nickel, chromium, lead and mercury reaches 90 percent or higher. The preparation method of the composite flocculant for adsorbing heavy metal ions has the characteristics that the process is simple; the cost is low; special equipment is not needed; the industrial implementation is easy, and the like. The consumption of chitosan by the composite flocculant is reduced; the cost is reduced.

Owner:TIANJIN JINLIN WATER TREATMENT SCI & TECH CO LTD

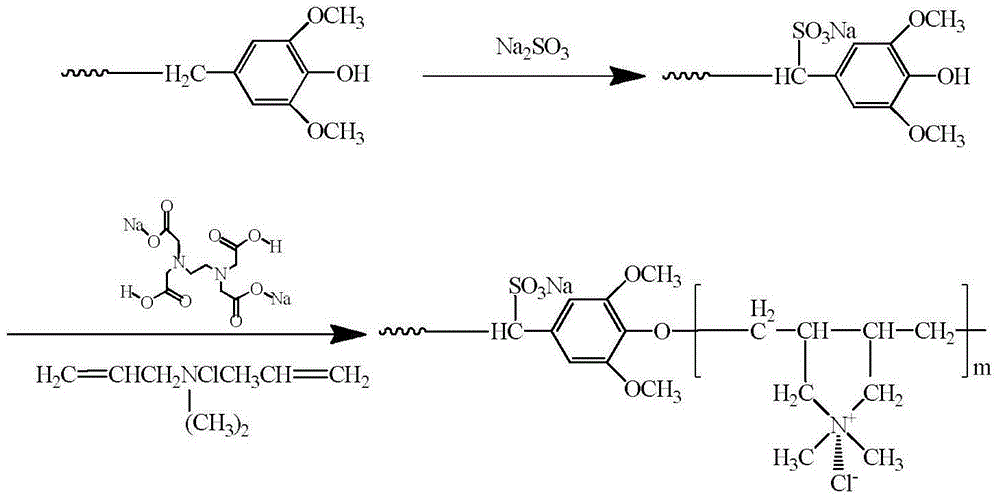

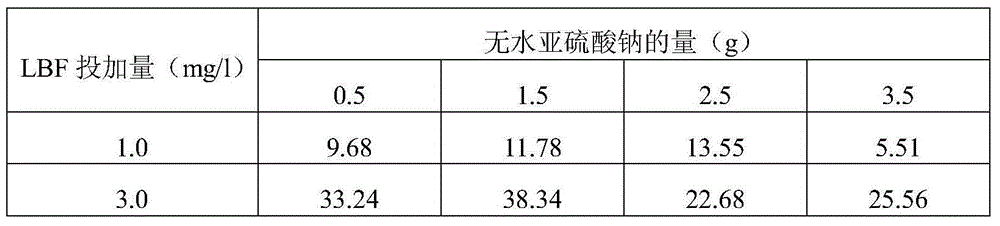

Preparation method for papermaking sludge based amphoteric polymer flocculent

ActiveCN105001381AIncrease coagulation effectSimple processSludge treatmentWaste water treatment from plant processingSulfite saltSludge

The present invention relates to a preparation method for a papermaking sludge based amphoteric polymer flocculent, comprising: dissolving a raw material of papermaking sludge directly with lye and crude extracting lignin; separating a supernatant fluid and adjusting pH of the supernatant fluid; cooling the supernatant fluid and adding an anhydrous sodium sulfite; then adding an initiator and dimethyl diallyl ammonium chloride; stirring the mixture for reaction; adding acetone and stirring the mixture; precipitating a reaction product; and vacuum filtering and drying the reaction product so as to obtain an amphoteric polymer flocculent product. When the obtained flocculant is used for treating a simulated water sample of colorant, a chroma removing rate of a dispersed yellow water sample can reach 66%, and a chroma removing rate of a methylene blue water sample can reach 35%; and combination with a conventional coagulant can significantly increase the coagulating treatment effect thereof. The preparation method in the present invention is simple to process and favorable for industrial production and application, realizing waste recycling, and the prepared flocculant has high coagulation efficiency and a wide application scope, and has a certain treatment effect on both anionic contaminants and cationic contaminants.

Owner:SHANDONG UNIV

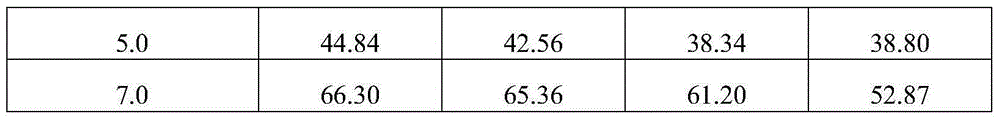

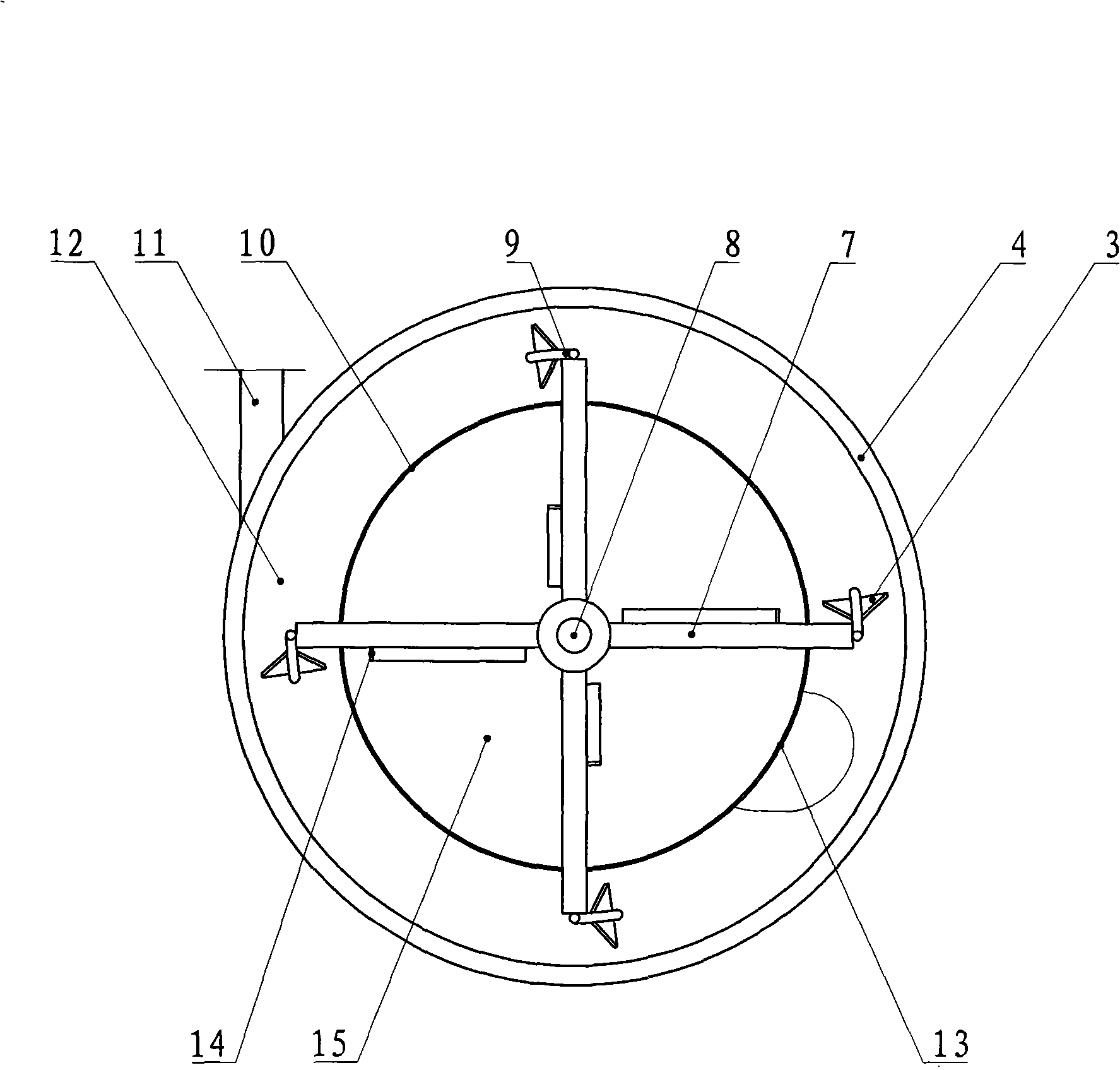

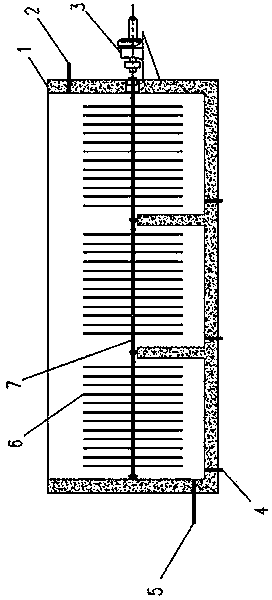

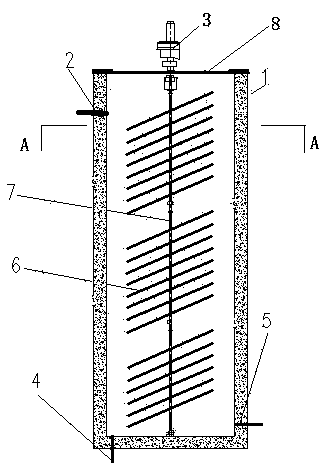

Flocculating concentration apparatus in sludge treatment

InactiveCN101328004AIncrease concentrationImprove flocculation efficiencySludge treatment by de-watering/drying/thickeningFlocculationCantilever

The invention provides a flocculation concentration device for sludge treatment which is a cylindrical tank[1]. A ring groove[2] is arranged within the outer wall on the top of the cylindrical tank, a ring division board with filter openings on arranged under a bottom wall[12] of the ring groove divides the tank into a main tank[15] and a jacket[1]. The blender has an agitating blade[13] in the ring groove and another agitating blade[14] in the main tank, an feed port of the cylindrical tank is arranged on the lower part of the ring groove, the agitating blades in the ring agitating groove and main tank are installed on the same agitating shaft[8] through a cantilever[7]. Comparing to the prior art, the flocculation concentration device in the sludge treatment provided by the invention integrates flocculation and concentration into a whole, furthermore the ring agitating groove of the flocculation part and the agitator with the filter jacket of the concentration part improve the efficiency of the flocculation and concentration. The device investment is greatly reduced because of the two in one of the device and the improvement of the device efficiency.

Owner:浙江科力尔环保设备股份有限公司

Method for preparing stevia rebaudiana polyphenols through composite chitosan flocculation method

ActiveCN109432153ARealize comprehensive utilizationReduce manufacturing costPlant ingredientsHigh concentrationIsochlorogenic acid

The invention discloses a method for preparing stevia rebaudiana polyphenols through a composite chitosan flocculation method and belongs to the technical field of plant extraction. The method comprises flocculating stevia rebaudiana water extract at room temperature with composite chitosan for impurity removal, and then absorbing supernatant through microporous resin to obtain effluent for further extraction of stevioside; then eluting the microporous resin with alcohol aqueous solutions of different concentrations, combining eluent eluted by low-concentration alcohol aqueous solutions with the undiluted effluent to obtain a combined solution with a content of total phenols lower than 0.5% on a dry basis for extracting stevioside; drying the eluent eluted by high-concentration alcohol aqueous solutions to obtain stevia rebaudiana polyphenols mainly containing isochlorogenic acid. The method for preparing the stevia rebaudiana polyphenols through the composite chitosan flocculation method achieves production of the stevia rebaudiana polyphenols with high content of isochlorogenic acid on the basis of an original stevioside production process, thereby achieving comprehensive utilization of stevia rebaudiana and increasing the economic benefits for enterprises.

Owner:DONGTAI HIRYE BIOTECH CO LTD +1

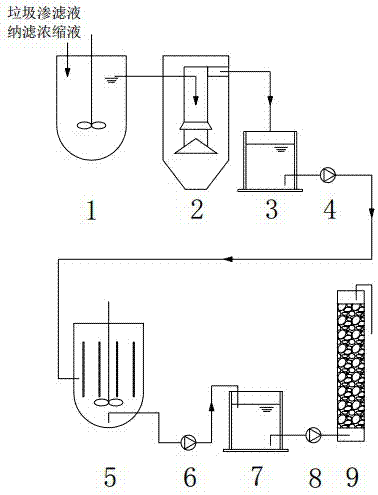

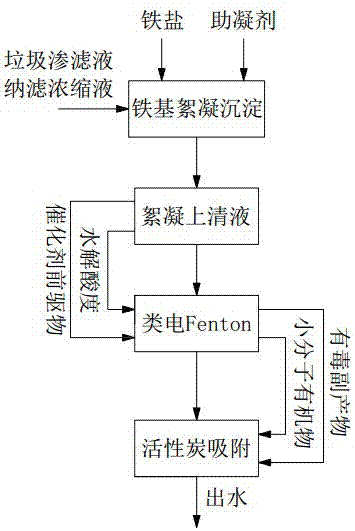

Safe and high-efficiency combined technology for landfill leachate nanofiltration concentrated solution treatment

ActiveCN107540135AImprove settlement performanceEfficient removalWater contaminantsMultistage water/sewage treatmentElectrolysisTwo step

The invention provides a safety and high-efficiency combined technology for landfill leachate nanofiltration concentrated solution treatment. The combined technology comprises three processes of iron-based flocculent precipitation treatment, electricity-like Fenton advanced oxidation and activated carbon adsorption treatment. The iron-based flocculent precipitation treatment can achieve a flocculent appropriate pH by controlling an adding mount of ferric salt to enhance a flocculation effect; in the electricity-like Fenton advanced oxidation, residual Fe<3+> of flocculation supernatant is utilized as a catalyst precursor, and an organic matter degrading effect is obviously improved compared with ordinary electrolysis; by means of arranging the activated carbon adsorption process, residuallow-molecular-weight organic matters after the former two steps and toxic and side byproducts generated in the electricity-like Fenton process can be adsorbed at the same time in high efficiency; finally safe and high-efficiency treatment on a concentrated solution is achieved; thus, the problems that the landfill leachate nanofiltration concentrated solution is difficult to treat and effluent hashigh toxicity in the field of water pollution control are solved.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

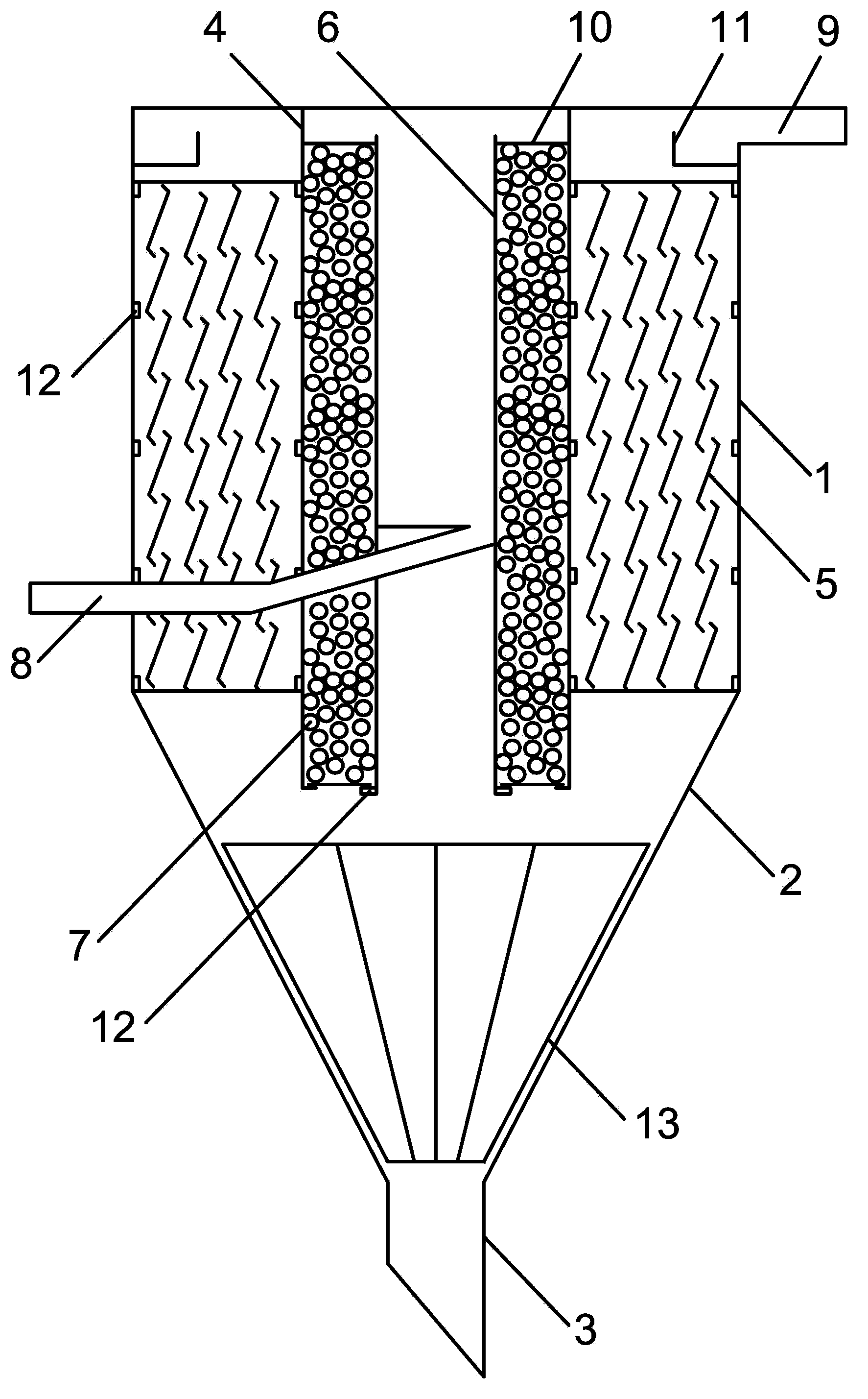

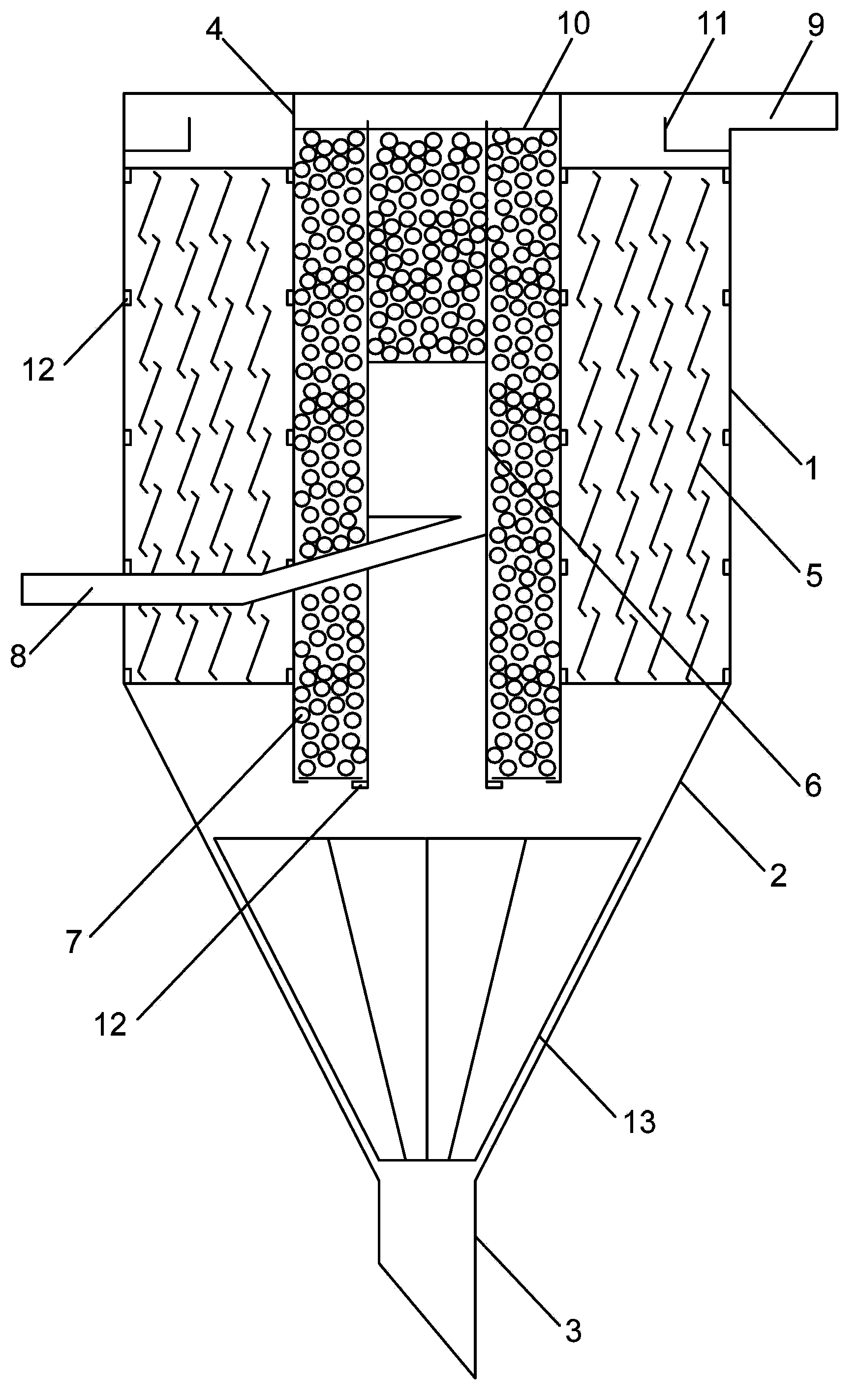

Micro-vortex high-efficiency clarification reactor and operation method for same

ActiveCN103880131ASimple structureLow running costWater/sewage treatment by flocculation/precipitationSettling basinEngineering

The invention discloses a micro-vortex high-efficiency clarification reactor and an operation method for the same. The reactor is used for solving the problem that devices are in the prior art is difficult to install, liable to obstruct, low in work efficiency, poor in using effect and short in service life. The micro-vortex high-efficiency clarification reactor includes: a clarification basin; a sludge settling basin which is disposed under the clarification basin and is communicated with the bottom of the clarification basin; a sludge discharge pipeline which is communicated with the bottom of the sludge settling basin; a flocculating reaction basin which is disposed in the clarification basin with the bottom of the flocculating reaction basin being communicated with the clarification basin and the sludge settling basin; an inclined plate settlement layer which is disposed between the clarification basin and the flocculating reaction basin and includes a plurality of inclined plates; a central basin which is disposed in the flocculating reaction basin with the top of the central basin being communicated with the upper part of the flocculating reaction basin; micro-vortex filling material which is arranged between the flocculating reaction basin and the central basin; a water inlet pipe which is tangentially connected to the lower part of the central basin; and a water outlet pipe which is communicated with the upper part of the clarification basin. The beneficial effects of the reactor are that the reactor is convenient to install and operate and is high in efficiency, excellent in processing effect, small in agent usage amount and long in service life. With the reactor, a mixing, a flocculating and a separating operation can be achieved synchronously.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Method of controlling red tide of sea water and algalbloom of fresh water

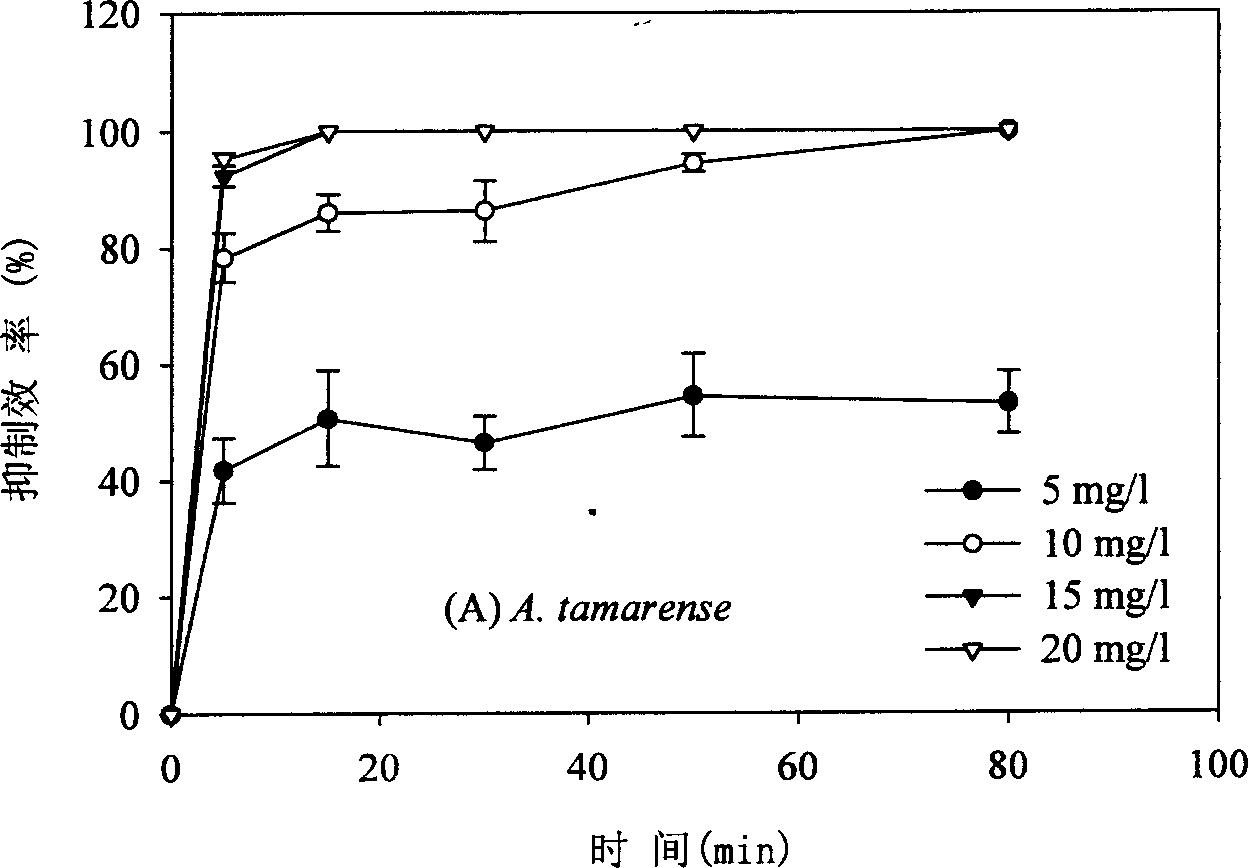

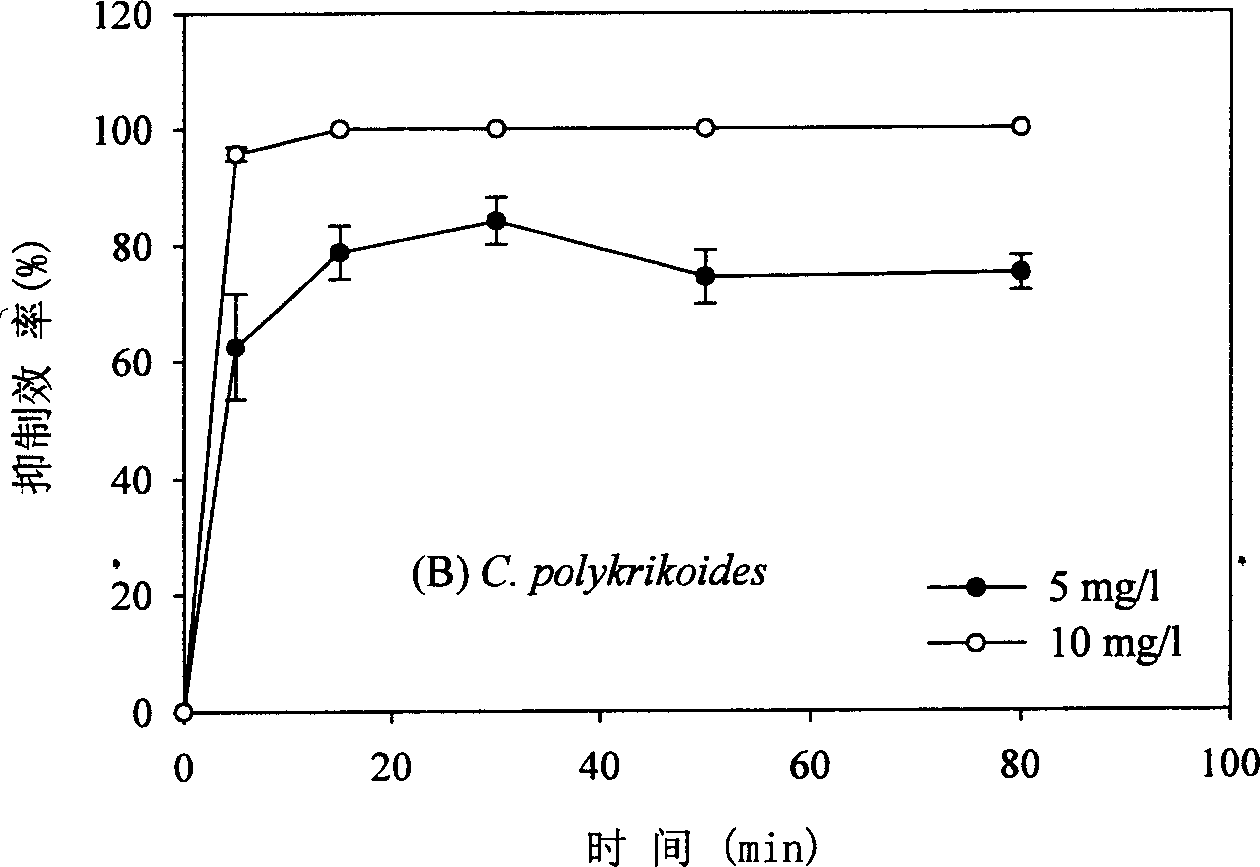

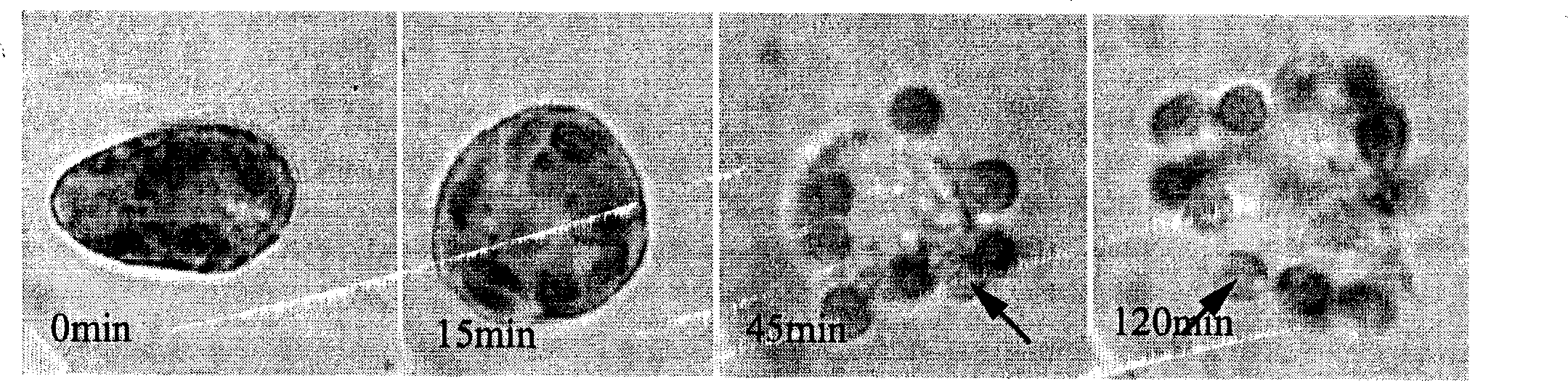

InactiveCN1847166AInhibition of growth and reproductionImprove flocculation efficiencyWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processRed tideSeawater

The present invention relates to red tide and algalbloom preventing and controlling technology, and is especially method of adopting glycolipid surfactant in treating red tide of sea water and algalbloom of fresh water. The effective component of the biological surfactant is sophor glycolipid as one kind of mixture comprising one acid type matter and one lactone type matter. It may be used alone to inhibit and kill harmful alga and crack their cells effectively and the effective concentration for eliminating alga in different kinds is 5-10 mg / l. It may be also used through mixing with clay mineral to raise the flocculant efficiency organic clay mineral obviously, and the optimal mixing weight ratio to loess is 1 to 100-200. The present invention has easy biodegradation, no harm to other life beings, no secondary pollution and easy storing.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

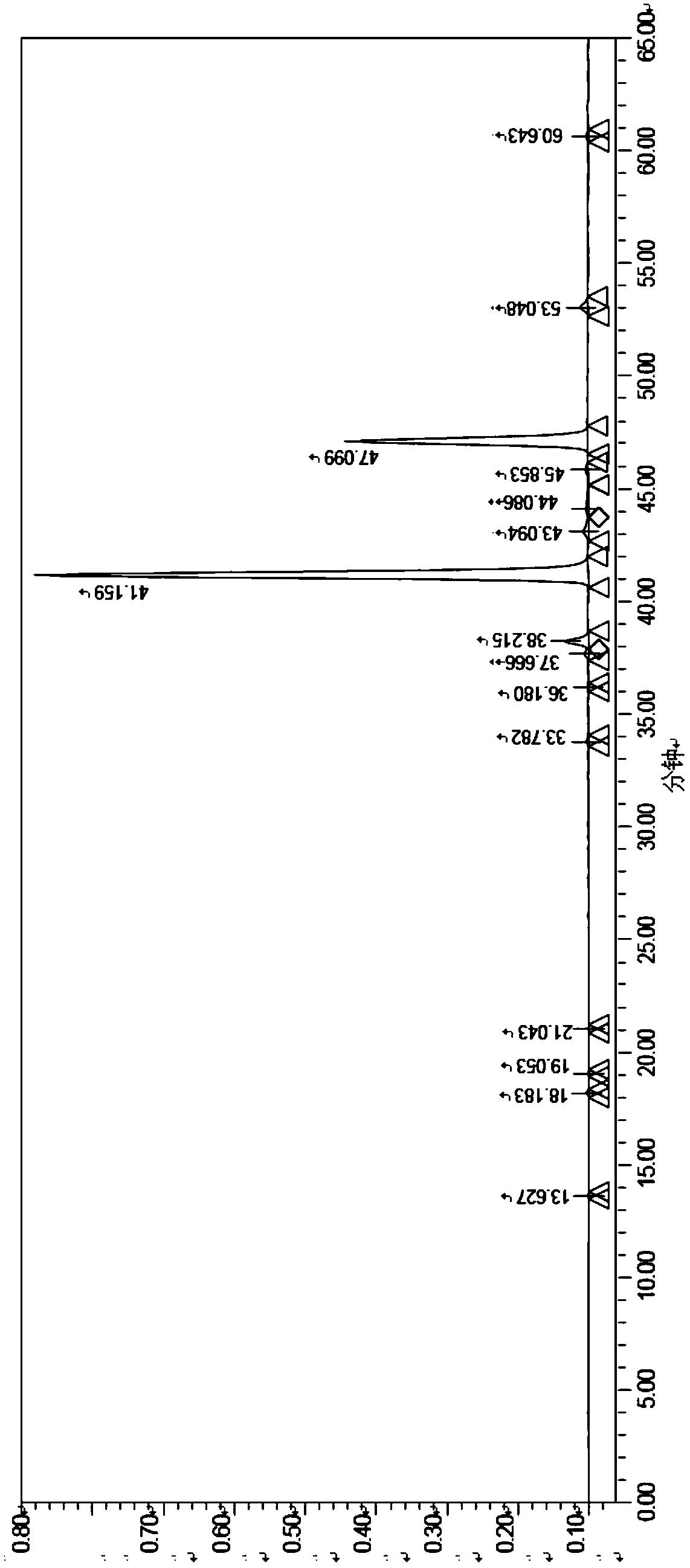

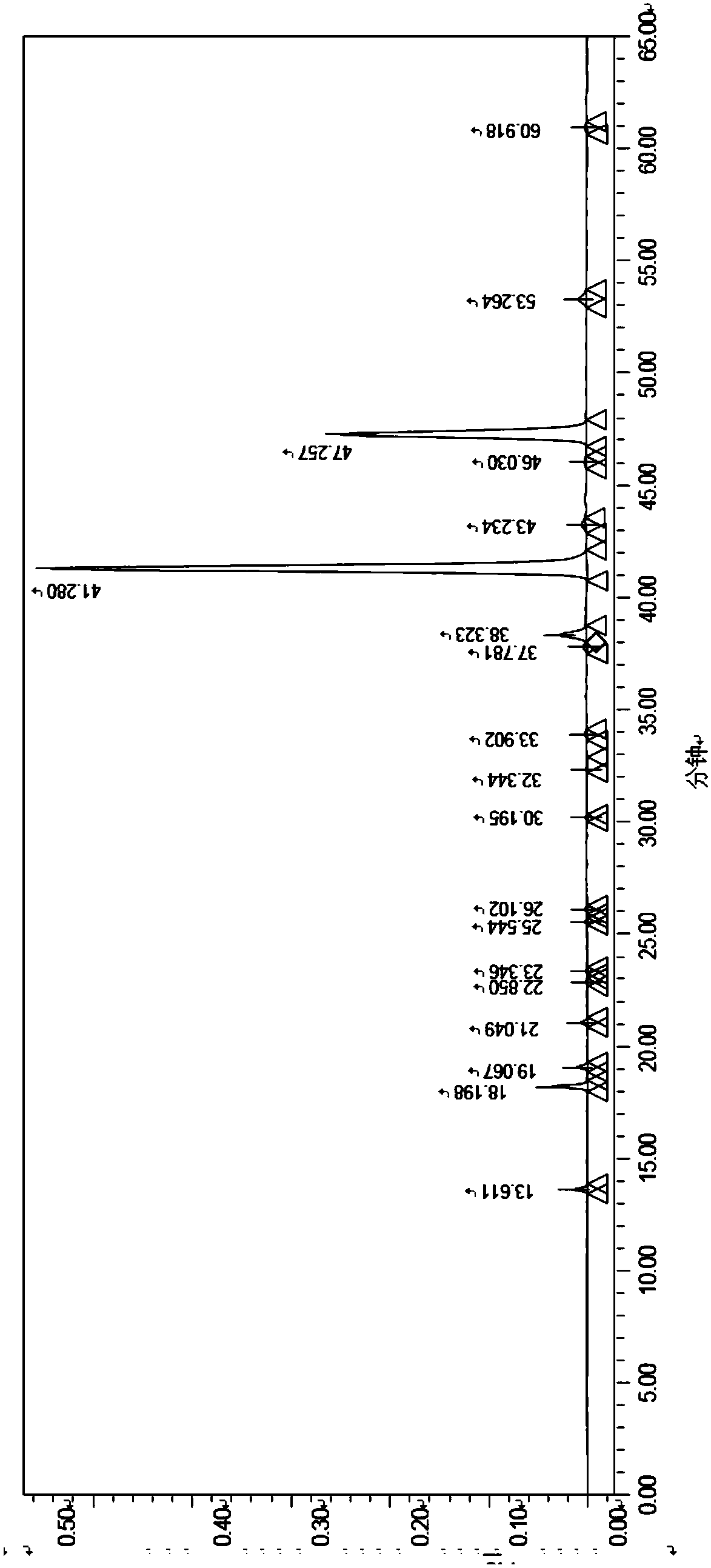

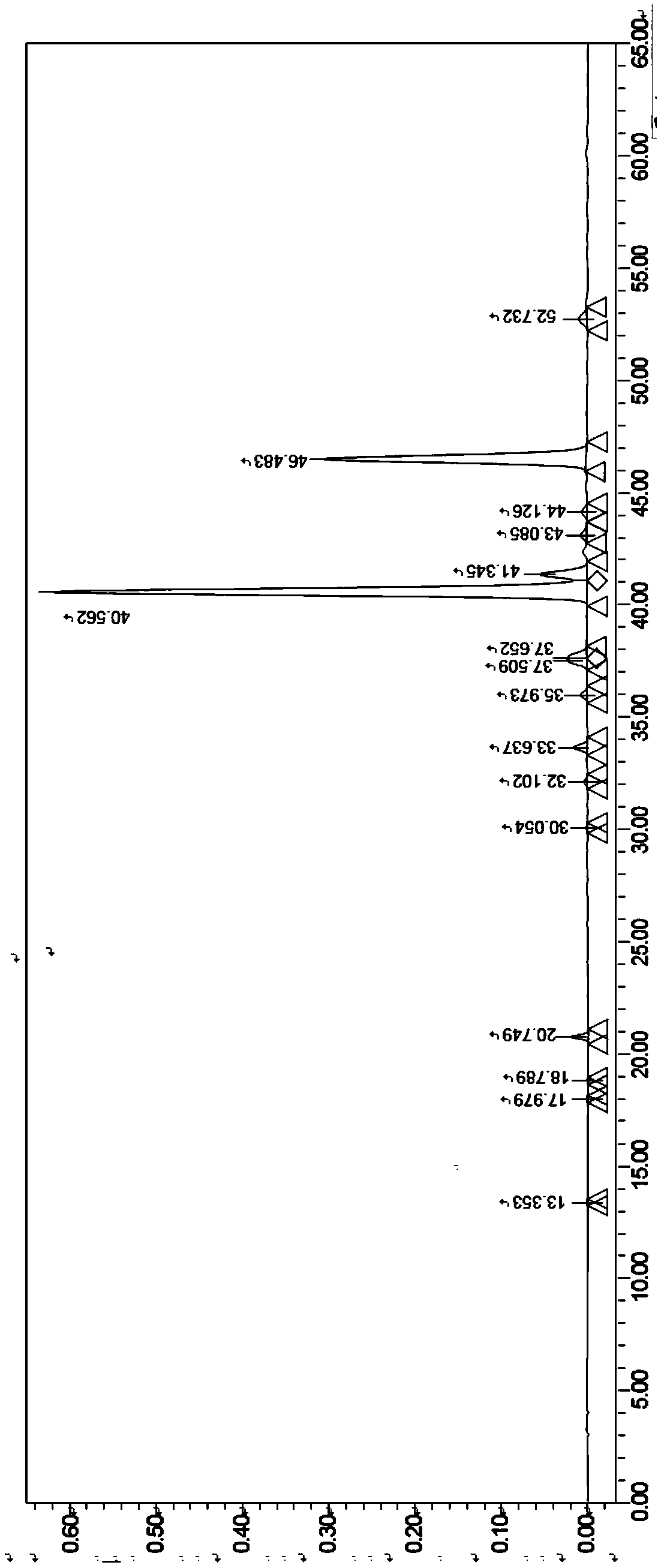

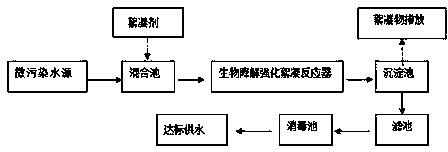

Method for treating micro-polluted source water by using biodegradation flocculation reaction tank

ActiveCN104108835AReduce processing costsImprove effluent qualityMultistage water/sewage treatmentWater sourceWater quality

The invention discloses a method for treating micro-polluted source water by using a biodegradation flocculation reaction tank, belonging to the technical field of water treatment. The method comprises the concrete steps of (1) enabling micro-polluted source water to enter a mixing tank, adding a coagulant, uniformly mixing, and reacting for 10-30s; (2) enabling effluent of the mixing tank to enter a biodegradation flocculation reaction tank so as to be treated, and reacting for 15-25min; (3) enabling effluent of the biodegradation flocculation reaction tank to enter a sedimentation tank so as to be subjected to solid-liquid separation; (4) enabling effluent of the sedimentation tank to sequentially enter a filter tank and a disinfecting tank and finally enter a water supply network after the water quality is casually inspected to be up to the standard. The method has the beneficial effects that a packing layer in the biodegradation flocculation reaction tank rotates along with a driving shaft to ensure that a biofilm formed by attached microorganisms is in repeated contact with micro-polluted source water, so that low-molecular weight organic matters and ammonia nitrogen in water are degraded, the flocculation efficiency is increased, and the water quality is further improved; in addition, the reaction tank is simple in inner structure, so that the water treatment cost is reduced.

Owner:山东华城工程技术有限公司

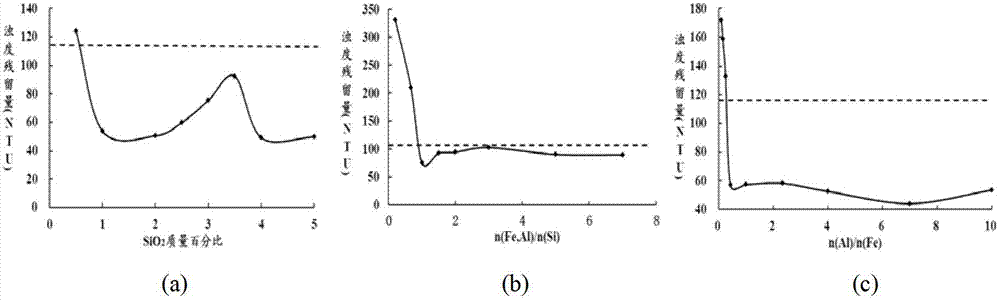

Method for removing silicon from waste water discharged from coal water slurry gasification process

InactiveCN110182994AImprove flocculation efficiencyPromote growthWater contaminantsMultistage water/sewage treatmentFlocculationCoal water

The invention provides a method for removing silicon from waste water discharged from a coal water slurry gasification process. The silicon removal method comprises the following steps: step S1, adjusting the pH value of the effluent to 10-13, and flocculating the effluent with a flocculant to obtain a first-stage mixed waste water; step S2, performing coagulation treatment on that first-stage mixed waste water by using a coagulant aid to obtain the second-stage mixed waste water; step S3, carrying out sedimentation treatment on that second-stage mixed waste water to obtain secondary supernatant and secondary precipitated sludge, and returning at least part of the secondary precipitated sludge to the second-stage mixed waste water for auxiliary coagulation treatment in the step S2. The invention adjusts the pH value of the effluent to 10-13 before the flocculation treatment to facilitate the formation of alum flower between the dissolved silicon and the flocculant, thereby improving the flocculation efficiency of the dissolved silicon; at that same time, the secondary precipitate sludge obtained by circumfluence sedimentation in the step S2 is used as a contact medium to acceleratethe growth of the precipitate, improve the coagulation effect and improve the silicon removal effect.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

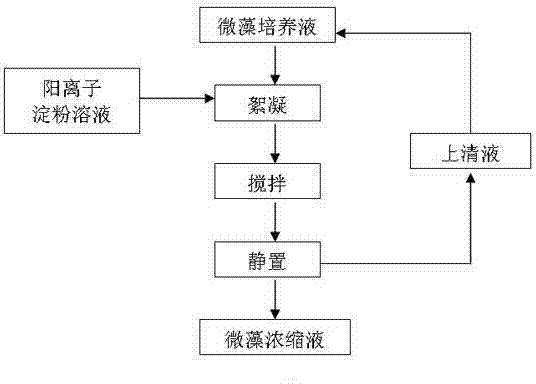

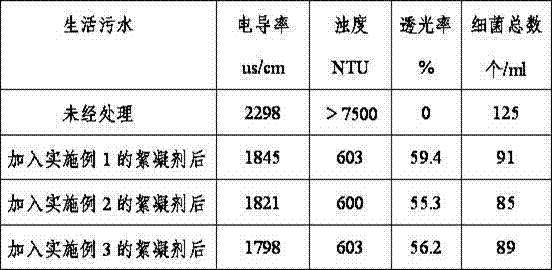

Environment-friendly microalgae collecting method

The invention discloses an environment-friendly microalgae collecting method. According to the method, microalgae is cultured into the concentration of 0.5 g / L-1.5g / L in a microalgae bioreactor, 80% of a microalgae culture solution is transferred into a flocculation reaction tank through a pipeline or a pump, a cationic starch solution with a substitution degree of 0.15-0.45 is added into the microalgae culture solution and is taken as a flocculating agent, the wet to dry weight ratio (w / w) of a cationic starch mass to the microalgae in the solution ranges from 0.01 to 0.20, the microalgae culture solution is stirred for 5-10 minutes at the rotation speed of 200 r / min to promote the microalgae to flocculate, the microalgae culture solution is subjected to static settlement for 10-30 minutes, a sedimentary microalgae concentrated solution is collected, and a liquid supernatant is circularly used for re-cultivating the microalgae. According to the environment-friendly microalgae collecting method, the cationic starch solution is taken as the flocculating agent, so that the method has the characteristics of non-toxicity, economy, environmental protection, high flocculation efficiency and the like, flocculated microalgae is dense, the enrichment factors are high, original biological characteristics of the microalgae can be better kept, and the microalgae can be directly used in the fields of food, feed, biodiesel and the like.

Owner:FUZHOU UNIV

Papermaking wastewater treatment agent and method for treating papermaking wastewater by using same

InactiveCN107746085AImprove flocculation efficiencyReduce usage and water treatment costsWater treatment parameter controlSpecific water treatment objectivesChemistryPapermaking

The invention discloses a papermaking wastewater treatment agent and a method for treating papermaking wastewater by using same. The papermaking wastewater treatment agent is prepared from an iron ionflocculant, a polyacrylamide flocculant, activated carbon, phyllosilicate, and the like. The method for treating the papermaking wastewater comprises the following steps: (1) adding lime milk into the papermaking wastewater, and adjusting the pH value to 7-11; then, adding the papermaking wastewater treatment agent and stirring; (2) when large flocculation is formed in the wastewater, stopping stirring, standing for settling, separating floccules in circulating water, and enabling the treated wastewater to enter next circulation for treating; (3) measuring the chemical oxygen demand (COD), suspended solids (SS) and chrominance index of the treated wastewater. The papermaking wastewater treatment agent disclosed by the invention has a good treatment effect on the papermaking wastewater, and is good in stability; the water quality of the papermaking wastewater treated by using the papermaking wastewater treatment agent meets emission standards.

Owner:GUANGDONG PAPER IND RES INST

Flocculant and preparation method thereof

ActiveCN102491465ARealize comprehensive utilizationHigh affinityWater/sewage treatment by flocculation/precipitationIron sulfateTurbidity

The invention discloses a flocculant. The flocculant comprises, by weight, 75-90% of calcium hydrate, 0.8-15% of iron sulfate, and 5-14.2% of aluminum sulfate. The flocculant of the invention, which can effectively remove turbidities and harm substances of metallic ions and the like, has the advantages of nontoxicity, harmlessness, no secondary pollution, fast flocculation, low price, and use convenience.

Owner:ELION ECOLOGICAL RESTORATION

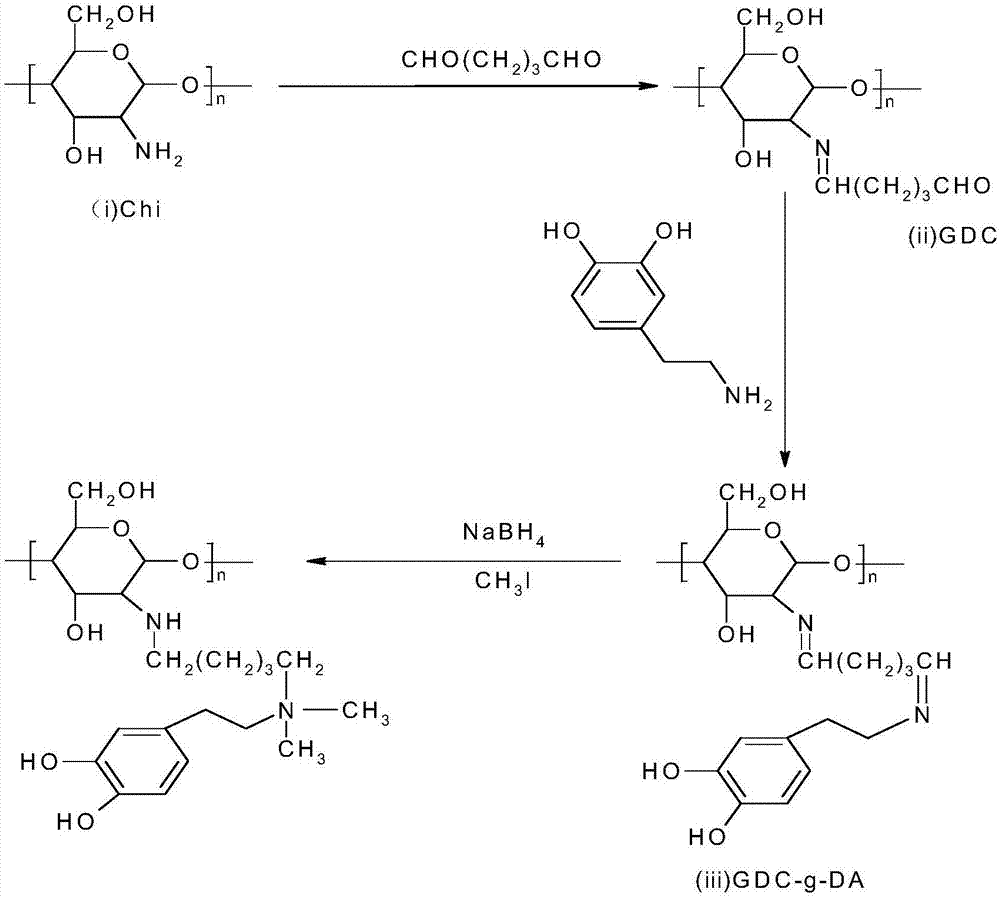

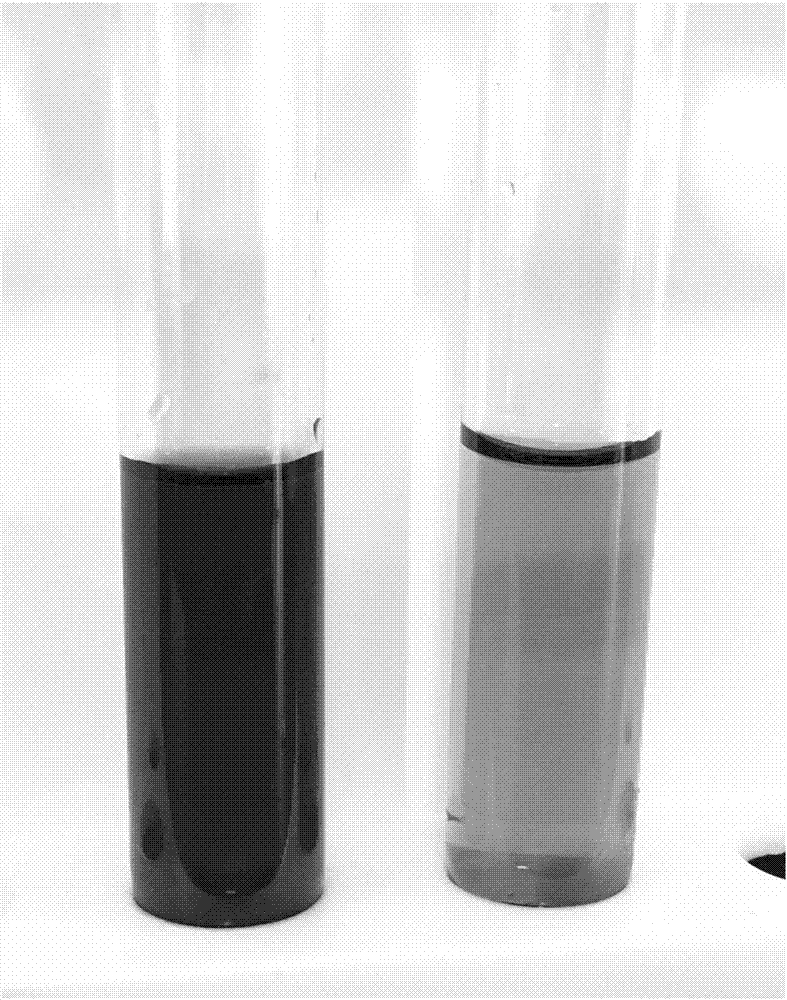

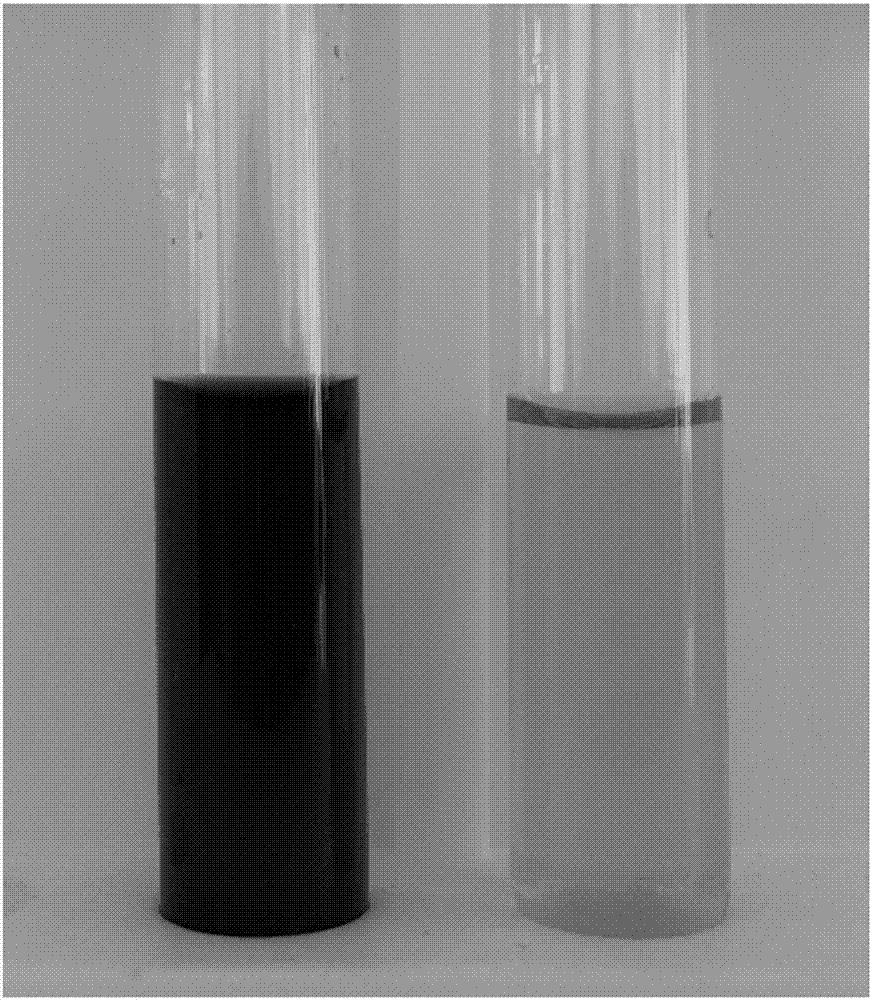

Dopamine-modified chitosan flocculant

ActiveCN107055729AGood biocompatibilityLow priceWaste water treatment from textile industryWater/sewage treatment by flocculation/precipitationFlocculationSolubility

The invention provides a chitosan flocculant for treating sewage containing polyacrylamide. The chitosan flocculant is prepared through grafting of chitosan with dopamine adopting an o-dyhydroxyl structure by the aid of glutaraldehyde under the acidic condition. Materials used in the flocculant are green and pollution-free and cause less damage to the environment. The novel flocculant synthesized by grafting chitosan with dopamine greatly increases the adsorption capability and the dissolubility of chitosan and has a flocculation good effect on sewage containing polyacrylamide; secondary flocculation of dye sewage can be realized by use of precipitates obtained after sewage containing polyacrylamide is treated by the flocculant, and a relatively ideal flocculation effect is obtained. By means of the flocculant, secondary recycling of polyacrylamide is realized, the flocculant has a better flocculation effect on the sewage containing polyacrylamide and printing and dyeing sewage, the flocculation efficiency is greatly improved, and the flocculation cost is saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Magnetic method for preprocessing flocculation of collected object for L - lactic fermentation liquid

InactiveCN1916179AImprove flocculation efficiencyFacilitate solid-liquid separationMicroorganism based processesFermentationLactic acid fermentationChemistry

This invention discloses a method for pretreating L-lactic acid fermentation solution with magnetic polymer by flocculation. The magnetic polymer is prepared from chitosan and ferroferric oxide in a weak acid condition. The method comprises: adding the magnetic polymer into L-lactic acid fermentation solution, stirring so that a flox occurs, applying a magnetic field for 1-2 min to separate the floc from the solution, and removing the floc to obtain L-lactic acid fermentation solution. The method has such advantages as simple process, high flocculation rate, compact floc structure, rapid solid-liquid separation, high treating efficiency and no influence on L-lactic acid content in the fermentation solution. The method has potential applications in the pretreatment of L-lactic acid fermentation solution.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Efficient integrated flocculation system

ActiveCN109399844AIncrease costAdd process stepsWater treatment parameter controlWater contaminantsTime rangeFlocculation

The invention provides an efficient integrated flocculation system which comprises a water inlet buffer chamber, an agent putting chamber, a coagulating stirring chamber, at least two overflow settling chambers, a special settling chamber, an oblique-plate settling chamber and a water outlet chamber connected with a water outlet. For solving the high cost and low efficiency of traditional sewage treatment, multiple types of industrial wastewater instable in suspended solid particle concentration can be treated by adopting the steps of single-time dosing, stirring flocculation, multi-stage sediment and the like, the integrated system can achieve dynamic adjustment according to water amount, the sizes of the devices are enough to ensure appropriate hydraulic retention time, and various sizesof devices all can achieve stable outlet water quality in a certain time range.

Owner:湖南钜晟环保科技股份有限公司

Microalgae culture solution treatment method

ActiveCN104342373AImprove flocculation efficiencyOvercome the difficulty of isolating microalgaeUnicellular algaeMicroorganism based processesOrganic acidWater soluble

The present invention provides a microalgae culture solution treatment method, which is characterized by comprising: (1) adjusting the pH value of a microalgae culture solution to be treated to 9.5-12 so as to obtain the microalgae culture solution with the adjusted pH value; and (2) carrying out contact on the microalgae culture solution with the adjusted pH value in the step (1) and a flocculant solution so as to flocculate the microalgae, wherein the flocculant solution contains chitosan and a water-soluble organic acid. With the technical scheme, the flocculation efficiency of the chlorella can be increased to more than 90% by adopting the method of the present invention.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manufacturing method of bayer process red mud flocculating agent

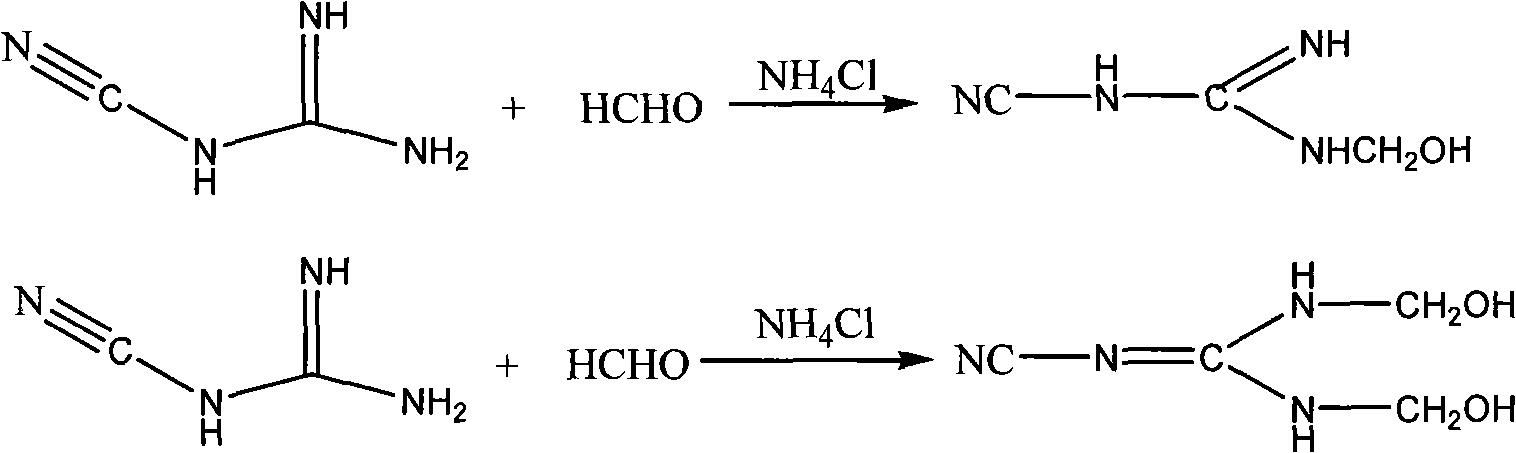

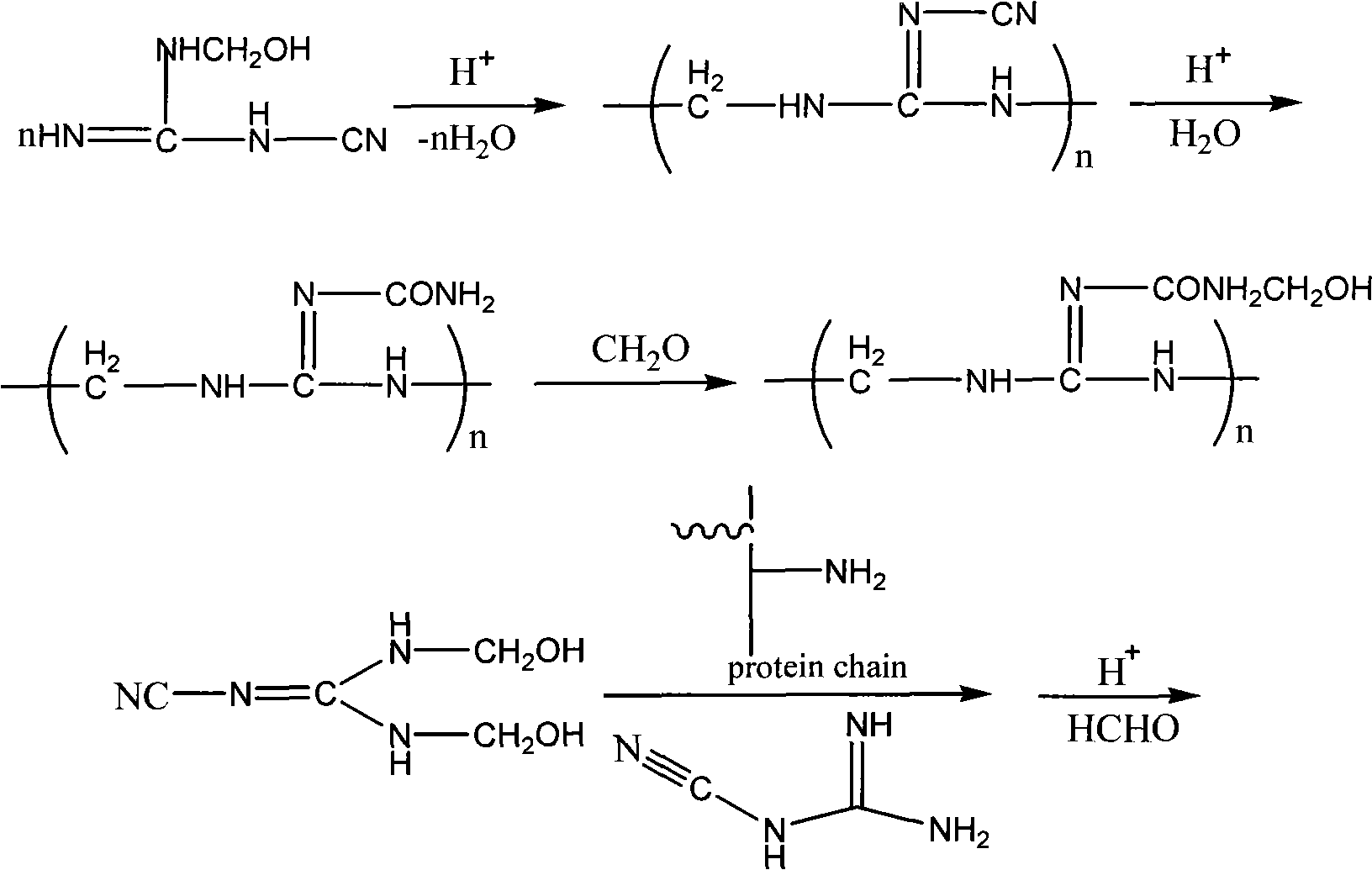

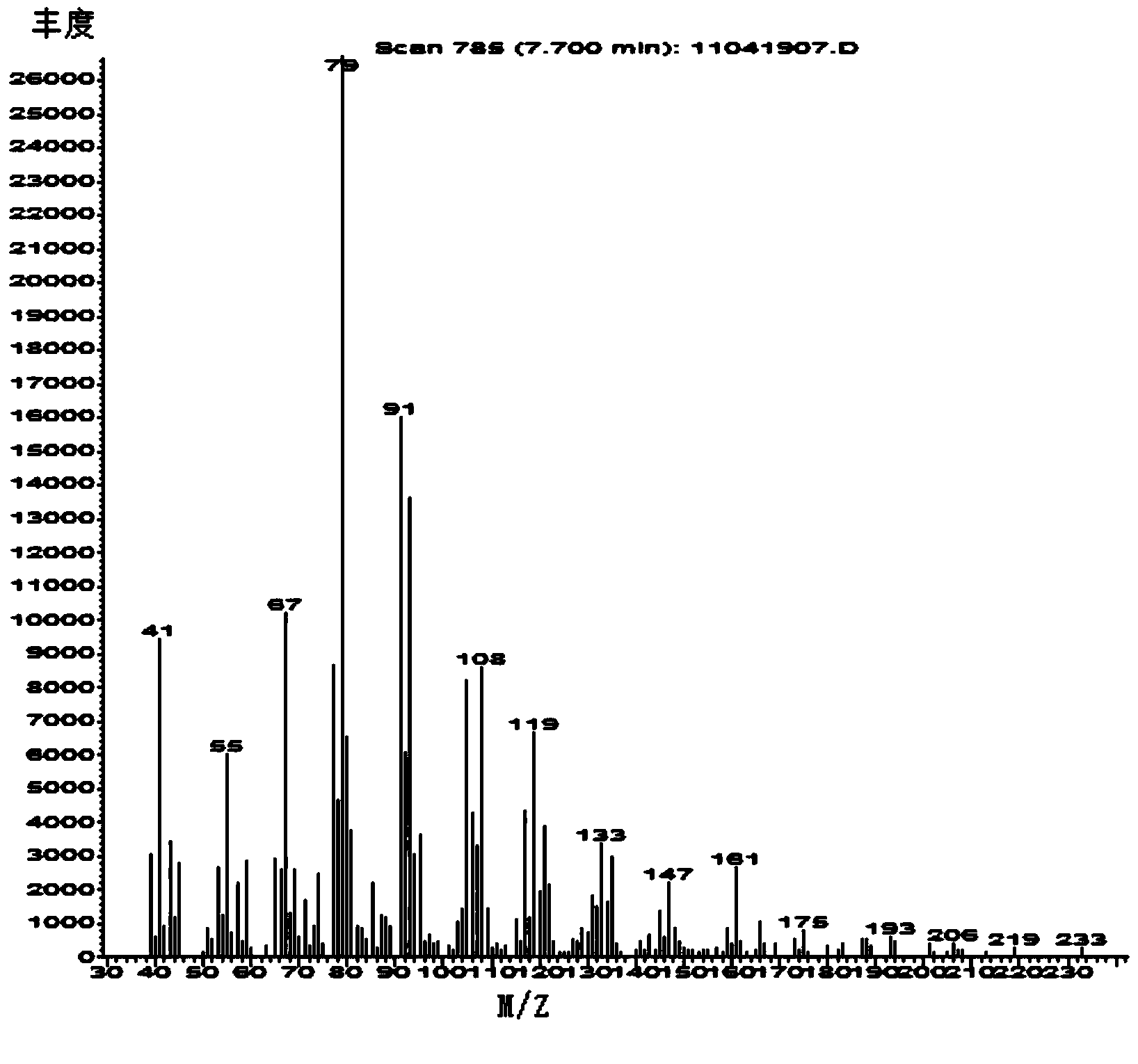

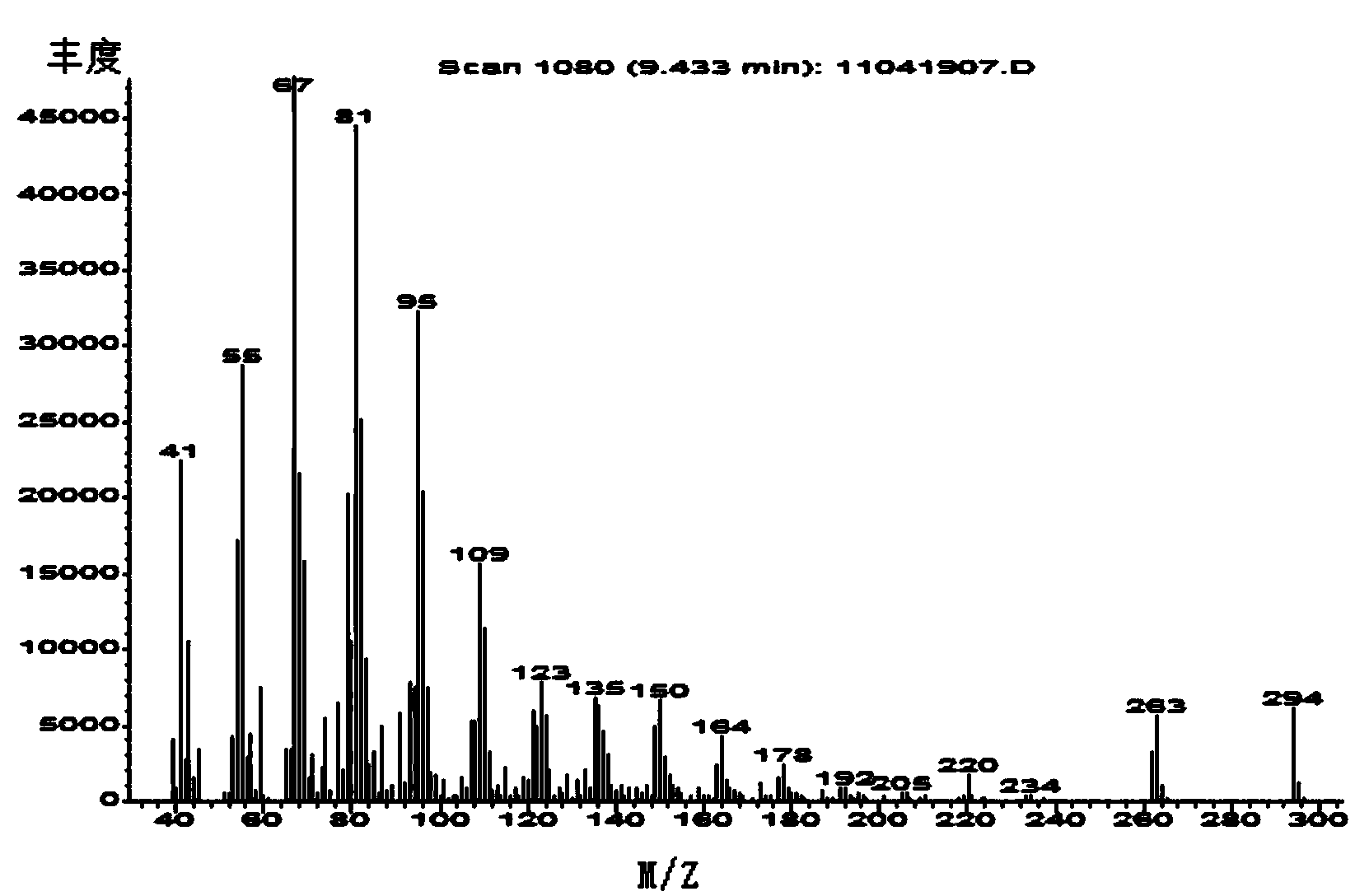

InactiveCN101117262AImprove flocculation efficiencySimple and fast manufacturing methodSludge treatment by de-watering/drying/thickeningRed mudMannich reaction

The invention relates to a manufacturing method of flocculating agents for the sedimentation of Bayer process red mud, which belongs to the environmental protection technical scope. The invention is characterized in that: polyacrylamide obtains cation and cationic polyacrylamide is prepared by the adoption of nonionic polyacrylamide as the raw material, through basic hydrolysis, modification of ester of hydroxamic acid and Mannich reaction, with the formation of Mannich base as the intermediate step; olyacrylamide is made to consist of anion group and cation group and zwitterionic polyacrylamide is prepared by the adoption of nonionic polyacrylamide as the raw material, through basic hydrolysis, modification of ester of hydroxamic acid and Mannich reaction, with the formation of Mannich base as the intermediate step. The invention has the advantages that the preparation method is simple; the flocculation efficiency of ferriferous and siliceous slag during the manufacturing process of prior Bayer process aluminum oxide reaches to more than 20m / h; the seston in the solution after flocculation is less than or equal to 1g / L; the manufacturing method is superior to the international standards; the cost is only 70-80 percent of the international similar products; the manufacturing method is in accordance with the national conditions, easy to go into production of an industrial scale, without the generation of secondary pollution and the three wastes during the production process, and eco-friendly.

Owner:淄博中科新材料有限公司

Mine water magnetic separation water purification process and device used in coal mine

ActiveCN110372071AImprove the effect of magnetic separation and purificationHigh magnetic seed recoveryWaste water treatment from quariesWater/sewage treatment by magnetic/electric fieldsFlocculationAfter treatment

A mine water magnetic separation water purification process and device used in coal mine are disclosed. The device mainly comprises a pipeline mixer, a coagulation tank, a magnetic seed adding tank, aflocculation device, a sedimentation tank, a magnetic separation device, a water purification after-treatment device, a sludge dewatering machine, wherein the pipeline mixer, the coagulation tank, the magnetic seed adding tank, the flocculation device and the sedimentation tank are connected in turn through the pipeline, and the magnetic mud outlet and water purifying outlet of the sedimentationtank are connected with the magnetic separation device and the water purifying after-treatment device through the pipeline; the mud outlet of the magnetic separation device is connected with the sludge dewatering machine through a pipeline; the magnetic seed port of the magnetic separation device is connected with the magnetic seed adding tank through a pipeline, and the sludge dewatering machineis connected with the water inlet end of the pipeline mixer through a pipeline. The process and the device of the invention have the advantages of high recovery rate of magnetic seeds, recycling treatment of demagnetized sludge, environmental protection, high efficiency and rapidity.

Owner:JIANGSU TIAN XIN WATER TREATMENT EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com