Method for preparing cationic organic flocculant by using paper-making sludge

An organic flocculant and papermaking sludge technology, which is applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effect of increasing the removal of anion impurities, facilitating purification, and excellent removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

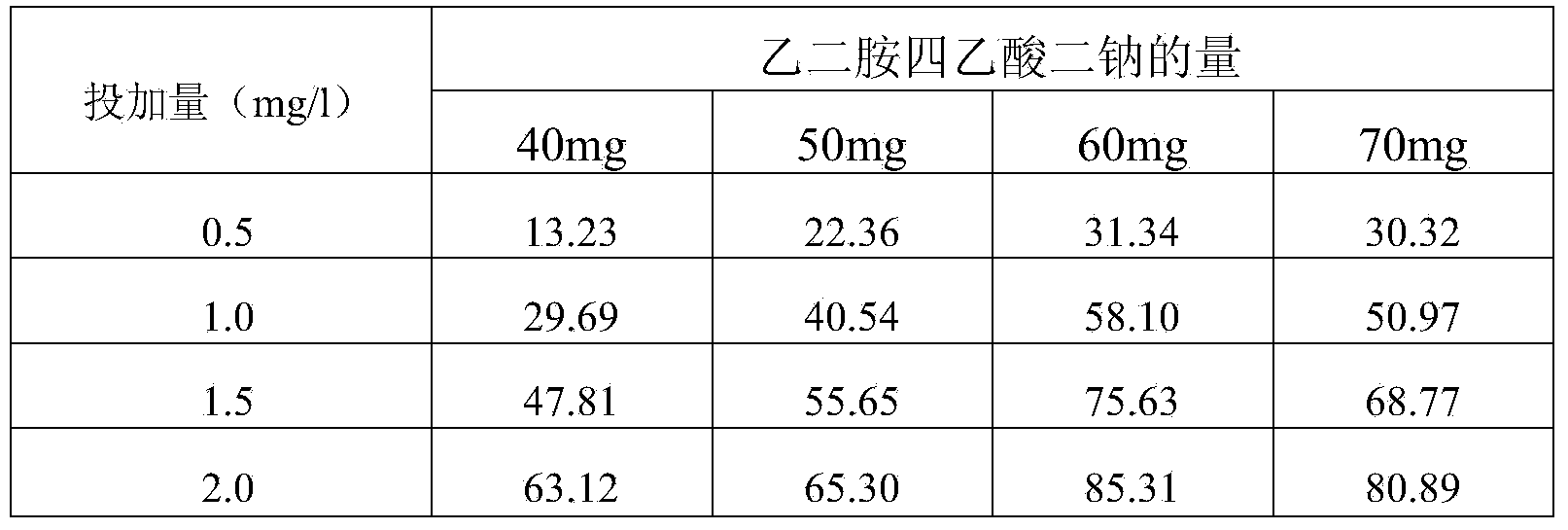

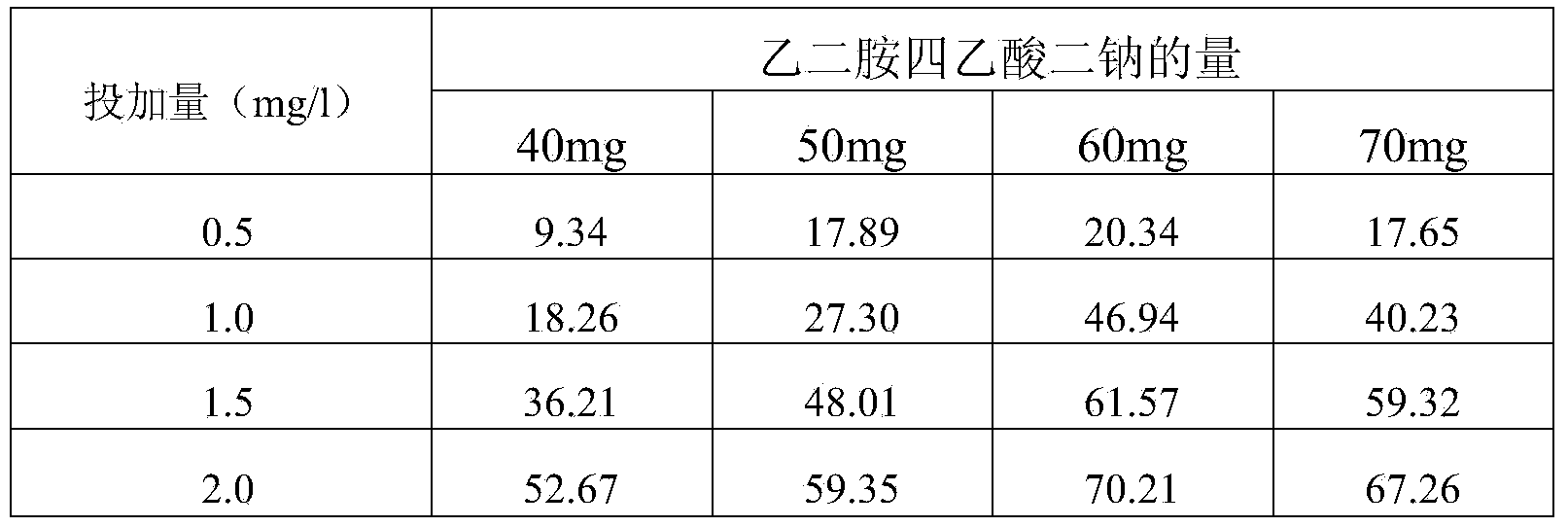

[0031] Embodiment 1. Preparation of cationic organic flocculant (L-AM-N) with different disodium edetate additions

[0032] (1) Take 2.0g of papermaking sludge, add 60ml deionized water and 10wt% NaOH solution, stir, make the pH stable at about 11.5, centrifuge at 8000rpm for 15min, take the supernatant and place it in the reactor, adjust the pH to 7.5;

[0033] (2) Put the reactor into a 70°C water bath, stir for 5 minutes, add potassium peroxodisulfate with a mass of 50 mg, and activate with nitrogen gas for 10 min, add disodium edetate with a mass of 40 mg, 50 mg, 60 mg, and 70 mg respectively , react for 5 minutes, add 2g of acrylamide monomer, add 8ml of 60wt% dimethyl diallyl ammonium chloride solution, continue to pass nitrogen for 5 minutes, and continue to react for 4 hours at 70°C;

[0034] (3) After the reaction, cool to room temperature, add 200ml of acetone to precipitate the product, filter, and vacuum-dry the filter residue at 60°C to obtain four products with ...

Embodiment 2

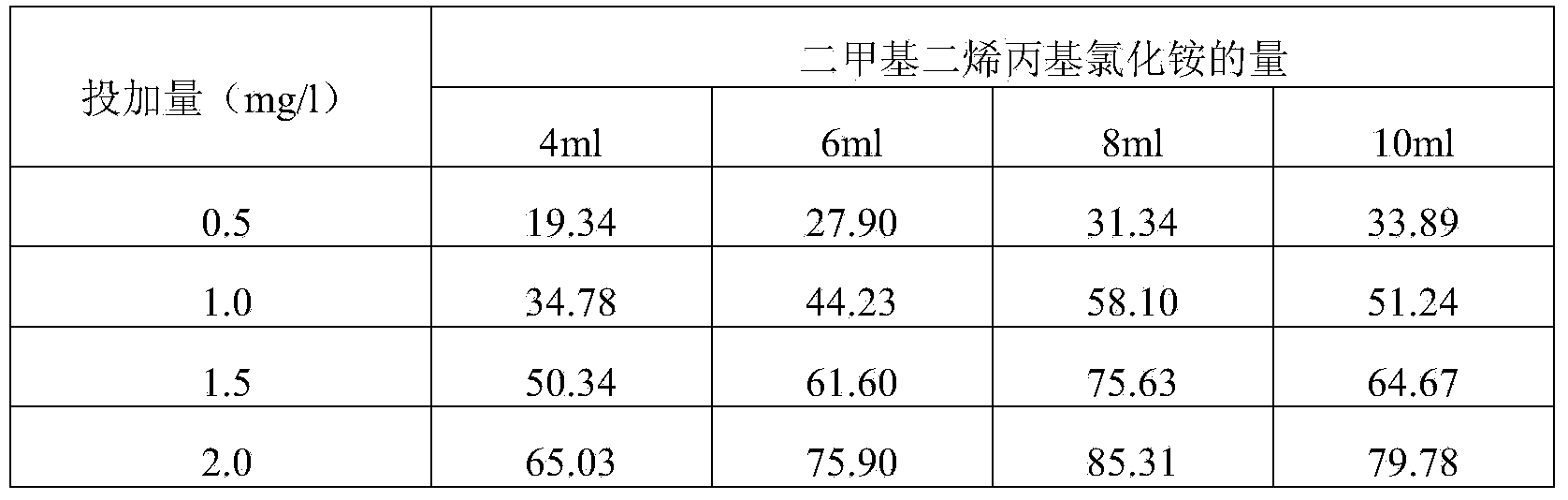

[0035] Embodiment 2. The preparation of the cationic organic flocculant (L-AM-N) of different dimethyl diallyl ammonium chloride addition amount

[0036] (1) Take 2.0g of papermaking sludge, add 60ml deionized water and 10wt% NaOH solution, stir, make the pH stable at about 11.5, centrifuge at 8000rpm for 15min, take the supernatant and place it in the reactor, adjust the pH to 7.5;

[0037] (2) Put the reactor into a water bath at 70°C, stir for 5 minutes, add potassium peroxodisulfate to a mass of 50 mg, activate with nitrogen for 10 minutes, add 60 mg of disodium edetate, react for 5 minutes, add 2 g of acrylamide mono body, add 60wt% dimethyl diallyl ammonium chloride solution in volumes of 4ml, 6ml, 8ml, 10ml respectively, continue to pass nitrogen gas for 5min, and continue to react for 4h at 70°C;

[0038] (3) After the reaction, cool to room temperature, add 200ml of acetone to precipitate the product, filter, and vacuum-dry the filter residue at 60°C to obtain four p...

Embodiment 3

[0039] Example 3. Preparation of cationic organic flocculants (L-AM-N) with different acrylamide additions

[0040]The steps are the same as in Example 2, except that the volume of the dimethyldiallylammonium chloride solution in the step (2) is fixed to 8ml, and the amount of acrylamide is respectively 1.5g, 2.0g, 2.5g, 3.0g to obtain cationic organic flocculant products with different acrylamide additions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com