Method for preparing ball clay through resource utilization of urban construction engineering muck

A technology for construction engineering and resource utilization, which is applied in the field of urban building engineering slag resource utilization and preparation of ball soil, can solve the problems of filter screen clogging, time lengthening, edge clogging and other problems, saving time and cost, speeding up filter press process, the effect of preventing filter clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the examples, but the present invention is not limited in any way, and any transformation or substitution made based on the teaching of the present invention belongs to the protection scope of the present invention.

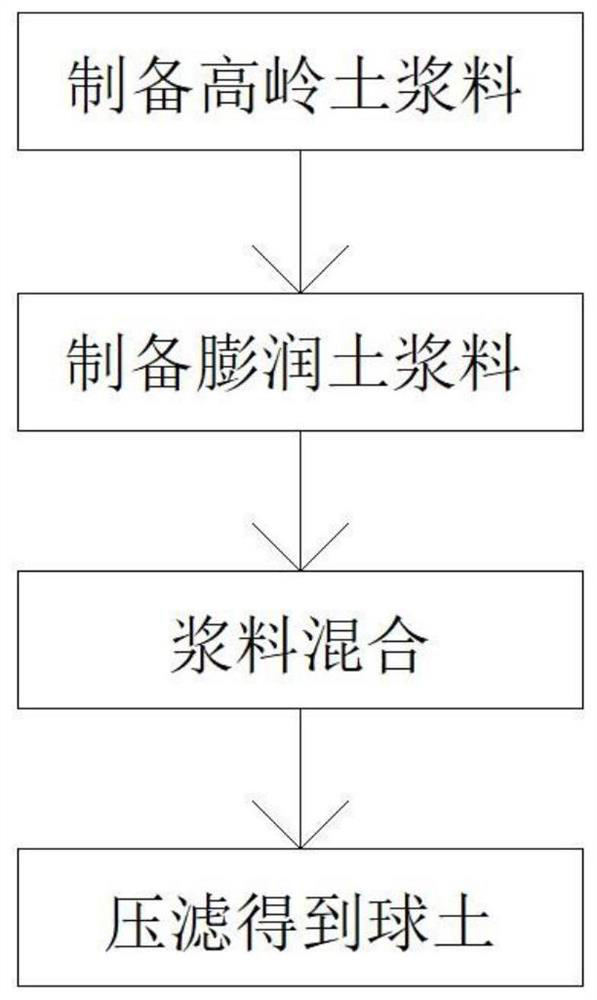

[0048] Such as figure 1 As shown, a kind of urban construction project slag resource utilization of the present invention prepares the method for ball soil, comprises the following steps:

[0049] 1. Preparation of kaolin slurry:

[0050] 1.1 Sand removal and impurity removal:

[0051] Pour the construction engineering dregs rich in kaolinite into the mixing tank, add water and diluent in sequence in proportion to form a slurry with a dry material percentage of 20%, then fully stir the slurry, and let it stand for a period of time , Use a screen to remove impurities such as sand, stone and mica deposited on the bottom of the pool, and remove impurities such as leaves and bark float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com