Environment-friendly microalgae collecting method

An environmentally friendly, microalgae technology, applied in the field of bioengineering, can solve the problems of high cost of chitosan, low concentration factor of microalgae, unsatisfactory economy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

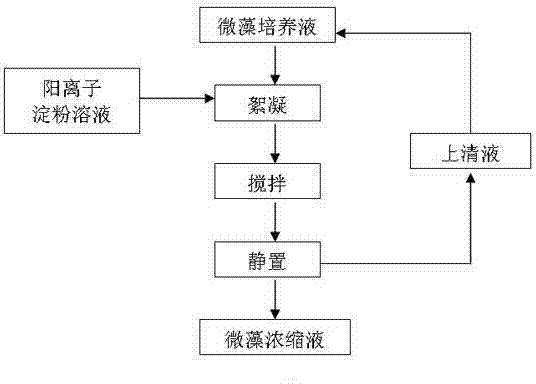

Method used

Image

Examples

Embodiment 1

[0020] Dissolve 1 part of cationic starch in 1000 parts of distilled water, gelatinize in a water bath at 80 °C for 30 min, and cool for 2 h to prepare a cationic starch solution. The microalgae were cultured in the microalgae bioreactor to grow to a concentration of 0.5 g / L, and 80% of the microalgae culture solution was transferred to the flocculation reaction tank through the pipeline, and the substitution degree was added to the microalgae culture solution in the flocculation reaction tank. The 0.15 cationic starch solution was used as a flocculant, so that the dry weight ratio (w / w) of the cationic starch mass to the microalgae in the solution was 0.20, and the microalgae culture solution was stirred at a speed of 200 r / min for 5 minutes to promote the flocculation of the microalgae, and then The microalgae culture solution was left to settle for 10 minutes, the precipitated microalgae concentrate was collected, and the supernatant was circulated for recultivation of the m...

Embodiment 2

[0022] Dissolve 1 part of cationic starch in 1000 parts of distilled water, gelatinize in a water bath at 80 °C for 30 min, and cool for 2 h to prepare a cationic starch solution. The microalgae were cultured in the microalgae bioreactor to grow to a concentration of 0.5 g / L, and 80% of the microalgae culture solution was transferred to the flocculation reaction tank through the pipeline, and the substitution degree was added to the microalgae culture solution in the flocculation reaction tank. The 0.22 cationic starch solution was used as a flocculant, so that the dry weight ratio (w / w) of the cationic starch mass to the microalgae in the solution was 0.15, and the microalgae culture solution was stirred at a speed of 200 r / min for 5 min to promote the flocculation of the microalgae. Then the microalgae culture solution was left to settle for 10 min, the precipitated microalgae concentrate was collected, and the supernatant was recycled for the re-cultivation of the microalgae...

Embodiment 3

[0024] Dissolve 1 part of cationic starch in 1000 parts of distilled water, gelatinize in a water bath at 80 °C for 30 min, and cool for 2 h to prepare a cationic starch solution. The microalgae were cultured in the microalgae bioreactor to grow to a concentration of 0.5 g / L, and 80% of the microalgae culture solution was transferred to the flocculation reaction tank through the pipeline, and the substitution degree was added to the microalgae culture solution in the flocculation reaction tank. The 0.45 cationic starch solution was used as a flocculant, so that the dry weight ratio (w / w) of the cationic starch mass to the microalgae in the solution was 0.08, and the microalgae culture solution was stirred at a speed of 200 r / min for 5 min to promote the flocculation of the microalgae. Then the microalgae culture solution was left to settle for 10 min, the precipitated microalgae concentrate was collected, and the supernatant was recycled for the re-cultivation of the microalgae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com