Dopamine-modified chitosan flocculant

A chitosan and flocculant technology is applied in the field of preparation of a new type of modified chitosan flocculant to achieve the effects of good biocompatibility, remarkable flocculation effect, and improved adsorption capacity and solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

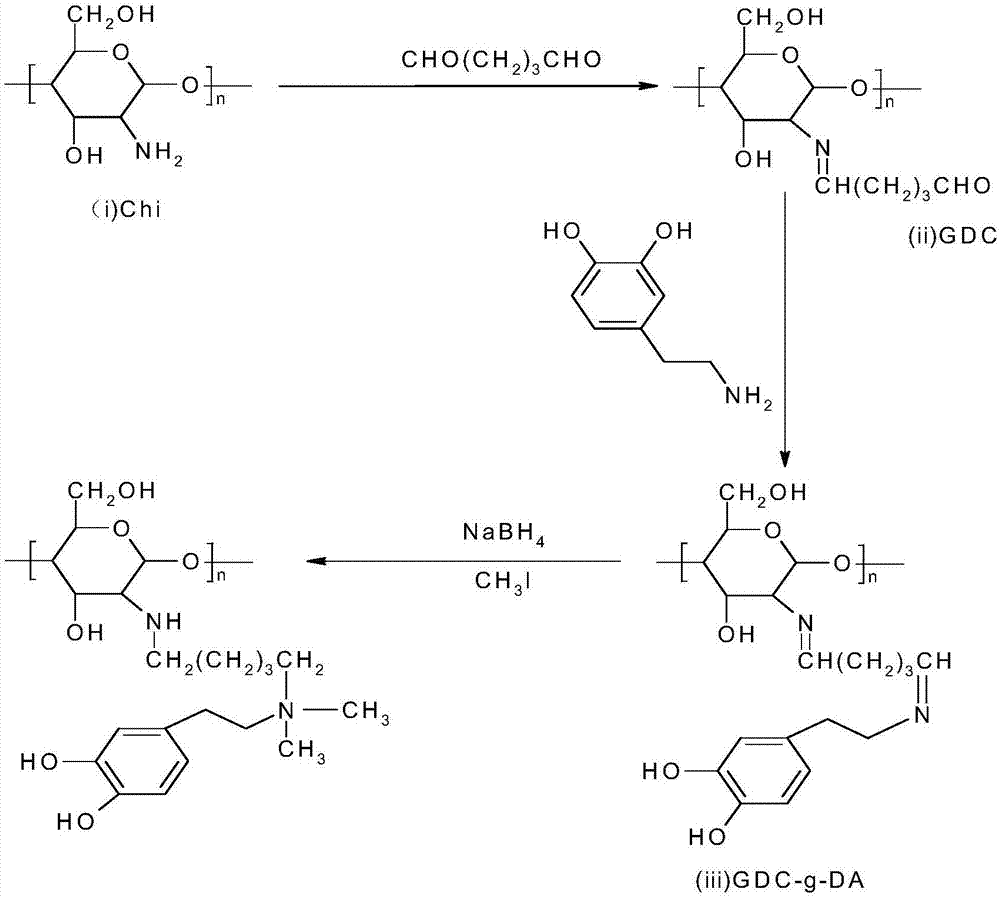

Method used

Image

Examples

Embodiment 1

[0028] (1) Dissolve 1 gram of chitosan (the degree of deacetylation is 80%, and the relative molecular mass is 350,000) in 50ml of acetic acid (0.1mol / L) solution, adjust to 0.1mol / L sodium hydroxide solution When the pH was equal to 5, 120 g of glutaraldehyde was added, and the reaction was stirred at 48° C. for 24 hours. The reacted solution was put into a dialysis bag with a molecular weight cut-off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0029] (2) Add 1 g of dopamine to the dialysate described in (1), and react with high-speed stirring at 25° C. for 12 hours. After the reaction, the solution was put into a dialysis bag with a molecular weight cut off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0030] (3) Add 0.5 g of sodium borohydride to the dialysate described in (2), and stir at 25° C. for 12 hours. The solution was centrifuged at 2000 rpm, and the lower la...

Embodiment 2

[0034] (1) Dissolve 1 gram of chitosan (the degree of deacetylation is 80%, and the relative molecular mass is 350,000) in 50ml of acetic acid (0.1mol / L) solution, adjust to 0.1mol / L sodium hydroxide solution When the pH was equal to 5, 120 g of glutaraldehyde was added, and the reaction was stirred at 48° C. for 24 hours. The reacted solution was put into a dialysis bag with a molecular weight cut-off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0035] (2) Add 3 g of dopamine to the dialysate described in (1), and react with high-speed stirring at 25° C. for 12 hours. After the reaction, the solution was put into a dialysis bag with a molecular weight cut off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0036] (3) Add 0.5 g of sodium borohydride to the dialysate described in (2), and stir at 25° C. for 12 hours. The solution was centrifuged at 2000 rpm, and the lower la...

Embodiment 3

[0040] (1) 1 gram of chitosan (deacetylation degree is 90%, relative molecular mass is 250,000), is dissolved in 50ml hydrochloric acid (0.1mol / L) solution, is adjusted to with the sodium hydroxide solution of mass fraction 0.1%. When the pH was equal to 5, 120 g of glutaraldehyde was added, and the reaction was stirred at 48° C. for 24 hours. The reacted solution was put into a dialysis bag with a molecular weight cut-off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0041] (2) Add 5 g of dopamine to the dialysate described in (1), and react with high-speed stirring at 25° C. for 12 hours. After the reaction, the solution was put into a dialysis bag with a molecular weight cut off of 14000, and the dialysis bag was dialyzed in 1 L of water for 12 hours, and repeated 7 times.

[0042] (3) Add 0.5 g of sodium borohydride to the dialysate described in (2), and stir at 25° C. for 12 hours. The solution was centrifuged at 2000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com