Flocculating concentration apparatus in sludge treatment

A thickening device and sludge treatment technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of large velocity gradient, destruction of flocs, and insufficient concentration, so as to improve equipment efficiency and reduce equipment investment The effect of reducing and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

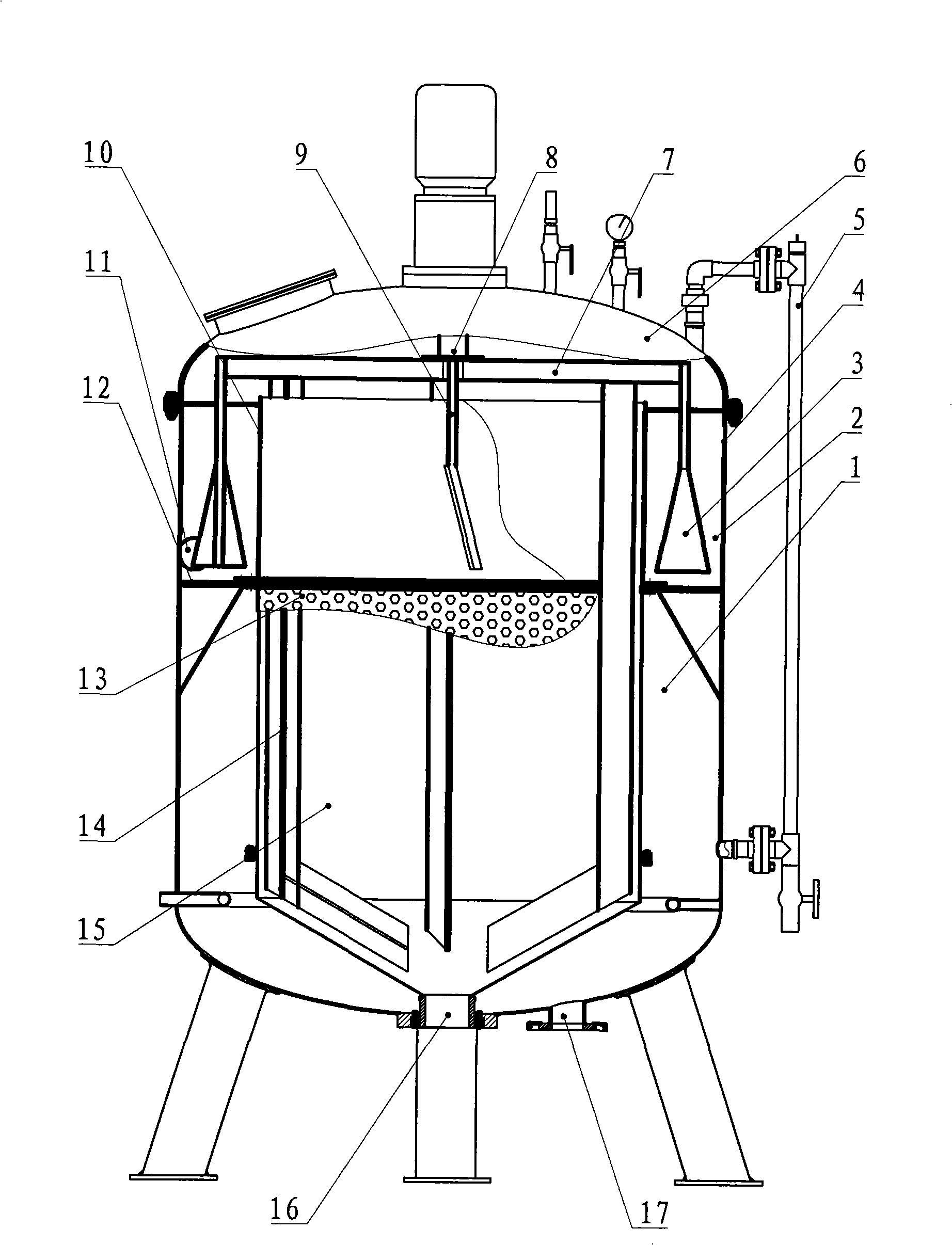

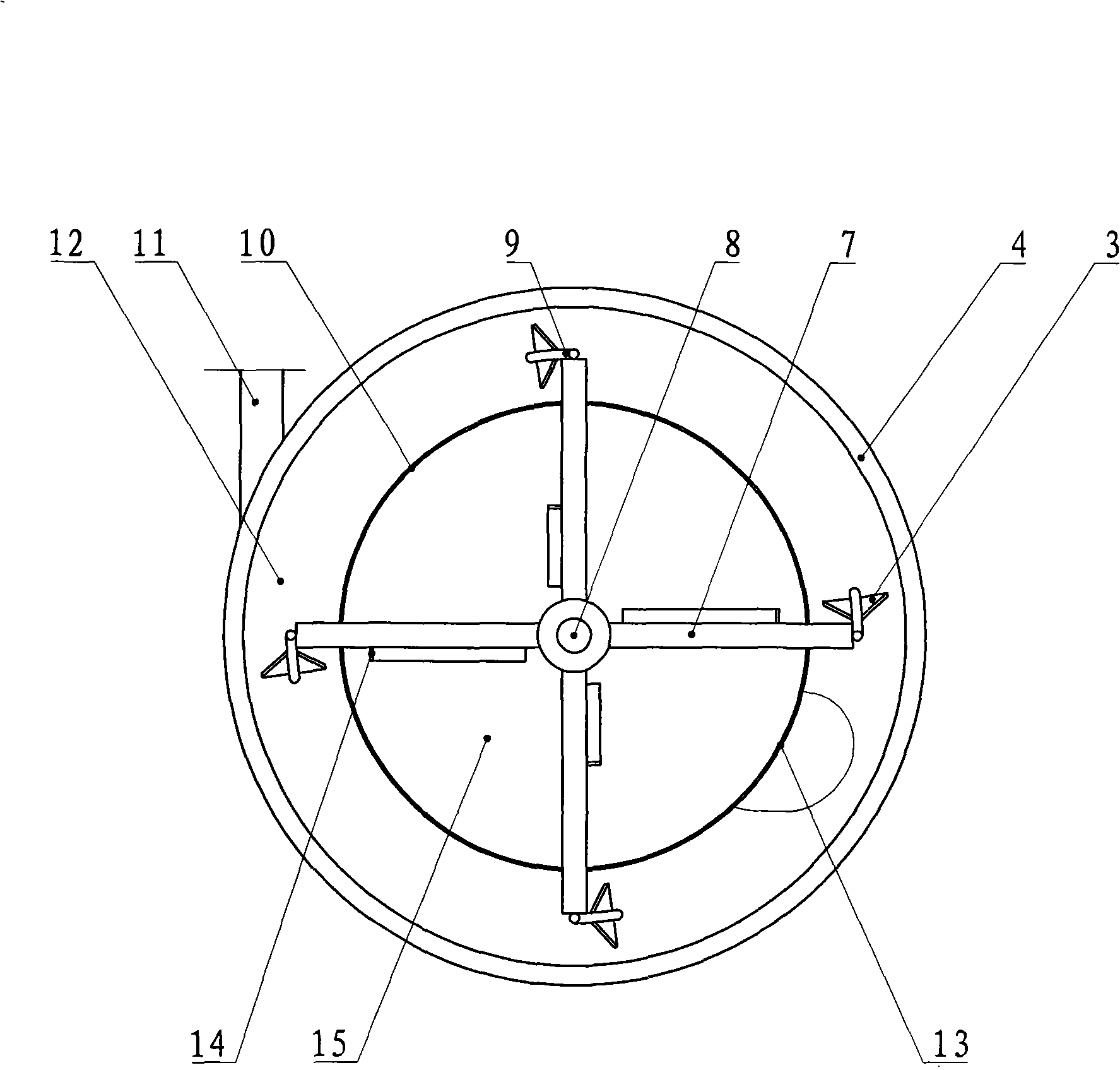

[0018] Such as figure 1 , 2 As shown, there is a flocculator, which is a circular tank body with a cylindrical body with an elliptical head sealed at the bottom and an elliptical cover with an upper cover. The upper outer ring of the circular tank is an annular groove 2, the lower outer ring is a jacket 1, and the middle position is the stirring tank 15 of the main tank. groove. The outer wall of the annular groove and the jacket is the tank wall 4, and their inner walls are respectively the overflow wall 10 of the annular groove and the partition wall between the jacket and the stirring tank of the main tank, and the partition wall is the upper cylindrical cylinder and the lower Conical bottom plate constitutes, the upper part of the cylindrical shell of the next wall is a grating 13, and the inner diameter of the cylindrical shell part of the overflow wall and the next wall is the same. There is a feed inlet 11 located on the upper side of the bottom wall 12 of the annula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com