Flocculant and preparation method thereof

A flocculant and calcium hydroxide technology, applied in the field of water treatment, can solve the problems of powerless acid sewage, small flocs, turbid water, etc., and achieve the effect of large flocs, strong affinity and fast sedimentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The components and weight percentages of the flocculant in this embodiment are as follows:

[0025] Iron sulfate 15%;

[0026] Aluminum sulfate 5%;

[0027] Other components (other impurities in carbide slag, which do not contribute to flocculation) 5%.

[0028] Its production process, concrete steps are as follows:

[0029] (1) Crushed carbide slag

[0030] Take a certain amount of carbide slag and crush it in a crusher.

[0031] (2) Mixed ingredients

[0032] According to the percentage content of each component, a certain amount of carbide slag, ferric sulfate and aluminum sulfate is weighed and mixed and stirred.

Embodiment 2

[0034] The components and weight percentages of the flocculant in this embodiment are as follows:

[0036] Iron sulfate 1%;

[0037] Aluminum sulfate 3%;

[0038] Other components (other impurities in carbide slag, which do not contribute to flocculation) 6%.

[0039] The production process of flocculant, the specific steps are as follows:

[0040] (1) Crushed carbide slag

[0041] Take a certain amount of carbide slag and crush it in a crusher.

[0042] (2) Mixed ingredients

[0043] According to the percentage content of each component, a certain amount of carbide slag, ferric sulfate and aluminum sulfate is weighed and mixed and stirred.

Embodiment 3

[0045] The components and weight percentages of the flocculant in this embodiment are as follows:

[0047] Iron sulfate 0.8%;

[0048] Aluminum sulfate 14%;

[0049] Other components (other impurities in carbide slag, which do not contribute to flocculation) 5.2 %.

[0050] The production process of flocculant, the specific steps are as follows:

[0051] (1) Crushed carbide slag

[0052] Take a certain amount of carbide slag and crush it in a crusher.

[0053] (2) Mixed ingredients

[0054] According to the percentage content of each component, a certain amount of carbide slag, ferric sulfate and aluminum sulfate is weighed and mixed and stirred.

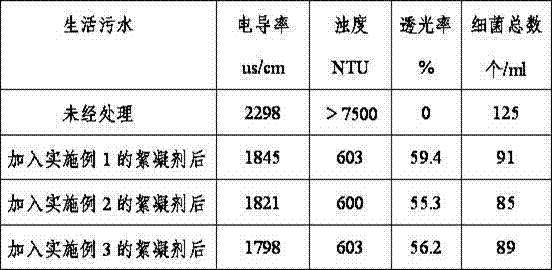

[0055] The flocculants described in Examples 1 to 3 are used in sewage treatment. The flocculation principle of the flocculants: the coagulation of carbide slag to sludge does not supply OH - , but provides a large amount of Ca 2+ , Ca 2+ By compressing the electric double layer, the stabilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com