Patents

Literature

101results about How to "Add process steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

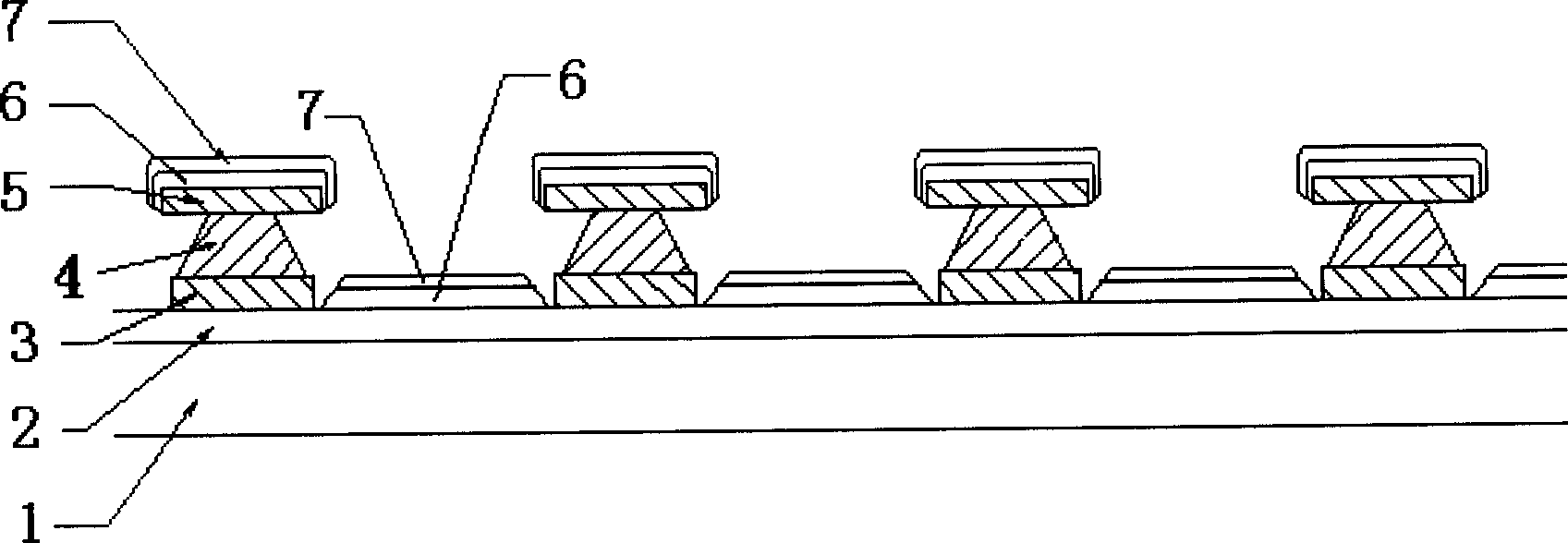

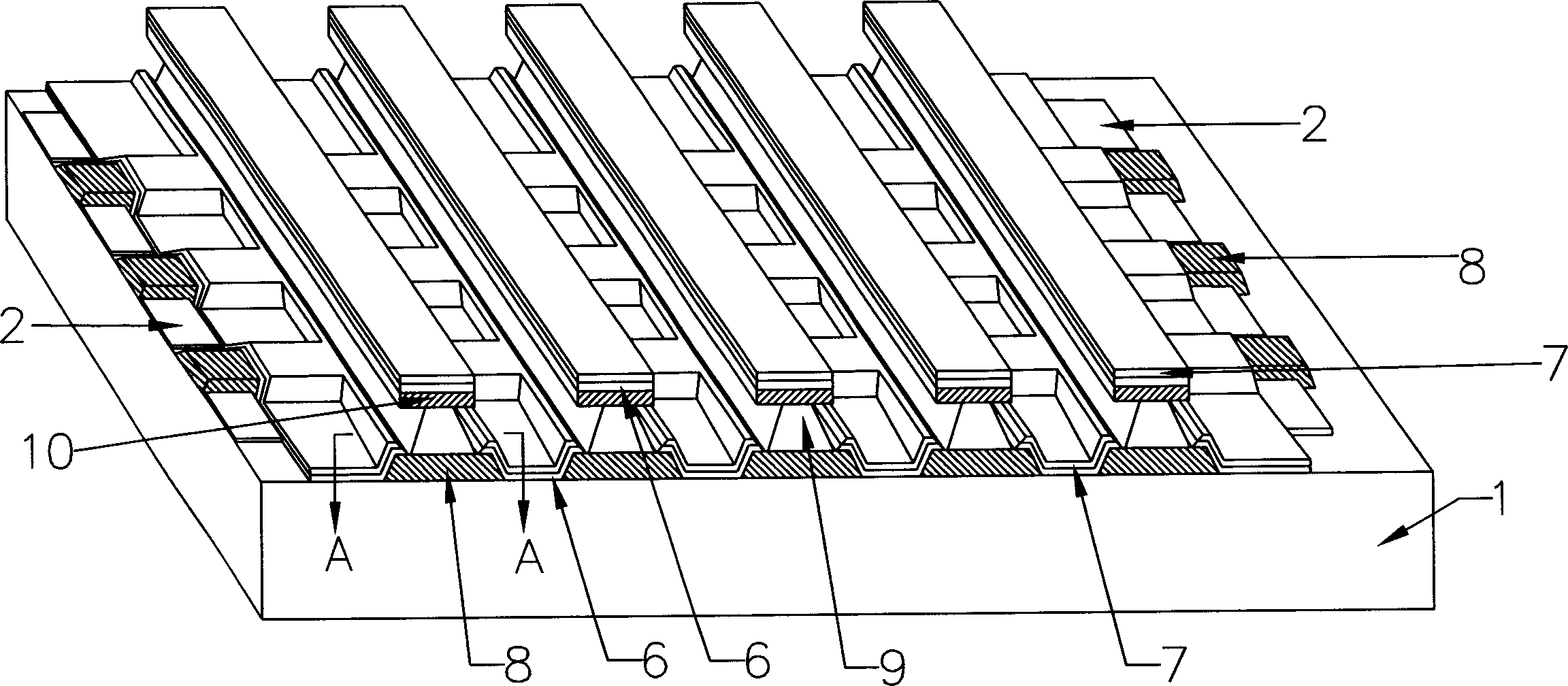

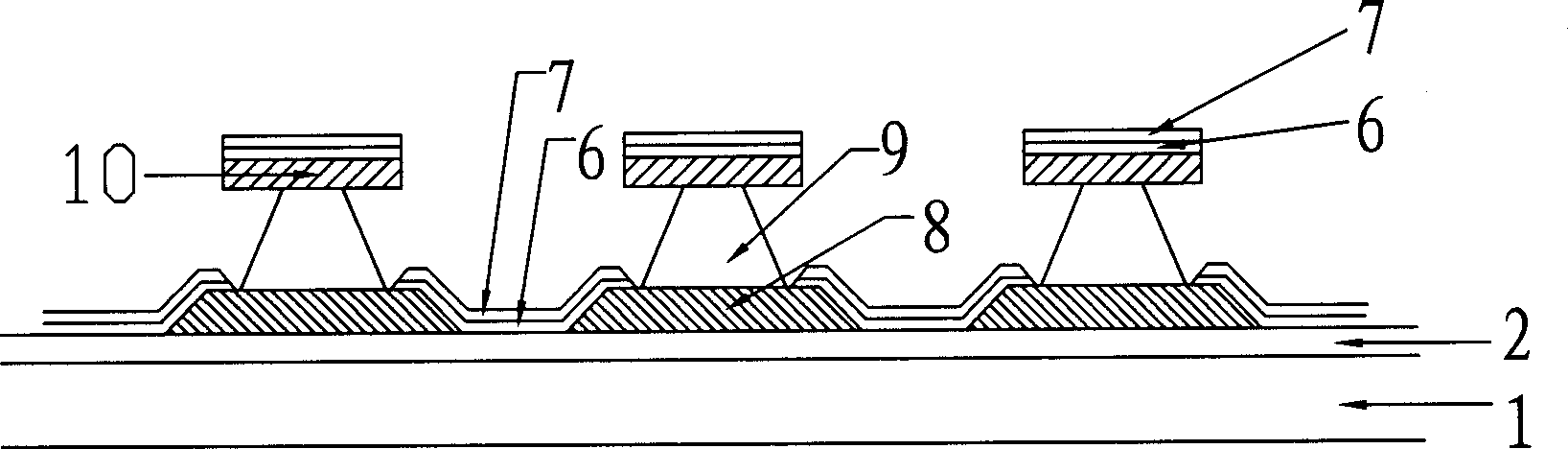

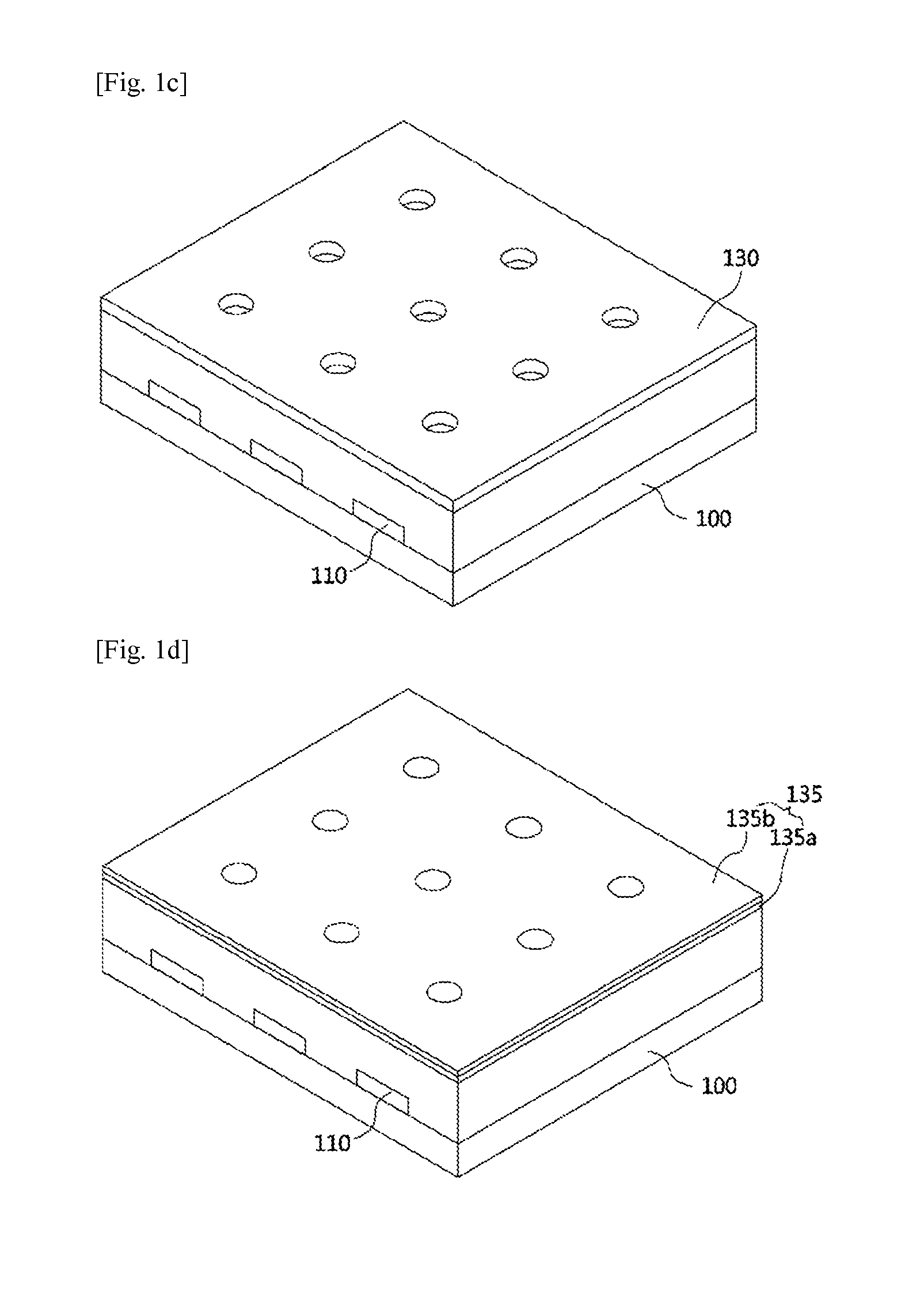

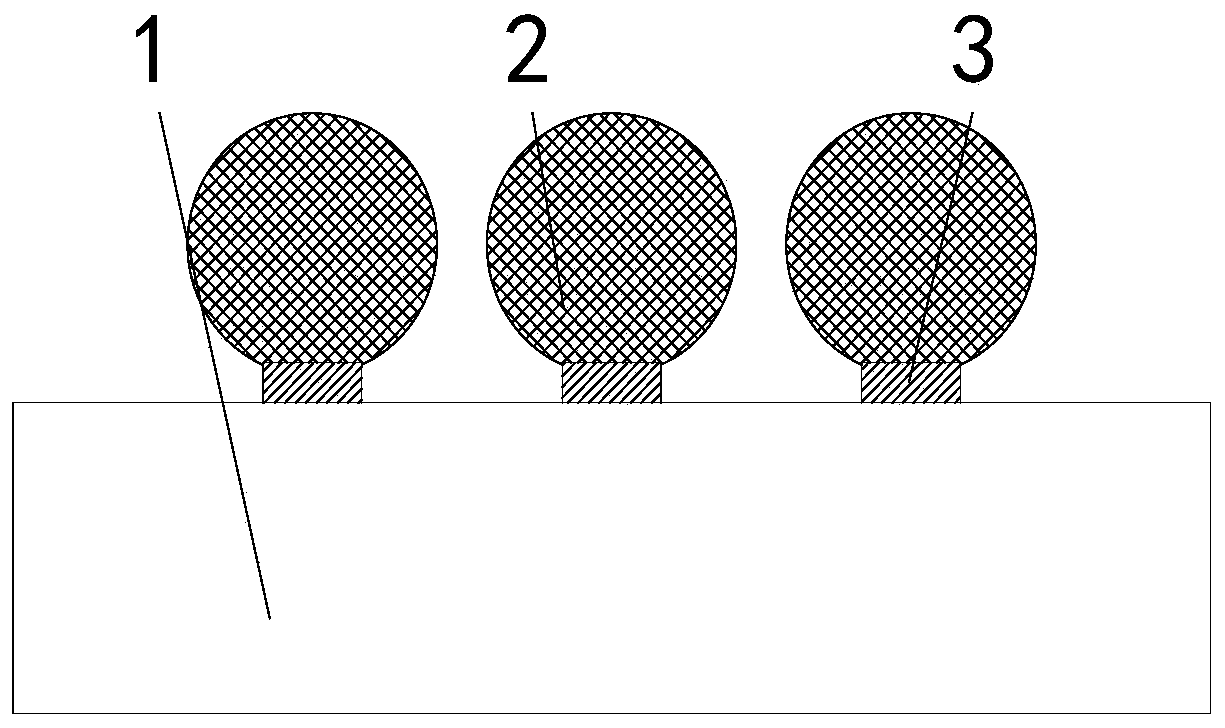

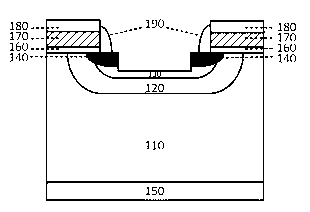

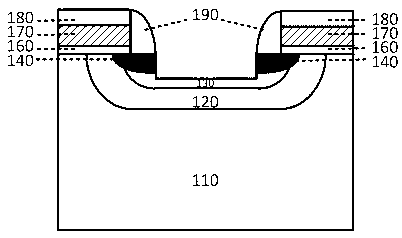

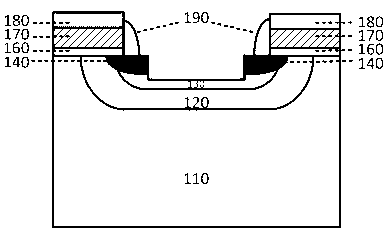

Orgnic electroluminescence device and its preparation device

InactiveCN1416300ALight evenlyIncrease contrastElectroluminescent light sourcesSolid-state devicesShadow effectOrganic electroluminescence

The invention belongs to the technique area of the semiconductor elements and devices. Three layers of the isolation pole are prepared on the graphics of the first electrode. The graphics of the first layer of the isolation pole is the mesh texture with the cross section being as trapezoid shape. The cross section of the lines on the second layer and the third layer of the isolation pole possess the shape with big at the upper and small at the lower. Then, the organic function layer and the second electrode are deposited in sequence. The shadow effect caused by the shape with big at the upper of the second layer and the third layer makes the second electrode possible to be partitioned. The first layer of the isolation pole being equivalent to 'insulating base' prevents the short circuit between the electrodes.

Owner:BEIJING VISIONOX TECH

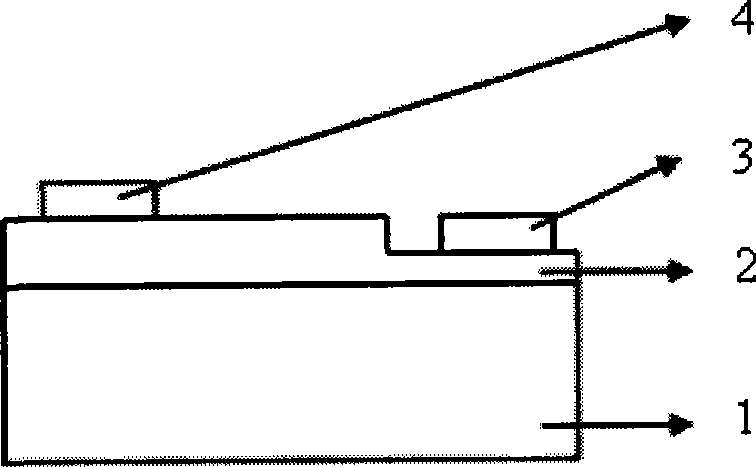

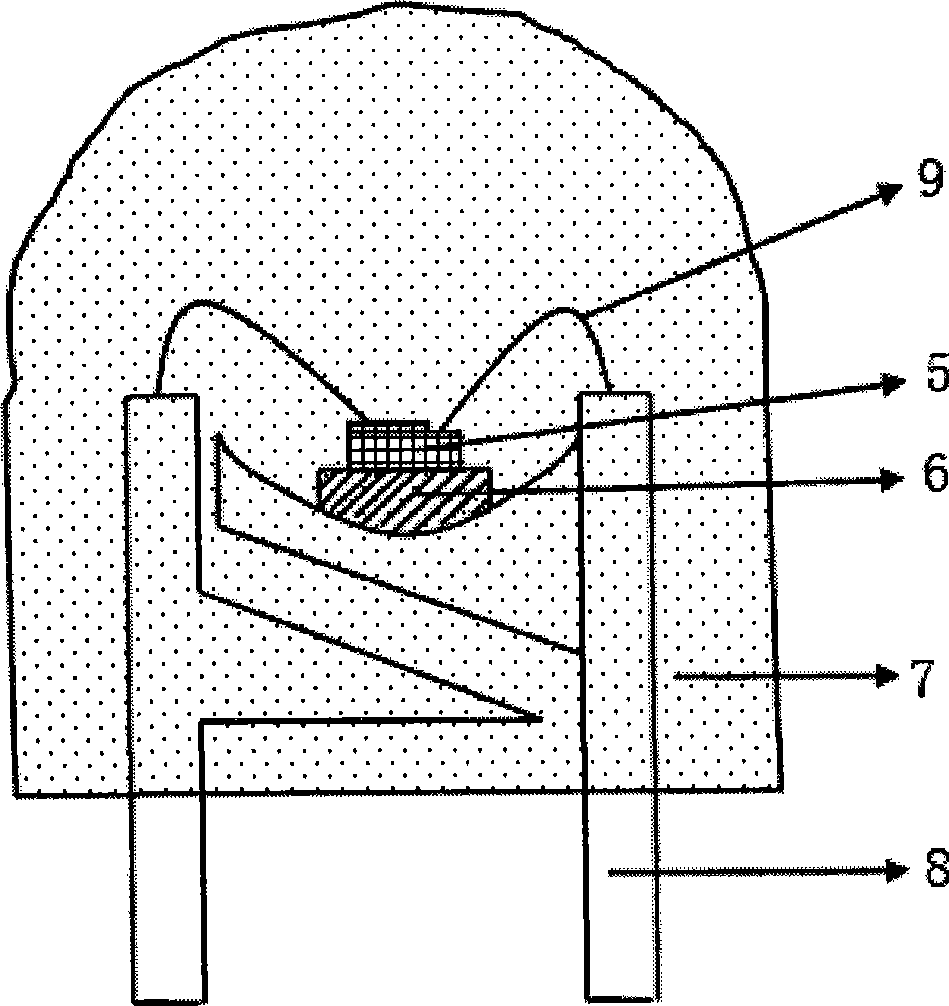

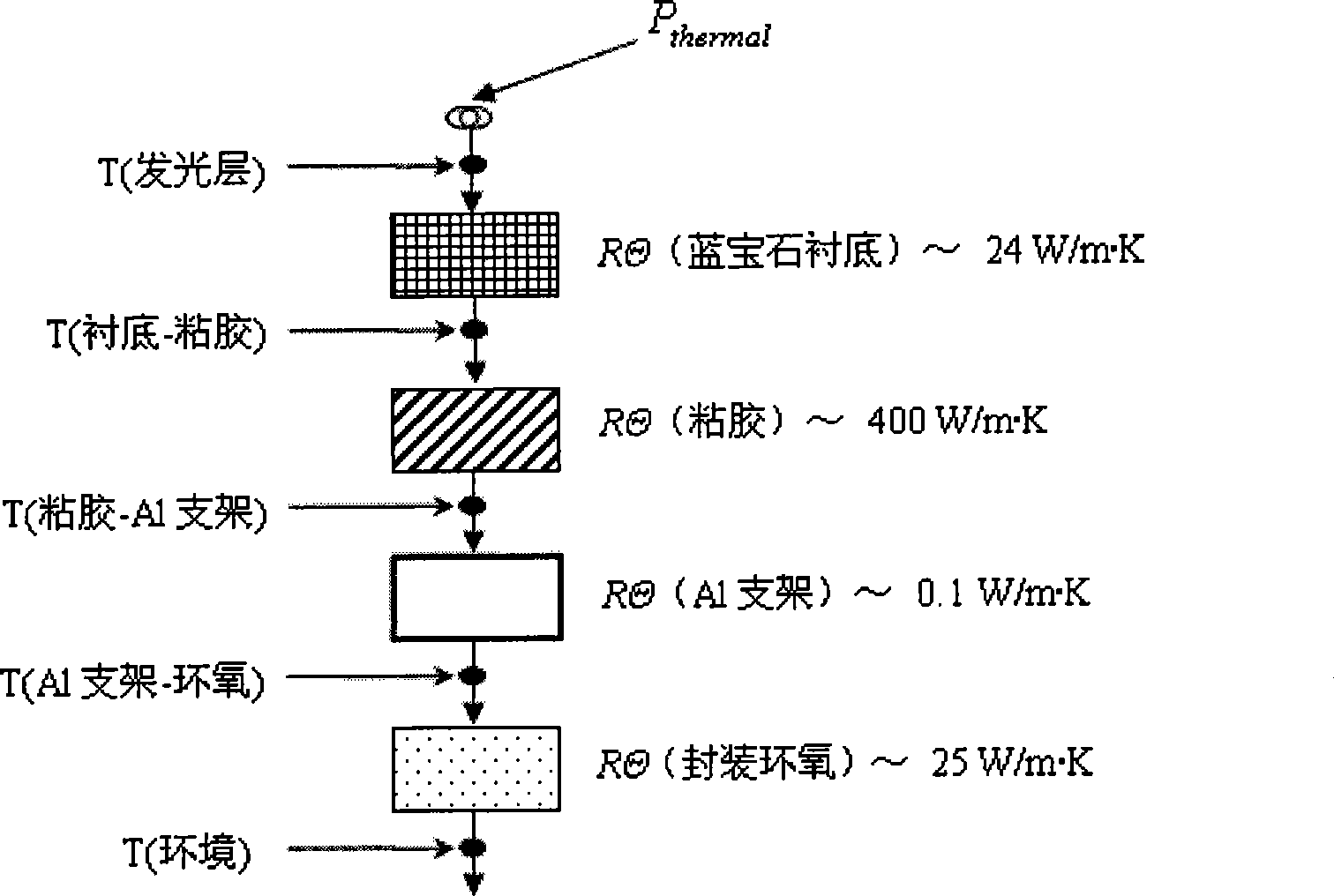

Structure of low thermal resistance LED and method for producing the same

InactiveCN101442099AExtended service lifeLower junction temperatureSolid-state devicesSemiconductor devicesDrain currentOptoelectronics

The invention provides a structure for a low thermal resistance LED chip and a method for manufacturing the same. The LED chip comprises P and N electrodes used for manufacturing electrodes, the LED luminous chip on a semiconductor epitaxial layer and a sapphire substrate, and a metallic reflector layer deposited on the bottom of the thinned sapphire substrate. The structure is characterized in that the LED chip comprises: (a) a heat radiating substrate with low thermal resistance, in which the size is larger than that of the LED luminous chip; and (b) solder deposited on the heat radiating substrate with low thermal resistance connected with the bottom of the metallic reflector layer. The area of the heat radiating substrate with low thermal resistance is 2 to 25 times larger than the area of the LED luminous chip. The invention can increase the area of heat dissipation channel when the LED luminous chip, significantly reduce thermal resistance of the LED luminous chip and packaged devices, reduce the light decay of LED devices and drain current, and prolong the life service of the devices.

Owner:HC SEMITEK CORP

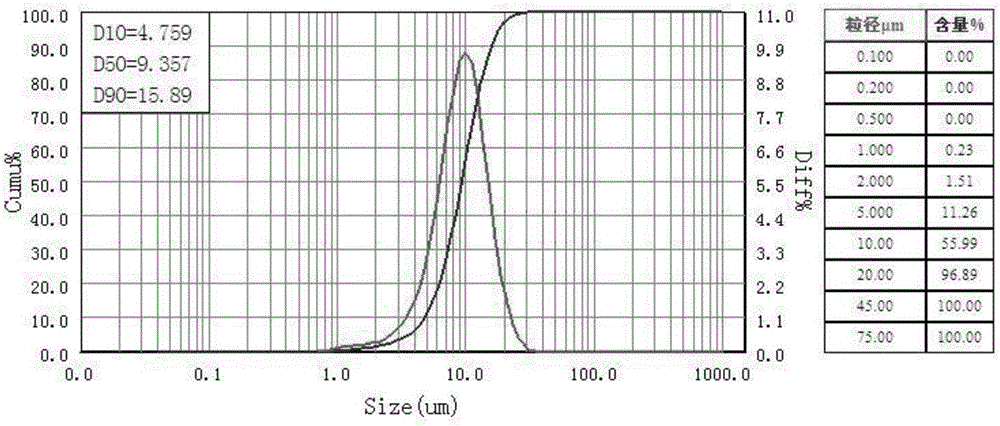

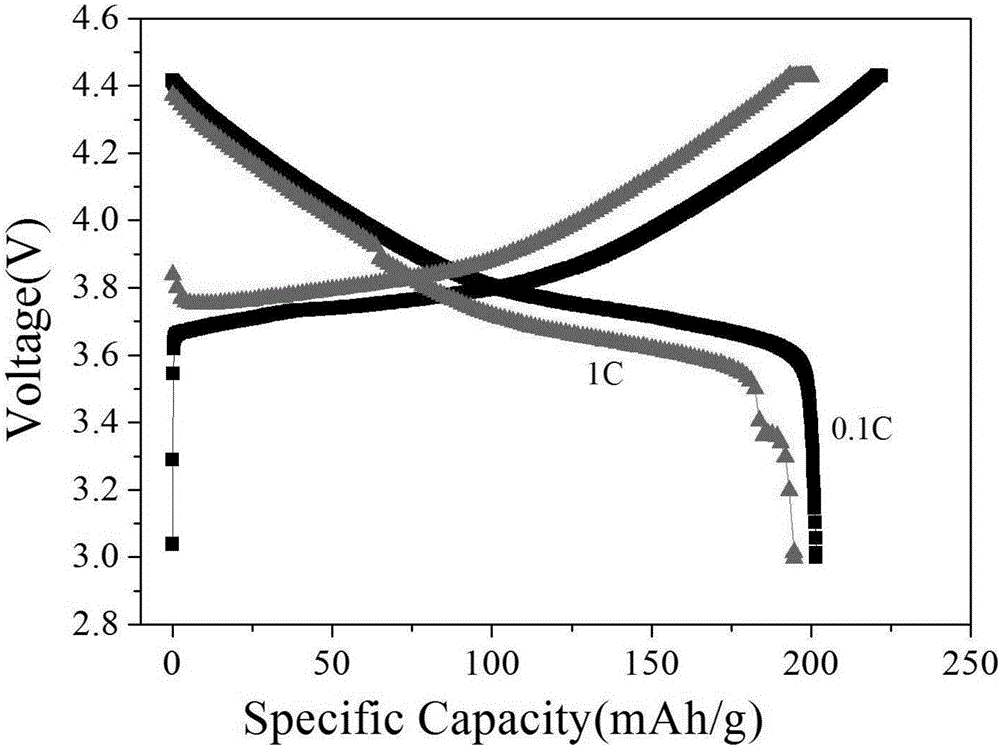

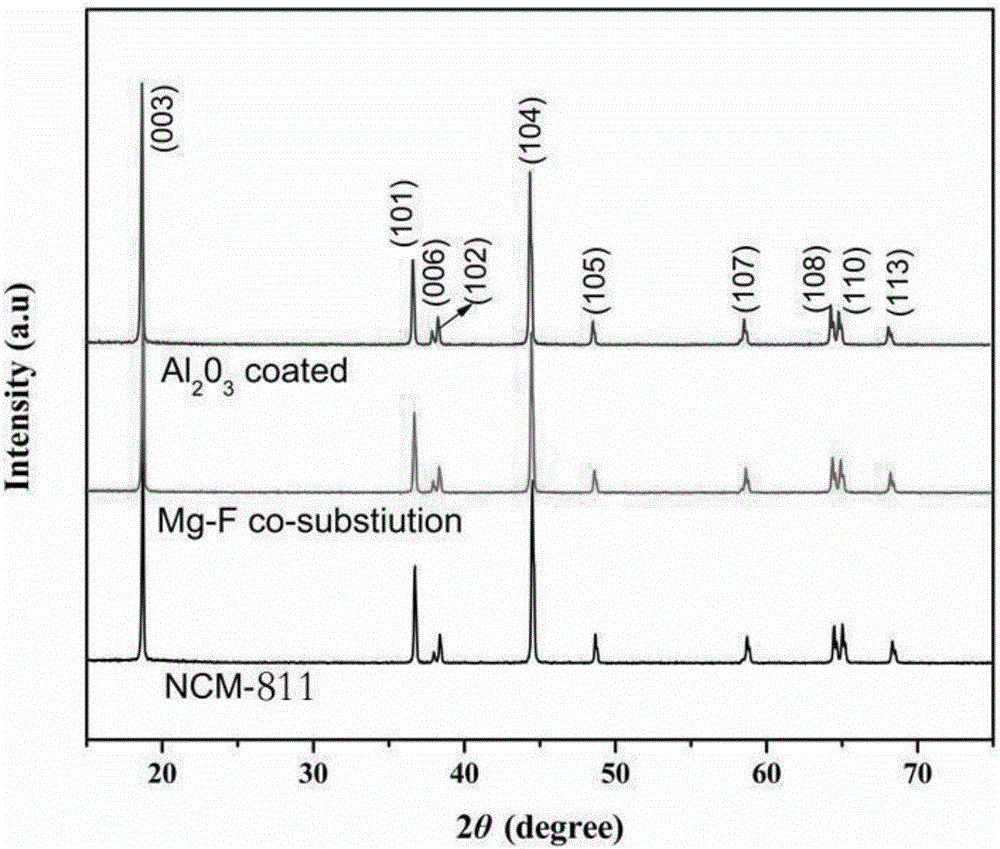

Lithium NCM (nickel cobalt manganese) material and preparation method thereof

InactiveCN107180963AReduce solubilityChange the band structureCell electrodesSecondary cellsManganeseCobalt

The invention discloses a lithium NCM (nickel cobalt manganese) material. The lithium NCM material is prepared by doping Mg (magnesium), Al (aluminum) or Ti (titanium) and F (fluorine) into a 811 type lithium NCM cathode material. The lithium nickel manganese cobalt material has the advantages that by simultaneously doping Mg, Al or Ti and F into the 811 type NCM electrode material, the rate discharge property and specific capacity of the material are effectively improved; the corrosion of HF (hydrogen fluoride) to the material is effectively inhibited, the dissolving of Co is reduced, and the structure stability and thermal stability of the material are greatly improved.

Owner:四川新锂想能源科技有限责任公司

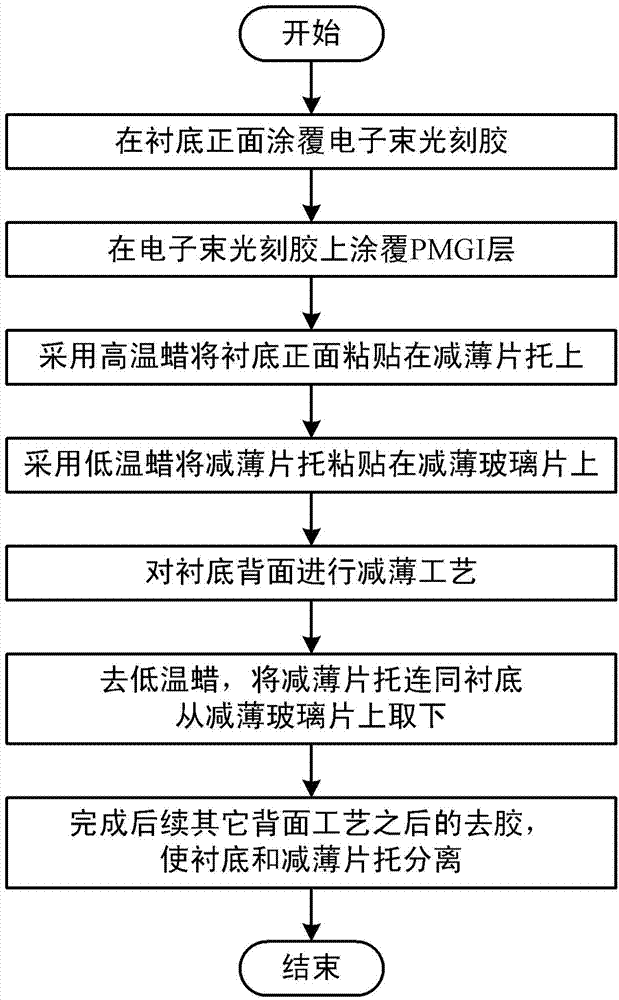

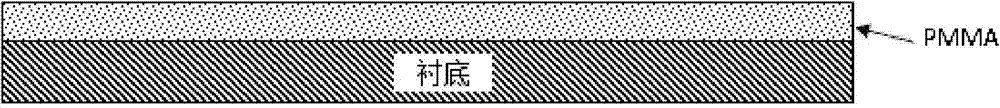

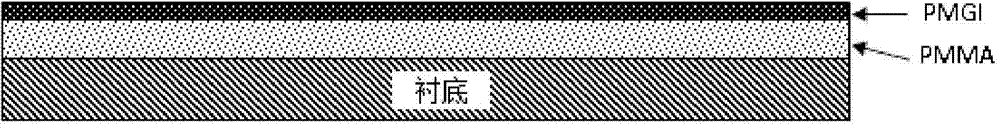

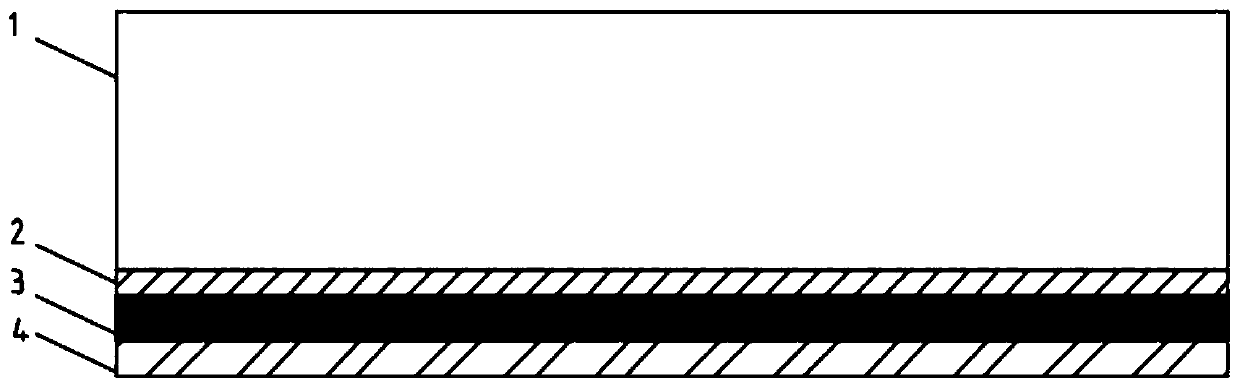

Sheet bonding method in substrate thinning technique

InactiveCN103489755AAvoid integration problemsImprove processing efficiencySolid-state devicesSemiconductor/solid-state device manufacturingWaxOptoelectronics

The invention discloses a sheet bonding method in a substrate thinning technique, which comprises the following steps: coating an electron beam photoresist on the front surface of a substrate; coating a PMGI layer on the electron beam photoresist; bonding the front surface of the substrate onto a thinning sheet support by using high temperature wax; bonding the thinning sheet support onto a thinning glass sheet by using low temperature wax; carrying out thinning technique on the back surface of the substrate; removing the low temperature wax, and taking the thinning sheet support with the substrate off the thinning glass sheet; and completing subsequent photoresist removal after other back surface techniques, and separating the substrate from the thinning sheet support. The method effectively solves the problem of mutual solubility between the photoresist and high temperature wax, and enhances the technical efficiency and technical yield of the thinning technique.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method for improving content of gamma-aminobutyric acid (GABA) in green tea

InactiveCN102870909AAdd process stepsEasy to usePre-extraction tea treatmentMicrowaveGamma-Aminobutyric acid

The invention discloses a method for improving content of gamma-aminobutyric acid (GABA) in green tea. The method comprises the following steps of: carrying out anaerobic treatment for the picked tea leave raw materials for 2 hours; carrying out aerobic treatment for the tea leave raw materials after the anaerobic treatment for 2 hours; carrying out the anaerobic treatment and the aerobic treatment for the tea leave raw materials after the aerobic treatment alternately; after de-enzyming, rolling, roasting the processed tea leave raw materials to be dehydrated, and obtaining a finished product tea. The method for improving the content of gamma-GABA in the green tea provided by the invention increases technological steps of the anaerobic treatment and the aerobic treatment, and combines microwave de-enzyming, rolling and drying, so that the content of the gamma-GABA in the obtained product is remarkably improved. The content of the GABA in the obtained green tea is more than 1.50mg / g, and partially reaches above 1.81mg / g, and the content is improved by above 20 times in comparison with the anaerobic treatment and the aerobic treatment, and the green tea has no foreign flavour essentially, so that the green tea has a broad market prospect.

Owner:GUIZHOU TEA RES INST

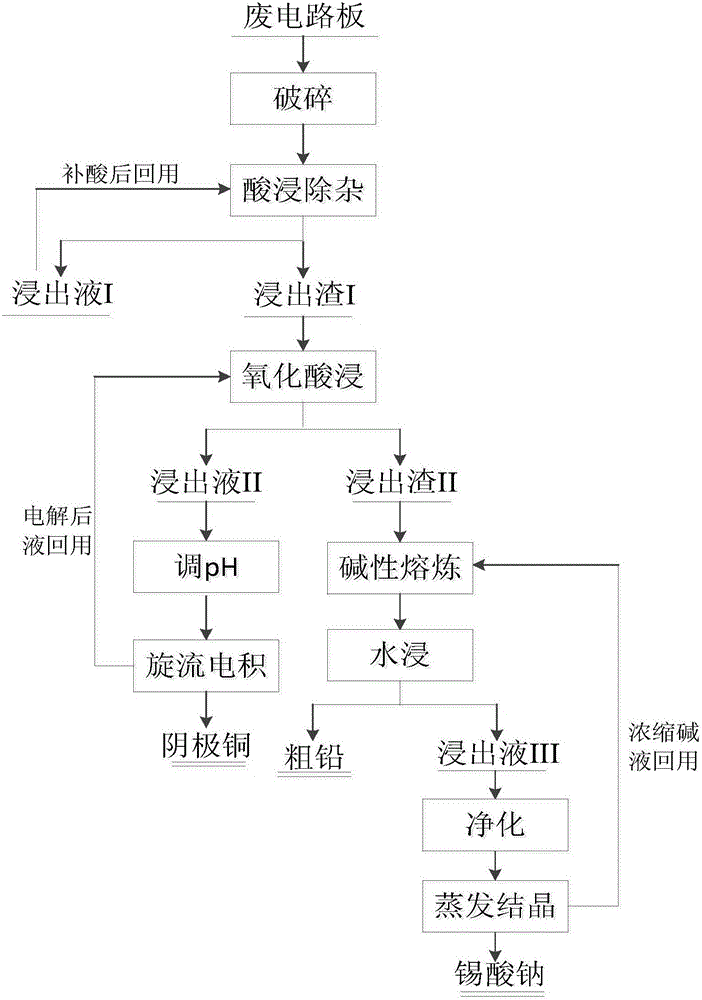

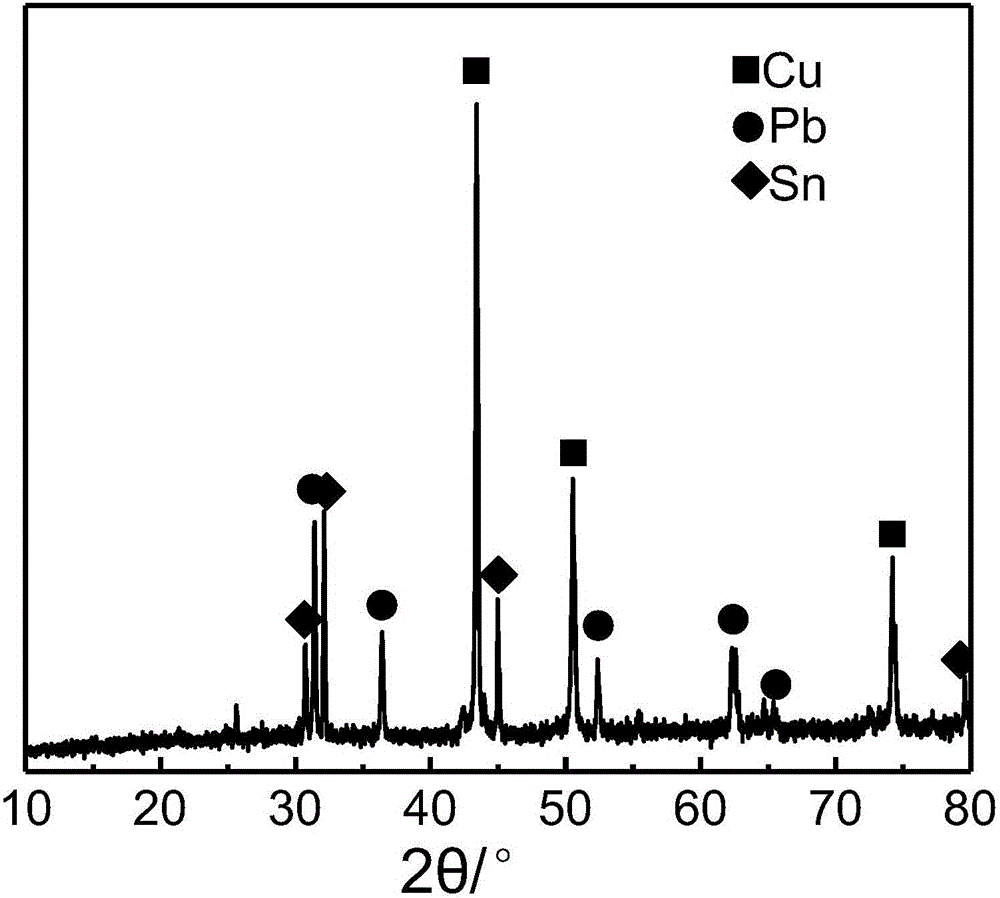

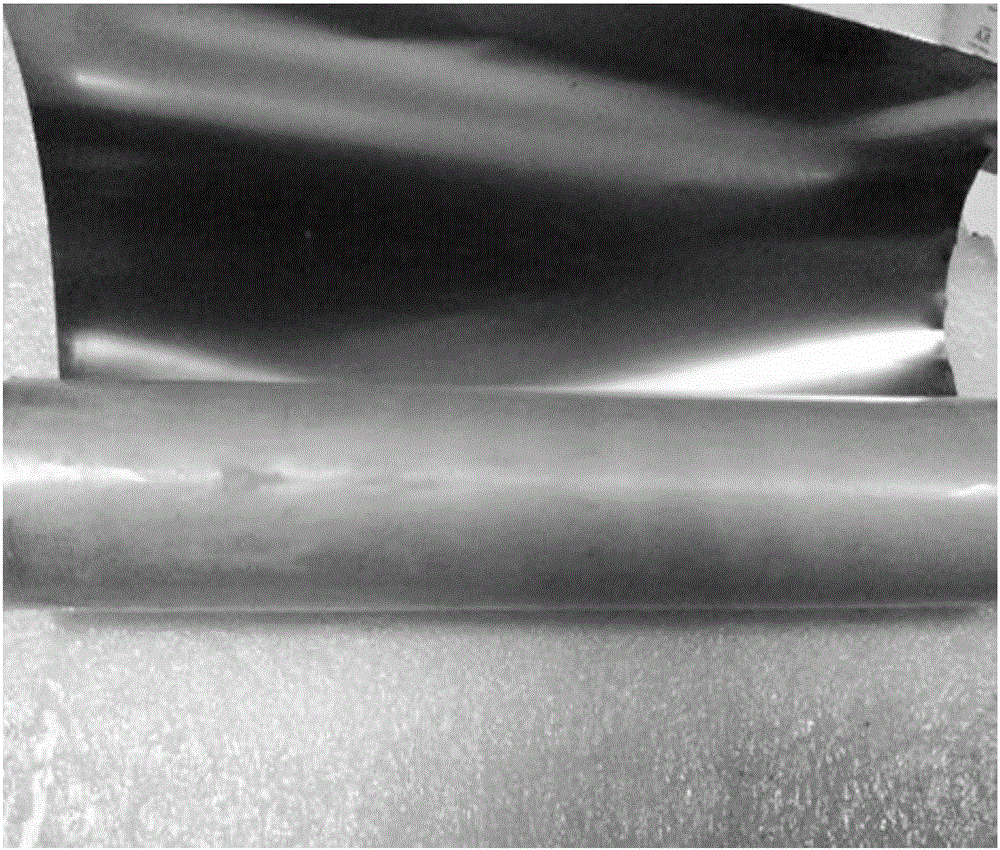

Method for recycling valuable metal in waste circuit board

The invention discloses a method for recycling valuable metal in a waste circuit board. The method includes the following steps that the waste circuit board is subject to smashing and reselection to prepare multi-metal powder; a dilute acid solution is added into the multi-metal powder, agitation leaching is carried out, filtering is carried out, and leaching slag I and leaching liquid I are obtained; an acid solution is added into the leaching slag I according to the liquid-solid mass ratio of the acid solution to the leaching slag I being 10-40:1, then an oxidizing agent is added, agitation leaching is carried out, filtering is carried out after leaching is finished, and leaching slag II and leaching liquid II are obtained; the leaching liquid II is subject to cyclone electrodeposition to obtain cathode copper and an after-electrolysis solution; alkali and a reducing agent are added into the leaching slag II, smelting is carried out under the condition that the temperature ranges from 400 DEG C to 600 DEG C, water leaching is carried out, filtering is carried out, and lead bullion containing precious metal and leaching liquid III are obtained; and the leaching liquid III is purified and is subject to evaporation and concentration to obtain a concentrated alkali solution and sodium stannate crystals. According to the method for recycling the valuable metal in the waste circuit board, the procedure is short, the efficiency is high, the cost is low, cleanness is achieved, and pollution is avoided.

Owner:广西自贸区西江资源循环科技产业股份有限公司

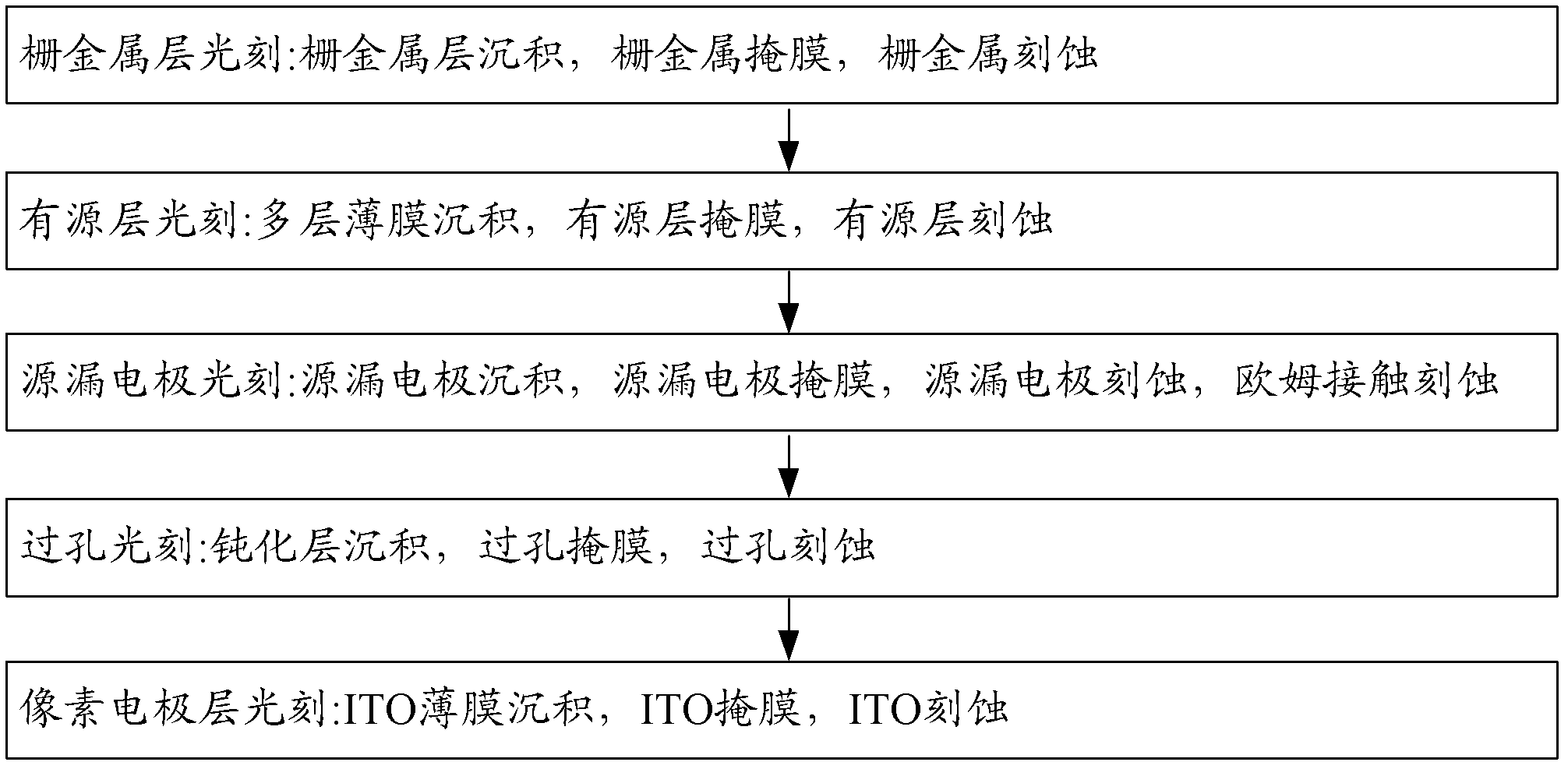

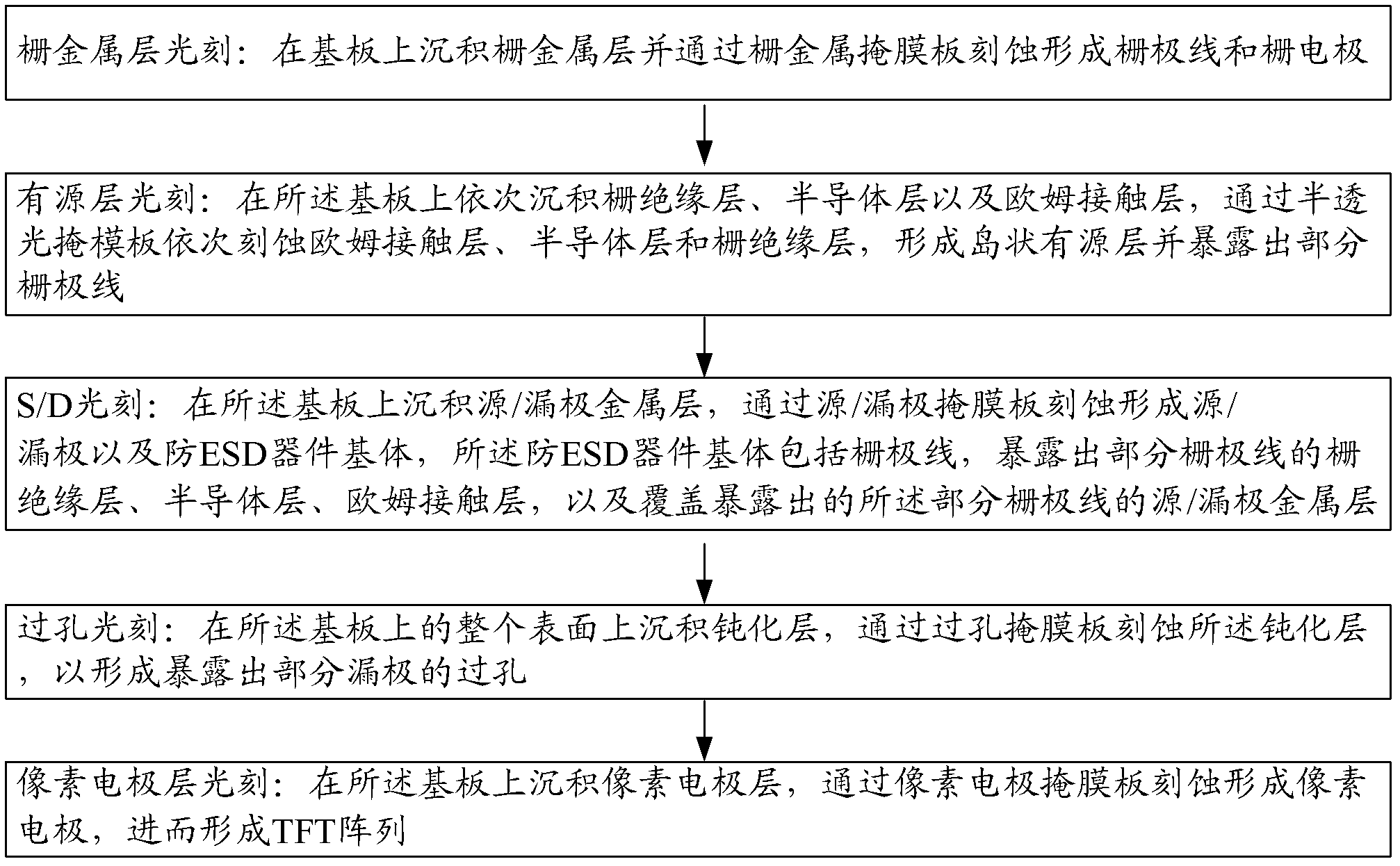

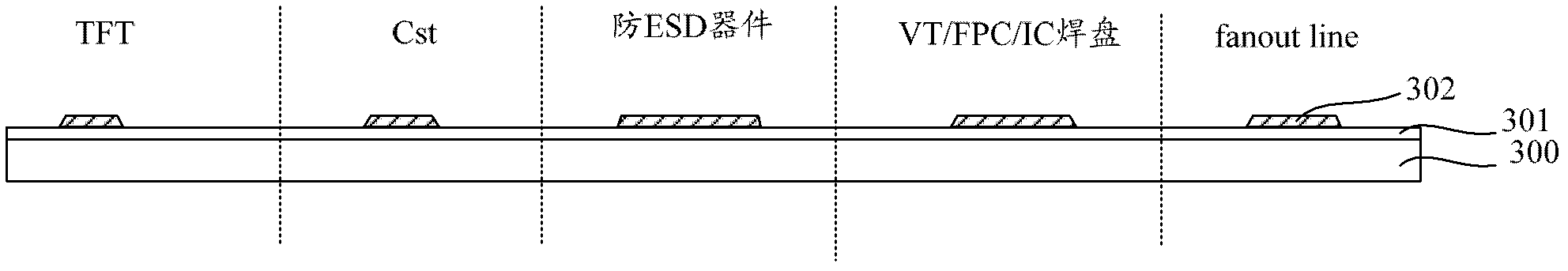

TFT-LCD (thin film transistor-liquid crystal display) array panel structure and production method thereof

ActiveCN103280428AElectrode corrosion is smallPrevent static electricitySolid-state devicesSemiconductor/solid-state device manufacturingLine resistanceLiquid-crystal display

The invention provides a TFT-LCD (thin film transistor-liquid crystal display) array panel structure and a production method thereof. An anti-ESD (anti-electrostatic discharge) element of which a gate metal layer is in direct contact with a source / drain metal layer is produced outside a TFT array in order to prevent each process station after source / drain metal deposition from being injured by static electricity, so that the product percent of pass can be increased; meanwhile, by correspondingly changing active mask, silicon islands are formed in the process of via-hole mask, consequently, the process steps are simplified, and the production cost is reduced; meanwhile, by correspondingly changing gate mask, active mask and source / drain mask, the gate metal is covered by the source / drain metal in the area of a VT / FPC / IC pad, consequently, the electrode corrosion of the gate metal layer can be reduced, and in the extending area of a fanout line, the line resistance can be decreased; and furthermore, before the deposition of the gate metal layer, a silicon nitride layer is first formed, so that the injuries of a substrate caused by dry etch can be reduced.

Owner:CHENGDU TIANMA MICROELECTRONICS

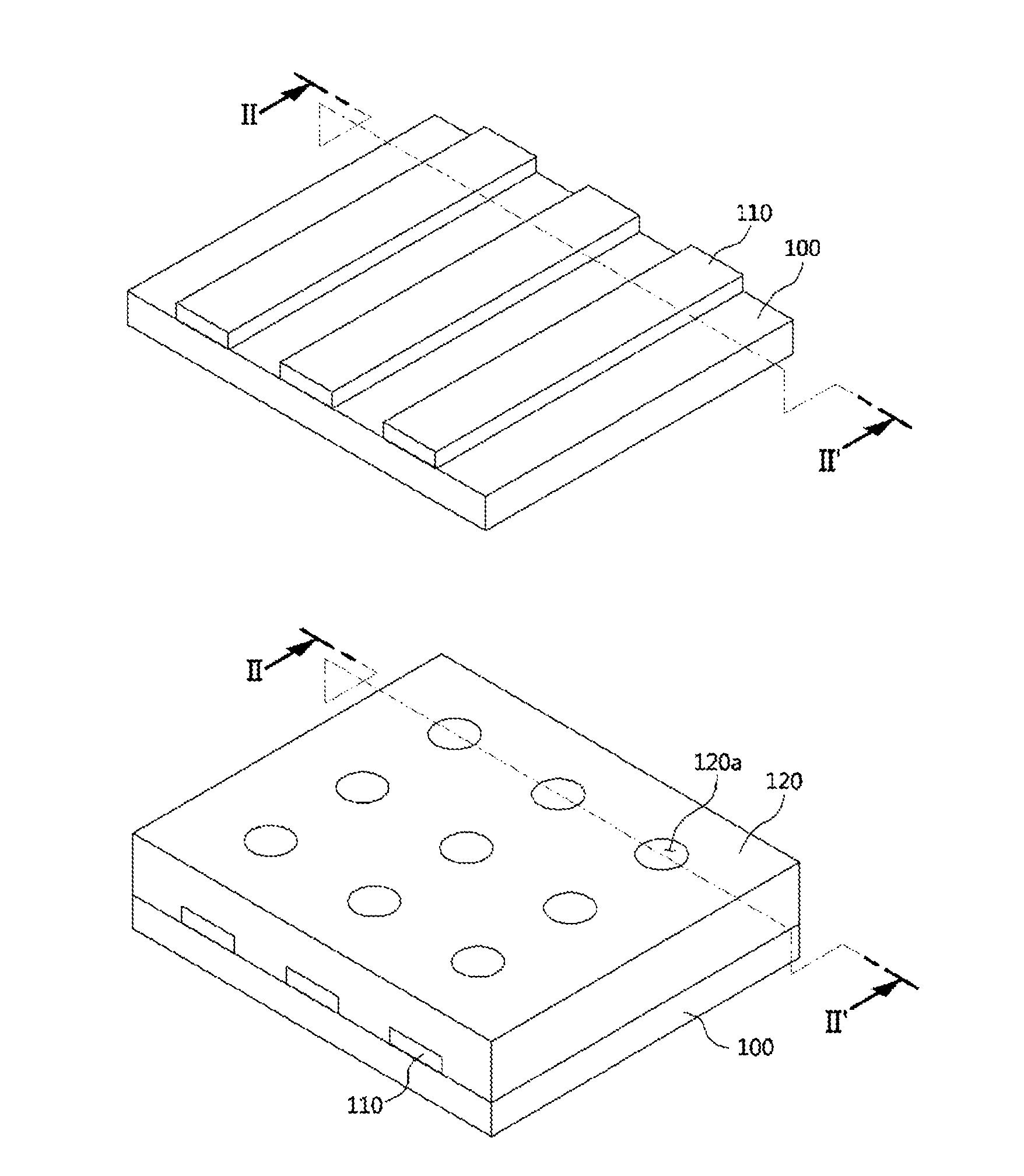

Resistance change memory device having threshold switching and memory switching characteristics, method of fabricating the same, and resistance change memory device including the same

ActiveUS20130270509A1Easy to integrateAdd process stepsSemiconductor/solid-state device manufacturingBulk negative resistance effect devicesMemory arrayElectrode

Disclosed are a resistance change memory device, a method of fabricating the same, and a resistance change memory array including the same. The resistance change memory device includes a first electrode and a second electrode. A hybrid switching layer is interposed between the first electrode and the second electrode. The hybrid switching layer is a metal oxide layer having both threshold switching characteristics and memory switching characteristics.

Owner:GWANGJU INST OF SCI & TECH

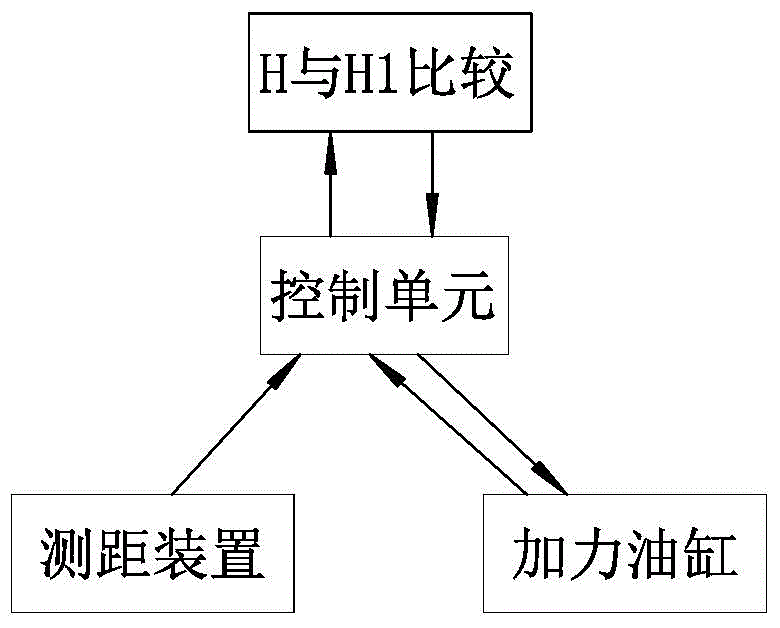

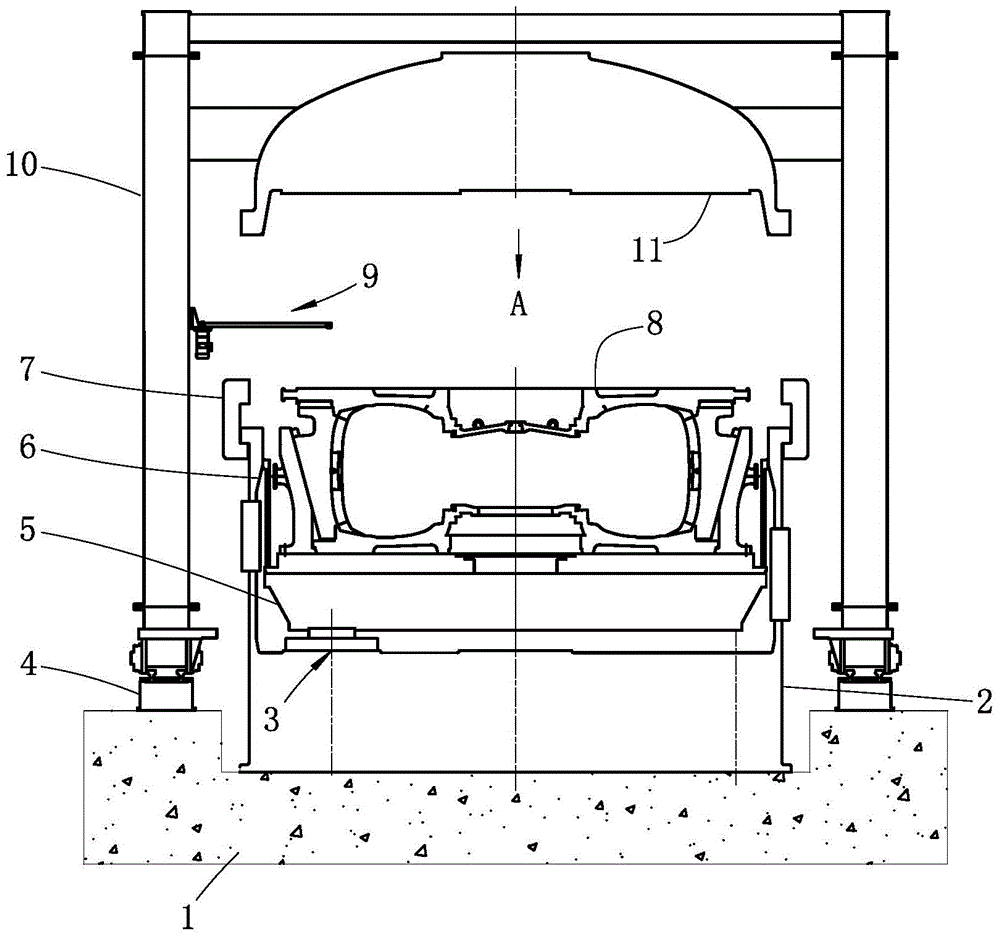

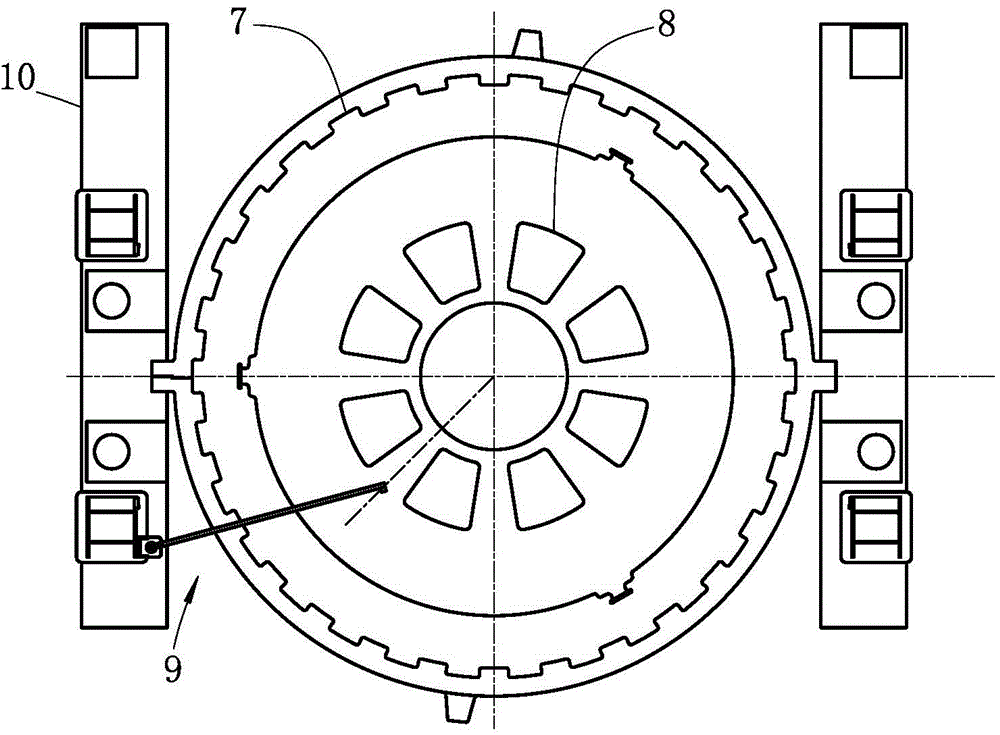

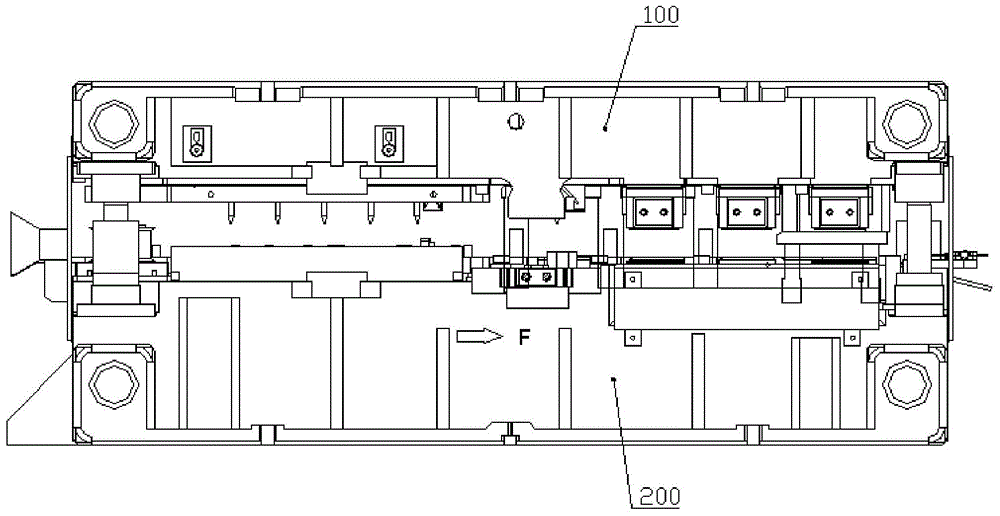

Automatic mold adjusting method and tyre vulcanizer

The invention discloses an automatic mold adjusting method, belonging to the technical field of tyre vulcanizers. Under a mold adjusting state, the automatic mold adjusting method comprises the following steps: (a) setting a standard mold height value H in a control unit of the vulcanizer, wherein the standard mold height value H is a distance between a fixed height position on the vulcanizer and an upper side plate of a standard mold; (b) replacing a tyre mold; (c) measuring an actual height value H1 from a fixed height position to an upper side plate of the replaced tyre mold, and transmitting the actual height value H1 into the control unit; (d) comprising H1 and H, driving a driving cylinder to drive the tyre mold to move by means of the control unit, wherein the movement distance delta H is equal to absolute (H-H1). According to the automatic mold adjusting method, the height adjustment of the mold can be automatically finished after the tyre mold is replaced, the labor intensity of operation workers is lightened, the mold replacement operation time is saved, the automation degree is improved and the production efficiency is improved; the automatic mold adjusting method is widely applied to the adjustment of the tyre mold in the vulcanizer.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

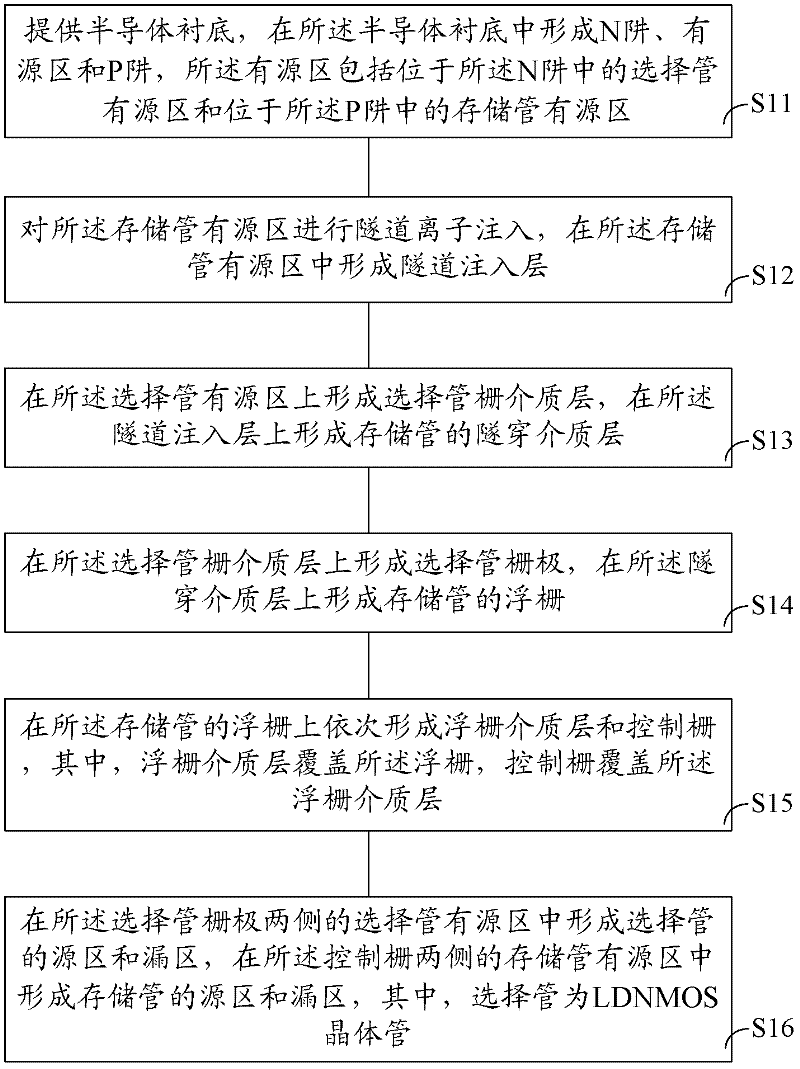

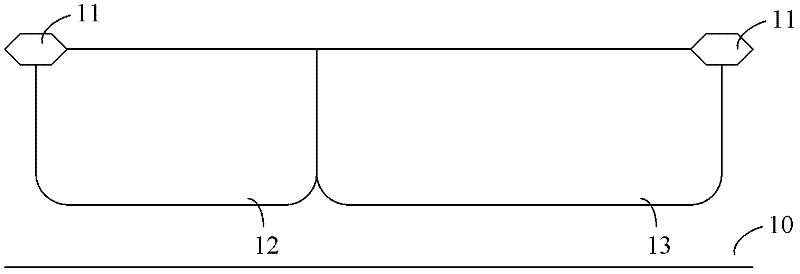

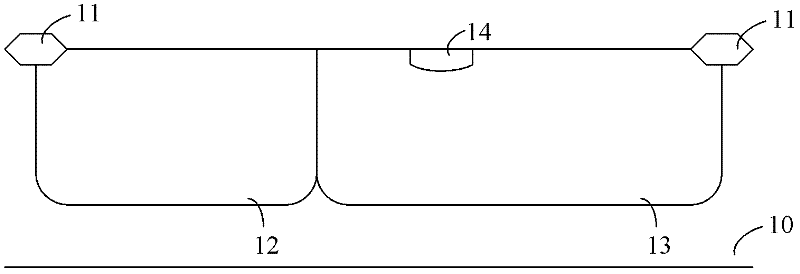

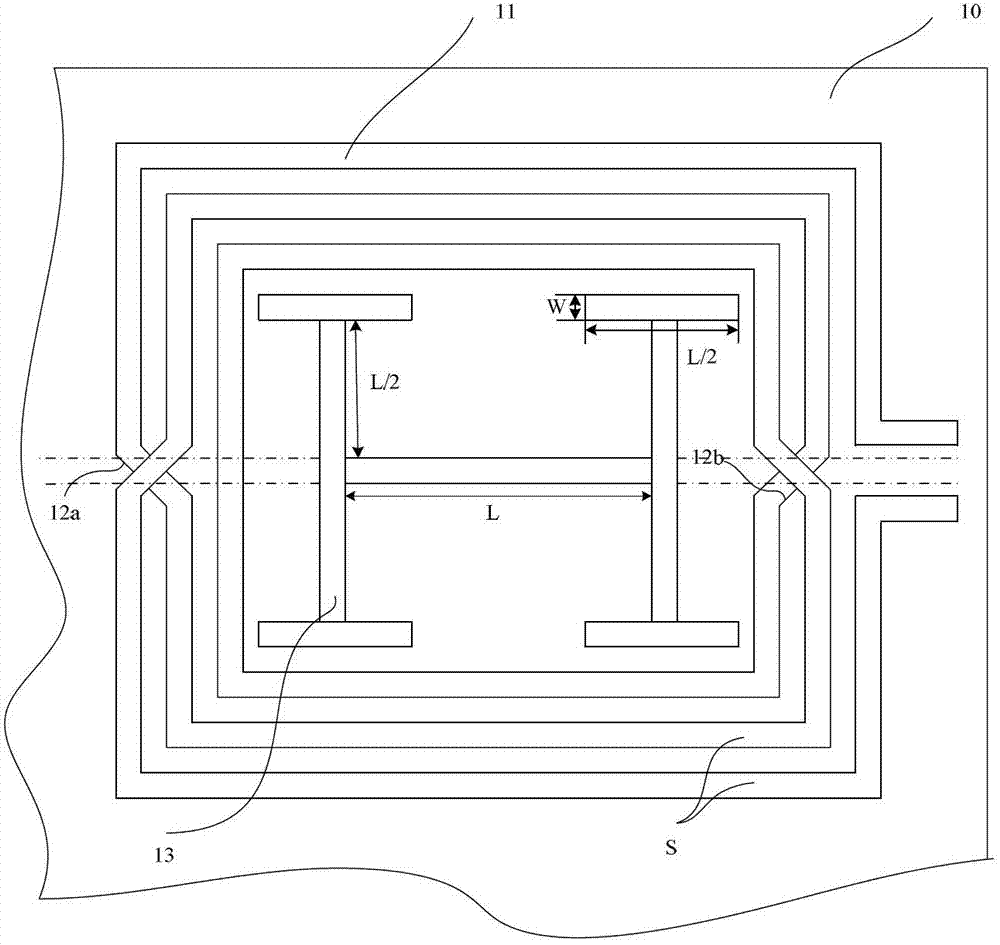

eeprom core structure embedded in bcd process and its forming method

ActiveCN102263110AReduce process complexityAdd process stepsTransistorSolid-state devicesCMOSDouble diffusion

The invention provides an electrically erasable programmable read-only memory (EEPROM) core structure formed by a process embedded into a monolithic integration process of manufacturing a bipolar transistor, a complementary metal oxide semiconductor (CMOS) device and a double-diffusion metal oxide semiconductor (DMOS) device on an identical chip (BCD) and a forming method. The EEPROM core structure formed by the process embedded into the BCD process comprises a selectron and a memotron which are connected in series, wherein the selectron is a laterally diffused n-CHANNEL metal oxide semiconductor (LDNMOS) transistor. In the invention, the forming process of the EEPROM core structure can be embedded into the BCD process to achieve favorability for reducing the complexity of the process.

Owner:ADVANCED SEMICON MFG CO LTD

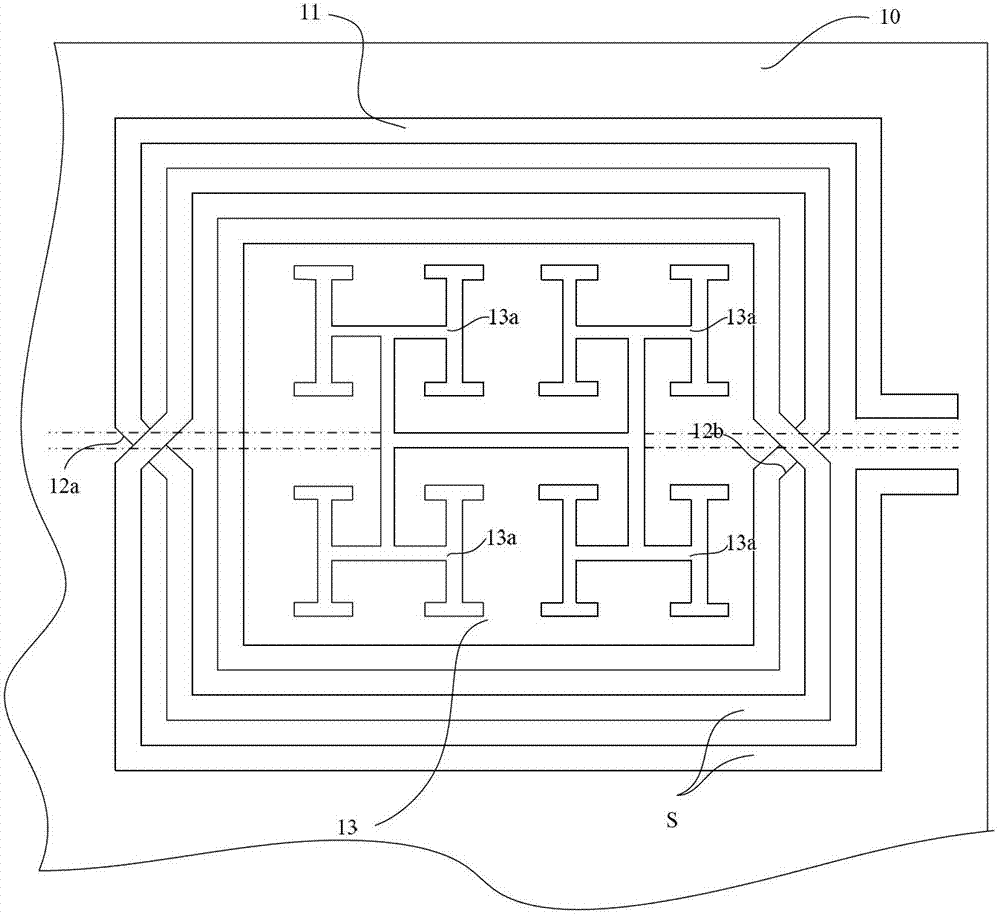

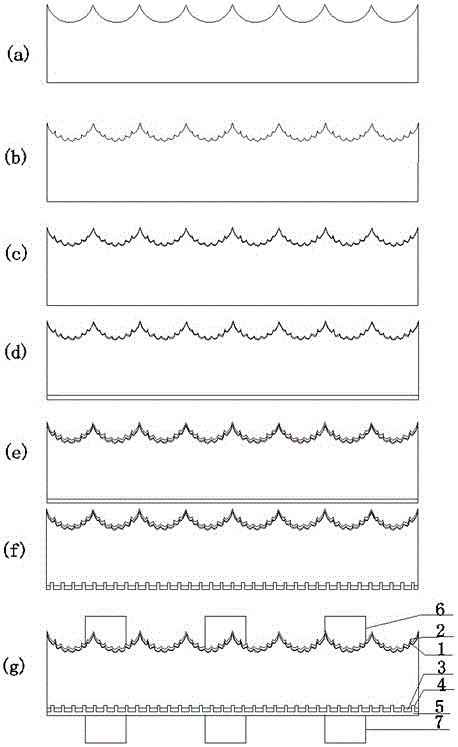

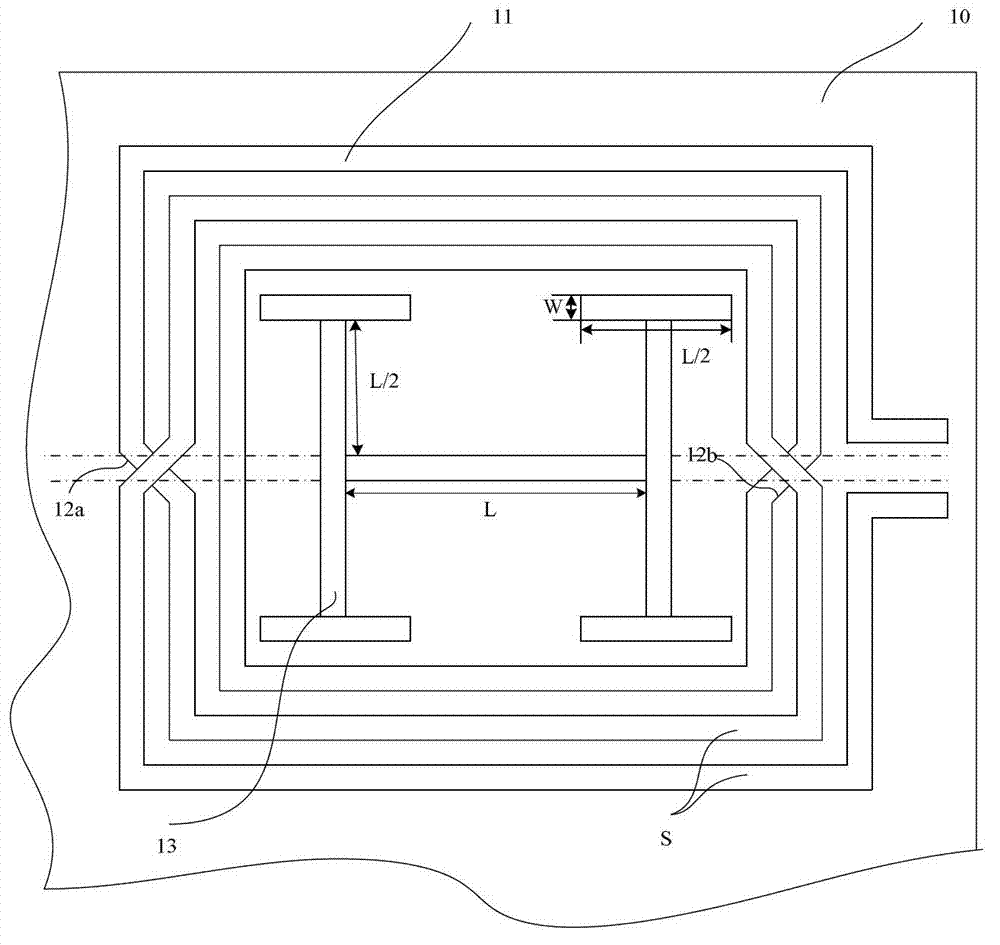

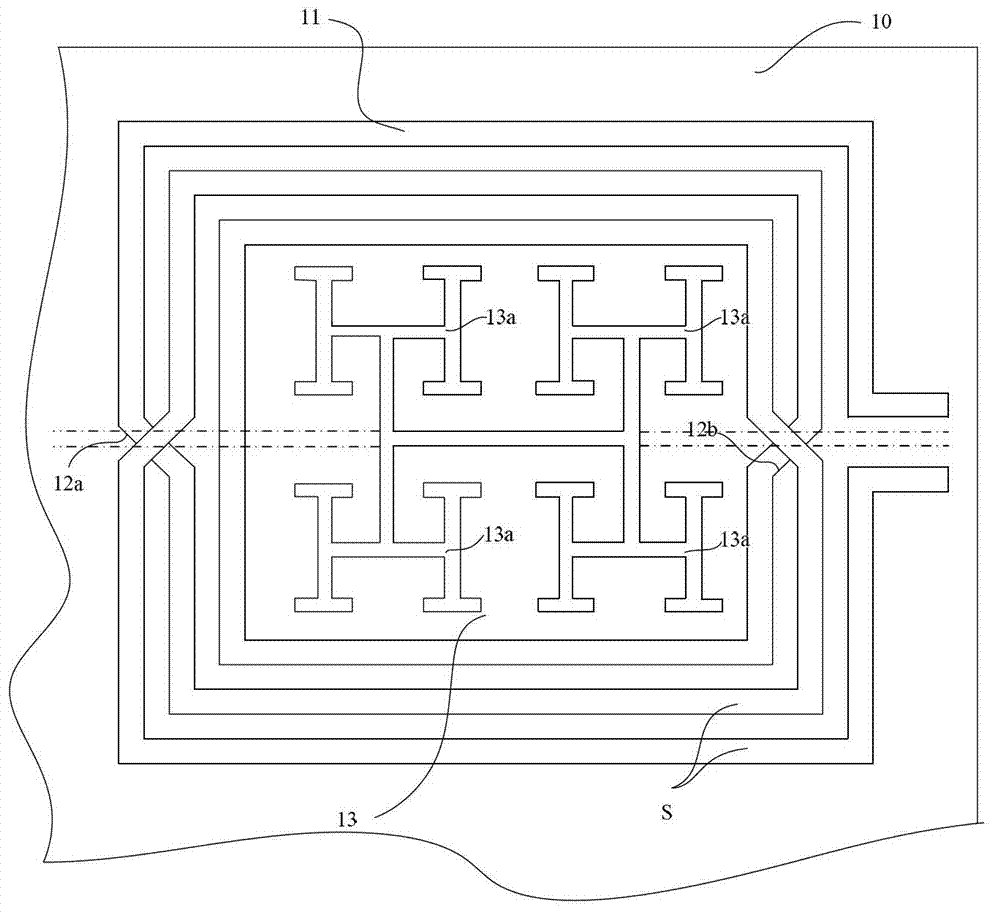

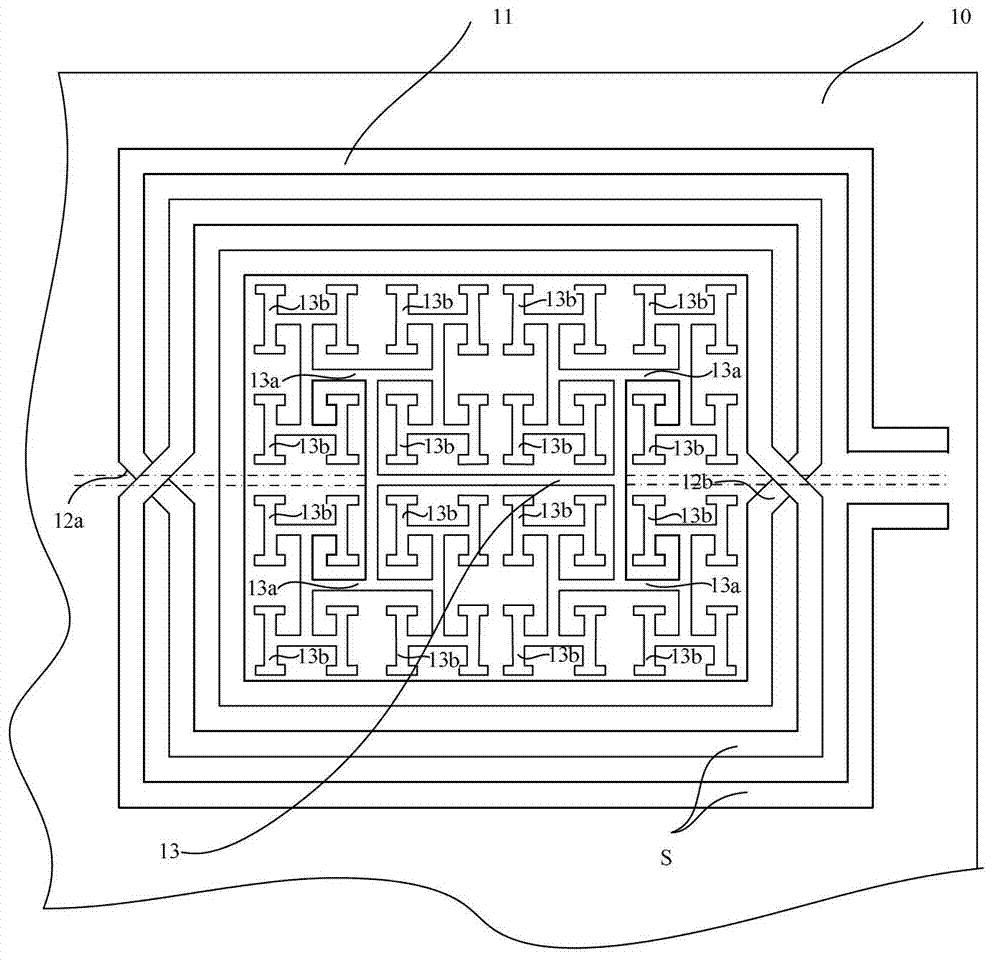

Novel fractal pattern grounding shield structure

ActiveCN102738124AEffective shieldingReduce energy lossSemiconductor/solid-state device detailsSolid-state devicesPatterned ground shieldTransformer

The invention relates to a grounding shield structure which applies a fractal theory. In existing on-chip spiral inductors and transformers, because an alternating electromagnetic field is produced, induction current is produced on a substrate, energy loss is produced, and an induction value and a Q value are reduced. The shield structure is arranged in the center of an inductor / transformer which is wound from a coil, and a pattern grounding shield layer of a first order, a second order, a third order and even a higher order is constructed with metal layers M1 and M2 with thin bottom layers based on H-shaped and crisscross basic units through the self similarity and iterative principle of the fractal theory. According to the novel fractal pattern grounding shield structure, the electromagnetic field which penetrates to the substrate is effectively shielded, so that the induction current which can be produced on the substrate and on the surface area of the substrate is reduced, and the effects of reducing the energy loss of the substrate and improving the induction value and a quality factor are achieved.

Owner:HANGZHOU DIANZI UNIV

Production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as chemical intermediate

The invention discloses a production method of bromo-3-chloro-5,5-dimethylhydantoin (BCDMH) serving as a chemical intermediate. The production method comprises the following steps that A, 5,5-dimethylhydantoin, flake caustic soda, liquid bromine and chlorine react; a reaction material is obtained; B, the reaction material is subjected to centrifugal spin-drying by a scraper bottom unloading centrifuge, subjected to centrifugal washing by deionized water, and spin-dried; a wet product after centrifugal treatment is dried to form a dry product; and C, the dry product is dissolved by acetone, and filtered; after the deionized water is added for diluting and cooling, BCDMH is separated through crystallization; and the dried wet product is BCDMH capable of serving as a chemical oxidizing agent. The content of BCDMH prepared by the method reaches above 99.3%; the content of bromine is 32.85%; the content of chlorine is 14.70%; a trichloromethane insoluble substance is less than or equal to 0.03%; iron ions are less than or equal to 8mg / kg; calcium ions are less than or equal to 24mg / kg; and BCDMH can serve as the chemical intermediate.

Owner:河北利仕化学科技有限公司

Glass passivation method for silicon mesa diodes

ActiveCN105470150AReduce residual volume and residual thicknessReduce process difficultySemiconductor/solid-state device manufacturingGlass corrosionSintering

The invention discloses a glass passivation method for silicon mesa diodes. The glass passivation method for silicon mesa diodes sequentially comprises the following steps: preparation of glass frit, glass coating, residual mesa top glass elimination, glass sintering and forming. The preparation proportion of the glass frit is optimized, mesa top glass is removed by an adhesion removal method, then a glass sintering process is carried out, difficulty of the process of eliminating the mesa top glass is reduced on the premise of achieving the ideal passivation effect, and the time of the process is shortened. According to a glass passivation device manufactured by the method, mesa top glass corrosion time can be shortened effectively, quality and precision of electrode window graphs are improved, the technology is simple and feasible, and production cost is reduced.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Chlorination method for industrial production of sucralose-6-acetate

InactiveCN102964397AReduce the difficulty of recyclingFacilitated releaseEsterified saccharide compoundsSugar derivativesOrganic solventSucrose

A chlorination method for industrial production of sucralose-6-acetate. The method comprises steps of: (a) adding thionyl chloride into an organic solvent below 30 DEG C to form a mixed solution, with a molar ratio of the organic solvent to thionyl chloride of 3.5-4.6:1; (b) adding sucrose-6-acetate with water content of 0.2%-0.8% into the mixed solution, and stirring, wherein a molar ratio of added sucrose-6-acetate to thionyl chloride is 1:7-9; and (c) slowly heating to 110-113 DEG C in 6-7 h; and after the reaction, subjecting the reaction product to neutralization, solvent removal, decolorization by adding water and crystallization to obtain the sucralose-6-acetate crude product. According to the invention, sucrose-6-acetate containing water is adopted for chlorination, and thionyl chloride is added once without cooling, so as to speed up the process, and reduce energy consumption. The employed solvent is more conducive to release of gas products such as sulfur dioxide generated in the chlorination process and promotion of yield increase, and reduces the generation of the other salts and separation burden.

Owner:LIYANG WEIXIN CHEM

Silicon piezoresistive type pressure sensor chip

ActiveCN104425485AImprove stabilityReduce leakage currentSolid-state devicesForce measurement using piezo-resistive materialsOhmic contactIsolation layer

The invention relates to a silicon piezoresistive type pressure sensor chip comprising a silicon piezoresistive type pressure sensor base body, an isolation layer, a stability enhancement layer, a metal layer, contact holes, and a silicon substrate heavily-doped region. The chip is characterized in that the silicon piezoresistive type pressure sensor is made of an SOI silicon wafer; and a silicon dioxide layer is buried below piezoresistors. The isolation layer covers the silicon piezoresistive type pressure sensor base body; the contact holes are etched in the isolation layer and are filled with metals; the metals and the silicon substrate heavily-doped region are in ohmic contact and the metals are also connected with the metal layer of the chip surface; the stability enhancement layer is arranged on the isolation layer; and the stability enhancement layer and the metals in the contact holes are electrically connected by the metal layer. A highest potential point of the chip is formed at the metal layer, thereby forming a power supply welding plate of the sensor. The chip has the following advantages: on the premise that the structure of the traditional silicon piezoresistive type pressure sensor chip is not changed substantially, the structure of the silicon piezoresistive type pressure sensor chip is changed slightly and a few process steps are added, so that the output stability is improved obviously.

Owner:WUHAN FINEMEMS

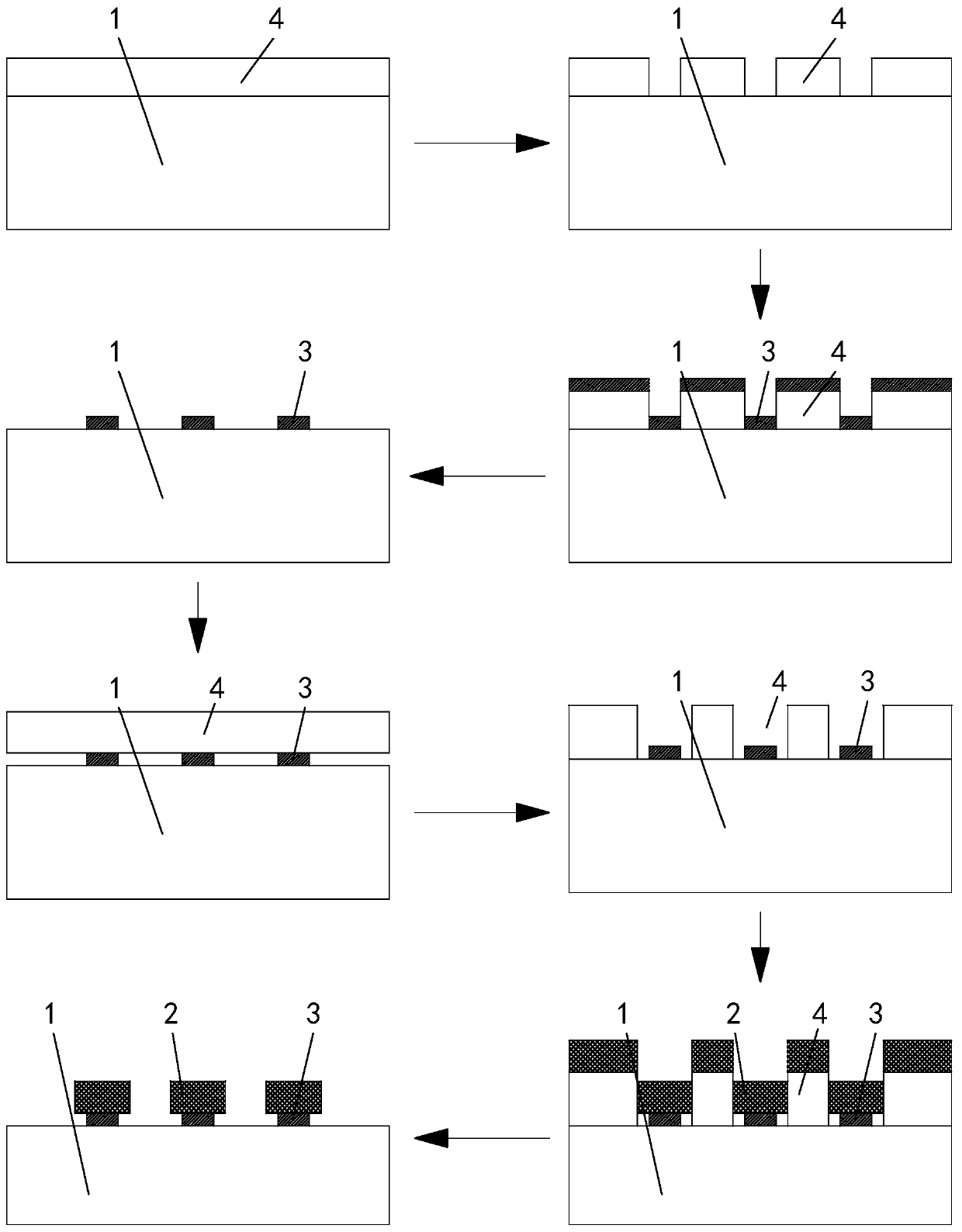

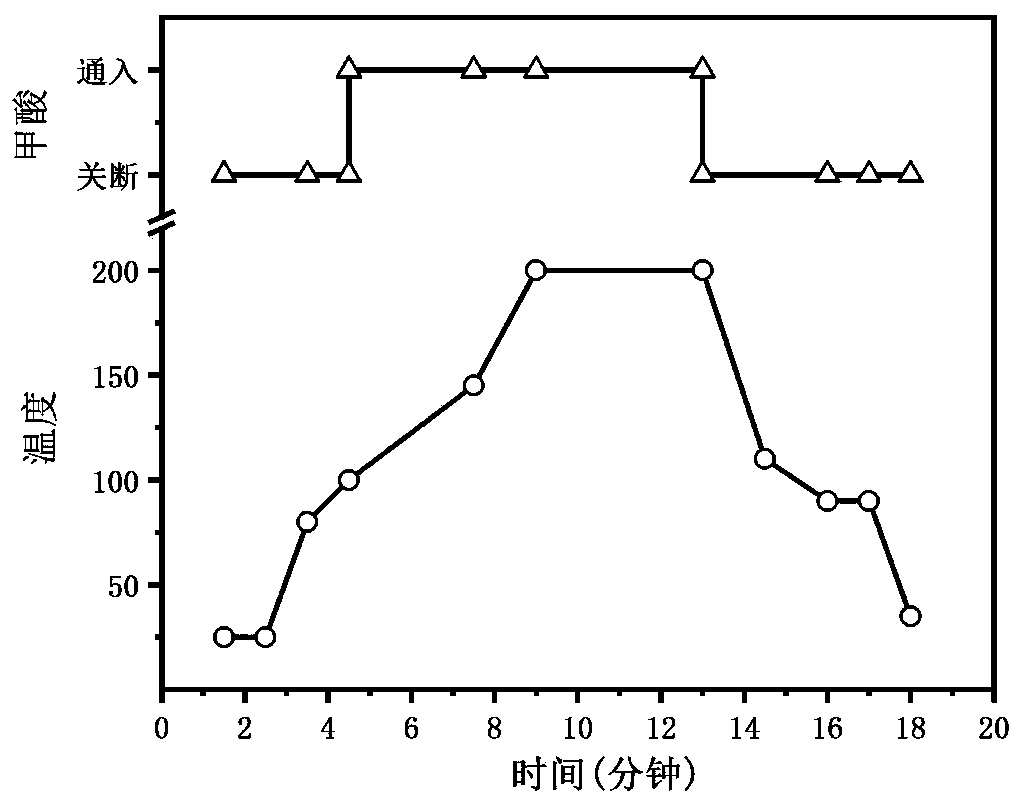

Indium column of infrared focal plane detector and preparation method thereof

ActiveCN111584672AQuality improvementGood size uniformityFinal product manufactureSemiconductor/solid-state device detailsEvaporation (deposition)Indium

The invention relates to a preparation method of an indium column of an infrared focal plane detector and the indium column prepared by the method. The method comprises the following steps of spin-coating thin photoresist on the surface of a chip, aligning to the center of a pixel or a reading unit electrode to carry out primary overlay, preparing a circular bottoming metal deposition hole, evaporating a composite metal film through electron beam evaporation, and obtaining a bottoming metal pattern array by adopting a wet stripping mode, secondly, spin-coating photoresist with medium thickness, aligning to the center of the bottoming metal pattern to carry out secondary overlay, preparing a square indium column deposition hole, depositing an indium film through vacuum thermal evaporation,and obtaining an indium column by adopting a wet stripping process, and finally, performing ball shrinkage in a formic acid atmosphere by adopting a reflux furnace to obtain the indium column array with a large height-width ratio. Compared with the prior art, the overall process difficulty is lower, the size of the prepared indium column can meet the requirement, the size uniformity is high, the surface of the indium column is uniform and smooth, and the consistency requirement of the inverted interconnection process can be completely met.

Owner:武汉华中旷腾光学科技有限公司

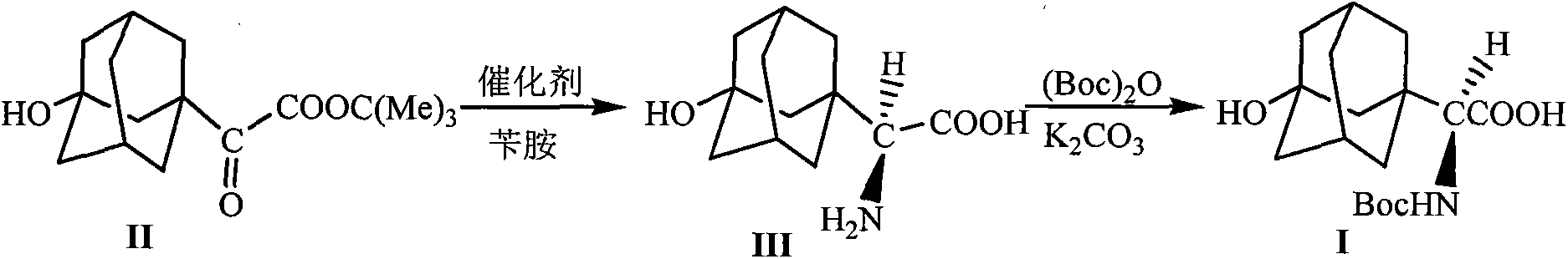

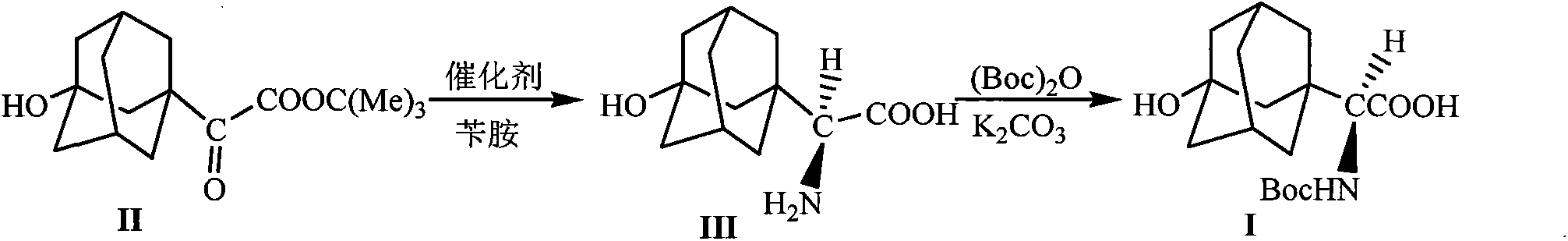

Method of synthesizing saxagliptin intermediate N-t-butyloxycarboryl-3-hydroxyl-1-adamantyl-D-glycine

ActiveCN103951588AAdd process stepsRaw materials are not easy to getCarbamic acid derivatives preparationOrganic compound preparationDi-tert-butyl dicarbonateCarbonic acid

The invention discloses a novel method of preparing an important saxagliptin intermediate N-t-butyloxycarboryl-3-hydroxyl-1-adamantyl-D-glycine. The method comprises the following steps: S1, carrying out an asymmetric reduction amination reaction on 2-(3-hydroxyl-1-adamantyl)-2-oxo-tert-butyl acetate and benzylamine under the effect of a self-made chiral acylamino alcohol catalyst, and hydrolyzing ester to obtain 3-hydroxyl-1-adamantyl-D-glycine; and S2, carrying out a reaction on 3-hydroxyl-1-adamantyl-D-glycine and di-tert-butyl dicarbonate ester to obtain N-t-butyloxycarboryl-3-hydroxyl-1-adamantyl-D-glycine. The synthetic method of the important saxagliptin intermediate N-t-butyloxycarboryl-3-hydroxyl-1-adamantyl-D-glycine provided by the invention is low in cost and available in raw materials, short in step, mild in reaction condition, simple and convenient to operate, high in synthetic efficiency, environment-friendly and suitable for industrialized production, and provides a novel path for preparing saxagliptin and intermediates thereof.

Owner:HUAIHAI INST OF TECH

Clothes swing ticket printing process capable of preventing color fading

InactiveCN106394036AAvoid printing color differenceAvoid RubbingOther printing apparatusPrinting after-treatmentEngineeringFading

The invention provides a clothes swing ticket printing process capable of preventing color fading. The clothes swing ticket printing process capable of preventing color fading is characterized by comprising the following steps of platemaking, type setting, color modulating, printing, drying treatment, powder removing treatment, gold blocking, laminating and slitting. According to the clothes swing ticket printing process capable of preventing color fading, in the sample color modulating process, sample color modulating is conducted through the same type printing press in the printing process, and therefore the occurrence of a printing chromatic aberration phenomenon is effectively avoided; in the clothes swing ticket printing process, the process steps of drying treatment, powder removing treatment, laminating and the like are additionally arranged, and therefore the bad phenomena such as friction color fading, white dots and set-off are effectively avoided.

Owner:HAIYAN XIMEI PRINTING

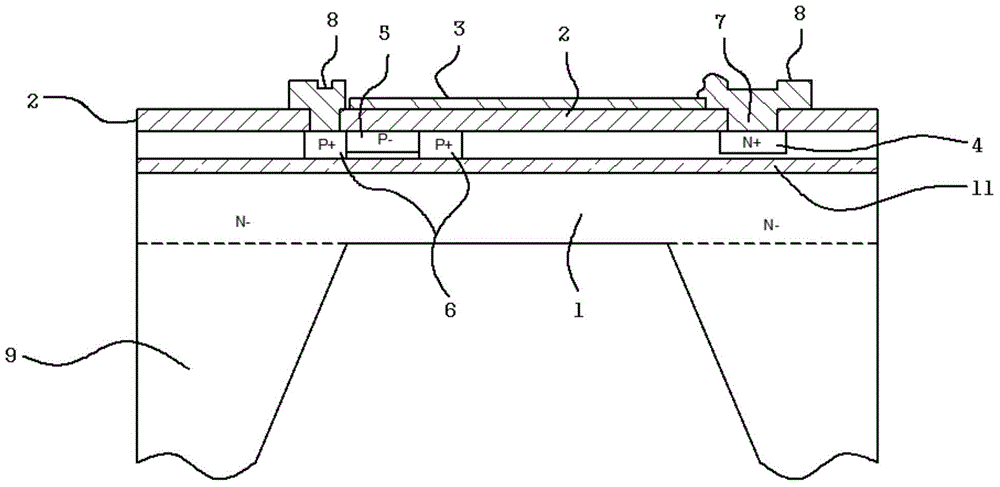

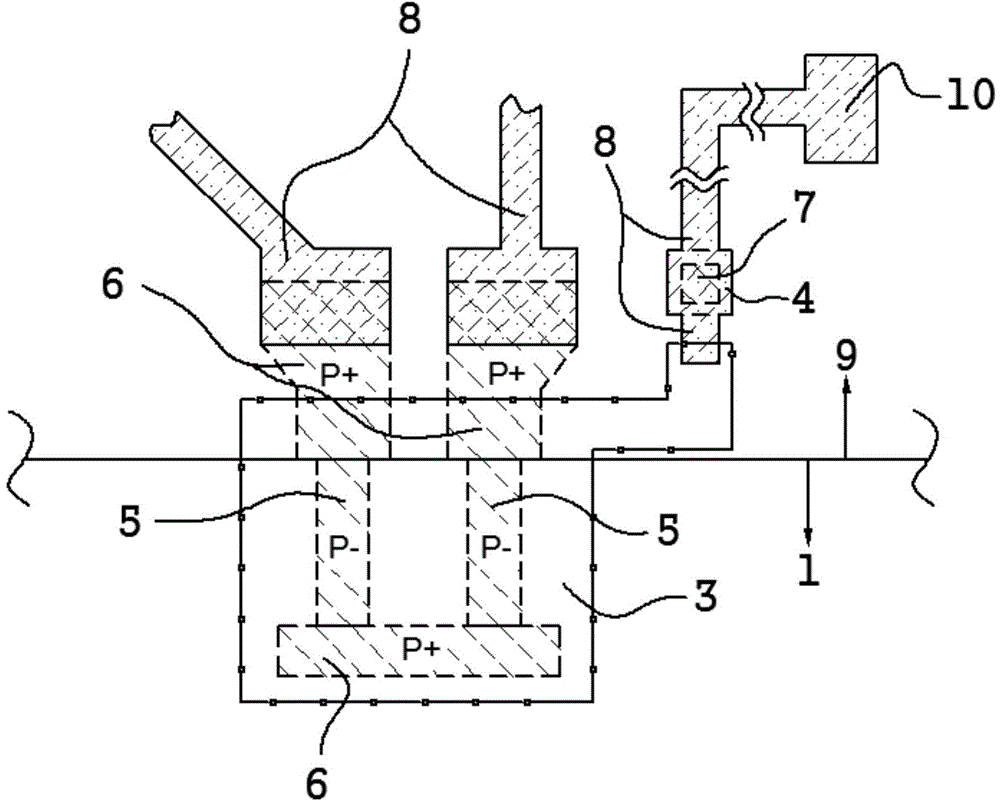

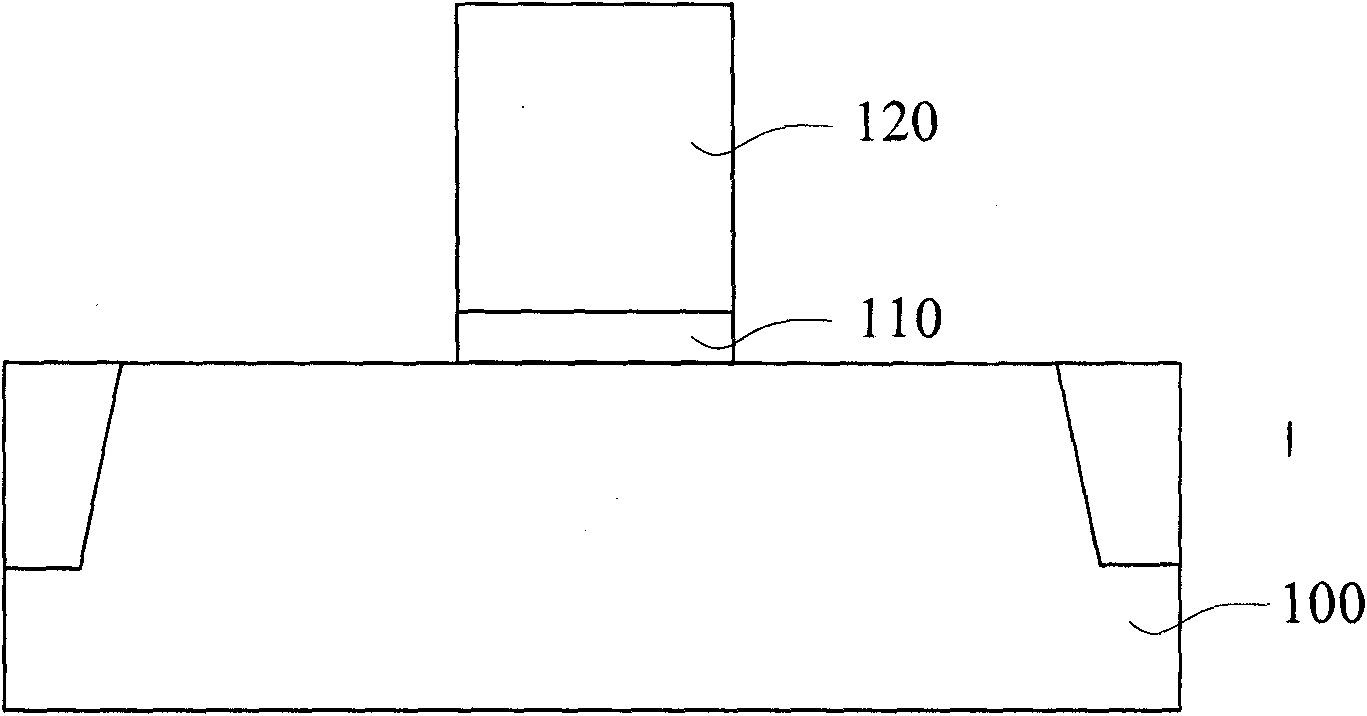

Full-self-aligned insulated gate bipolar transistor device and manufacturing method thereof

ActiveCN103219238AReduce widthLatch-up improvementSemiconductor/solid-state device manufacturingChinese charactersElectron

The invention relates to a semiconductor device in the field of power electronics, and in particular relates to a full-self-aligned insulated gate bipolar transistor device and a manufacturing method thereof. The device comprises a first conduction type substrate, and is characterized in that a second conduction type base region is formed in a first primary plane of the first conduction type substrate; and a second conduction type deep diffusion region is formed in the second conduction type base region and is in the shape of a Chinese character 'ao' meaning concave. The bipolar transistor device adopts insulated side walls and a technology of full self alignment, photolithography is not needed, the width of a polysilicon window can be reduced to 4 microns and even 2 microns, and thus more refined patterns can be achieved.

Owner:中国东方电气集团有限公司 +1

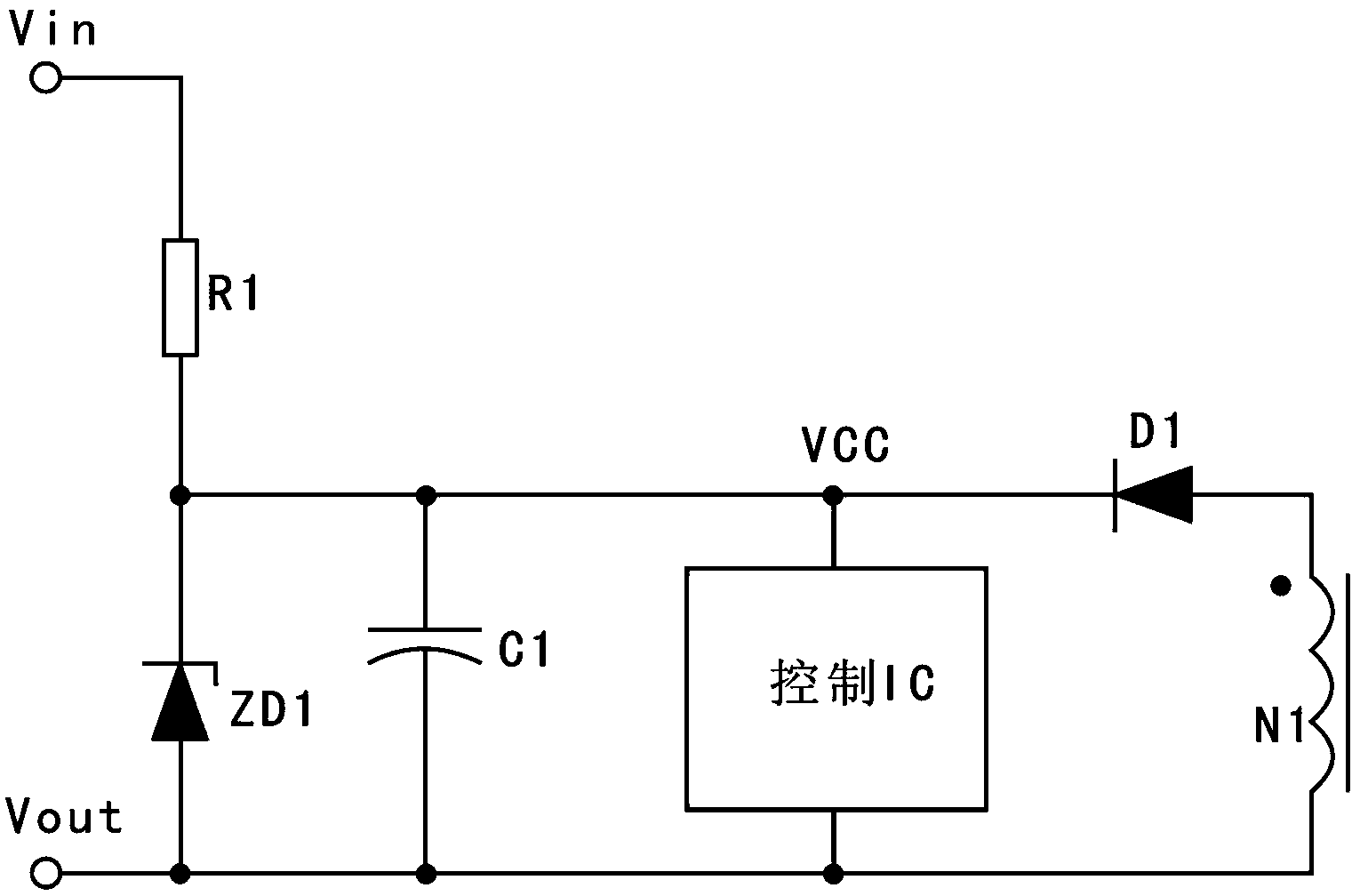

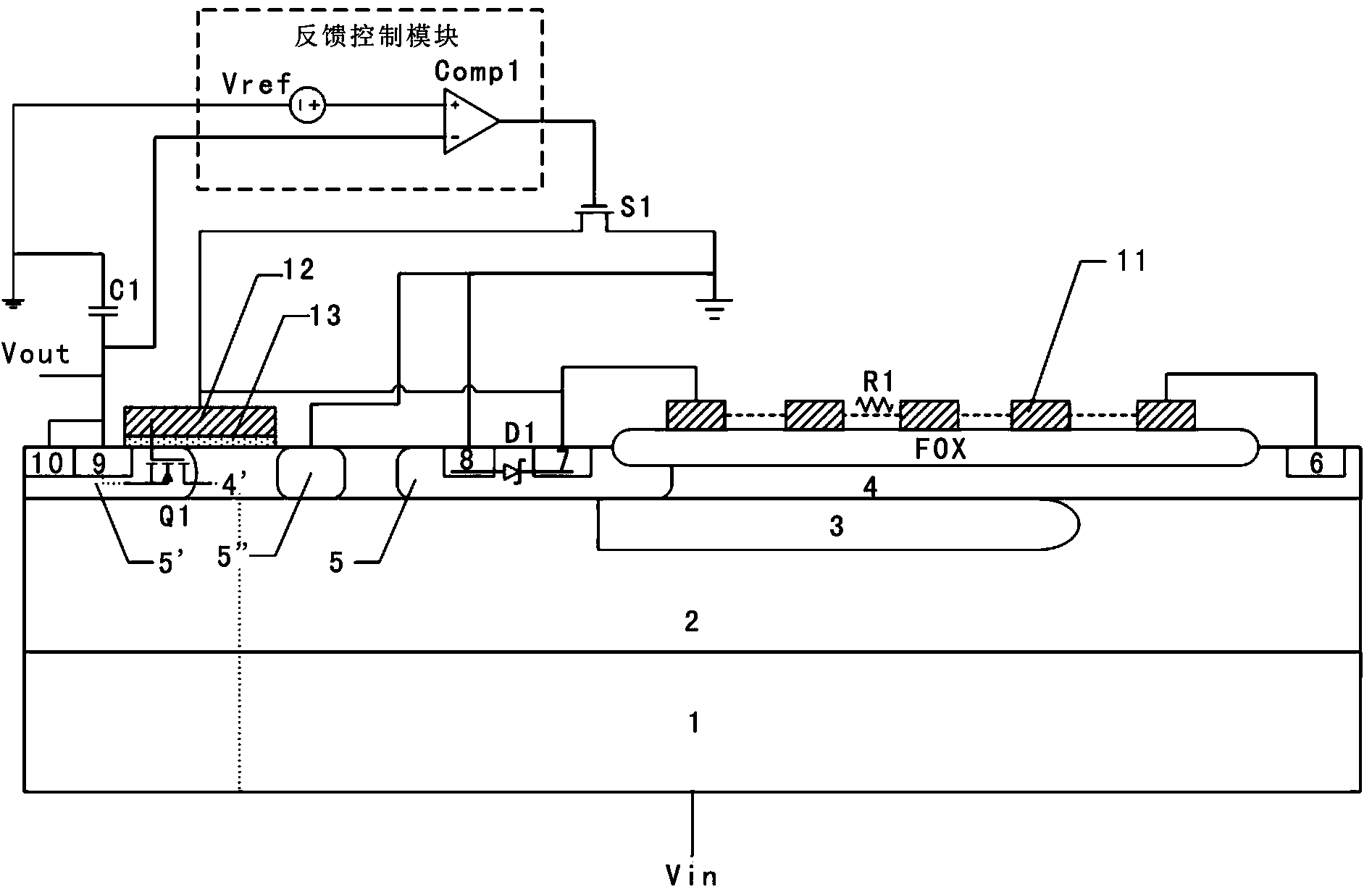

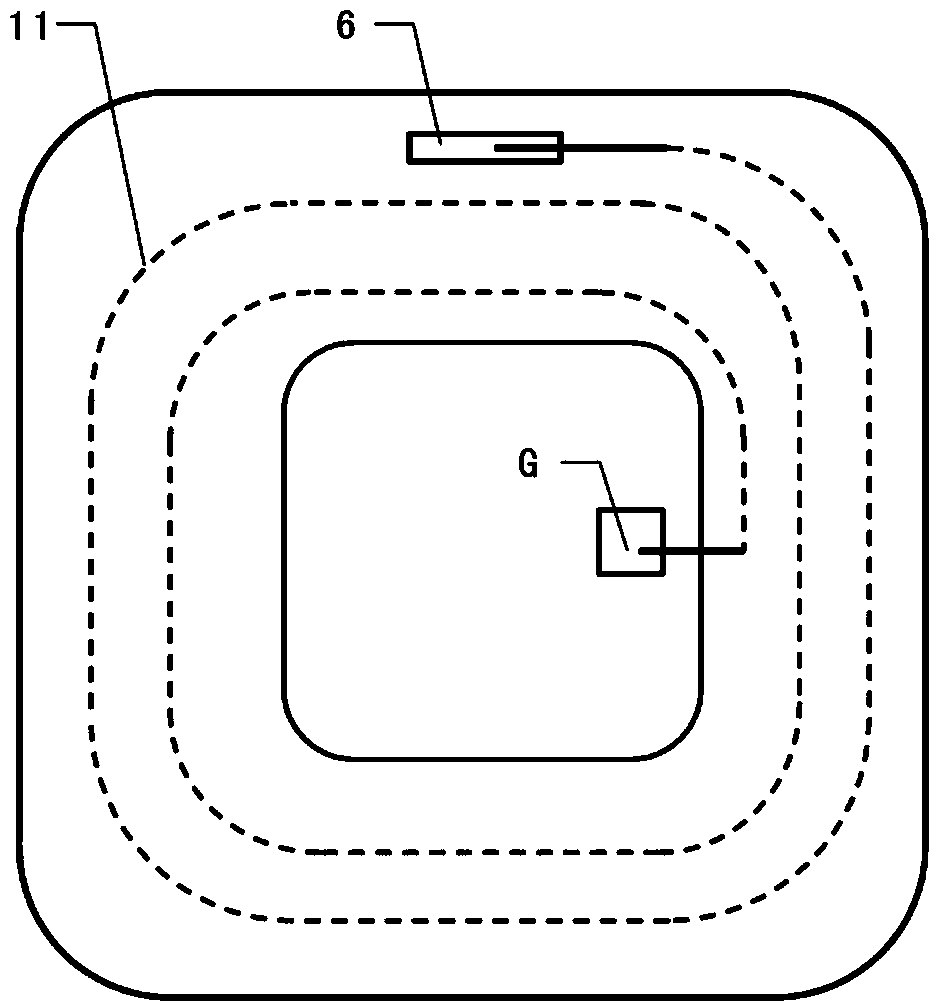

Semiconductor starting device based on spiral polycrystalline silicon field effect transistor charging and manufacturing process of semiconductor starting device

InactiveCN104362149AImprove efficiencyReduce areaSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceElectronic switch

The invention discloses a semiconductor starting device based on spiral polycrystalline silicon field effect transistor charging. The semiconductor starting device is characterized in that the first end of a resistor is connected with the drain of a field effect transistor to serve as an input end, the second end of the resistor, the grid of the field effect transistor and the first end of an electronic switch are connected with the cathode of a diode, the source of the field effect transistor and the cathode signal input end of a feedback control module are connected with the first end of a capacitor to serve as an output end, the output end of the feedback control module is connected with the control input end of the electronic switch, and the anode signal input end of the feedback control module, the second end of the capacitor, the second end of the electronic switch and the anode of a voltage stabilizing diode are grounded. The invention further discloses a manufacturing process of the semiconductor starting device. The manufacturing process uses the field effect transistor integrated by a BCD process, the resistor and the voltage stabilizing diode. The semiconductor starting device has the advantages that the integrated field effect transistor is used to directly charge the capacitor, and due to the fact the integrated field effect transistor is low in resistance and power consumption when the field effect transistor is on, high power efficiency, low loss and low heating value are achieved.

Owner:CHENGDU SMET TECH

Method for eliminating graphic defects of semiconductor wafer edge region

InactiveCN1885159AWill not affect other processingExtension of timePhotosensitive material processingComputer visionSemiconductor

The invention relates to a method for eliminating the image defect at the edge area of semi-conductor crystal chip, which is characterized in that: the invention adds the process that washing the edge of chip after the developing process that forming optical etching image; and eliminates the constriction deformation image in the edge area, to avoid the constriction deformation image being removed to cause defects on other qualified images of chip, to improve the pass percentage of product.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Process for manufacturing efficient polycrystalline cell

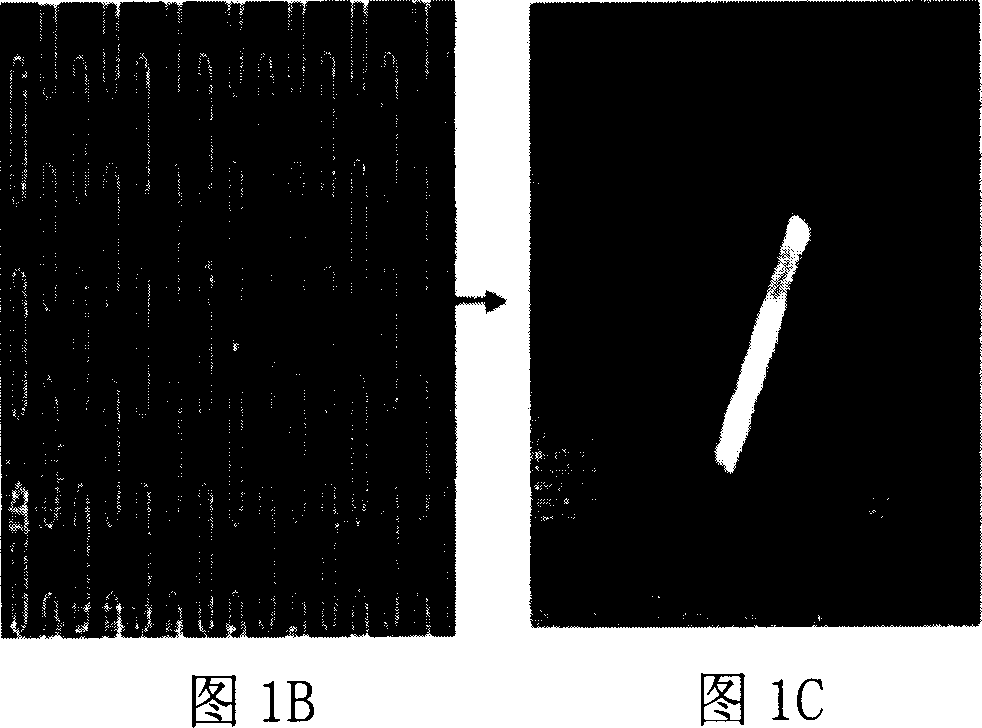

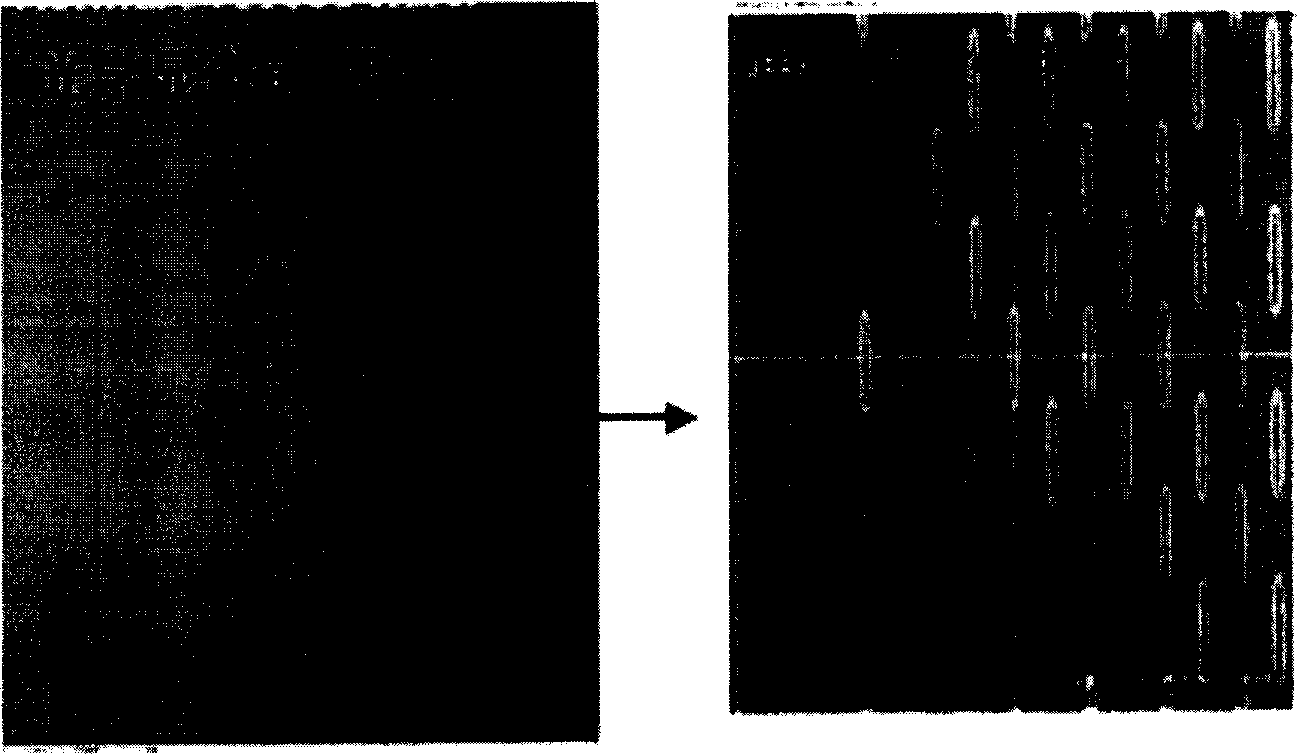

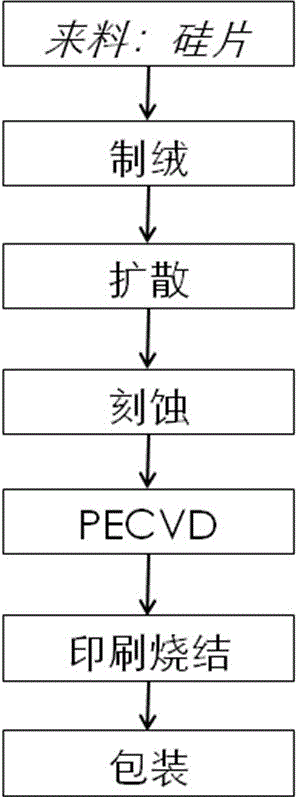

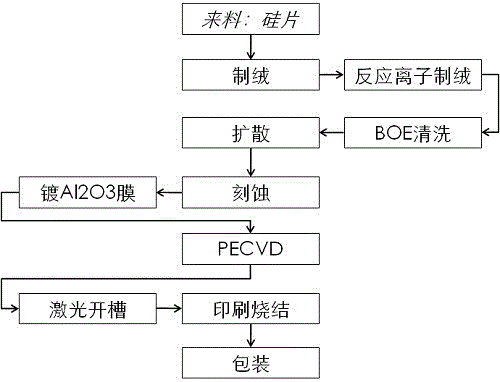

InactiveCN105702803ATake advantage ofAdd process stepsFinal product manufactureSemiconductor/solid-state device manufacturingMetallurgyThin membrane

The invention discloses a process for manufacturing an efficient polycrystalline cell. The process includes the steps of silicon wafer surface texturing, diffusion, etching, silicon nitride thin film deposition, and printing and sintering in sequence, and is characterized in that a step of texturing through reactive ion etching is added between the silicon wafer surface texturing step and the diffusion step, a step of plating a Al2O3 film is added between the etching step and the silicon nitride thin film deposition step, the Al2O3 film is deposited on the reverse side of the silicon wafer, a laser grooving step is added between the silicon nitride thin film deposition step and the printing and sintering step, and laser grooving is performed on the Al2O3 film. The photoelectric conversion efficiency of a polycrystalline cell manufactured by application of the process provided by the invention can be improved.

Owner:HEFEI & SOLAR TECH

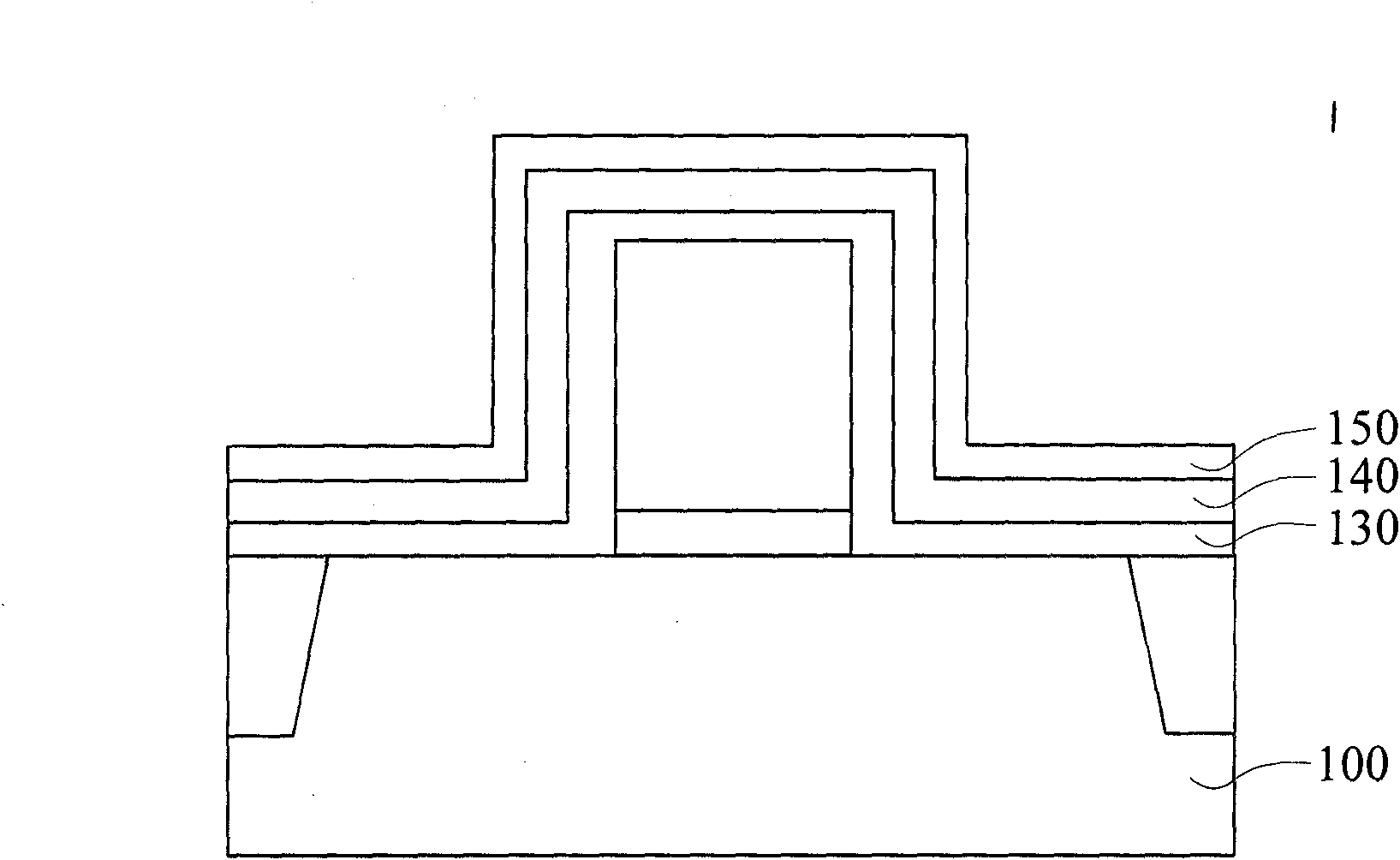

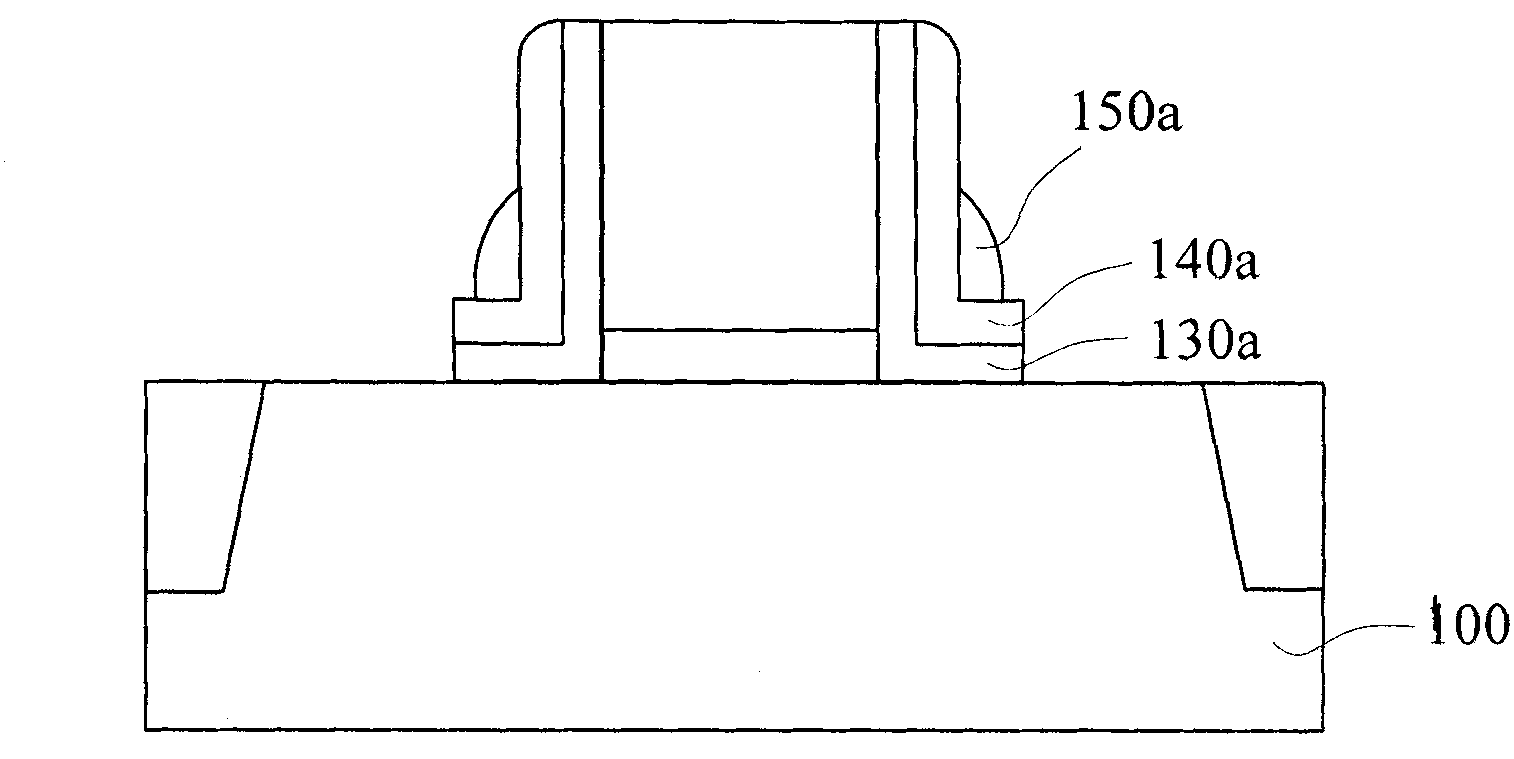

Manufacture method of semiconductor device

ActiveCN101872726AIncrease etch rateQuality assuranceSemiconductor/solid-state device manufacturingSemiconductor devicesBlock layerEtching

The invention discloses a manufacture method of a semiconductor device, comprising the following steps of: providing a semiconductor substrate on which a grid electrode is formed; forming a first oxidation layer, a silicon nitride layer and a second oxidation layer on the semiconductor substrate and the grid electrode in sequence; etching the second oxidation layer, the silicon nitride layer and the first oxidation layer until the top of the grid electrode is exposed to form a side wall layer; executing an argon ion implantation process; executing a wet etching process; forming a source electrode and a drain electrode in the semiconductor substrate at both sides of the side wall layer; forming self-aligned blocking layers on the surfaces of the semiconductor substrate, the side wall layer and the grid electrode, wherein the self-aligned blocking layers are provided with openings for exposing the grid electrode, the source electrode and the drain electrode; executing an argon ion sputtering process; and forming self-aligned metal silicides on the surfaces of the grid electrode, the source electrode and the drain electrode. According to the invention, the second oxidation layer remaining at the corners of the side wall layer can be removed effectively to ensure the quality of the self-aligned metal silicides and improve the electrical behavior of the semiconductor device.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

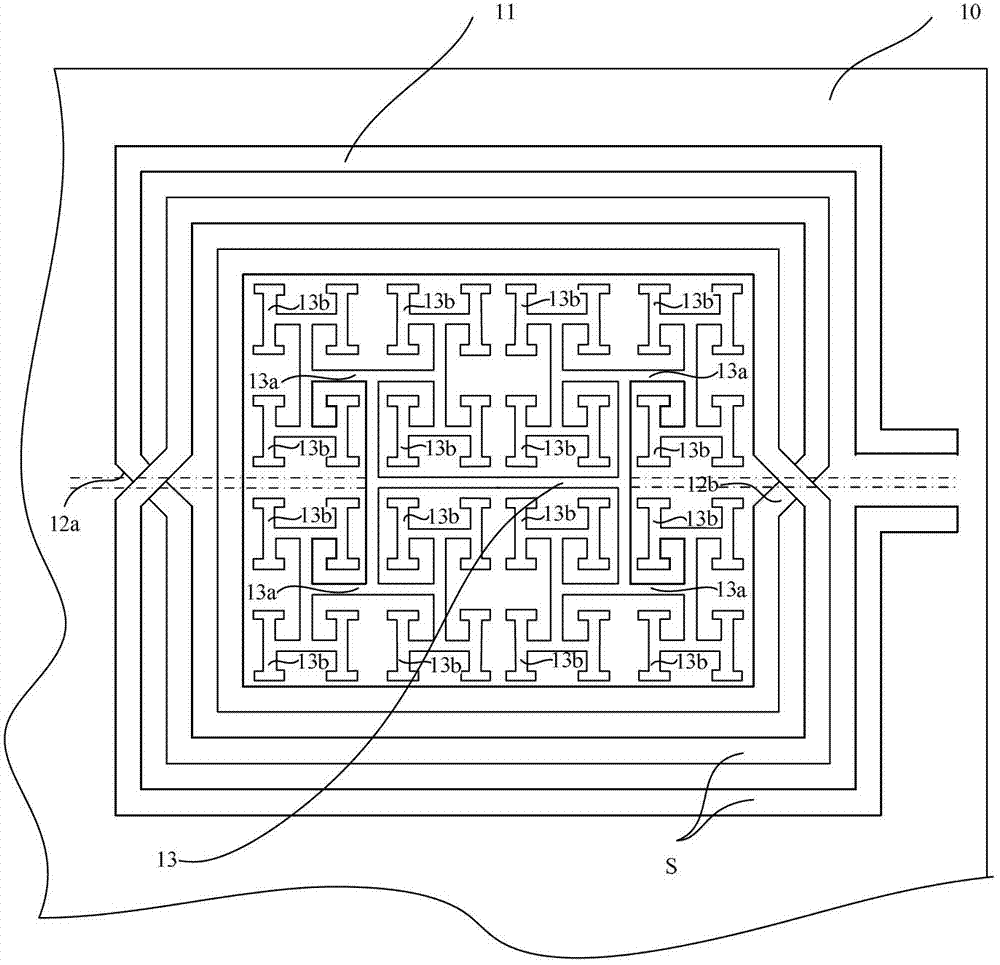

Novel fractal PGS (Program Generation System) structure

ActiveCN102738127AEffective shieldingReduce energy lossSemiconductor/solid-state device detailsSolid-state devicesPatterned ground shieldTransformer

The invention relates to a novel fractal PGS (Program Generation System) structure. As the existing the on-chip spiral inductor and transformer generate an alternating electromagnetic field, induced current is caused on a substrate to generate energy consumption and reduce the inductance and the Q value. The PGS is located in the central part of a coil-wound inductor / transformer, a first-order, second-order, third-order, or even higher order pattern grounded shield layer is constructed by a metal layer with a thin bottom on the basis of an H-shaped basic unit and a cross-shaped basic unit through the self-similarity of fractal theory and the iterative theory. The novel fractal PGS structure screens out the electromagnetic field which permeates the substrate effectively, reduces the induced current which is capable of generating on the substrate and the substrate surface area, achieves the substrate energy consumption and improves the function of inductance and quality factor.

Owner:HANGZHOU DIANZI UNIV

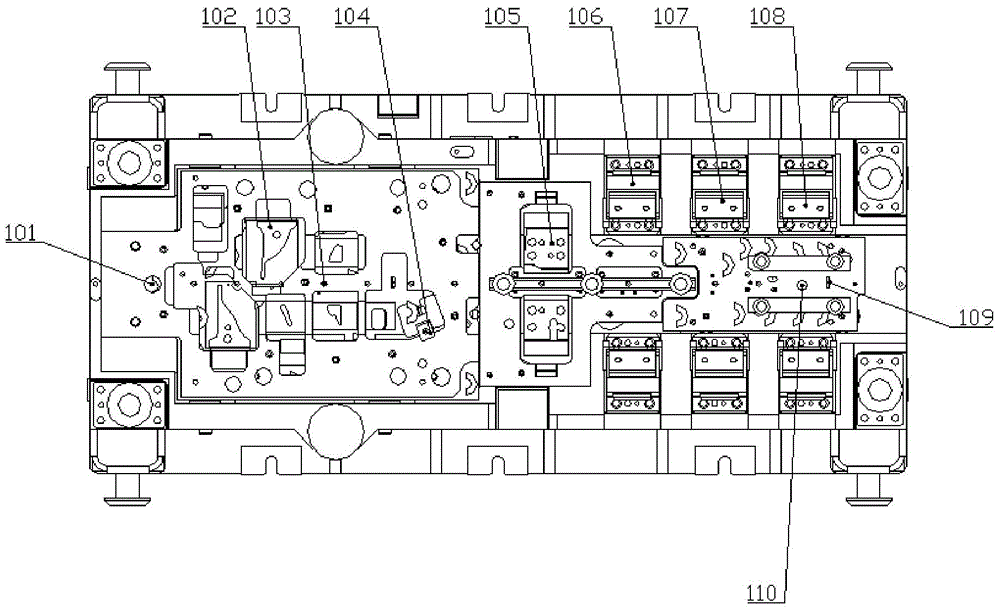

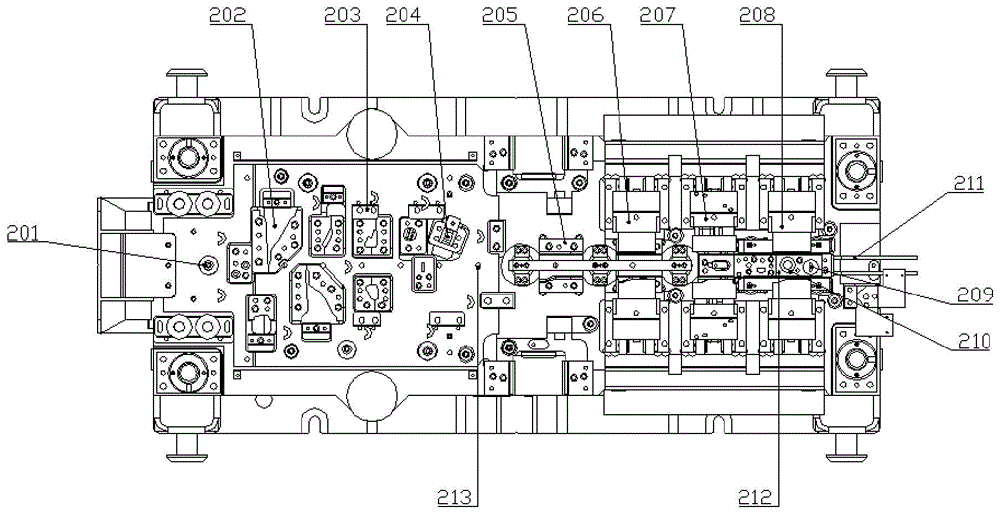

Novel machining die for automobile support

The invention provides a novel machining die for an automobile support and belongs to the technical field of producing and machining of automobile parts. The novel machining die for the automobile support comprises an upper die plate and a lower die plate, wherein the upper die plate is matched with the lower die plate. The upper die plate and the lower die plate are each sequentially provided with a positioning hole punching mechanism, a continuous punching mechanism, a lateral tongue bending mechanism, a bending mechanism, a pressing mechanism, a lateral punching mechanism, a top surface punching mechanism and a cutting-off and finished-product falling mechanism. The novel machining die for the automobile support is compact in structure, high in production efficiency and good in product quality.

Owner:天津博昊科技发展有限公司

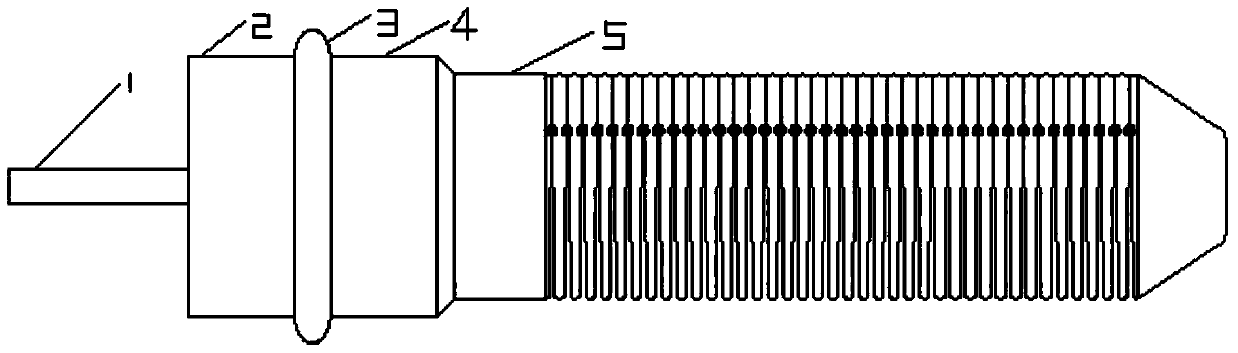

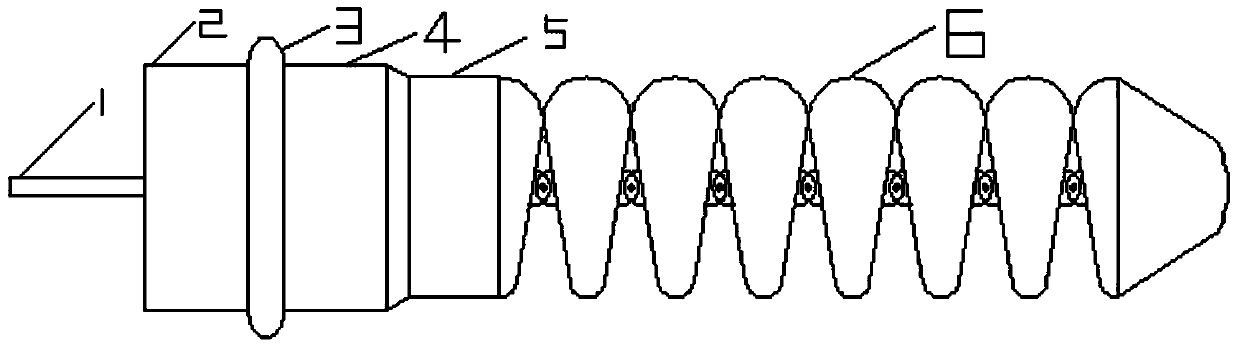

Manufacturing process of large-aperture variable-turn-angle PVC (polyvinyl chloride) pipe

InactiveCN103692671ARealize small angle bendingChanging the Turning DilemmaTubular articlesTurn angleEconomic benefits

The invention relates to a manufacturing process of a large-aperture variable-turn-angle PVC (polyvinyl chloride) pipe. The manufacturing process comprises the following five steps: mixing, extruding, performing cooling and forming, performing fixed-length cutting, flaring and packaging for sale. According to the manufacturing process, an improved flaring mould is adopted, so that a pipe opening of the large-aperture PVC pipe can be bent at a small angle, the problem that an existing PVC straight pipe makes a turn through a connecting piece is solved, and a processing process of the flaring step is correspondingly changed; a process step of horizontally rotating the flaring mould is added on the basis of an existing flaring machine, so that the large-aperture PVC pipe can be bent; the flaring mould in the process is convenient to use, the effect is remarkable, the manufacturing process is simple, and good economic benefit can be created.

Owner:山东华信塑胶股份有限公司

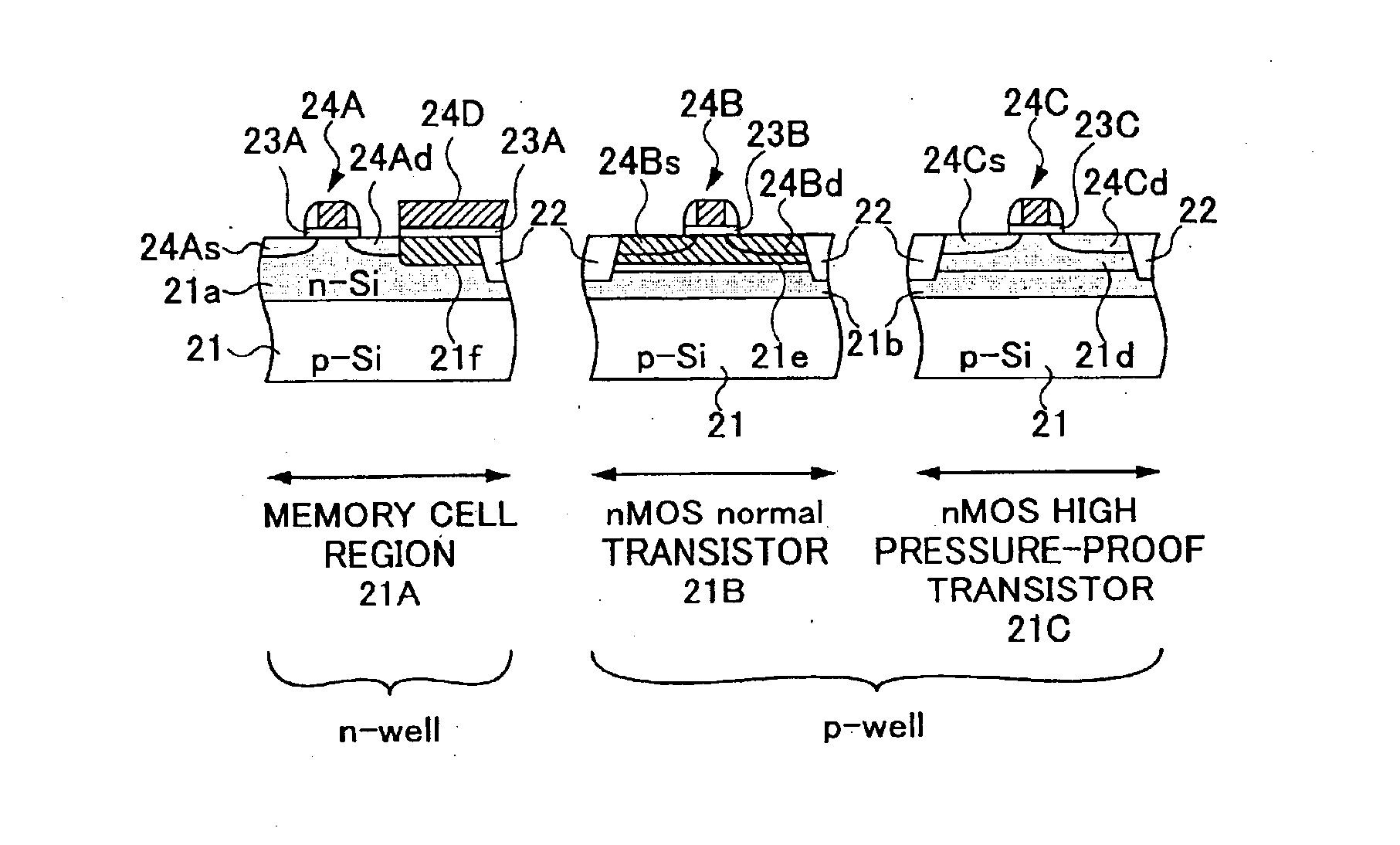

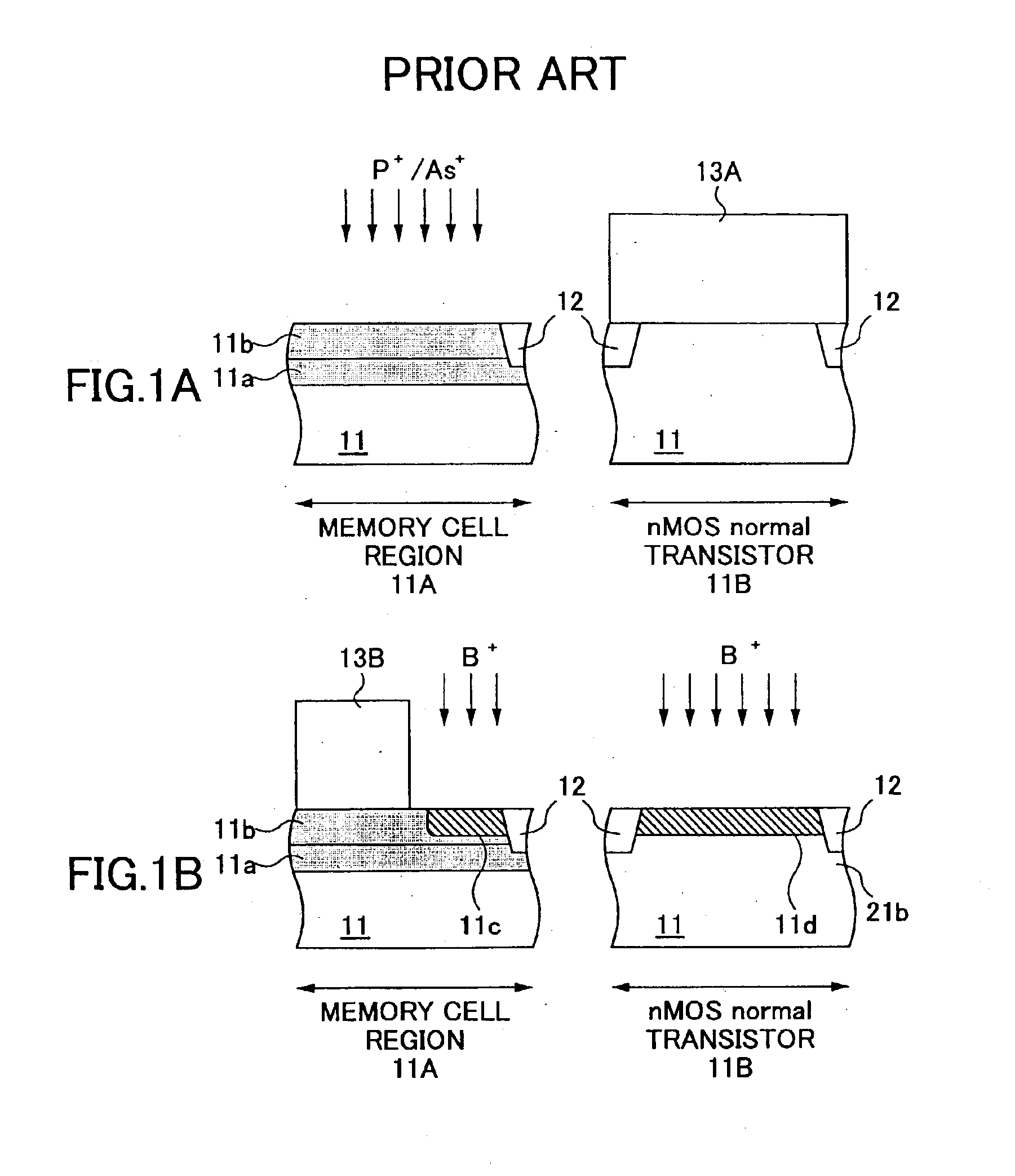

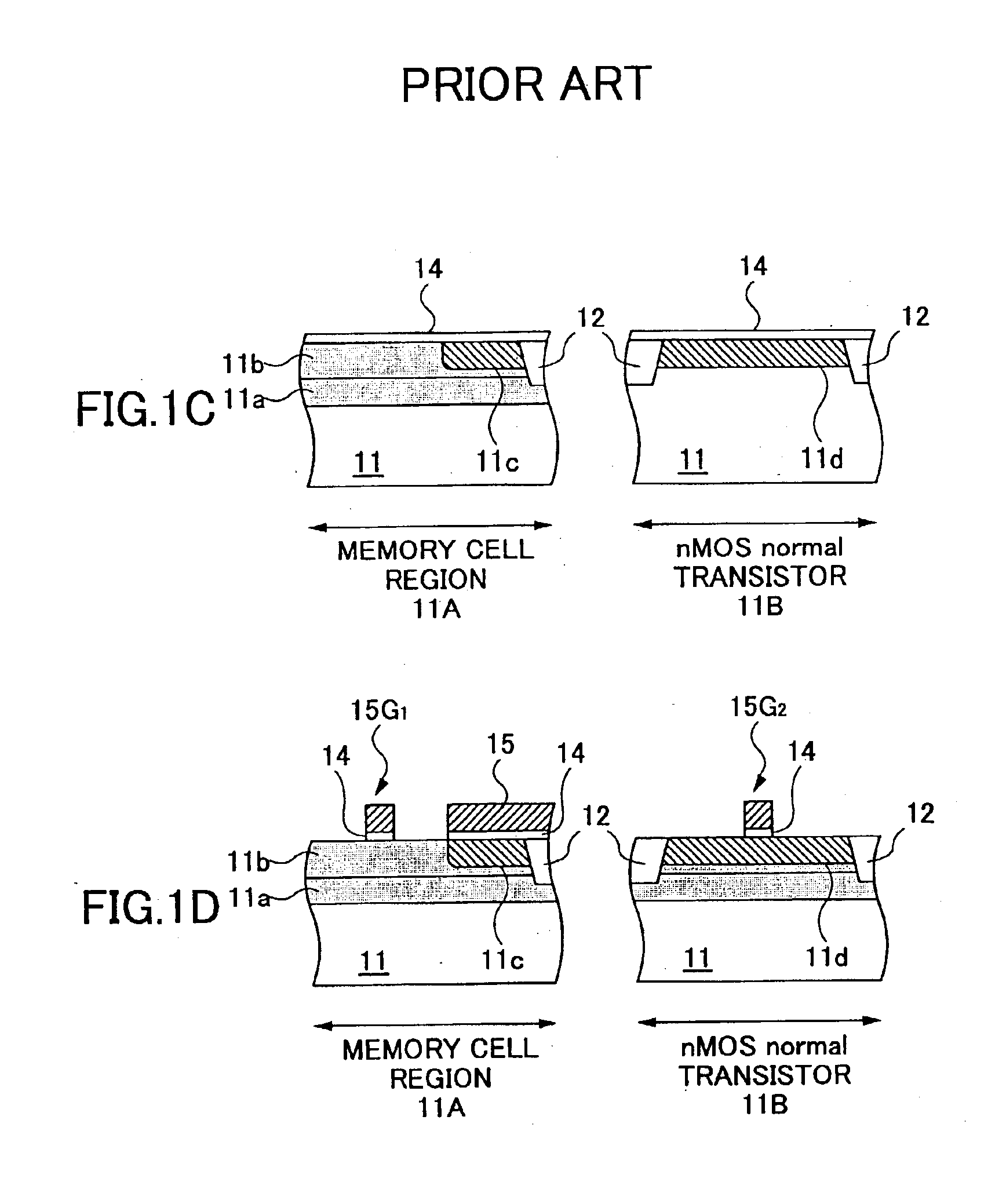

Semiconductor integrated circuit apparatus and fabrication method thereof

InactiveUS6847075B2Obviates problemAdd process stepsTransistorSolid-state devicesIntegrated circuitN channel

A semiconductor integrated circuit apparatus having a planar capacitor can use a plurality of source voltages therein. According to the semiconductor integrated circuit apparatus, it is possible to not only control thresholds of individual MOS transistors but also reduce the threshold voltage of the planar capacitor without any additional fabrication process. The semiconductor integrated circuit apparatus includes a p-channel memory transistor and a capacitor in a first n-type element region, an n-channel low-voltage MOS transistor in a second p-type element region, and an n-channel high-voltage MOS transistor in a third p-type element region. A channel region of the second MOS transistor is doped under a high density profile by using a p-type impurity element. At the same time, the p-type impurity element is imported in a capacitor region of the first element region under the substantially same profile.

Owner:FUJITSU LTD

Passivation contact solar cell and preparation method thereof

InactiveCN111276568AIncrease the open circuit voltageIncrease short circuit currentFinal product manufacturePhotovoltaic energy generationEngineeringSolar battery

The invention relates to a passivation contact solar cell and a preparation method thereof. The solar cell comprises an N-type crystalline silicon substrate, wherein the front surface of the N-type crystalline silicon substrate sequentially comprises an emitter layer, an aluminum oxide passivation layer, a silicon nitride antireflection layer and a metal slurry layer from bottom to top; wherein the back surface of the N-type crystalline silicon substrate sequentially comprises a tunneling oxide layer, a phosphorus-doped polycrystalline silicon layer, a silicon nitride antireflection layer anda metal slurry layer from bottom to top. According to the solar cell, the open-circuit voltage and the short-circuit current of the cell can be remarkably improved, so that the efficiency of an n-typepassivation contact cell can be improved; moreover, the light utilization rate can also be improved, the back surface recombination rate is reduced, the cell efficiency is improved by 0.15% or above,meanwhile, additional process steps do not need to be added, and the method is simple and suitable for mass production.

Owner:TAIZHOU ZHONGLAI PHOTOELECTRIC TECH CO LTD

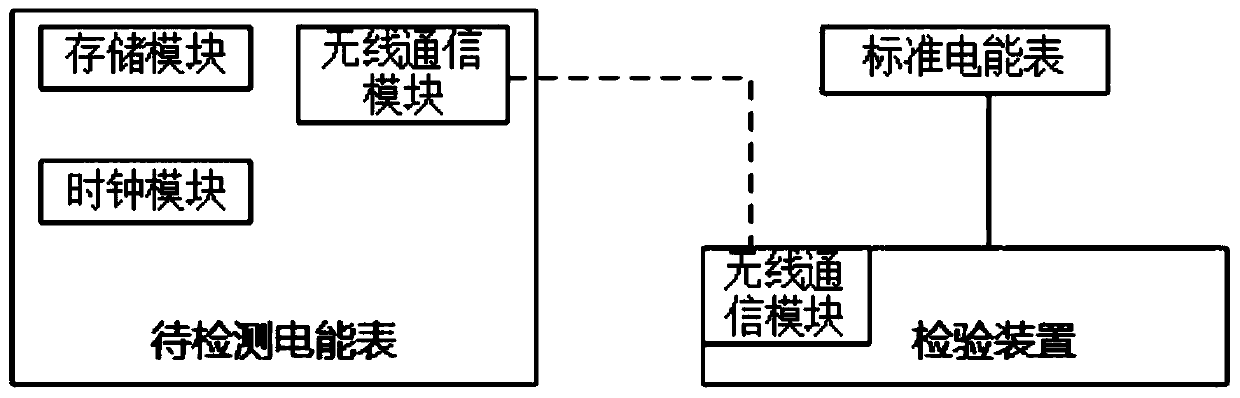

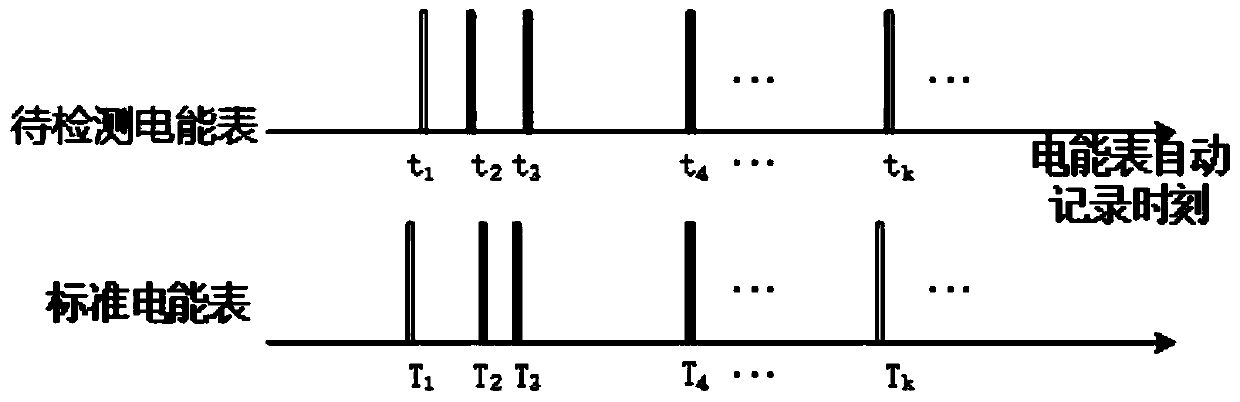

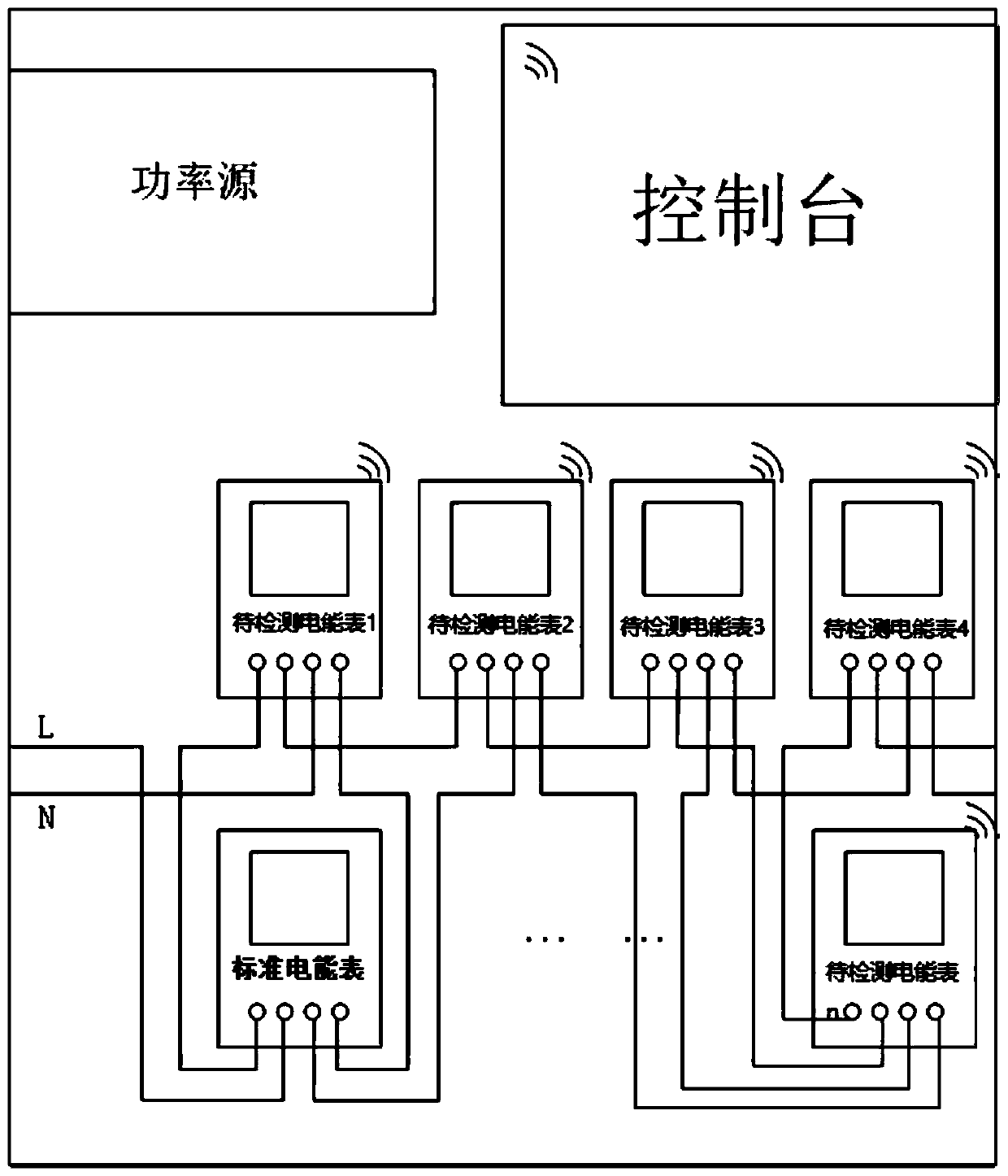

Error detection system for electric energy of electric energy meter and detection method thereof

ActiveCN110907886AAdd process stepsThe detection method is complicatedElectrical measurementsMechanical engineeringPhysics

The invention discloses an error detection system for the electric energy of an electric energy meter and a detection method thereof. The system comprises a to-be-detected electric energy meter, a standard electric energy meter and a detection device, a first clock module of the to-be-detected electric energy meter is used for outputting a first current moment of the to-be-detected electric energymeter when the to-be-detected electric energy meter meters the electric energy of a preset threshold value each time, a second clock module of the standard electric energy meter is used for outputting a second current moment of the standard electric energy meter when the standard electric energy meter meters the electric energy of the preset threshold every time, and the inspection device is usedfor carrying out error detection on the to-be-detected electric energy meter according to the first current moment and the second current moment, so that the technical problem that a detection methodis more complex when the electric energy error detection is carried out on the existing electric energy meter, is solved.

Owner:GUANGDONG ELECTRIC POWER SCI RES INST ENERGY TECH CO LTD

Method for recycling walnut polyphenol and flavone in walnut kernel peeling wastewater through macroporous resin

ActiveCN104857072AThe operation process is simple and convenientReduce process stepsNervous disorderAntinoxious agentsChemistryVacuum evaporation

The invention discloses a method for recycling walnut polyphenol and flavone in walnut kernel peeling wastewater through macroporous resin. The method comprises the operating steps of pretreatment of the walnut kernel peeling wastewater, separation, purification and regeneration of the macroporous adsorption resin, concentration and drying. The concentration of the walnut flavone in the pretreated walnut kernel peeling wastewater is reduced to 0.34mg / mL-0.67mg / mL through dilution, the pH value is adjusted to be 7-9 through concentrated hydrochloric acid, a solution is poured into an adsorption tank filled with the macroporous resin to be adsorbed, the adsorption time is more than 4 hours, after adsorption is finished, desorption is conducted through 60%-80% ethyl alcohol to obtain an ethyl alcohol walnut flavone solution, the solution is processed through vacuum evaporation, concentration and drying, the ethyl alcohol is recycled, and finally fine walnut flavone extract is obtained. The recycling rate of the walnut flavone is more than 70%, and the purity of the walnut flavone is more than 50%. The technological process is simple, the cost is low, the benefit is high, the macroporous resin can be regenerated and recycled, and the method is suitable for industrial recycling of walnut flavone compounds in the walnut kernel peeling wastewater.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com