Novel machining die for automobile support

A technology for automobile brackets and processing molds, which is applied in the directions of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of the two sides of the automobile brackets facing outwards, waste of manpower and material resources, and inconvenient to pick and place parts. Compact, cost-effective, productive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

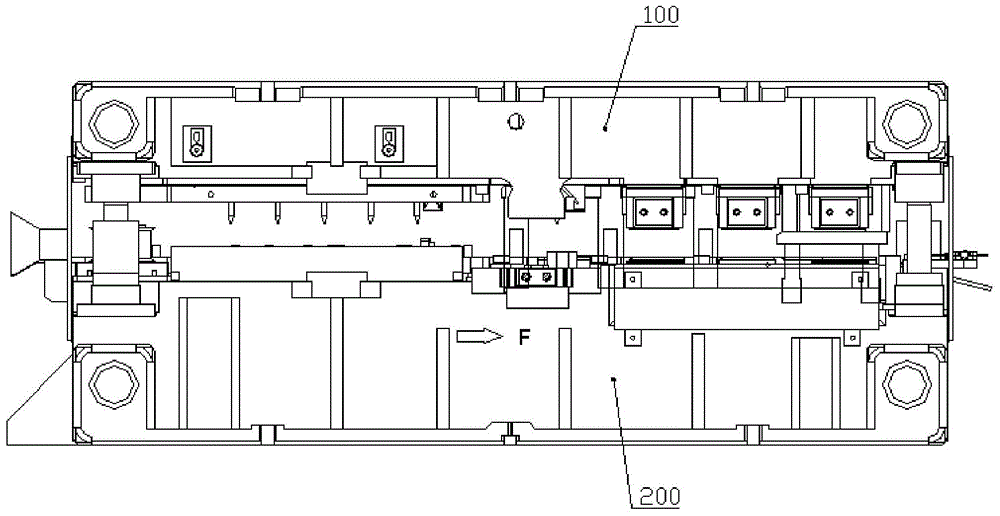

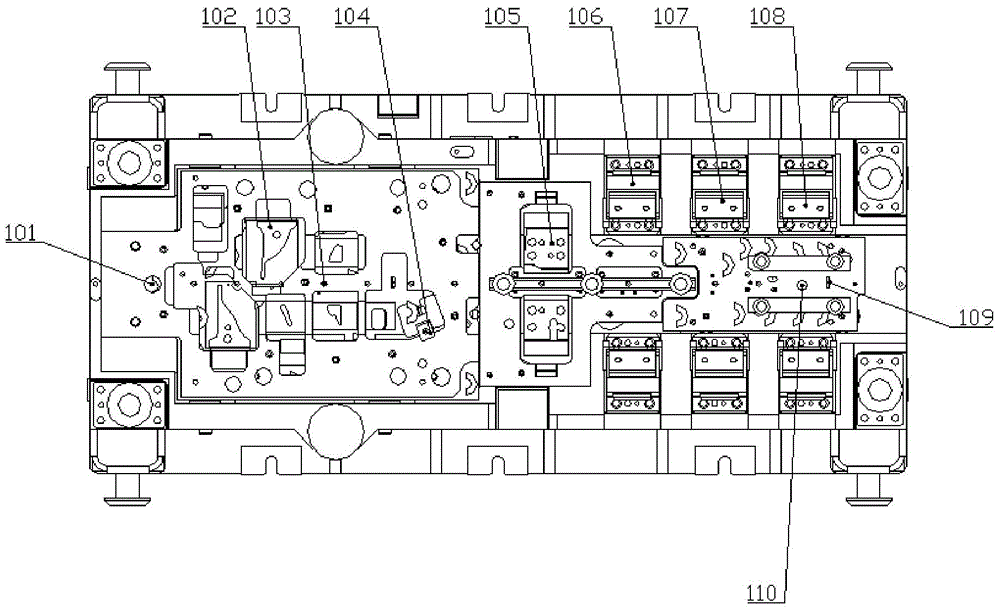

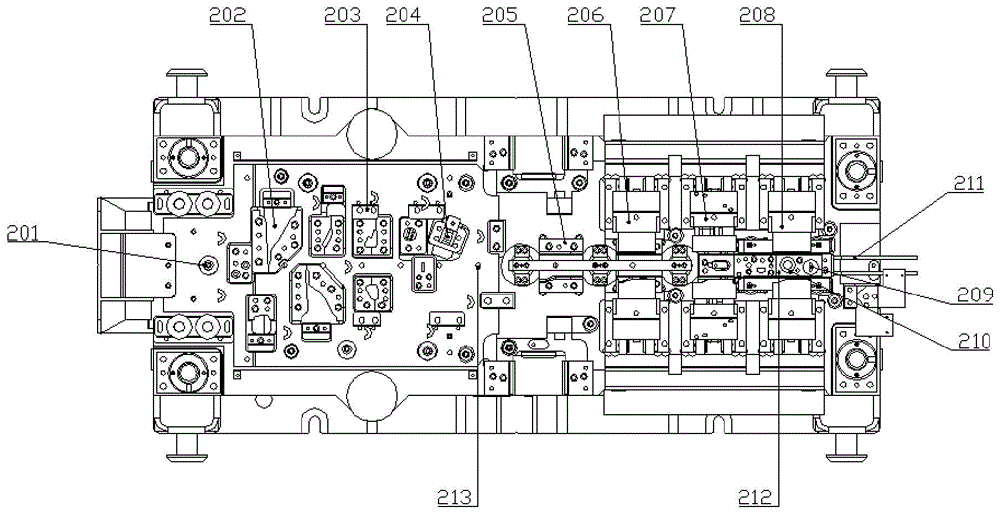

[0027] Such as Figure 1-Figure 7 As shown, the present invention provides a new type of processing mold for automobile brackets, which includes an upper template 100 and a lower template 200 that cooperate with each other. mechanism, bending mechanism, pressing mechanism, side punching mechanism, top punching mechanism and cutting finished product mechanism.

[0028] In this embodiment, positioning is performed by punching positioning holes 213 on the material plate, which can play a guiding and positioning role for its transmission, and can also effectively ensure that each process adopts the same positioning, so as to ensure the production quality of the workpiece. The positioning hole punching mechanism includes a positioning punch 101 arranged on the upper template 100 , and a positioning punch 201 arranged on the lower template 200 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com