Silicon piezoresistive type pressure sensor chip

A pressure sensor, silicon piezoresistive technology, applied in the field of silicon piezoresistive pressure sensor chips, can solve problems such as sensor output instability, achieve the effects of improving output stability, reducing leakage current, and reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

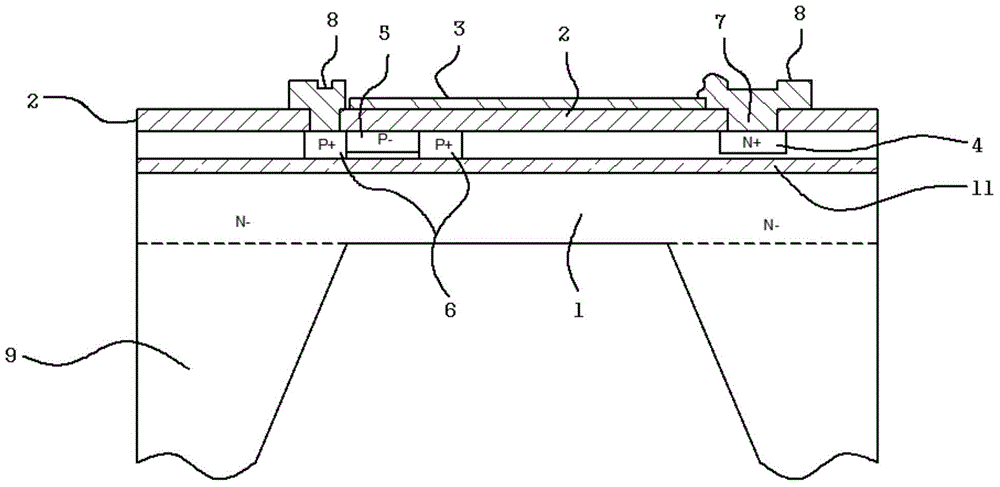

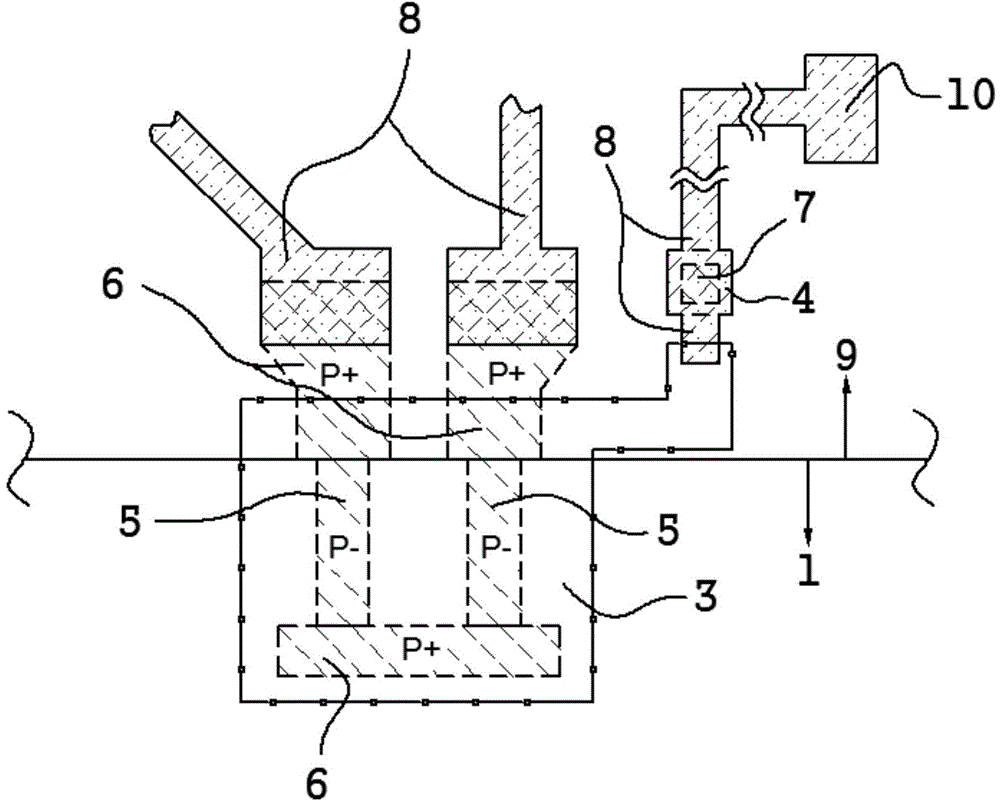

[0014] see figure 1 , figure 2 , this embodiment includes: silicon piezoresistive pressure sensor basic body (including piezoresistor 5, internal interconnection 6, pressure sensing diaphragm 1, pad 10, silicon substrate, etc. 9, silicon dioxide buried layer 11), isolation Layer 2, Stabilization Layer 3 (in figure 2 The area enclosed by lines with beads), the metal layer 8, the contact hole 7 and the heavily doped region 4 of the silicon substrate are represented in the middle. This embodiment proposes a structure for improving the output stability of a silicon piezoresistive pressure sensor chip using a pressure sensor chip made of an SOI (silicon on insulating layer) silicon wafer, and the surface of the SOI (silicon on insulating layer) silicon wafer The substrate is connected to the highest potential point of the chip (that is, the power supply pad ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com