Glass passivation method for silicon mesa diodes

A mesa diode, glass passivation technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of increasing production costs and high equipment requirements, achieving low dependence, good graphics quality, and reduced process difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

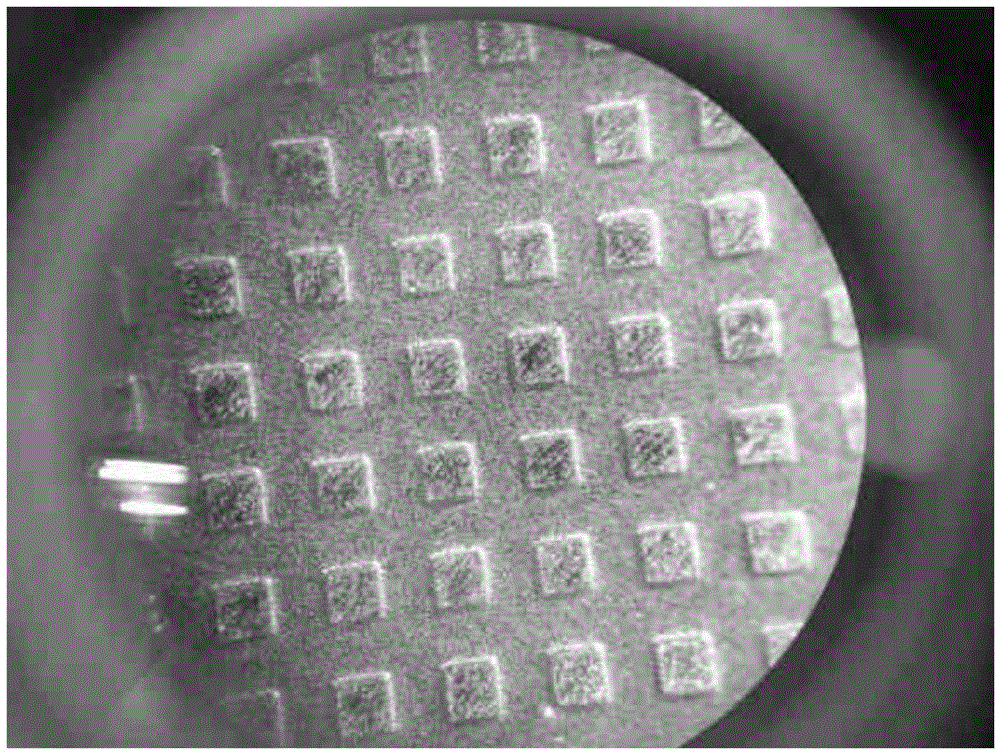

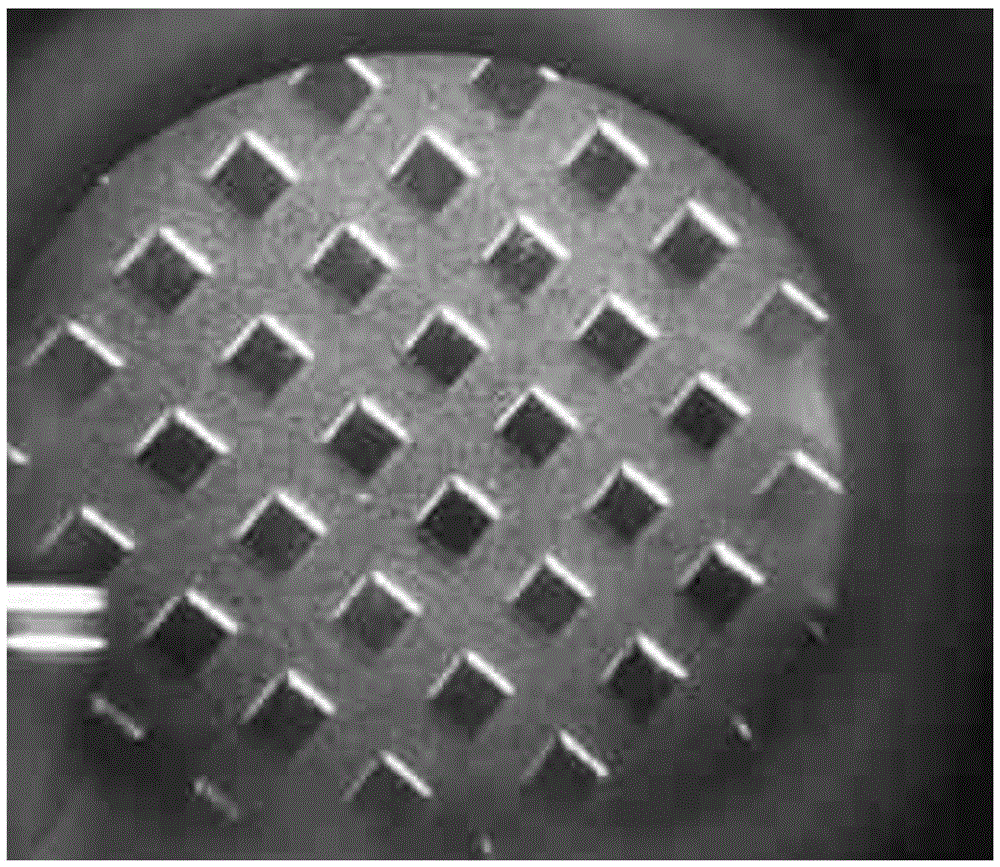

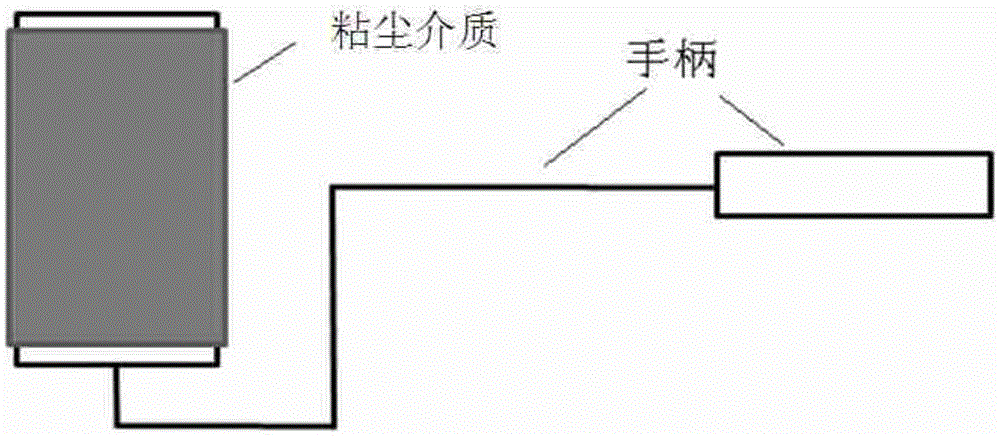

[0041]In this embodiment, the glass passivation of silicon mesa diodes is carried out by referring to the above method. Wherein, the glass paste is prepared according to the following method: ethyl cellulose is added to the butyl carbitol solution in a ratio of 1g: 25ml, and after it is fully dissolved, it becomes a solvent for preparing the glass paste, and the paste solvent is mixed with the glass The powder was placed in an agate ball mill jar at a ratio of 1ml: 2g for ball milling, the ball milling speed was 220 rpm, and the ball milling time was 8 hours to obtain a glass slurry, which was then evenly coated with a stainless steel scraper with a flat knife edge. On the silicon wafer with PN junction and chip mesa groove, fill the mesa groove with glass paste, dry the above-mentioned wafer coated with glass paste with an infrared lamp, and place the wafer on a flat quartz plate , use a silica gel sticky roller to roll over the wafer evenly, and remove the glass powder on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com