Motor cooling system and motor with same

A technology for motor cooling and cooling system, which is applied in cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of complex motor heat dissipation structure, complicated installation and maintenance, etc., to simplify the structure, reduce production costs, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention realizes the cooling of the whole stator core by setting a cooling circuit in the stator core, so that the cooling liquid flows in the cooling circuit to take away the heat generated when the motor is running.

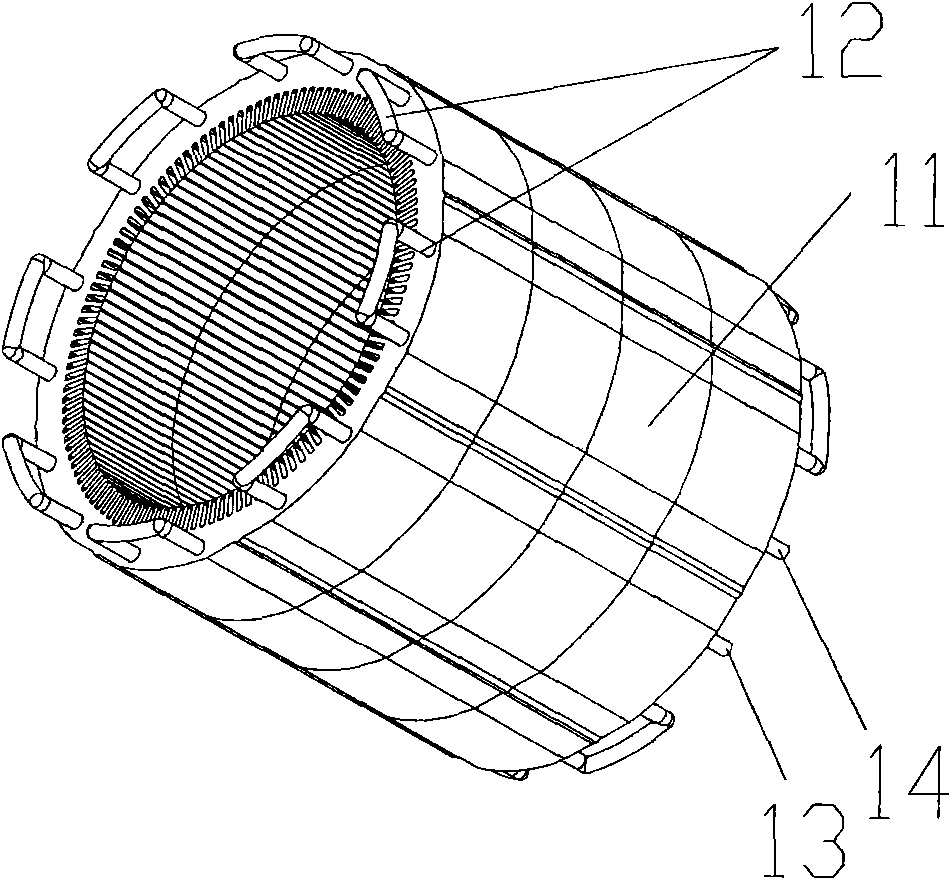

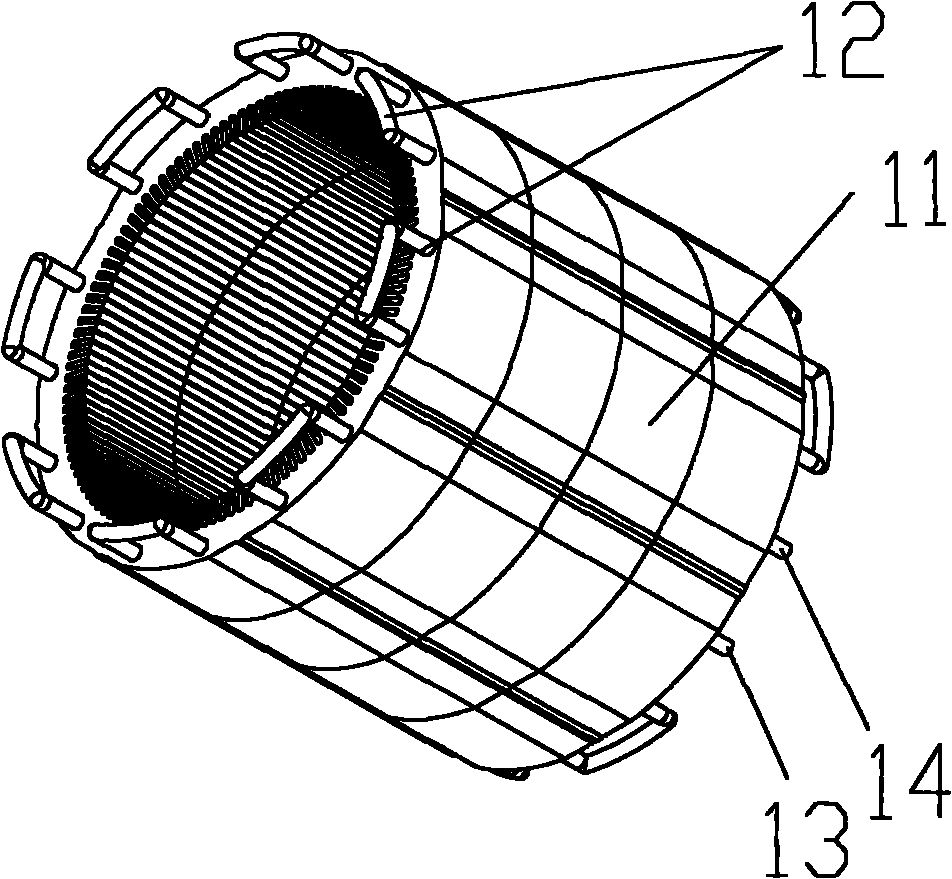

[0021] Such as figure 1 Shown is a schematic structural diagram of an embodiment of the motor cooling system of the present invention. The system includes a stator core 11 and a cooling circuit 12, wherein the cooling circuit 12 is installed in the stator core 11 and has:

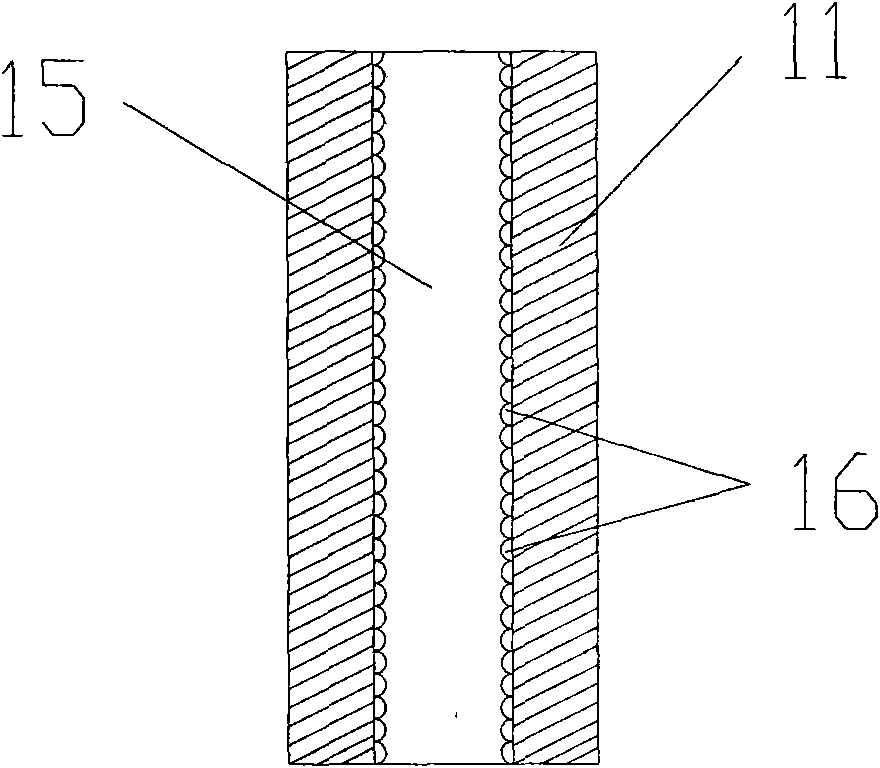

[0022] Specifically, in one embodiment, the stator core 11 is provided with multiple (for example figure 1 16) spaced through holes (for example, along the direction of the rotor shaft. The plurality of through holes are located at different positions on the circumference of the stator core and are evenly distributed).

[0023] The cooling circuit 12 is arranged through a plurality of through holes on the stator core 11 . The cooling circuit 12 includes a cooling liquid inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com