MEMS wafer level vacuum packaging structure and method

A vacuum packaging and wafer-level technology, applied in the direction of microstructure technology, microstructure devices, processing microstructure devices, etc., can solve problems such as unstable bonding process and metal lead interconnection, so as to reduce process difficulty and improve reliability performance and yield, and the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

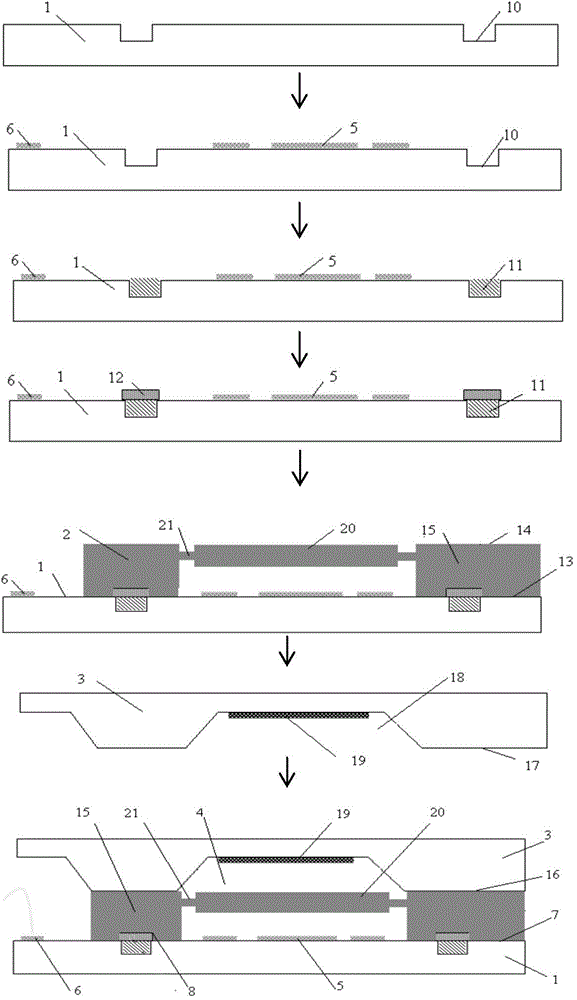

[0038] The present invention will be further described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

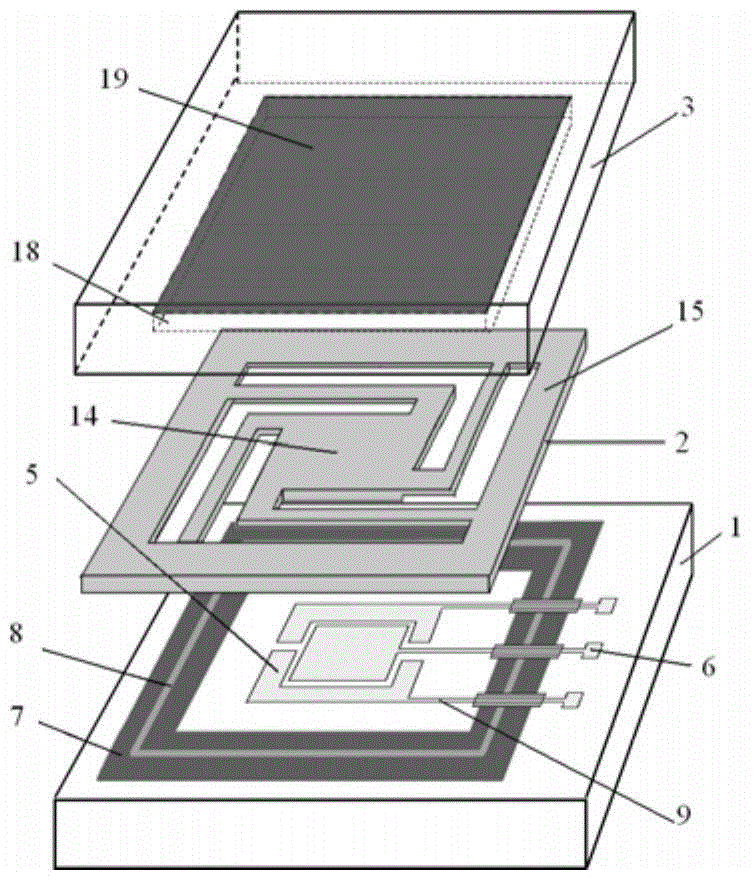

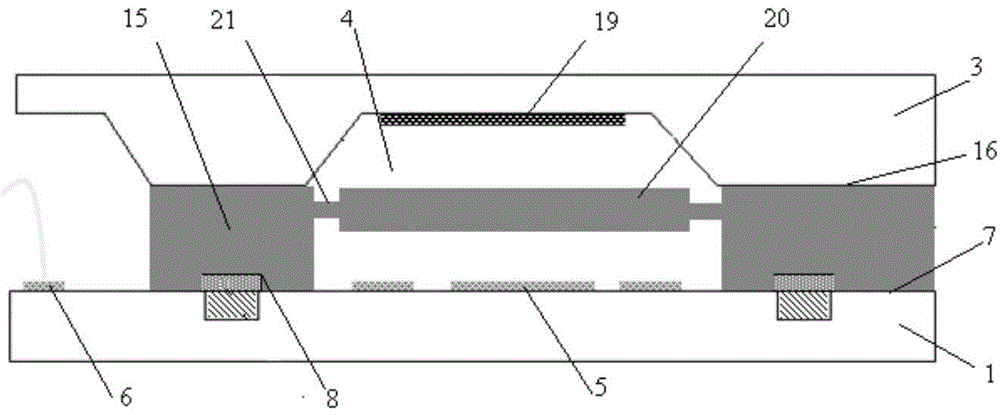

[0039] 1-insulating substrate; 2-MEMS chip structure layer; 3-cover plate; 4-vacuum chamber; 5-metal electrode; 6-pad; 7-first bonding ring; 8-second bonding ring; 9-metal lead; 10-groove I; 11-electric insulation layer; 12-bonding layer; 13-third bonding ring; 14-sensitive unit; 15-support structure; 16-fourth bonding ring; 17 - fifth bonding ring; 18 - groove II; 19 - film getter, 20 - sensitive mass; 21 - cantilever beam.

[0040] like figure 1 , figure 2 Shown is a three-dimensional view of the MEMS wafer-level vacuum packaging structure and a cross-sectional view of the MEMS wafer-level vacuum packaging structure of the present invention. The MEMS wafer-level vacuum packaging structure includes an insulating substrate 1, a MEM...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com