Fingerprint sensor and driving method thereof

A fingerprint sensor and sensing electrode technology, applied in the direction of acquiring/arranging fingerprints/palmprints, instruments, characters and pattern recognition, etc., can solve the problems of difficult manufacturing process, difficult mass production, high power consumption, etc. The effect of high difficulty, reduced power consumption, and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only some structures related to the present invention are shown in the drawings but not all structures.

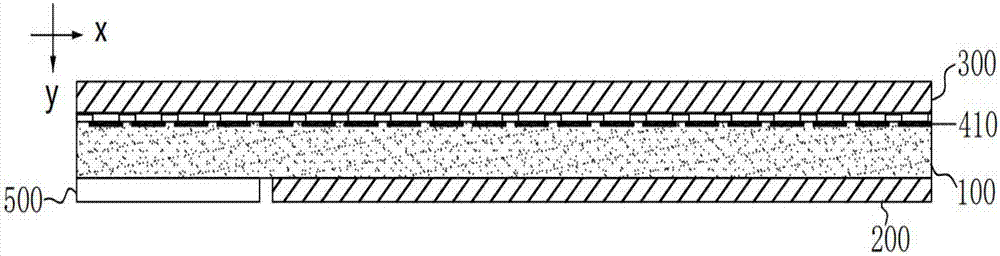

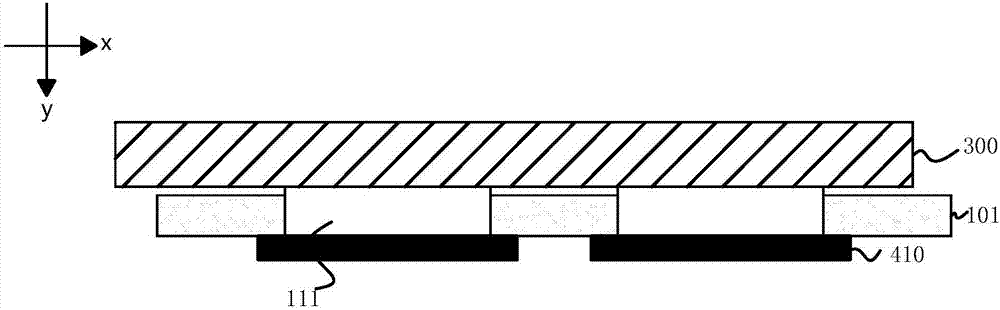

[0032] Figure 1a Shown is a schematic structural diagram of a fingerprint sensor provided by an embodiment of the present invention, see Figure 1a , the fingerprint sensor specifically includes:

[0033] chip 100;

[0034] The drive element 200 is used to emit an ultrasonic signal when turned on;

[0035] The piezoelectric element 300 is arranged on one side of the chip 100, and is used to convert the ultrasonic signal reflected by the target finger into an electric charge;

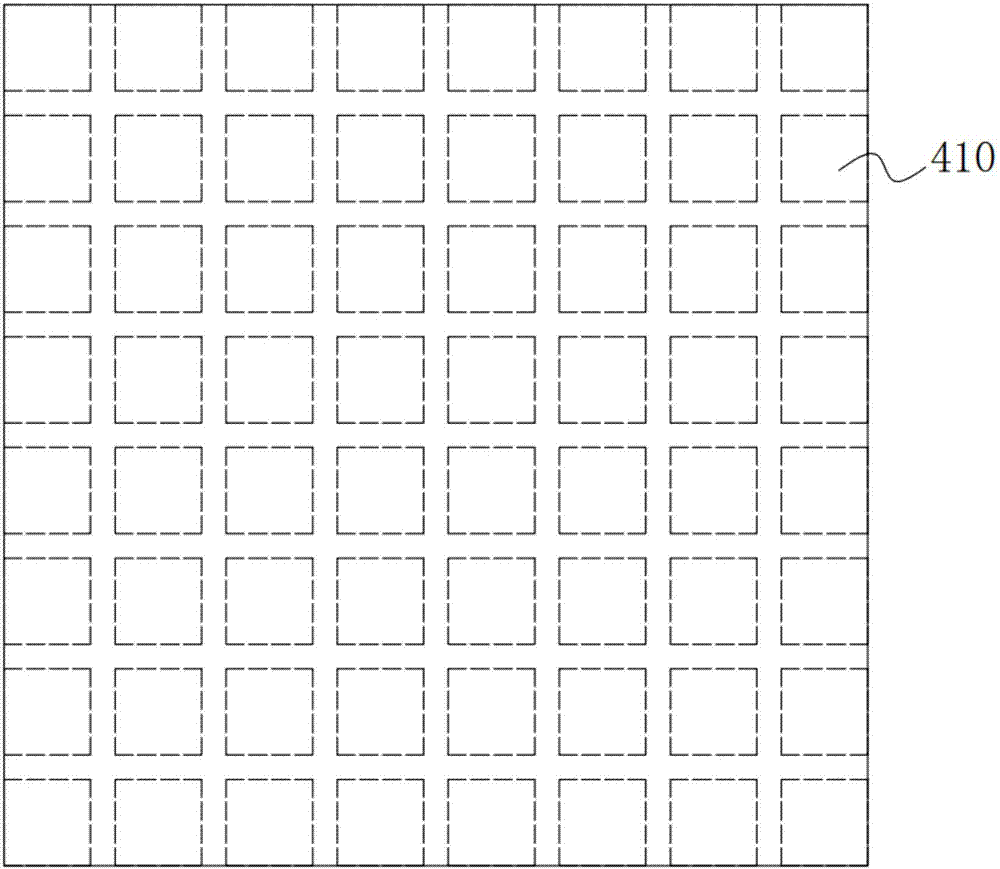

[0036] A plurality of pixel units ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com