Structure of low thermal resistance LED and method for producing the same

A technology of light-emitting diodes and light-emitting chips, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve problems such as reducing thermal resistance, and achieve the effects of reducing thermal resistance, improving service life, and increasing diffusion channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

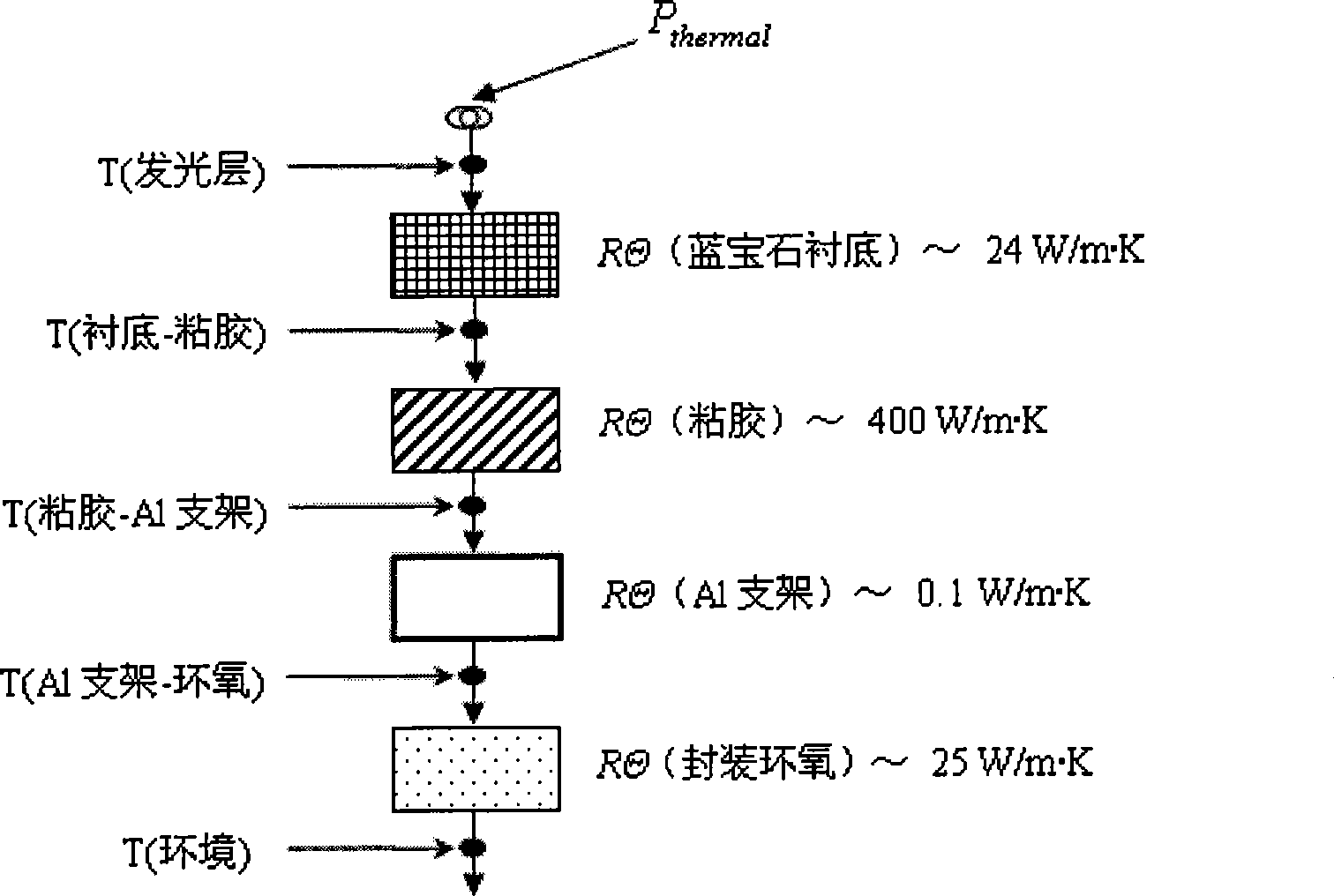

[0034] The structure and manufacturing method of a low thermal resistance light emitting diode chip of the present invention will be further described below with reference to the accompanying drawings and embodiments.

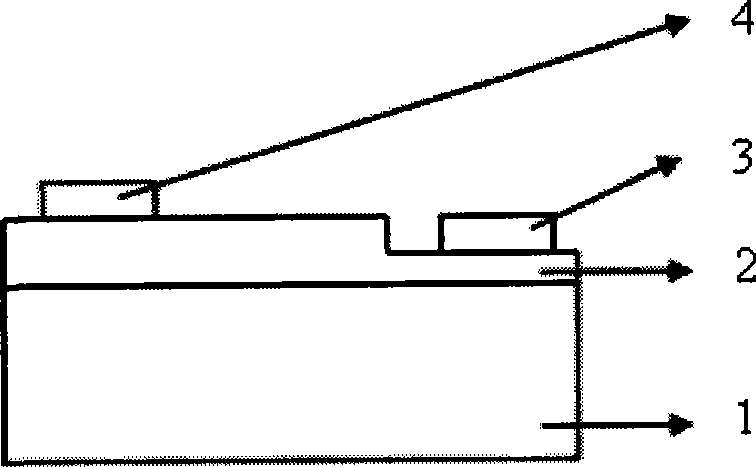

[0035] figure 1 Marks in: 1-Sapphire substrate, 2-Epitaxial layer, 3-N electrode, 4-P electrode;

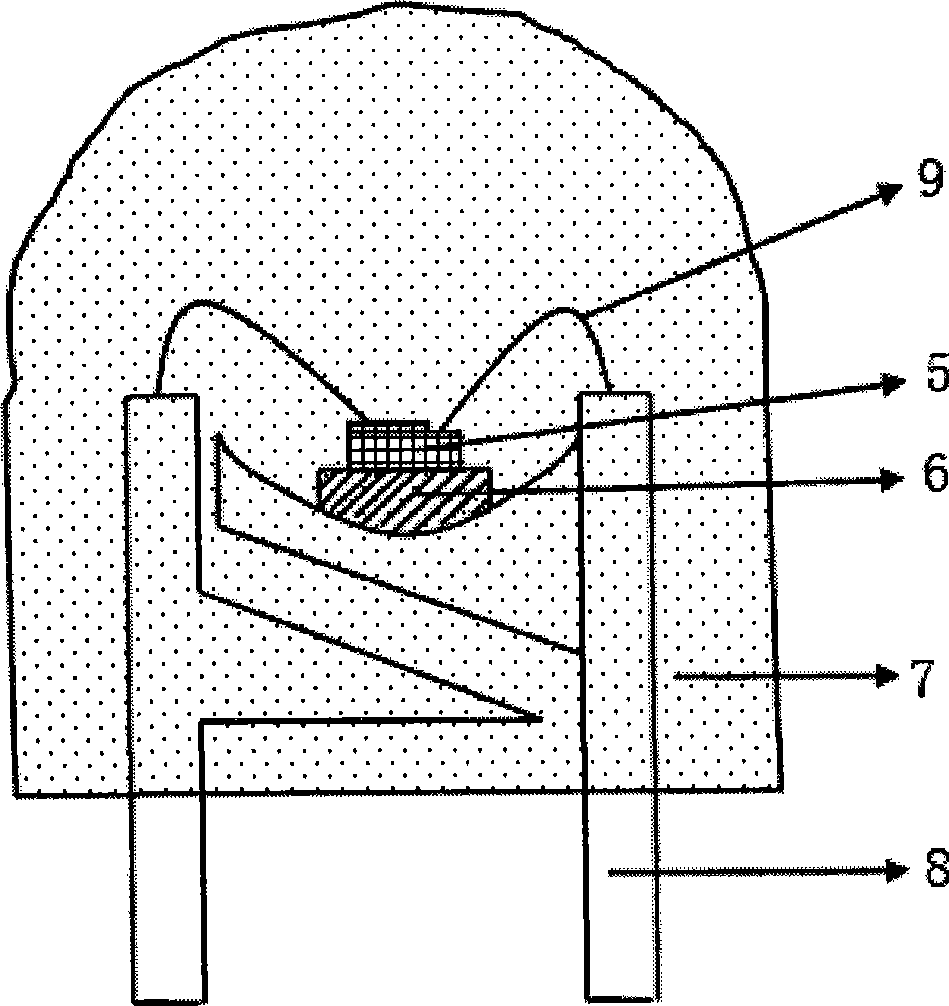

[0036] Figure 2A Marks in: 5-LED light-emitting chip, 6-adhesive, 7-epoxy, 8-bonding bracket, 9-gold wire;

[0037] image 3 The mark in: 10-low thermal resistance base, 11-metal reflective layer;

[0038] Figure 4 Mark in: 12-solder, 13-low thermal resistance heat sink substrate;

[0039] Figure 5A Mark in: 14-paraffin, 15-accompanying film;

[0040] The drawings used above are schematic diagrams, which are not drawn according to normal scale, but will not affect the understanding of the features and beneficial effects of the present invention by those skilled in the art.

[0041] Figure 4 The structure of the low thermal resistance LED light-emitting chip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com