Process for manufacturing efficient polycrystalline cell

A high-efficiency, battery technology, applied in sustainable manufacturing/processing, final product manufacturing, semiconductor/solid-state device manufacturing, etc., can solve problems such as difficulties, achieve good film density, good passivation effect, and easy to promote.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

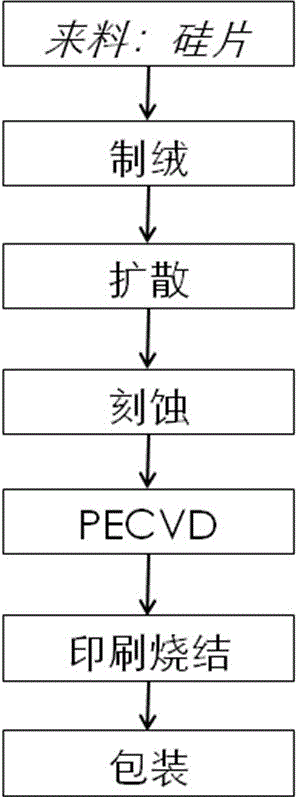

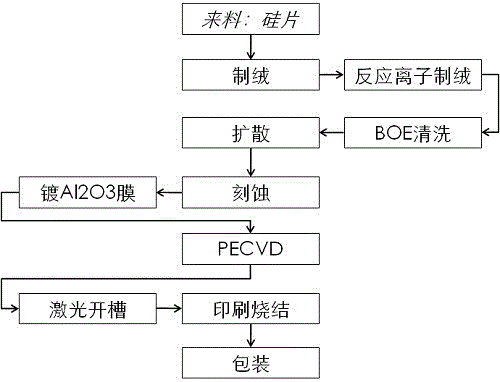

[0029] Such as Figure 2~3 As shown, in a preferred embodiment, the process for manufacturing high-efficiency polycrystalline cells of the present invention includes the following specific steps:

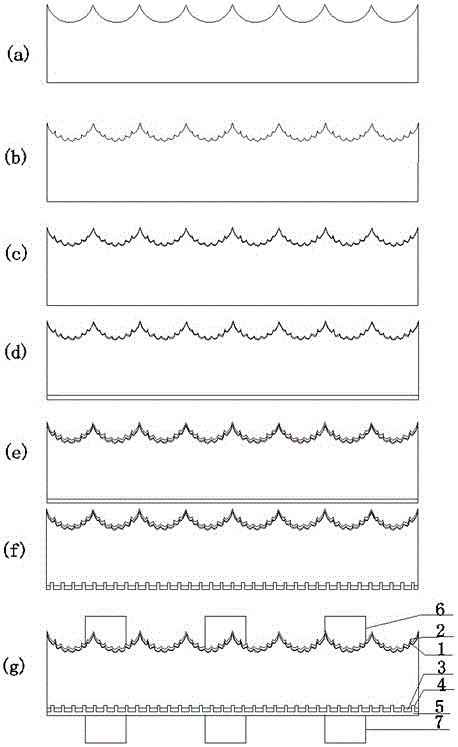

[0030] (1) Texturing: P-type polycrystalline silicon wafers are used to make texture according to the traditional polycrystalline wet method: that is, use Rena texturing machine, use a mixed solution of nitric acid and hydrofluoric acid with a mass ratio of 70:520, and make texture at a temperature of 6°C. Form the suede surface with light-trapping structure on the surface, and the silicon chip is corroded deeply about 2 microns in this step; image 3 as shown in (a);

[0031] (2) Reactive ion etching texturing : use the Tysol-RIE texturing machine produced by Changzhou Bitai Technology to carry out this step; use O 2 and SF 6 The reactive ions generated in the vacuum chamber of the texturing machine carry out bombardment etching on the surface of the silicon wafer, forming s...

Embodiment 2

[0042] In another preferred embodiment, the process for manufacturing high-efficiency polycrystalline cells of the present invention includes the following specific steps:

[0043] (1) Texturing: P-type polycrystalline silicon wafers are used to make texture according to the traditional polycrystalline wet method: that is, use a Schmid texture machine, use a mixed solution of nitric acid and hydrofluoric acid with a mass ratio of 70:520, and make texture at a temperature of 10°C. Form the suede surface with light-trapping structure on the surface, and the silicon wafer is corroded deeply about 5 microns in this step; image 3 as shown in (a);

[0044] (2) Reactive ion etching texturing : use the Tysol-RIE texturing machine produced by Changzhou Bitai Technology to carry out this step; use O 2 and SF 6 The reactive ions generated in the vacuum chamber of the texturing machine carry out bombardment etching on the surface of the silicon wafer, forming such as image 3 (b) ...

Embodiment 3

[0053] The process for manufacturing high-efficiency polycrystalline cells of the present invention comprises the following specific steps:

[0054] (1) Texturing: P-type polycrystalline silicon wafers are used to make texture according to the traditional polycrystalline wet method: that is, use Rena texturing machine, use a mixed solution of nitric acid and hydrofluoric acid with a mass ratio of 70:520, and make texture at a temperature of 8°C. Form the suede surface with light-trapping structure on the surface, and the silicon chip is corroded to a depth of about 4 microns in this step; image 3 as shown in (a);

[0055] (2) Reactive ion etching texturing : Use the Tysol-RIE texturing machine produced by Changzhou Bitai Technology to carry out this step; use SF 6 and Cl 2 The reactive ions generated in the vacuum chamber of the texturing machine carry out bombardment etching on the surface of the silicon wafer, forming such as image 3 (b) The shown nanoscale microstr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com