Semiconductor starting device based on spiral polycrystalline silicon field effect transistor charging and manufacturing process of semiconductor starting device

A field effect transistor and spiral technology, which is applied in the field of integrated circuit start-up devices, can solve the problems affecting power conversion efficiency, heat dissipation and reliability, the resistance value of resistor R1 cannot be too large, and the size of switching power supply is large, so as to improve power supply efficiency. , Low power consumption, small chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

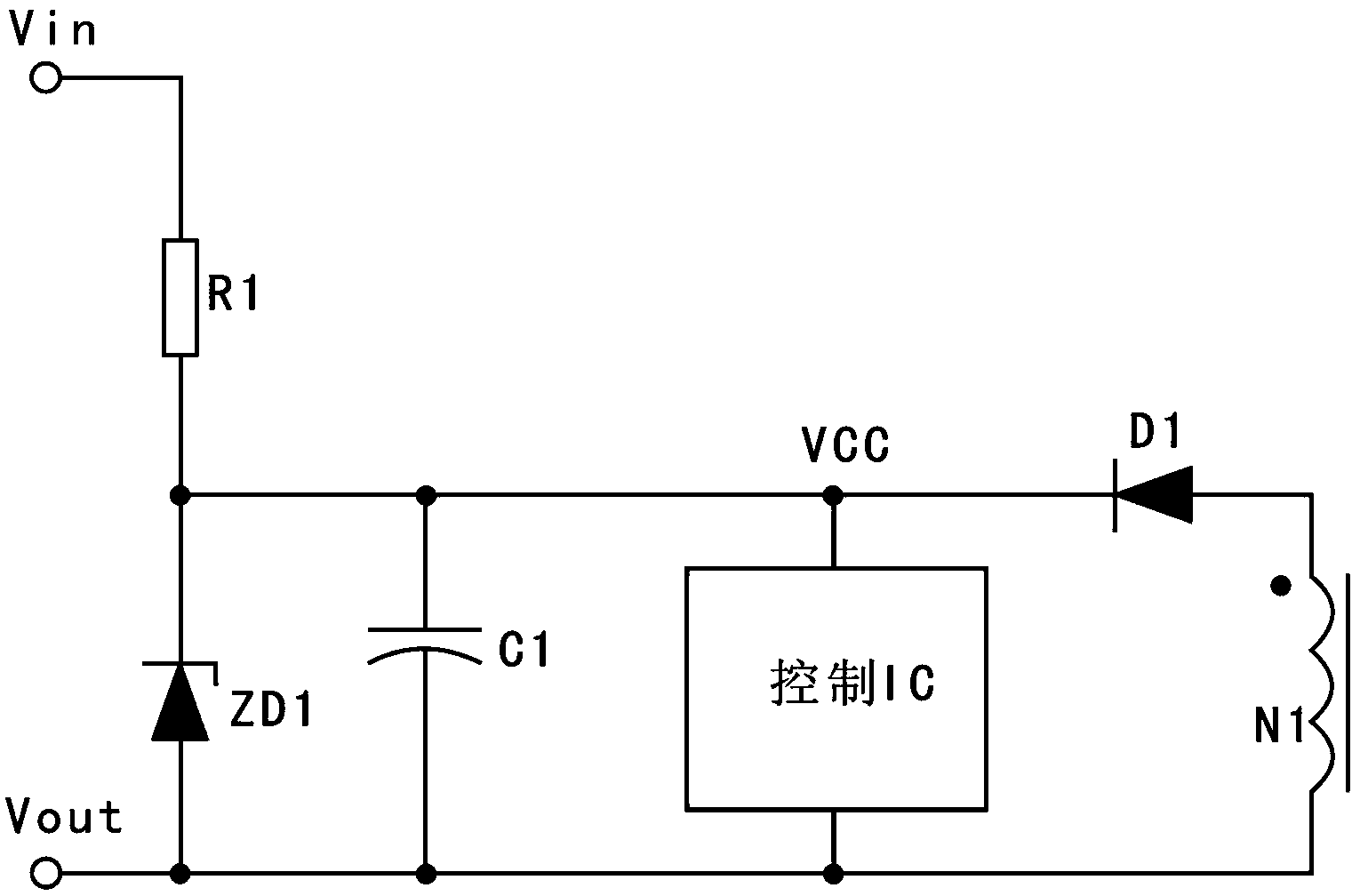

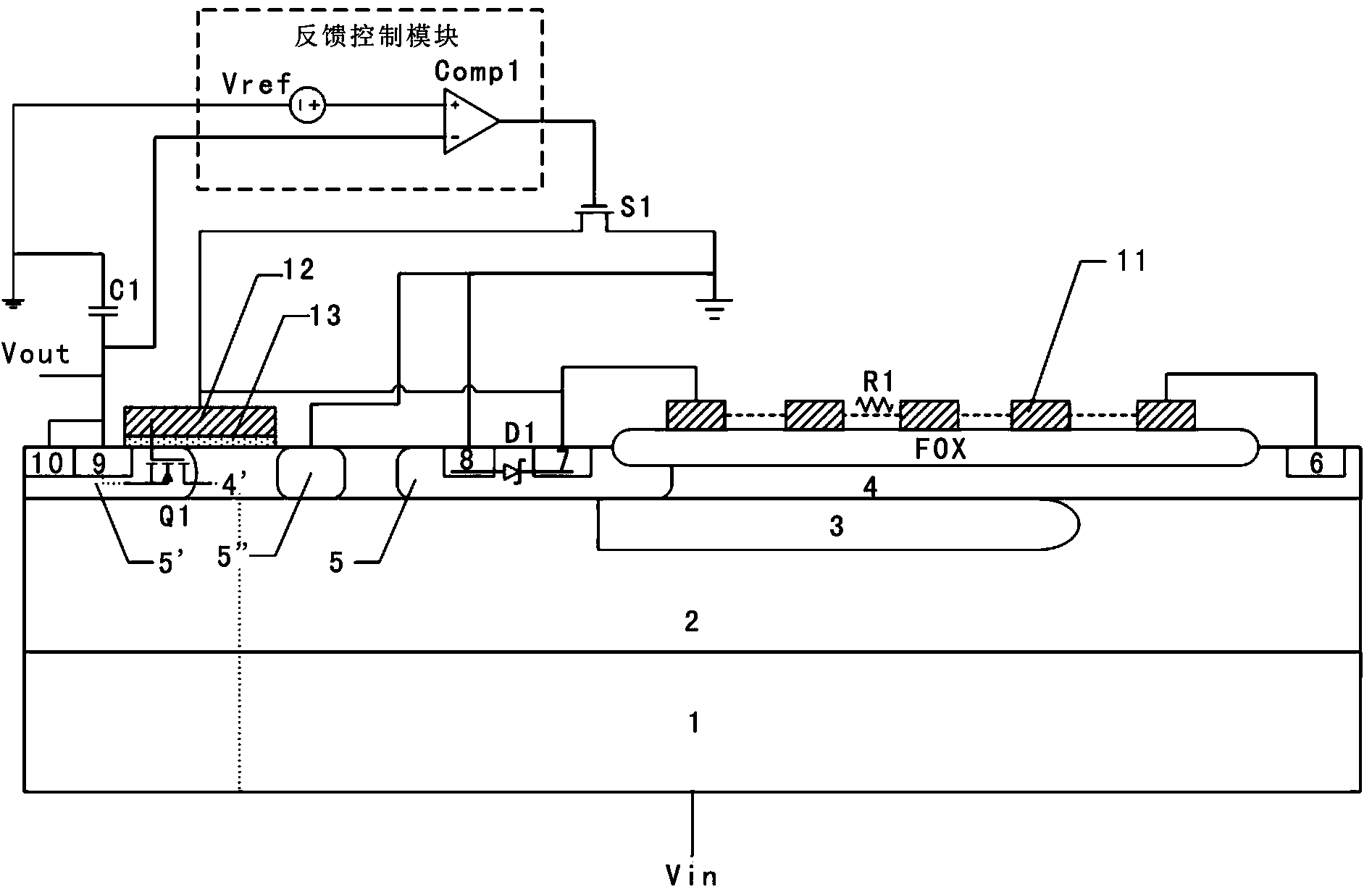

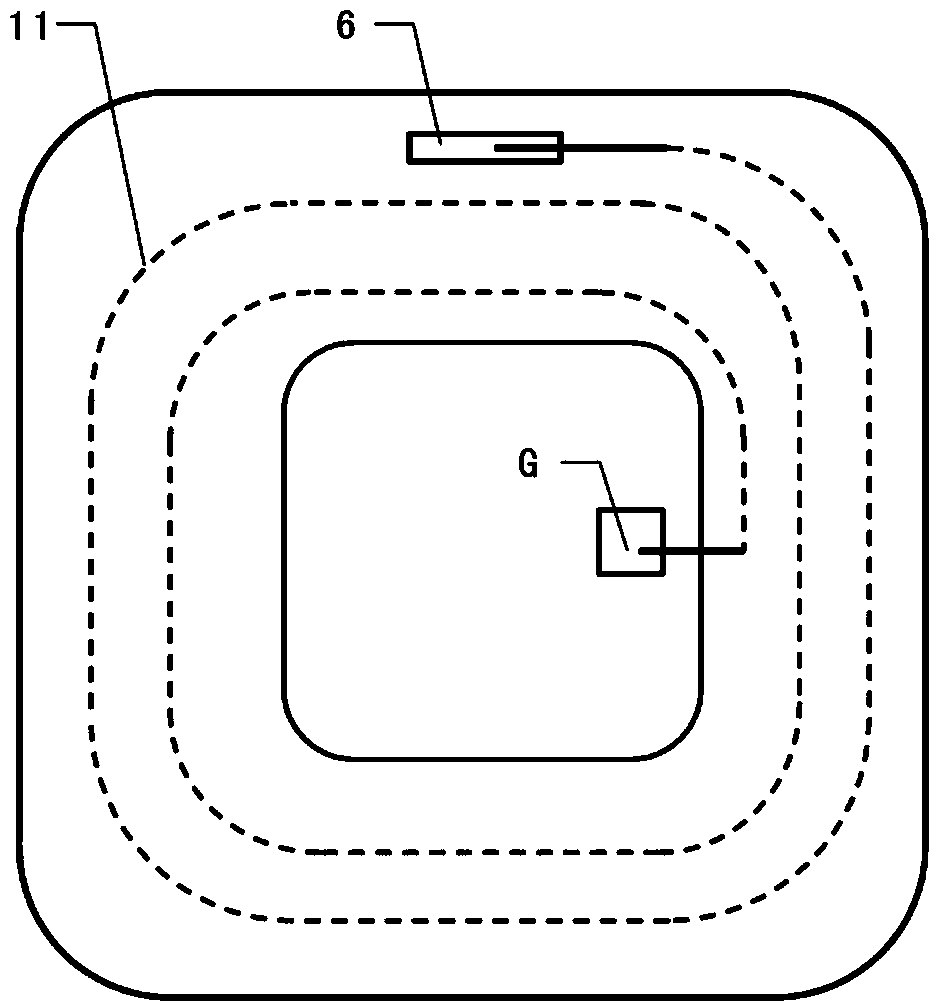

[0025] Such as figure 2 with image 3 as shown, figure 2 The power input terminal, power output terminal, resistor R1 and capacitor C1 are respectively connected with figure 1 Correspondingly, so adopted the same symbol; The semiconductor start-up device charged based on the spiral polysilicon type field effect tube of the present invention, the input voltage Vin of its power supply input is charged by capacitor C1, and the two ends of capacitor C1 are power output terminals, Its output voltage Vout supplies power to the main circuit (not shown in the figure), an N-type lightly doped epitaxial layer 2 is provided on the N-type high-concentration substrate 1, and a P type buried layer 3, a first N well 4 is arranged on the P type buried layer 3, a first N type heavily doped 6 and a thick oxide layer FOX are arranged on the first N well 4, and a spiral shape is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com