eeprom core structure embedded in bcd process and its forming method

A nuclear structure and process technology, applied in the direction of instruments, semiconductor devices, electrical components, etc., can solve the problems of loss of industrial production, complex and complicated process flow, etc., and achieve the effect of reducing process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

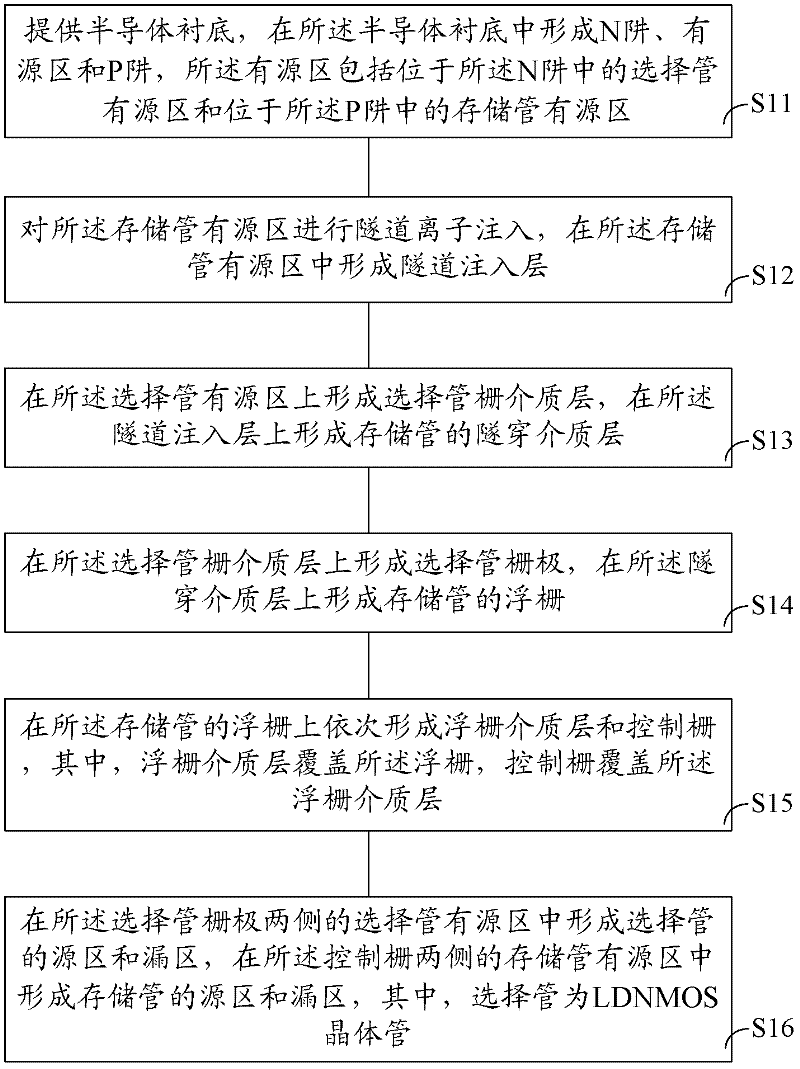

[0033] The formation process of the conventional EEPROM core structure in the prior art and the process steps of the BCD process are relatively complicated. If the EEPROM is simply embedded in the BCD process, the process steps of the two will be superimposed, which will lead to an overly complicated process, which is not conducive to large-scale of industrial production.

[0034] The selection transistor in the EEPROM core structure embedded in the BCD process of the embodiment of the present invention adopts the LDNMOS transistor, and the LDNMOS transistor can be formed by using the BCD standard process, which is beneficial to reduce its process complexity.

[0035] In addition, in the method for forming the EEPROM core structure embedded in the BCD process of the embodiment of the present invention, the process of tunnel ion implantation is added to the standard BCD process to form the tunnel implantation layer of the storage tube, which is formed by conventional steps in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com