Method for treating micro-polluted source water by using biodegradation flocculation reaction tank

A technology of biodegradation and reaction pool, which is applied in the field of water treatment to achieve the effect of simple internal structure, reducing the probability of biological clogging, reducing costs and the risk of producing disinfection by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

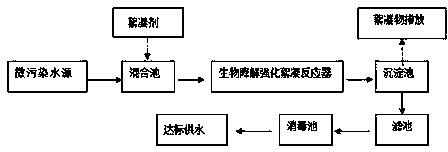

[0030] combined with figure 1 , with figure 2 , with image 3 For further explanation, the micro-polluted source water of a certain reservoir is treated by the method of the present invention, polyaluminum chloride is added in the mixing tank, and the reaction is 20s; the effluent of the mixing tank enters two horizontal semi-submerged biodegradation flocculation reaction tanks in sequence React for 15 minutes, immersion rate is 60%, adopt 2-stage speed, linear velocity 0.5m / s-0.2m / s; the effluent from the biodegradation flocculation reaction tank enters the sedimentation tank for solid-liquid separation, and the effluent enters the filter tank and disinfection tank for filtration in turn ,disinfect.

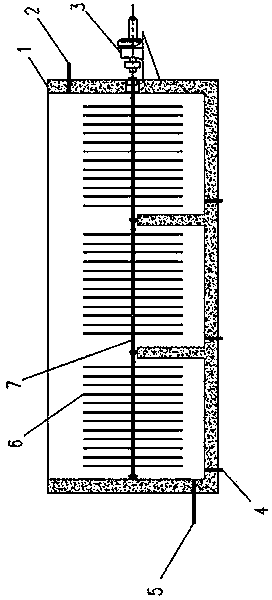

[0031] Horizontal biodegradable flocculation reaction tank: including the reaction tank body 1, the upper part of the reaction tank body is provided with a water inlet pipe 2, the lower part is provided with a water outlet pipe 5, the bottom is provided with a vent pipe 4, an...

Embodiment 2

[0035] combined with figure 1 , with image 3 For further explanation, the micro-polluted water source water of a certain reservoir is treated by the method of the present invention, and polyferric sulfate is added in the mixing tank, and the reaction is 30s; 20min, 4 speeds, linear velocity 0.5m / s-0.2m / s; the effluent from the biodegradation enhanced flocculation reaction tank enters the sedimentation tank for solid-liquid separation, and the effluent enters the filter tank and disinfection tank for filtration and disinfection.

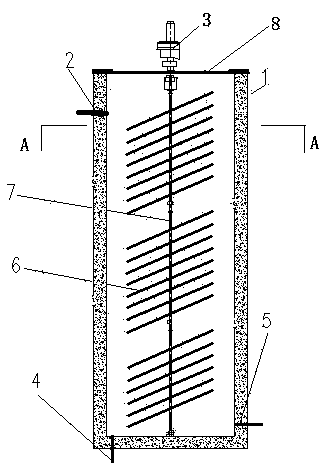

[0036] The vertical biodegradation flocculation reaction tank includes a reaction tank body 1, the upper part of the reaction tank body is provided with a water inlet pipe 2, the lower part is provided with a water outlet pipe 5, and the bottom is provided with a vent pipe 4, and the inside of the reaction tank body 1 is provided with a packing layer 6, The drive shaft 7, the drive 3, the drive 3 is installed outside the reaction tank body 1 through...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com