Method for preparing flocculating agent from paper mill sludge

A papermaking sludge and flocculant technology, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the effects of environmental protection, simple production method and high flocculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

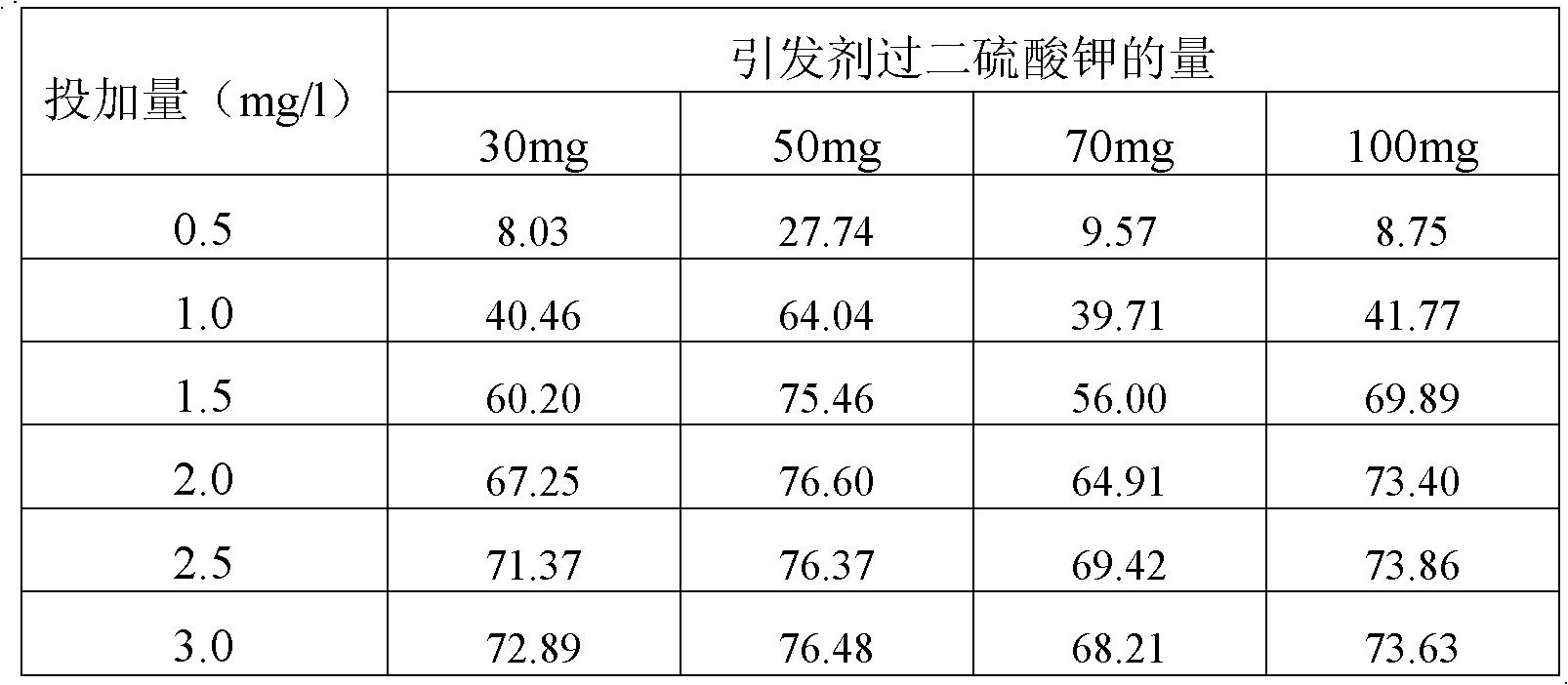

[0027] The preparation of the flocculant (L-AM) of embodiment 1. different initiator additions

[0028] Weigh 2.0g of papermaking sludge, add 60ml of deionized water and 10% NaOH solution, stir to stabilize the pH at about 11.5, after about 40min the pH remains basically unchanged, centrifuge at 8000rpm for 5min, take the supernatant, and adjust the pH to 7.5 , put the reactor into a water bath at 70°C, stir for 3min to 5min, add the initiator potassium peroxodisulfate, the amount of the initiator is 30mg, 50mg, 70mg, 100mg respectively, pass nitrogen to exhaust the air, after 15min, add 6g For acrylamide monomer, pass nitrogen gas for about 3 minutes to 5 minutes, and continue to react at 70°C for 3 hours. After the reaction, the product was cooled to room temperature, and 500ml of acetone was added to precipitate the product, vacuum filtered, and the filter residue was vacuum-dried at 50°C to obtain five products with different initiator dosages.

Embodiment 2

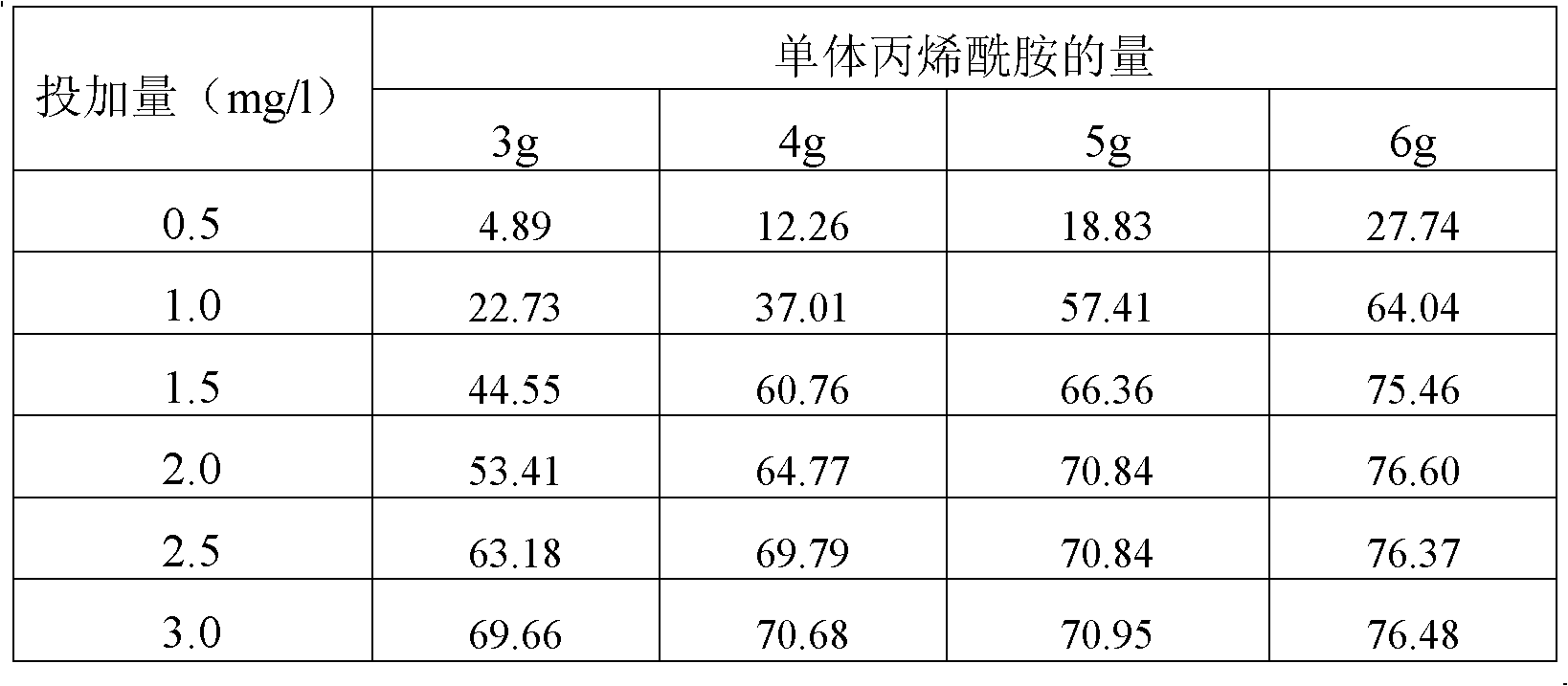

[0029] Example 2. Preparation of flocculants (L-AM) with different acrylamide additions

[0030] The same as described in Example 1, except that the amount of the initiator is fixed at 50 mg, and the amount of acrylamide is respectively 3 g, 4 g, 5 g, and 6 g, so that flocculant products with different addition amounts of acrylamide are obtained.

Embodiment 3

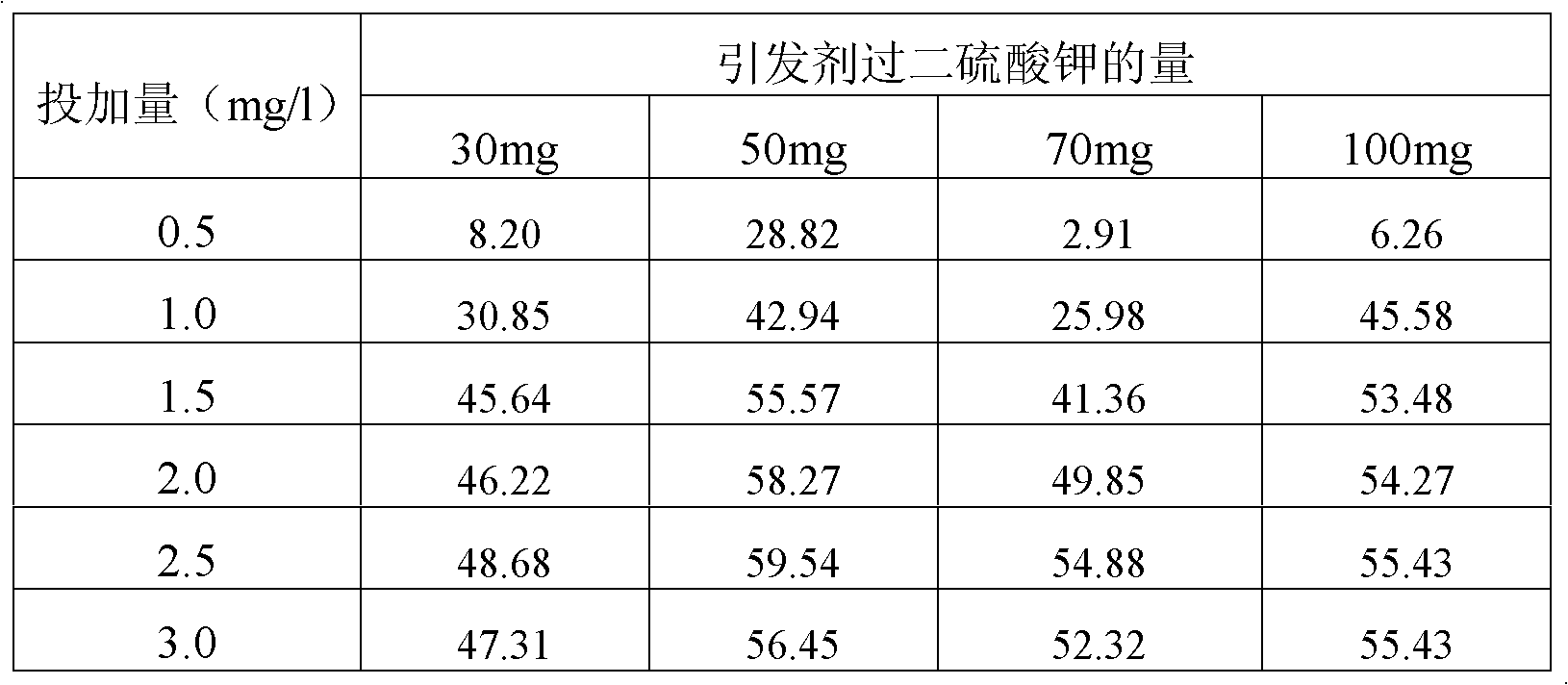

[0031] Example 3. Preparation of flocculant (L-AM) under different synthetic pH environments

[0032] The same as that described in Example 2, except that the amount of acrylamide was fixed at 5 g, and the pH of the supernatant was adjusted to 3.5, 5.5, 7.5, and 9.5, respectively, to obtain flocculant products under different reaction pH environments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com