Preparation method for papermaking sludge based amphoteric polymer flocculent

A technology of amphoteric polymers and papermaking sludge, applied in sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as poor flocculation effect and limited application range of flocculants, and reduce emissions , It is conducive to large-scale production and has a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

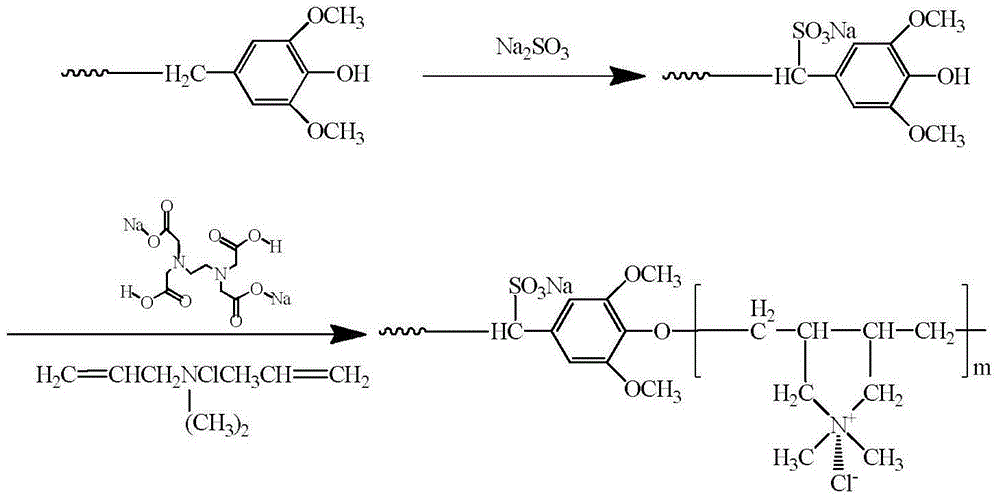

Method used

Image

Examples

Embodiment 1

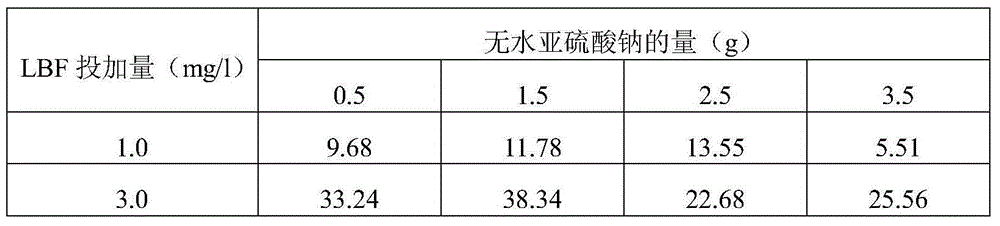

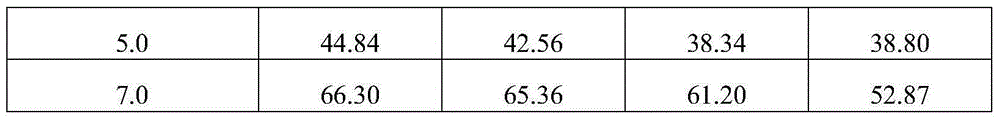

[0036] Embodiment 1. Preparation of papermaking sludge-based amphoteric polymer flocculant (LBF) with different sodium sulfite additions

[0037] (1) Take 2.0g of papermaking sludge and add it to 50ml of deionized water, add dropwise 1mol / L NaOH solution under stirring, adjust the pH to 11.0, stir for 10min until the mixture is uniform, then centrifuge at 8000rpm for 15min, and take the supernatant , adjust the pH to 7.5;

[0038](2) Heat the supernatant after pH adjustment to 90°C, stir for 5min, add anhydrous sodium sulfite 0.5g, 1.5g, 2.5g, 3.5g respectively, and continue stirring for 2h; lower the reaction temperature to 60°C in a water bath, Add 50 mg of disodium edetate, and the reaction time is 10 min; add 6 ml of dimethyl diallyl ammonium chloride, continue to stir and react for 2 h, and the reaction temperature is 60°C;

[0039] (3) After the reaction, cool to room temperature, add 500ml of acetone, stir to precipitate the reaction product, vacuum filter, take the fi...

Embodiment 2

[0040] Embodiment 2. Preparation of papermaking sludge-based amphoteric polymer flocculant (LBF) with different additions of dimethyl diallyl ammonium chloride

[0041] (1) Take 2.0g of papermaking sludge and add it to 50ml of deionized water, add dropwise 1mol / L NaOH solution under stirring, adjust the pH to 11.0, stir for 10min until the mixture is uniform, then centrifuge at 8000rpm for 15min, and take the supernatant , adjust the pH to 7.5;

[0042] (2) Heat the supernatant after pH adjustment to 90°C, stir for 5 minutes, add 2.5 g of anhydrous sodium sulfite, and continue stirring for 2 hours; lower the reaction temperature to 60°C in a water bath, add 50 mg of disodium edetate, The reaction time is 10 minutes; add 4ml, 6ml, 8ml, 10ml of dimethyl diallyl ammonium chloride respectively, continue to stir and react for 2h, and the reaction temperature is 60°C;

[0043] (3) After the reaction is finished, cool to room temperature, add 500ml of acetone, stir to precipitate th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com