Safe and high-efficiency combined technology for landfill leachate nanofiltration concentrated solution treatment

A technology of landfill leachate and concentrate, which is applied in the direction of polluted groundwater/leachate treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Emissions and other issues, to achieve the effects of low content of toxic by-products, saving acid and alkali reagents, and improving current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

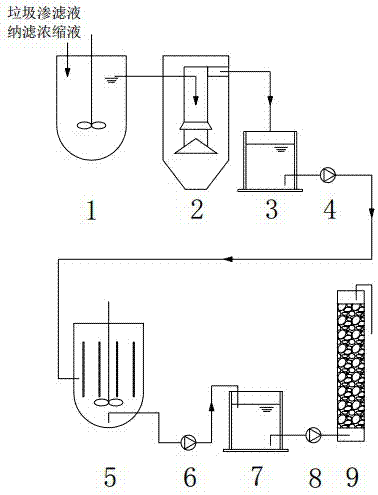

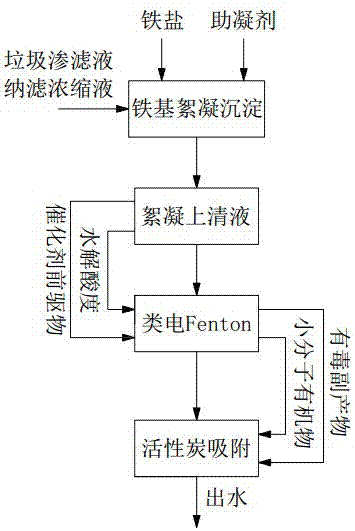

Method used

Image

Examples

Embodiment 1

[0026] The leachate nanofiltration concentrate is taken from an old urban domestic waste landfill in eastern China. The leachate treatment adopts MBR biochemical system (A / O process) + external ultrafiltration (UF) + nanofiltration (NF) treatment process. The chromaticity of the nanofiltration concentrate produced by it is 4000 times, the COD is 2450 mg / L, and the BOD5 is 100 mg / L, the salinity is 14000 mg / L, the conductivity is 17690 μS / cm, and the heavy metal concentration is shown in Table 1. First, add 5 mmol / L FeCl to the flocculation stirring tank equipped with the above-mentioned nanofiltration concentrate 3 . 6H 2 O (1.35 g / L), and stirred rapidly at a stirring speed of 200 r / min for 7 min, then added 5 mg / L polyacrylamide to the reacted solution, and slowly stirred at a stirring speed of 50 r / min Stir for 20 min. After the flocculation effluent flows into the sedimentation tank to precipitate iron sludge, its supernatant removes 60% of COD, 60% of chroma and Fe 3+...

Embodiment 2

[0030] The leachate nanofiltration concentrate is taken from a municipal solid waste landfill in central China. The leachate treatment adopts the biofilm method + external ultrafiltration (UF) + nanofiltration (NF) treatment process. The nanofiltration concentrate produced by it is Chromaticity is 3500 times, COD is 3350 mg / L, BOD 5 The concentration of heavy metals is 120 mg / L, the salinity is 13800 mg / L, the conductivity is 16690 μS / cm, and the concentration of heavy metals is shown in Table 2. First, add 10 mmol / L Fe(NO 3 ) 3 . 9H 2 O (4.04 g / L), and stirred rapidly at a stirring speed of 400 r / min for 18 min, then added 10 mg / L polyacrylamide to the reacted solution, and slowly stirred at a stirring speed of 120 r / min Stir for 70 min. After the flocculation effluent flows into the sedimentation tank to precipitate iron sludge, its supernatant removes 65% of COD, 60% of chroma and Fe 3+ About 1.5 mmol / L remained. The flocculation supernatant in the supernatant tank w...

Embodiment 3

[0034] The leachate nanofiltration concentrate was taken from a domestic waste landfill in a city in southern China. The leachate was treated by a medium-temperature anaerobic system + nitrification / denitrification + external ultrafiltration (UF) + nanofiltration (NF) treatment process. The resulting nanofiltration concentrate has a chromaticity of 4500 times, a COD of 4200 mg / L, and a BOD of 5 The concentration of heavy metals is 160 mg / L, the salinity is 15000 mg / L, the conductivity is 17500 μS / cm, and the concentration of heavy metals is shown in Table 3. First, add 10.00 g / L polyferric sulfate to the flocculation stirring tank equipped with the above-mentioned nanofiltration concentrate, and stir rapidly at a stirring speed of 100 r / min for 10 min, and then add 15 mg / L to the reacted solution. L of chitosan was stirred slowly for 100 min at a stirring speed of 200 r / min. After the flocculation effluent flows into the sedimentation tank to precipitate iron sludge, its supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com