Magnetic separation method and device for treating oil-containing graphite wastewater

A magnetic separation device and magnetic separation technology, which are applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve problems that do not involve the removal of suspended solids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

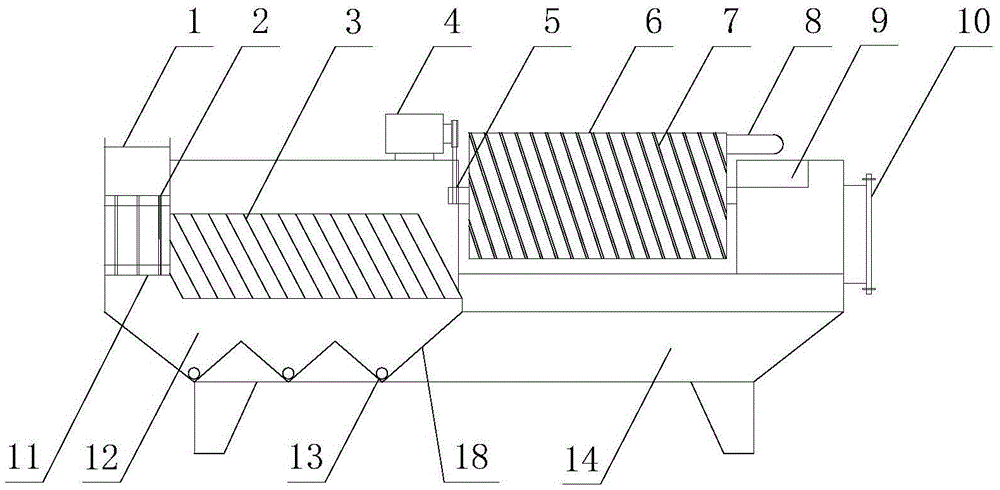

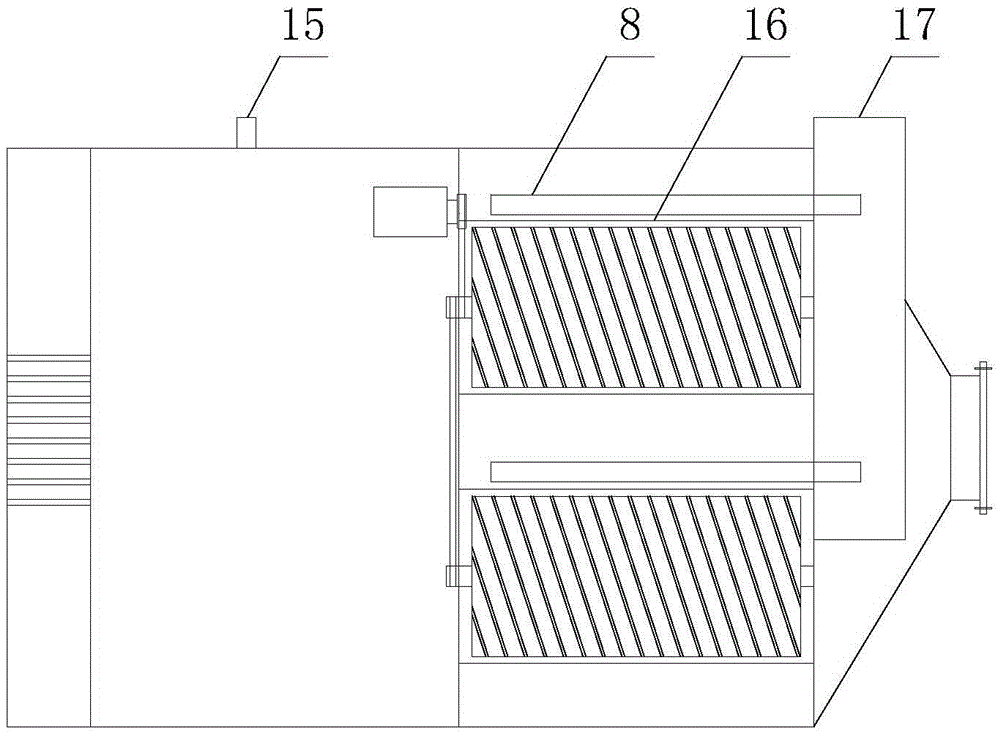

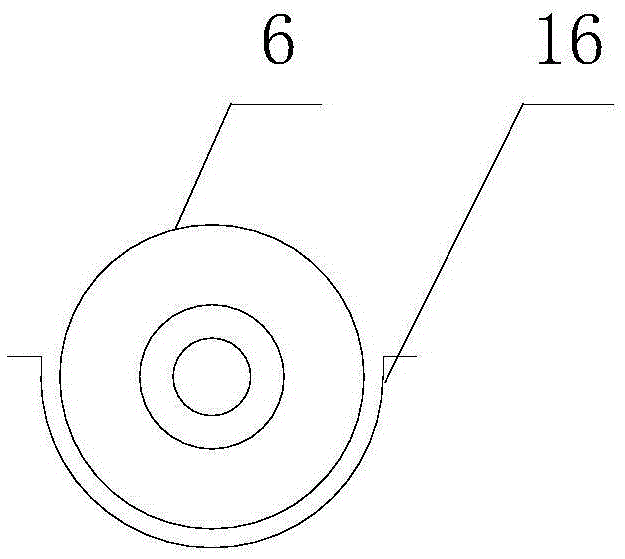

[0041] A magnetic separation method for processing oily graphite wastewater is as follows:

[0042] Send the oil-containing graphite wastewater with an oil content of 49.7mg / L and a total suspended solids of 196.3mg / L into the pressurized dissolved air flotation tank, the dissolved air pressure is 0.30MPa, the reflux ratio is 15%, and the separation load is 13m 3 / m 2 h, the hydraulic retention time is 30min, and about 40% of oil is removed; after the air flotation treatment, the air flotation water is sent to the water inlet tank 1 in the magnetic separation device, and enters the purification process through the pre-magnetic processor 11 in the middle of the water inlet tank 1 Water tank 12, the waste water after the pre-magnetization is flocculated in the purified water tank 12, then precipitates part of the flocs in the inclined tube sedimentation tank 3, the flow rate of the inclined tube sedimentation tank 3 is 25mm / s, and the effluent enters the water tank 16, and the ...

Embodiment 2

[0044] A magnetic separation method for processing oily graphite wastewater is as follows:

[0045] Send the oil-containing graphite wastewater with an oil content of 49.7mg / L and a total suspended solids of 196.3mg / L into the pressurized dissolved air flotation tank, the dissolved air pressure is 0.25MPa, the reflux ratio is 10%, and the separation load is 10m 3 / m 2 h, the hydraulic retention time is 20min, and about 40% of oil is removed; after the air flotation treatment, the air flotation water is sent to the water inlet tank 1 in the magnetic separation device, and enters the purification through the pre-magnetic processor 11 in the middle of the water inlet tank 1 Water tank 12, the pre-magnetized waste water is flocculated in the purified water tank 12, and then part of the flocs are precipitated in the inclined tube sedimentation tank 3. Under the action of a magnetic field, the remaining flocs and suspended matter in the water are adsorbed on the disk 7, and the pro...

Embodiment 3

[0047] A magnetic separation method for processing oily graphite wastewater is as follows:

[0048] Send the oil-containing graphite wastewater with an oil content of 49.7mg / L and a total suspended solids of 196.3mg / L into the pressurized dissolved air flotation tank, the dissolved air pressure is 0.35MPa, the reflux ratio is 12%, and the separation load is 11m 3 / m 2 h, the hydraulic retention time is 25min, and about 40% of oil is removed; after the air flotation treatment, the air flotation water is sent to the water inlet tank 1 in the magnetic separation device, and enters the purification process through the pre-magnetic processor 11 in the middle of the water inlet tank 1 Water tank 12, the pre-magnetized waste water is flocculated in the purified water tank 12, and then part of the flocs are precipitated in the inclined tube sedimentation tank 3. Under the action of a magnetic field, the remaining flocs and suspended matter in the water are adsorbed on the disk 7, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com