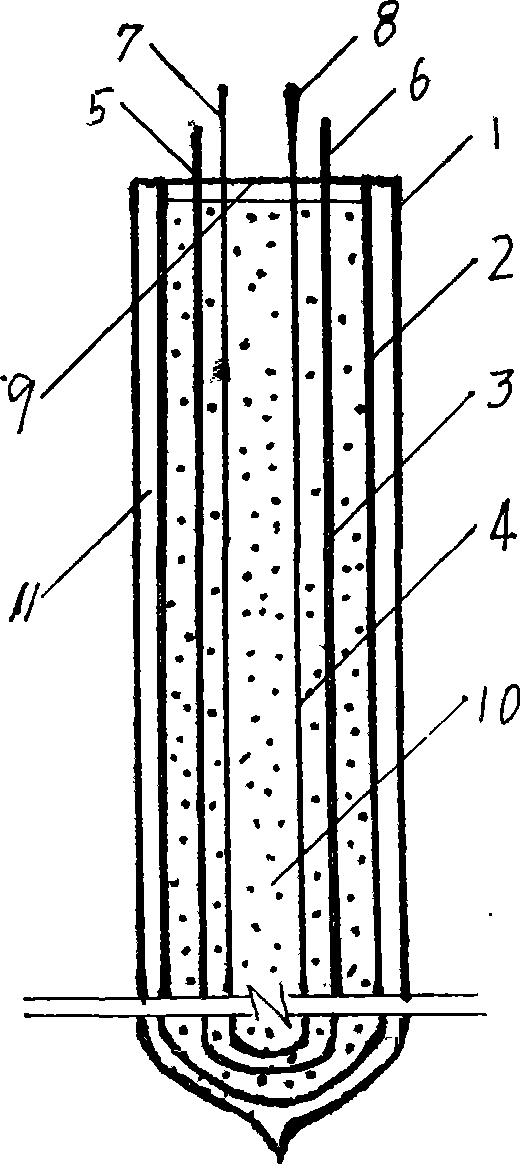

Cold-resistant pressure-bearing solar heat-collection and energy-storage pipe with electric heating function

A technology of solar heat collection and electric heating, applied in the direction of solar heat energy, solar heat collector, solar heat collector using working fluid, etc. Collecting water capacity and energy storage in the collector tube can solve the problem of solar energy and building integration design, solve industrial technical problems, and reduce the weight of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1, when the melting point of the added phase-change energy storage material is at 45-60°C, it can replace the commonly used heat collectors in roof-mounted, wall-mounted, wall-mounted and balcony railing-mounted waterless tanks The solar water heater can also be used on the module in the central heating water supply project, canceling the water tank in the hot water project.

Embodiment 2

[0013] Example 2, when the melting point of the added phase-change energy storage material is 105-110°C, it can be used in a solar water boiler.

Embodiment 3

[0014] Example 3, when the melting point of the added phase change energy storage material is 110-200°C, it can be used as a heat source for a solar thermal power plant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com