Method and treatment device for purifying water of micro polluted water source

A technology of micro-pollution and water source, applied in the direction of oxidation water/sewage treatment, sterilization/microdynamic water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of high price ratio and ineffective soluble pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

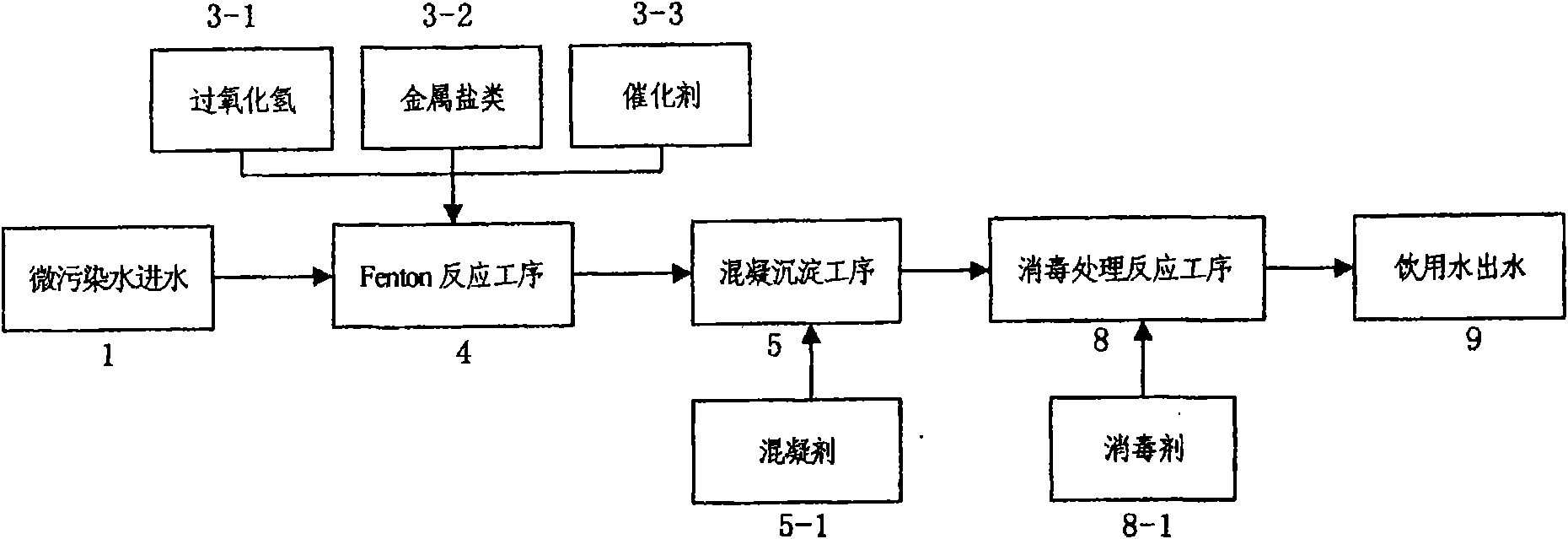

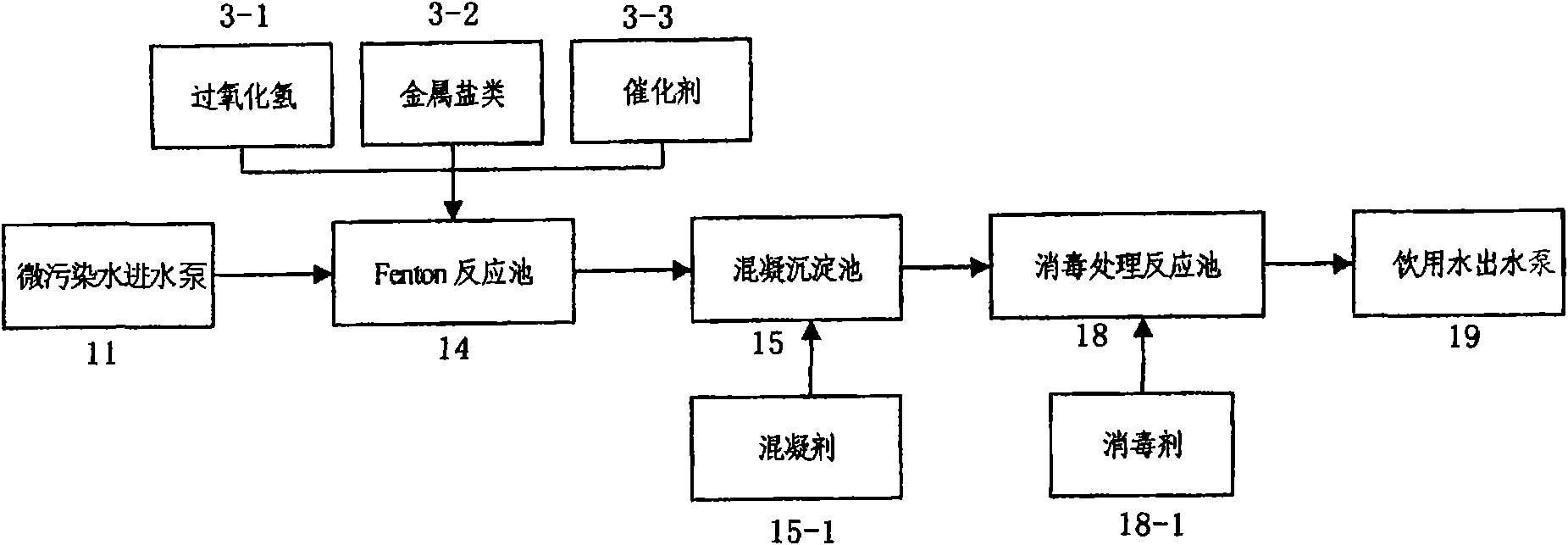

[0084] take figure 1 The process shown and image 3 The shown device purifies slightly polluted water to meet the requirements of the Sanitary Standard for Drinking Water. The treatment of slightly polluted water and each unit is as follows:

[0085] Slightly polluted water enters the Fenton reaction process through the water inlet pump, and hydrogen peroxide (H), metal salts (F1) and catalyst (A1) are added to the Fenton reaction tank, and the Fenton reaction is carried out after mixing by the mixing device; Fenton reaction process There is a stirring device in the middle to stir, and after a period of reaction, it enters the coagulation and sedimentation process; in the coagulation and sedimentation tank, the small suspended matter, colloidal matter, and metal salts in the wastewater are precipitated by adding a coagulant (B1). The treated clear water can directly enter the disinfection and oxidation reaction process because the relevant indicators reach the "Drinking Water...

Embodiment 2

[0089] The process of Example 1 is adopted to purify slightly polluted water, so as to meet the requirements of the "Drinking Water Hygienic Standard", and the processing conditions of each unit are shown in Table 3.

[0090] table 3:

[0091]

Embodiment 3

[0093] Adopt embodiment 1 process to carry out micro-polluted water body purification, to reach " drinking water sanitation standard " requirement, each unit treatment situation is as table 4.

[0094] Table 4:

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com