Method for preparing beta-Bi2O3/TiO2-NTs composite photocatalyst with high stability visible light catalytic activity

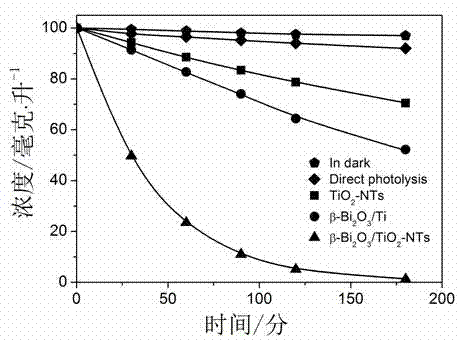

A catalytic activity and visible light technology, applied in the field of material chemistry, can solve problems such as hindering the application of visible light catalysts, weak hole oxidation ability, and decreased photocatalytic activity, so as to achieve enhanced photocatalytic activity, high space utilization, and reduced contact probability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

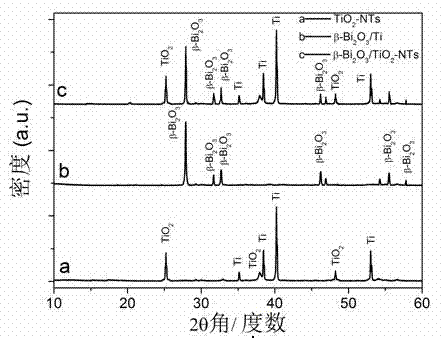

[0034] β-Bi 2 o 3 / Ti photocatalyst preparation. Described method specifically comprises the following steps:

[0035] (1) Set the thickness to 0.08mm and the size to 3cm 2 The surface of the pure titanium sheet is mechanically polished and cleaned;

[0036] (2) Add 0.1mol / L Bi(NO 3 ) 3 ·5H 2 O, 3 mol / L HCl, 0.04 mol / L EDTA are prepared as electroplating solution;

[0037] (3) The Ti prepared in step (1) was used as the working electrode, the platinum sheet was used as the auxiliary electrode, and the saturated calomel electrode (SCE) was used as the reference electrode. At room temperature, Bi nanoparticles were deposited on the Ti sheet by pulse electrodeposition. Above, the pulse deposition current is cathode pulse (-80mA 10ms), anode pulse (80mA 1ms), rest time (0A 1s), and the number of pulse cycles is 100 times; then placed in a tube furnace for calcination in an oxygen atmosphere, the calcination time is 2h , to prepare β-Bi 2 o 3 / Ti photocatalyst products; ...

Embodiment 2

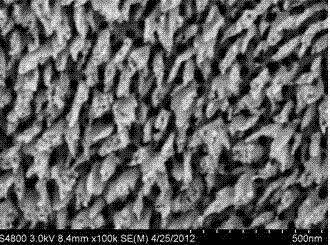

[0040] A preparation method of β-Bi2O3-TiO2-NTs composite photocatalyst with high stable visible light catalytic activity, the method is to use the pulse electrodeposition method, and use the titanium dioxide nanotubes grown vertically on the titanium base as the carrier to prepare β-Bi2O3-TiO2-NTs composite photocatalyst 2 o 3 / TiO 2 -NTs composite photocatalyst. Described method specifically comprises the following steps:

[0041] (1) Set the thickness to 0.1mm and the size to 6cm 2 The surface of the pure titanium sheet is mechanically polished and cleaned;

[0042] (2) With 1.0wt%NaF and supporting electrolyte 2.0wt%Na 2 SO 4 As the solute, add alcohol additive 50 wt% polyethylene glycol (PG400), the solvent is the balance of water, and prepare the electrolyte;

[0043] (3) The titanium sheet in step (1) is used as the working electrode, the platinum sheet is used as the counter electrode, and the distance between the working electrode and the counter electrode is 1....

Embodiment 3

[0051] A β-Bi with High Stable Visible Light Catalytic Activity 2 o 3 / TiO 2 -The preparation method of NTs composite photocatalyst, this method is to adopt the pulse electrodeposition method, with the titania nanotube that grows vertically on the titanium base as carrier, prepare β-Bi 2 o 3 / TiO 2 -NTs composite photocatalyst. Described method specifically comprises the following steps:

[0052] (1) Set the thickness to 0.1mm and the size to 6cm 2 The surface of the pure titanium sheet is mechanically polished and cleaned;

[0053] (2) With 1.0wt%NaF and supporting electrolyte 2.0wt%Na 2 SO 4 As the solute, add alcohol additive 50 wt% polyethylene glycol (PG400), the solvent is the balance of water, and prepare the electrolyte;

[0054] (3) The titanium sheet in step (1) is used as the working electrode, the platinum sheet is used as the counter electrode, and the distance between the working electrode and the counter electrode is 1.0 cm, and the electrochemical anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com