Micro-electrolysis filling material

A micro-electrolysis, cylindrical technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve problems such as iron sludge blockage, large amount of sludge, easy passivation, etc. Achieve the effects of reducing flow resistance, increasing specific surface area, and easy biofilm formation

Inactive Publication Date: 2010-06-23

常州海龙环保设备厂

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The technical problem to be solved by the present invention is: to overcome the problems of traditional iron filing fillers, which are easy to passivate, harden, iron mud clogging, and large amount of sludge, prolong the service life of the filler, save the cumbersome filler replacement link, and reduce the waste water treatment. cost

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

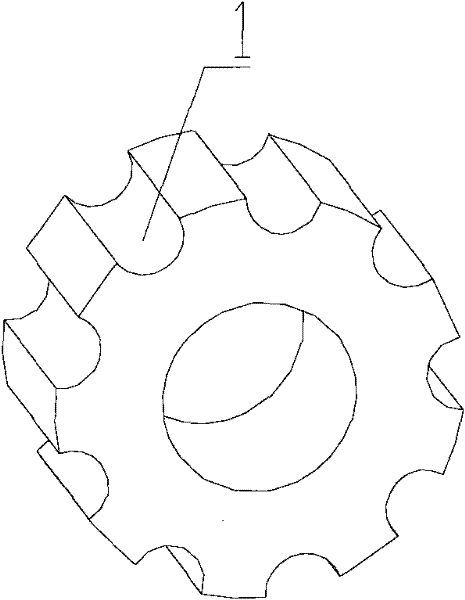

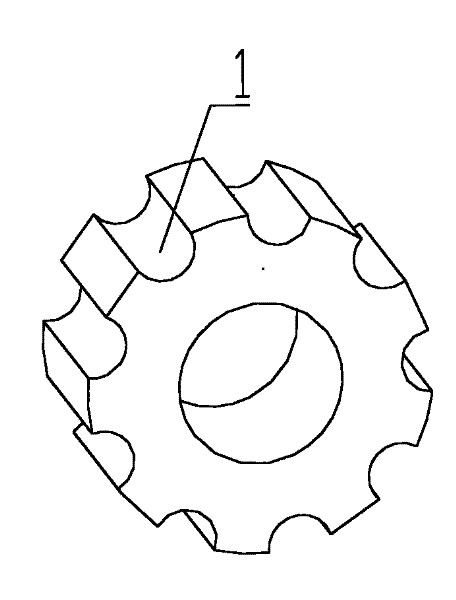

[0011] Such as figure 1 As shown, a micro-electrolytic packing, the packing has a cylindrical structure, and is uniformly arranged on the outer wall of the packing so that the end surface of the packing presents a gear-shaped groove 1 . The groove 1 is parallel to the axis of the packing. The height of the packing is 25-28mm, and the overall diameter is 35-40mm.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of micro-electrolysis filling material used in wastewater treatment. The filling material has a cylinder structure, and the lateral wall of the filling material is uniformly provided with grooves which can make the end face of the filling material be in a gear shape. The regulated structure of the filling material keeps an adequate gap between the cumulated filling materials, thereby ensuring the complete catalyzed reaction of the filling materials and the water and simultaneously reducing the flow resistance of the water, the physical form of the filling material increases the specific surface area of the filling material as far as possible, and therefore, the micro-electrolysis effect is obvious, and the bio-film can be applied easily.

Description

technical field [0001] The invention relates to the technical field of micro-electrolytic fillers for sewage treatment. Background technique [0002] The existing iron-carbon bed micro-electrolysis tower filler is fine-grained iron filings, which is ideal for treating high COD wastewater, especially acidic organic wastewater. It is also a conventional technology commonly used by almost all environmental protection companies, but this kind of filler is used in After two months of operation in the micro-electrolysis tower, the effect will drop sharply, which is mainly caused by the passivation of the iron-carbon bed, hardening and other reasons. At the same time, due to the large amount of iron sludge, the micro-electrolysis tower will be silted up, and backwashing can slow down the iron sludge. Blockage, alone cannot solve the problem of the decline in sewage treatment effect, which can only be replaced with new fillers frequently. However, the workload of replacing the pack...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/461

Inventor 徐俊徐建兴徐烨

Owner 常州海龙环保设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com