Method for preparing catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems that the gas phase ultra-stable process is difficult to industrialize, increase production costs and environmental protection costs, and endanger the health of operators. Achieve the effects of high crystallinity, high production efficiency, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

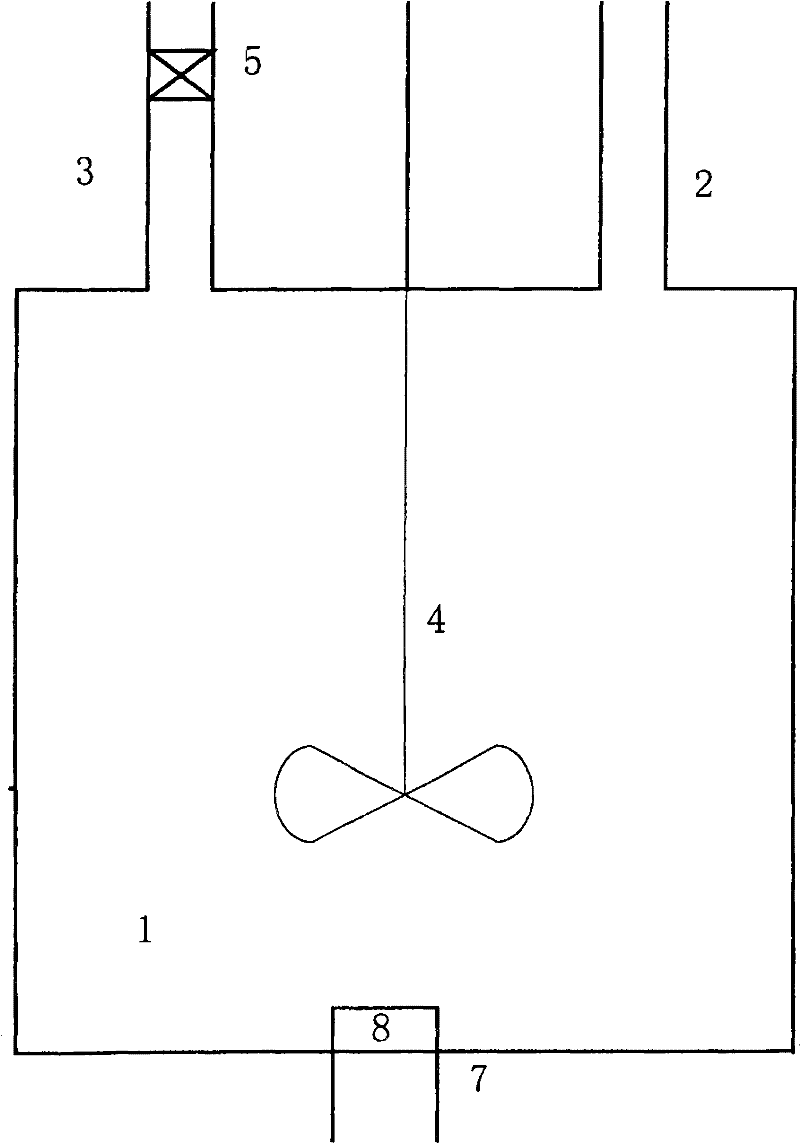

[0018] According to the preparation method of catalytic cracking catalyst provided by the present invention, the gas phase silicon tetrachloride and the molecular sieve can be directly mixed and sent into the reactor for reaction; it is also possible to mix the inert gas, that is, the carrier gas, with the gas phase silicon tetrachloride, Form a mixed gas, and then mix the mixed gas with molecular sieves and send them into the reactor for contact reaction; you can also mix the inert gas with the molecular sieves first, so that the molecular sieves are driven by the inert gas in a flowing state and gas-phase silicon tetrachloride. Mixing; the inert gas, molecular sieve and gas phase silicon tetrachloride can also be mixed evenly at the same time and then sent together into the reactor for reaction. Preferably, the inert gas, that is, the carrier gas, is first mixed with gaseous silicon tetrachloride to form a mixed gas, and then the mixed gas is uniformly mixed with molecular si...

Embodiment approach

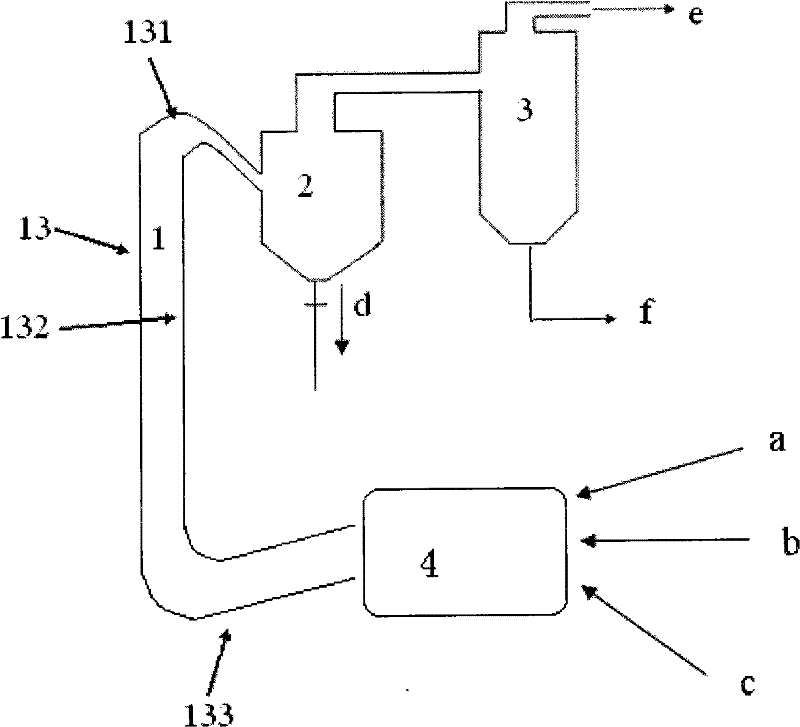

[0028] According to a preferred embodiment of the present invention, the pipe body 13 further includes a second inclined section 133, one end of the second inclined section 133 is connected to the other end of the vertical section 132, and the first The feed port is located at the other end of the second inclined section 133 . Such setting can prevent the molecular sieve solid material from flowing too fast under the action of gravity, and increase the contact reaction time between the reaction materials.

[0029] Further preferably, the position of the feed inlet is higher than the position where the second inclined section 133 is connected to the vertical section 132, so that the material can quickly and directly enter the second inclined section 133, and then be further conveyed .

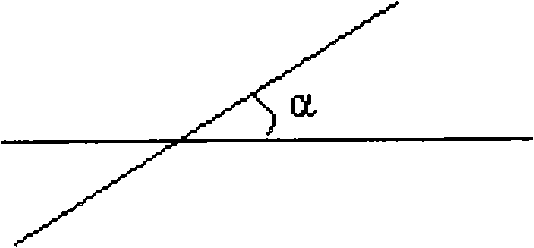

[0030] The included angle between the second inclined section 133 and the vertical section 132 can be 10-90°, preferably 30-80°, that is, when the vertical section 132 is perpendicular to the h...

Embodiment 1

[0047] Made of industrial grade stainless steel with a thickness of 3mm NiCr18Ti figure 2 In the shown molecular sieve vapor phase silicon replenishment equipment, the tube body 13 of the tubular reactor 1 is composed of a first inclined section 131, a vertical section 132 and a second inclined section 133, the length of the first inclined section 131 is 20 meters, and the diameter is 0.8 meters, the length of the vertical section 132 is 40 meters, and the diameter is 0.8 meters. The length of the second inclined section 133 is 15 meters, and the diameter is 0.8 meters. The vertical section 132 is perpendicular to the horizontal plane, and the axis of the first inclined section 131 and The angle α between the horizontal planes is 75° (that is, the angle between the first inclined section 131 and the vertical section 132 is 15°), and the angle β between the axis of the second inclined section 133 and the horizontal plane is 65° (that is, the angle between the second inclined s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com