Lubricant composition and method for improving anti-wear and friction reduction properties of lubricant

A technology of lubricating oil composition and antioxidant, applied in lubricating composition, petroleum industry, additives, etc., can solve problems such as difficulty in starting the engine, unstable idle speed, poor drivability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

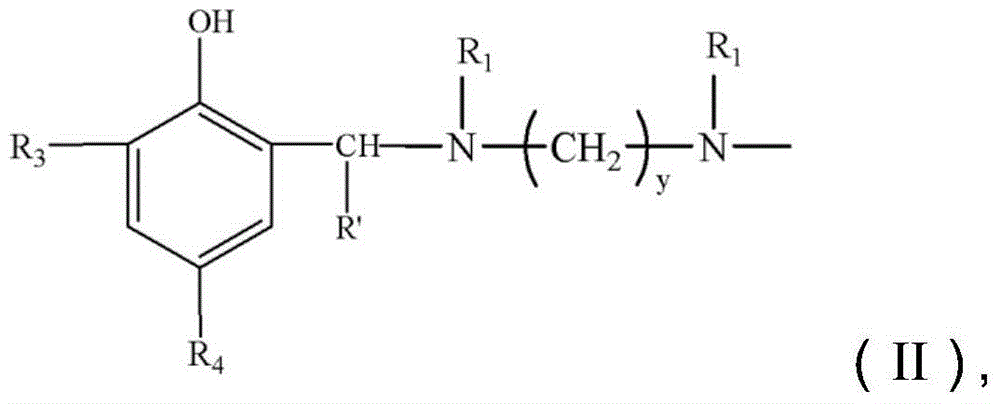

[0145] Embodiment 1 synthetic polyisobutylene o-cresol

[0146] In a 500ml four-necked flask equipped with a stirrer, a thermometer, a condenser and a dropping funnel, add 34.93g (0.323mol) of o-cresol, 6.88g (0.048mol) of boron trifluoride ether catalyst, and 100ml of n-hexane solvent React with 161.61g (0.162mol) of polyisobutylene (Mn=1000) at 80°C for 2h. After the reaction, the reaction mixture was washed once with 5% potassium hydroxide solution by mass fraction, and washed with hot water to neutrality to remove the catalyst, and then the solvent and unreacted o-cresol were distilled off under reduced pressure. The hydroxyl value of the synthetic product polyisobutylene o-cresol is 53.49 mg / g. For the determination of hydroxyl value, refer to the acetic anhydride method in GB / T7383-2007.

[0147] An example reaction is as follows:

[0148]

Embodiment 2

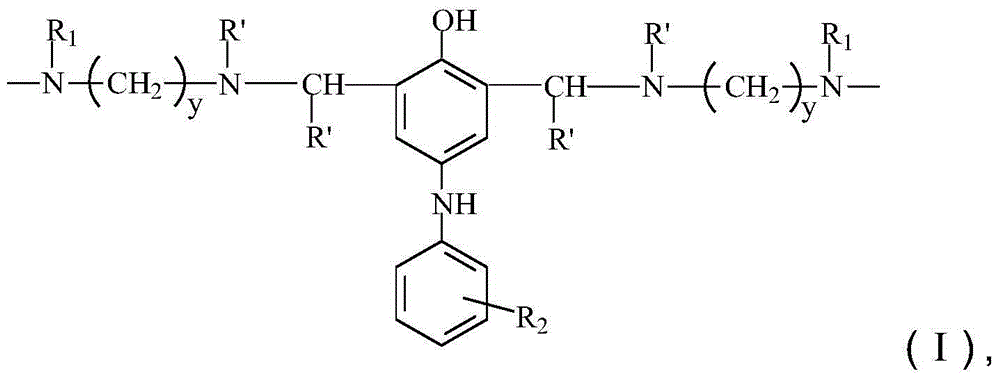

[0150] The polyisobutylene o-cresol 47.16g (0.045mol) that makes in embodiment 1 is added in the 500ml four-necked beaker that stirrer, thermometer and separator are equipped with under nitrogen protection, then add 2.70g (0.045mol) ethylenediamine, 3.83g (0.047mol) of formaldehyde, and 47ml of toluene was added as a reaction solvent, and after reacting at 80°C for 1.5h, the temperature was lowered to room temperature, and 4.17g (0.0225mol) of p-hydroxydiphenylamine, 3.83g ( 0.047mol) formaldehyde, reacted at 70°C for 1h. After the reaction is finished, the solvent and a small amount of water generated are distilled off under reduced pressure to obtain the final Mannich base detergent. An example reaction is as follows:

[0151]

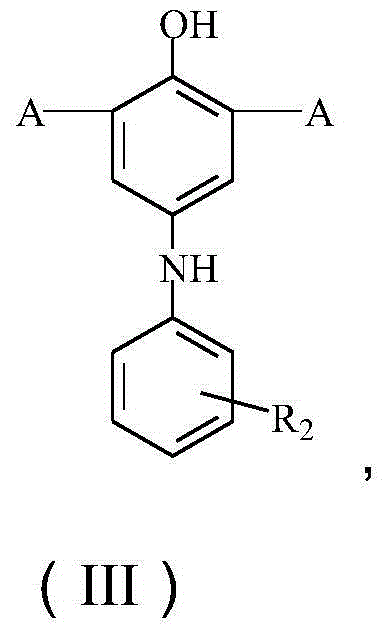

Embodiment 3

[0153] The polyisobutylene o-cresol 53.37g (0.051mol) that makes in embodiment 1 is added in the 500ml four-necked beaker that stirrer, thermometer and separator are equipped with under nitrogen protection, then add 7.46g (0.051mol) triethylenetetramine, 4.38g (0.054mol) of formaldehyde, and 54ml of xylene was added as a reaction solvent, after reacting at 100°C for 1.5h, the temperature was cooled to room temperature, and 5.87g (0.0255mol) of 4-hydroxyl-2'- Nitrodiphenylamine and 4.38g (0.054mol) formaldehyde were reacted at 80°C for 1h. After the reaction is finished, the solvent and a small amount of water generated are distilled off under reduced pressure to obtain the final Mannich base detergent. Refer to Example 2 for an exemplary reaction scheme.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total base number | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com