A multi-component nanocomposite of ultra-high molecular weight polyethylene suitable for water lubrication

A technology of ultra-high molecular weight and composite materials, which is applied in the field of ultra-high molecular weight polyethylene multi-component nano-composite materials, can solve the problems of inability to promote high load-carrying capacity and passivation capacity reaction boundary film, etc., achieve good wear resistance, improve performance, The effect of increasing the formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

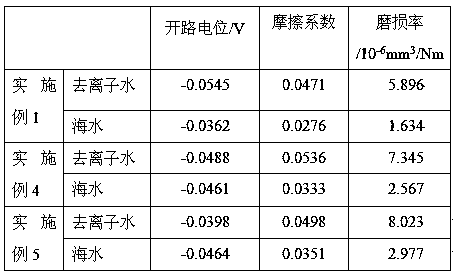

Examples

Embodiment 1

[0026] Heat 4.0g of hexagonal boron nitride in 2.0mol / L sodium hydroxide solution at 100°C for 2 hours, filter it out, add 100ml of 2.0mol / L 3-chloropropyltrimethoxysilane acetone solution, and stir at 50°C for 16 hours , through conventional separation to obtain the treated hexagonal boron nitride; 4.0g treated hexagonal boron nitride, 20.0mg cuprous chloride, 40.0mg2, 2 bipyridine and 200ml12mol / L1-vinyl-3-ethylimidazole tetrafluoro The dimethylformamide solution of borate was mixed and stirred, and reacted at 50° C. for 12 hours under a nitrogen atmosphere to obtain hexagonal boron nitride grafted with 1-vinyl-3-ethylimidazolium tetrafluoroborate.

[0027] 32.4g of ultra-high molecular weight polyethylene, 6.8g of carbon fiber and 3.3g of hexagonal boron nitride grafted with 1-vinyl-3-ethylimidazolium tetrafluoroborate were carried out in a high-speed mixer at a speed of 10000r / min Mix well, then transfer to a 50mm×60mm mold for hot pressing and sintering, rise the room tem...

Embodiment 2

[0029] Heat 3.0g of hexagonal boron nitride in a 2.0mol / L sodium hydroxide solution at 120°C for 1.5 hours, filter it out, add 100ml of 1.5mol / L 3-chloropropyltrimethoxysilane acetone solution, and stir at 55°C for 18 Hours, the processed hexagonal boron nitride was obtained by conventional separation; 3.0g processed hexagonal boron nitride, 15.0mg cuprous chloride, 30.0mg2, 2 bipyridine and 200mL10.0mol / L1-vinyl-3-ethyl The dimethylformamide solution of imidazolium tetrafluoroborate was mixed and stirred, and reacted at 55°C for 16 hours under nitrogen atmosphere to obtain hexagonal boron nitride grafted with 1-vinyl-3-ethylimidazolium tetrafluoroborate .

[0030] 28.5g of ultra-high molecular weight polyethylene, 6.1g of carbon fiber and 2.8g of hexagonal boron nitride grafted with 1-vinyl-3-ethylimidazolium tetrafluoroborate were fully mixed at a speed of 10000r / min in a high-speed mixer. Mixed, then transferred to a 50mm×60mm mold for hot-pressing sintering, the room temp...

Embodiment 3

[0032] Heat 2.5g of hexagonal boron nitride in 2.0mol / L sodium hydroxide solution at 120°C for 3 hours, filter it out, add 100ml of 1.25mol / L 3-chloropropyltrimethoxysilane acetone solution, and stir at 50°C for 20 Hours, the processed hexagonal boron nitride was obtained by conventional separation; 2.5g processed hexagonal boron nitride, 12.5mg cuprous chloride, 37.5mg 2,2 bipyridine and 200ml8.0mol / L1-vinyl-3-ethane The dimethylformamide solution of imidazole tetrafluoroborate was mixed and stirred, and reacted at 50°C for 18 hours under nitrogen atmosphere to obtain hexagonal nitriding grafted with 1-vinyl-3-ethylimidazole tetrafluoroborate boron.

[0033]25.4g of ultra-high molecular weight polyethylene, 6.0g of carbon fiber and 2.3g of hexagonal boron nitride grafted with 1-vinyl-3-ethylimidazolium tetrafluoroborate were carried out in a high-speed mixer at a speed of 12000r / min Mix well, then transfer to a 50mm×60mm mold for hot-pressing and sintering, the room temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com