Re-manufacturable large tillage depth rotary tillage blade suitable for returning whole straws to field

A technology of remanufacturing and rotary ploughing blades, applied in the field of rotary ploughing blades in large ploughing depths, which can solve the conflict, the poor effect of returning straw in full, the toughness, bending strength and surface wear resistance can not meet the requirements of large ploughing depths at the same time. Function requirements and other issues, to achieve the effect of sharp cutting soil, good wear resistance and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

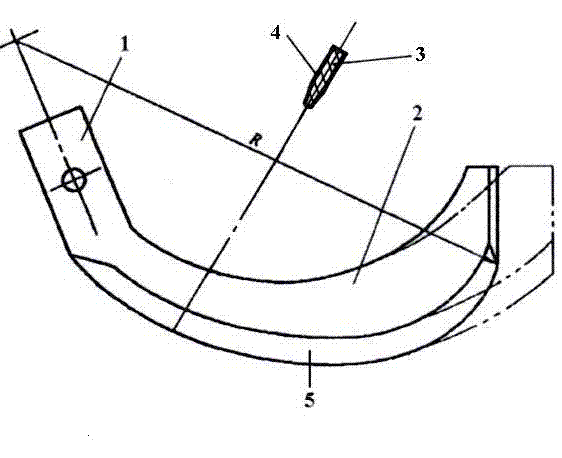

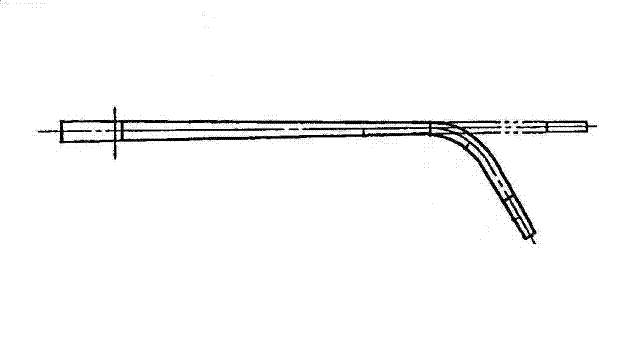

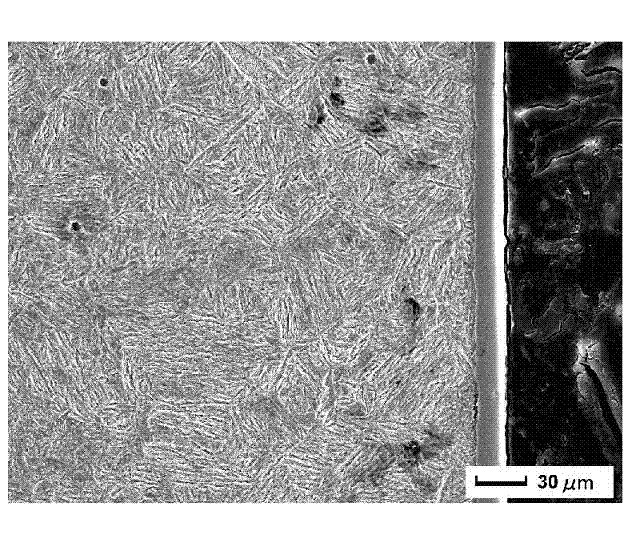

Embodiment 1

[0031] A remanufactured deep tillage rotary cultivator that is suitable for full return of straw to the field. It adopts 65Mn supplied by Xinfu Steel Company, with a blade turning radius R of 285mm. After cutting and forging, it is processed by a sandblasting machine. Clean the surface, remove the surface oxide scale, etc. to obtain a clean surface, bury the rotary knife in the solid powder boronizing agent of the infiltration box, cover it with clay and seal the box cover with the box body with high temperature sealant, and then perform boronizing ( Or chromium, titanium, vanadium and niobium, and the various co-infiltration treatments containing rare earth), then air-cooled to room temperature; reheat the boronized rotary knife to 850°C (or 830, 840, 860 or 870°C), heat preservation for 15 minutes and then oil quenching. After cooling to room temperature, perform medium temperature tempering at 420°C × 2h (or 430, 440 or 450°C × 2h) to obtain the large Rotary tiller for deep ...

Embodiment 2

[0036] A remanufactured deep tillage rotary cultivator suitable for full return of straw to the field. It adopts the supplied 60Si2Mn produced by Xinfu Steel Co., with a tip turning radius R of 300mm. After cutting and forging, it is processed by a sandblasting machine. Clean the surface, remove the surface oxide scale, etc. to obtain a clean surface, bury the rotary knife in the solid powder chromizing agent of the infiltration box, cover it with clay and seal the box cover and the box with a high temperature sealant, and then perform chromizing ( Or boronizing, titanium infiltrating, vanadium infiltrating and niobium infiltrating and the various co-infiltration treatments containing rare earth), and then air-cooled to room temperature; reheat the chromized rotary knife to 850°C (or 830, 840 , 860 or 870 ℃), heat preservation for 15 minutes, oil quenching, after cooling to room temperature, 450 ℃ × 2h (also 420, 430, 440 ℃ × 2h) medium temperature tempering, you can obtain the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com