Patents

Literature

34results about How to "Self-sharpening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

CBN (Cubic Boron Nitride) grinding wheel

ActiveCN106625297AReduce grinding temperatureReduce power lossAbrasion apparatusGrinding devicesProcessing accuracyThermal conductivity

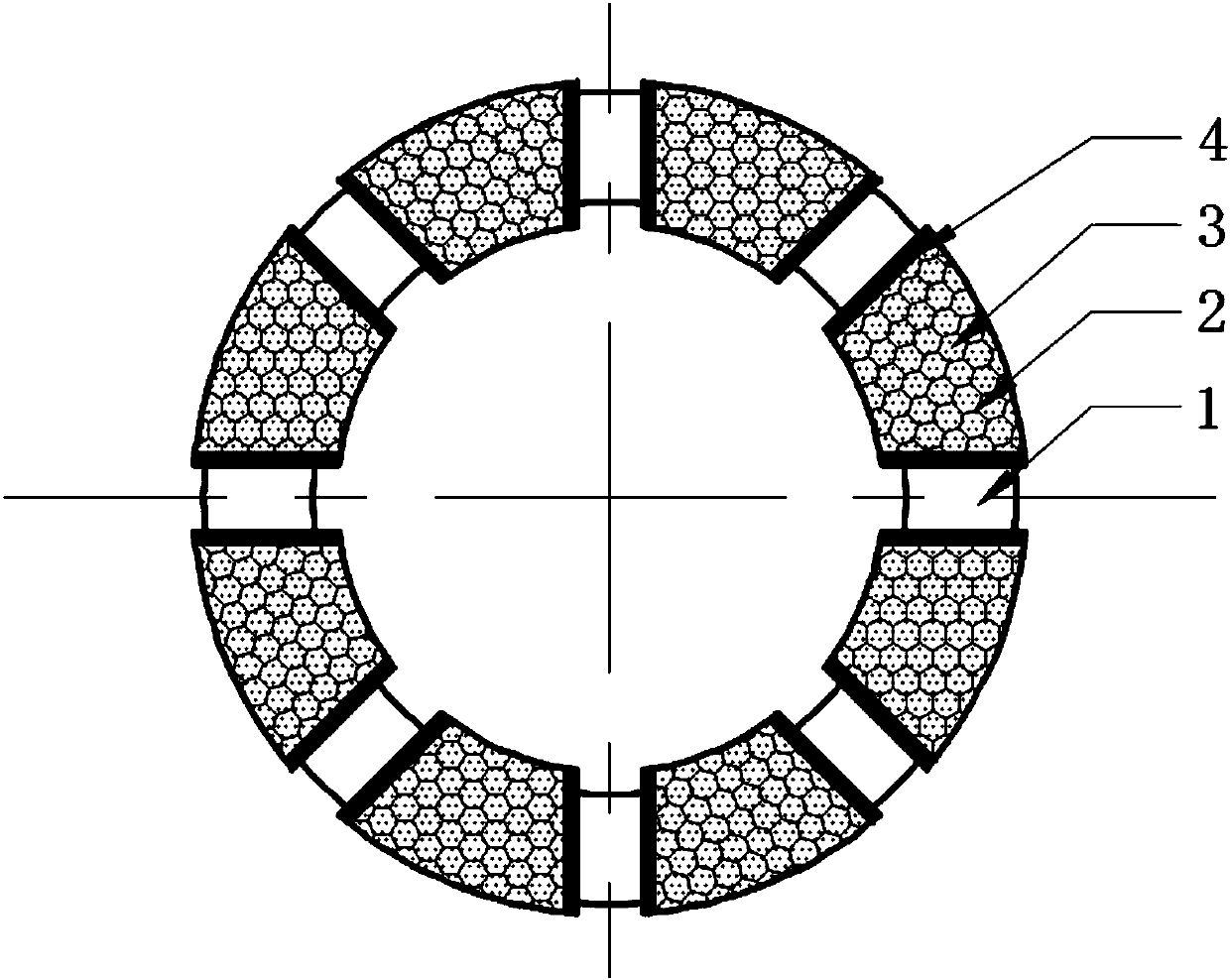

The invention relates to the field of superhard materials, and concretely relates to a CBN (Cubic Boron Nitride) grinding wheel. The invention provides the CBN grinding wheel, which has favorable shock resistance and shape retention, and can bear a larger load during a high-speed grinding process. The CBN grinding wheel comprises a steel core and an abrasive ring. The steel core and the abrasive ring are combined through a binding agent. The CBN grinding wheel is characterized in that the abrasive ring is prepared from the following raw materials in percentage by mass: 30 to 70 percent of CBN abrasive, 20 to 60 percent of metal binding agent, and 2 to 10 percent of auxiliary adhesion agent. The CBN grinding wheel provided by the invention has favorable heat conductivity and is beneficial for reducing the grinding temperature, so that the power loss is reduced, and the grinding speed is improved; the auxiliary adhesion agent in a formula is beneficial for forming pores, and the characteristic of high holding force of the metal binding agent is combined, so that a chip space can be effectively enlarged, and abrasives are more sufficiently utilized; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature, low power loss, good processing accuracy, long service life and the like.

Owner:磐维科技(青岛)有限公司

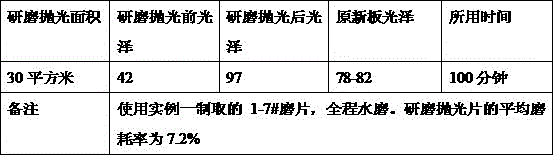

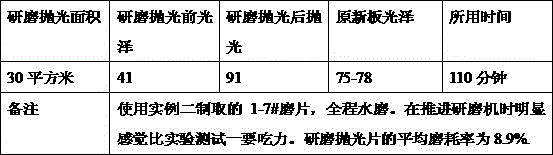

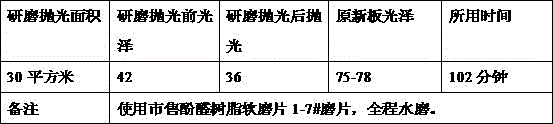

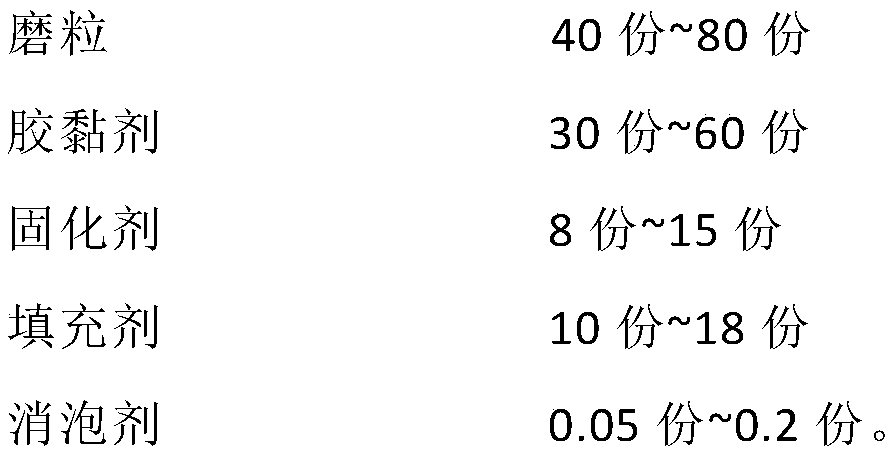

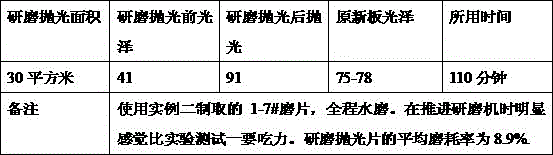

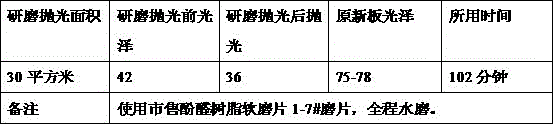

Preparation method of polyurethane matrix stone grinding and polishing disc

ActiveCN106272125AGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideZinc

The invention discloses a preparation method of a polyurethane matrix stone grinding and polishing disc, and relates to a synthesis technology adopting a prepared polyurethane matrix and mixed artificial diamond micro powder, silicon carbide, silicon oxide, aluminium oxide and zinc oxide super fine powder as abrasive components. The novel stone grinding and polishing material can better meet the requirement on high luster during the decorative stone processing process or the later renovation process, the efficiency is higher, and the material has better environmental protection property.

Owner:王建秋

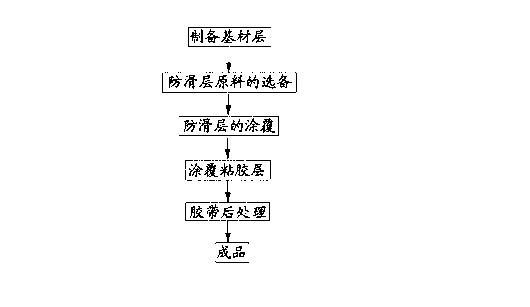

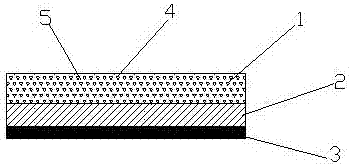

Novel anti-skid adhesive tape

InactiveCN103254837AExtended service lifeEasy to useFilm/foil adhesivesNatural mineral layered productsFiberAdhesive

The invention discloses a novel anti-skid adhesive tape. The adhesive tape comprises an anti-skid layer, a substrate layer and an adhesive layer, wherein the anti-skid layer and the adhesive layer are respectively formed at two sides of the substrate layer, the substrate layer is made of wear-resisting fiber cloth, the anti-skid layer comprises the following main components in percentage: 40%-50% of sand and 50%-60% of fillers, the raw materials of the anti-skid layer are formed on the substrate layer through a coating process, and a strong adhesive is adopted by the adhesive layer. The novel anti-skid adhesive layer disclosed by the invention is in multi-layer composite structure design, and the combination strength among the layers is high; the anti-skid layer is the sand coating and has a self-sharpening property in use, and thus the service life of the adhesive tape is greatly prolonged; and meanwhile, the substrate layer made of the wear-resisting fiber cloth is high in strength and good in corrosion resistance and mold resistance, so that the use performance of the adhesive tape is more excellent.

Owner:KUNSHAN HANBAO TAPE TECH

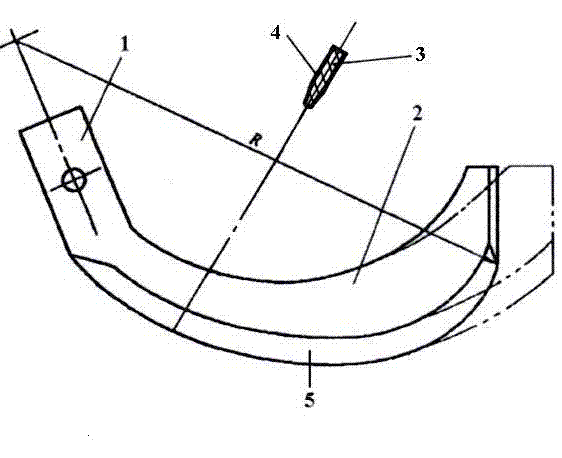

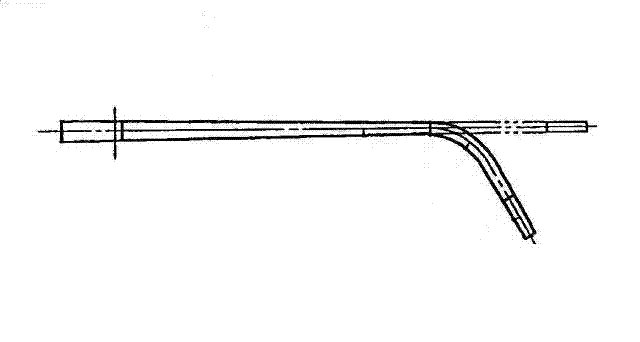

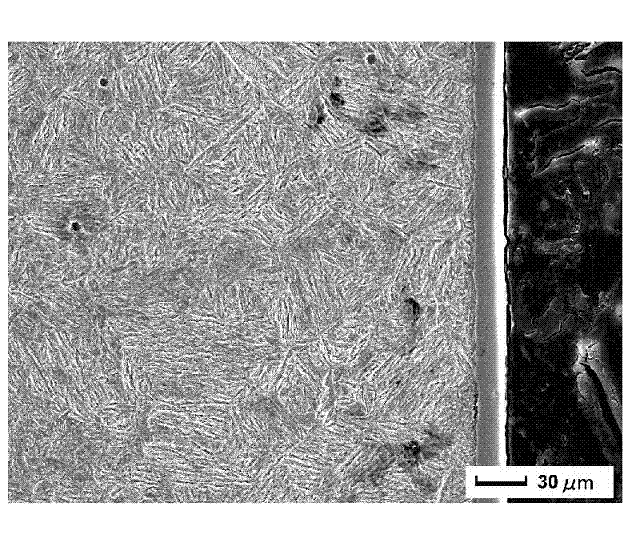

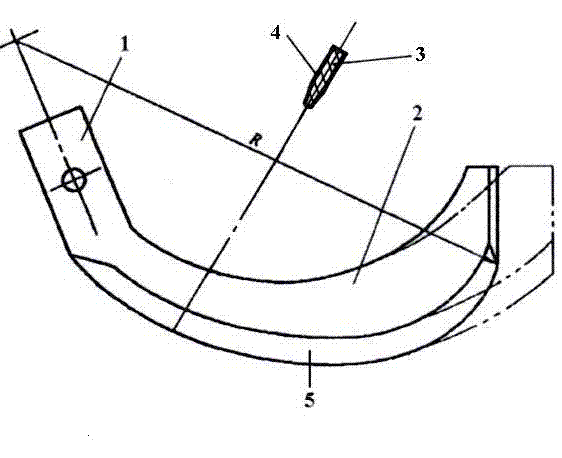

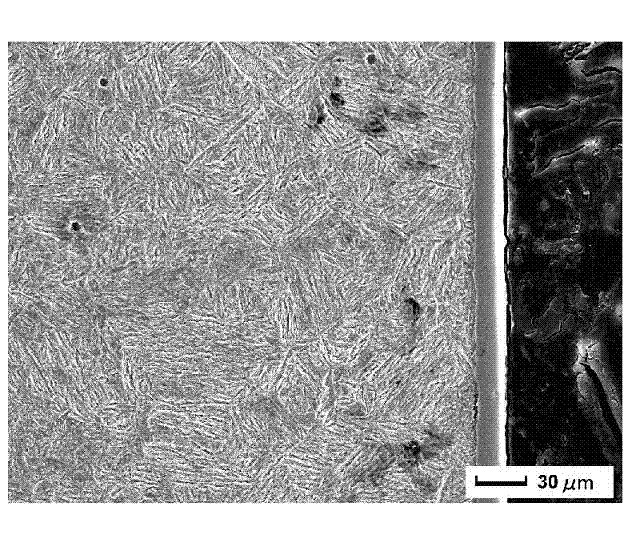

Re-manufacturable large tillage depth rotary tillage blade suitable for returning whole straws to field

The invention discloses a remanufacturable large tillage depth rotary tillage blade suitable for returning whole straws to a field. The blade provided by the invention is characterized in that the blade point rotation radius R is not less than 280 millimeters, and is manufactured through the following steps: firstly forging 65Mn or 60Si2Mn utilized as a raw material to obtain a blank satisfying the requirements on size and shape; then carrying out whole hot dipping on the blank; forming a hot-dipped hardened layer with the depth of 10-150 microns and the hardness no less than 1000HV to obtainan intermediate blank the whole surface of which is provided with the hardened layer; and thirdly, carrying out heat treatment on the intermediate blank the whole surface of which is provided with the hardened layer, wherein the heat treatment process comprises whole quenching and medium temperature tempering, so as to obtain a large tillage depth rotary tillage blade the center of which is tempering troostite and the surface of which is the hot-dipped hardened layer. The rotary tillage blade provided by the invention has the characteristics of high-strength surface, high tenacity, high strength, capability of ensuring the requirement on one-time continuous or 150-hour 20cm large tillage rotary tillage operation; and meanwhile, the rotary tillage blade can be repeatedly manufactured, thusgreatly lowering the comprehensive cost of the rotary tillage blade.

Owner:JIANGSU UNIV

Metal base CBN grinding wheel and manufacturing method thereof

PendingCN109877719AHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesGrinding wheelMetal

The invention discloses a metal base CBN grinding wheel and a manufacturing method thereof. The grinding wheel comprises a steel core and an abrasive ring; the abrasive ring is prepared by the following components in percentage by mass: 30-65% of CBN abrasive, 30-60% of metal bonding agent, and 5-15% of auxiliary bonding agent; and the metal bonding agent comprises the following components in percentage by mass: 50-60% of Cu powder, 30-45% of Sn powder, and 5-10% of Ti powder. The manufacturing method comprises the following steps: all the raw materials of the abrasive rings are uniformly mixed in proportion, and then, are uniformly mixed with the auxiliary bonding agent to dry as dried mixtures; the mixtures before drying are 90-95%; and the mixtures are sintered at corresponding temperature and time after screening and pressure molding, are cooled to discharge from a furnace, and are bonded with steel cores to prepare the metal base CBN grinding wheel. The grinding wheel is excellentin heat conductivity, and effectively enlarges the space for accommodating falling grains; the grinding wheel is high in grinding efficiency, low in grinding temperature, low in power loss, excellentin machining precision and long in service life; the method is short in sintering time; and the manufactured grinding wheel is sharp in grinding and high in grinding precision, and achieves self-sharpness.

Owner:NORTHEASTERN UNIV

Method for preparing novel antiskid adhesive tape

The invention discloses a method for preparing a novel antiskid adhesive tape. The preparation method comprises the following steps of: a) preparing a base material layer; b) selecting and preparing raw materials of an antiskid layer; c) coating the antiskid layer; d) coating an adhesive layer; and e) carrying out after-treatment on an adhesive tape. The invention discloses a preparation method of the novel antiskid adhesive tape. The preparation method is reasonable in working procedure arrangement, is simple and convenient to implement, and is moderate in cost; the adhesive tape is of a multi-layer composite structure and has high interlayer bonding intensity; the antiskid layer is a sand material coating, has a self-sharpening property in the using process, and effectively prolongs the service life of the adhesive tape; and the base material layer is made of an abrasion-resistant filter material, and the base material layer has favorable abrasion-resistant and anti-bacterial functions, and is high in intensity; and using performances of the adhesive tape are more excellent.

Owner:KUNSHAN HANBAO TAPE TECH

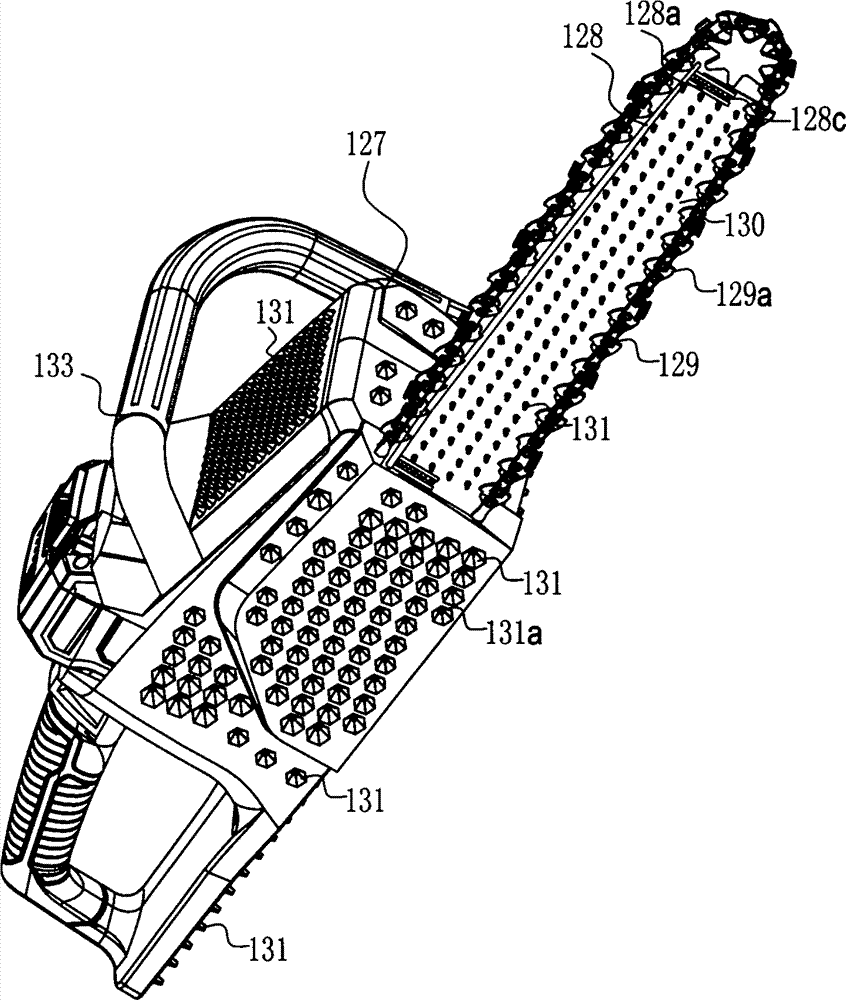

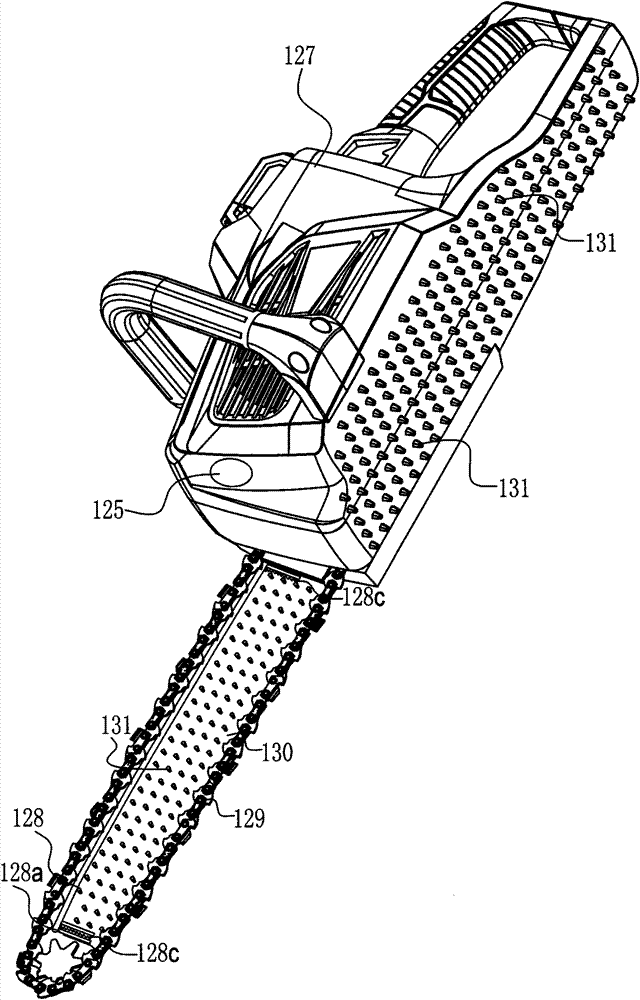

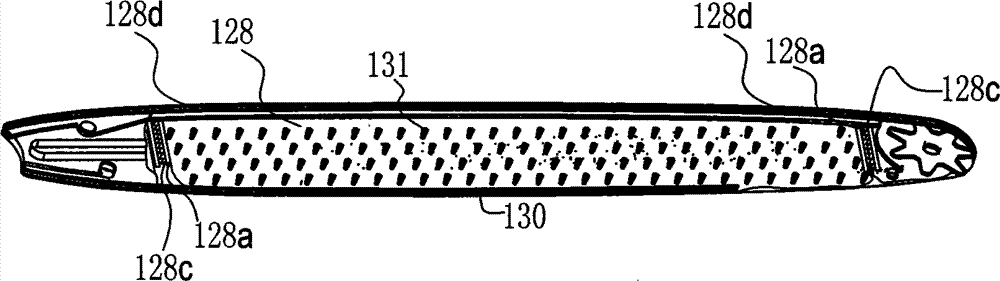

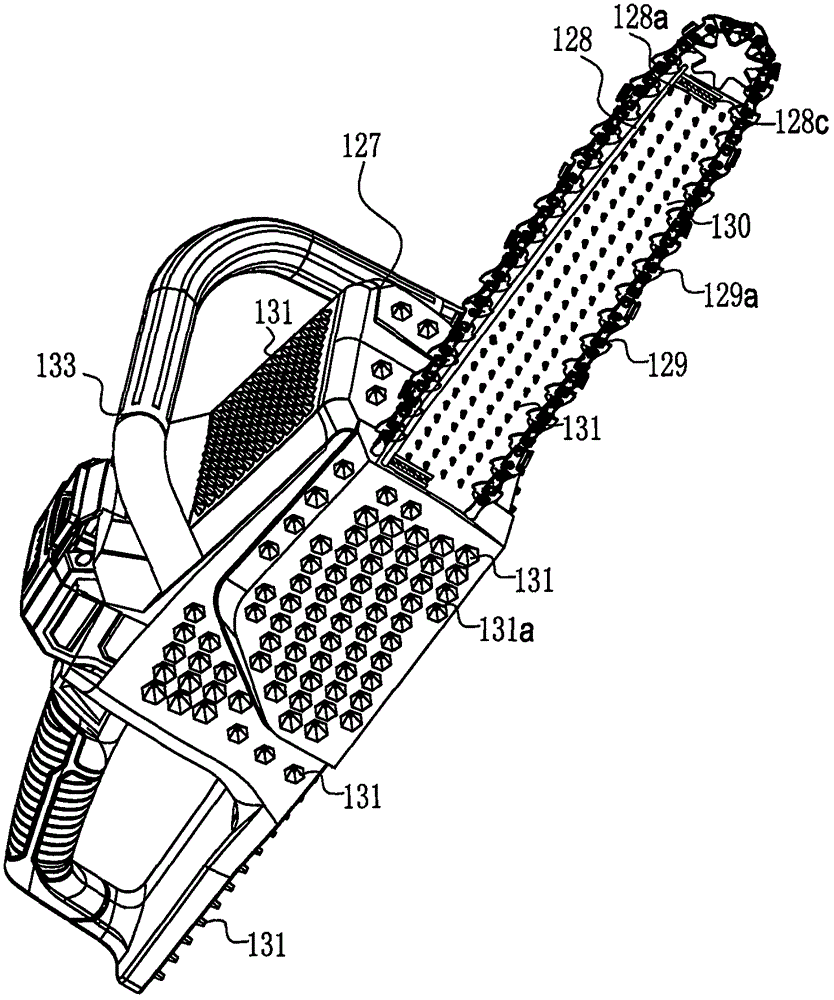

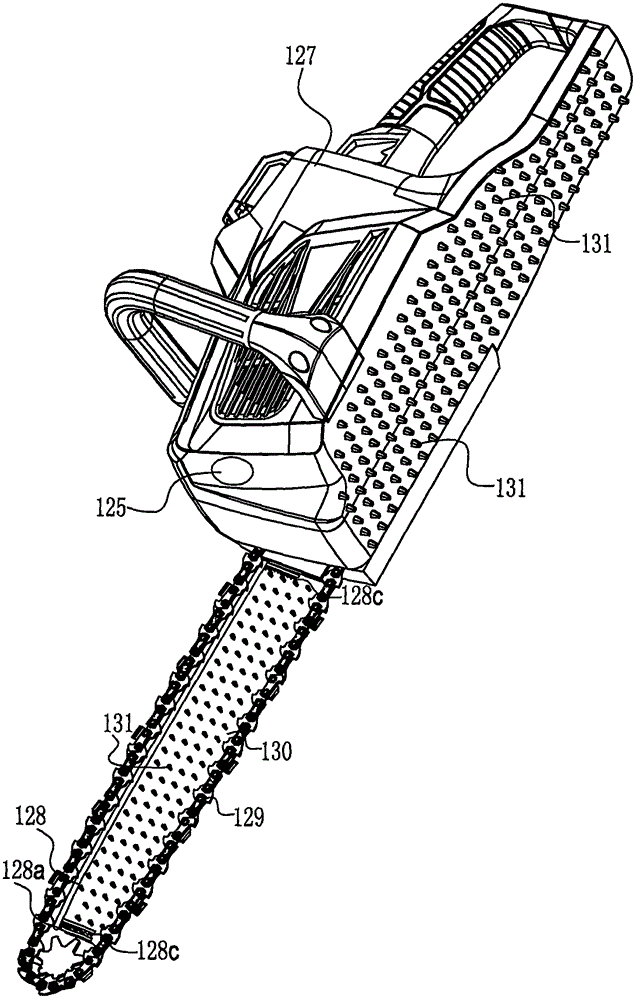

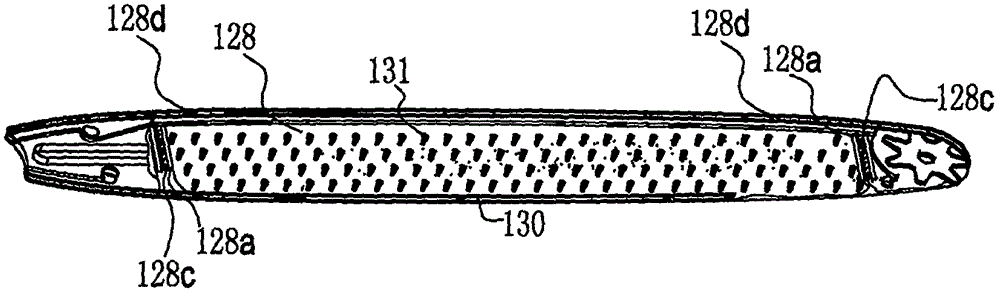

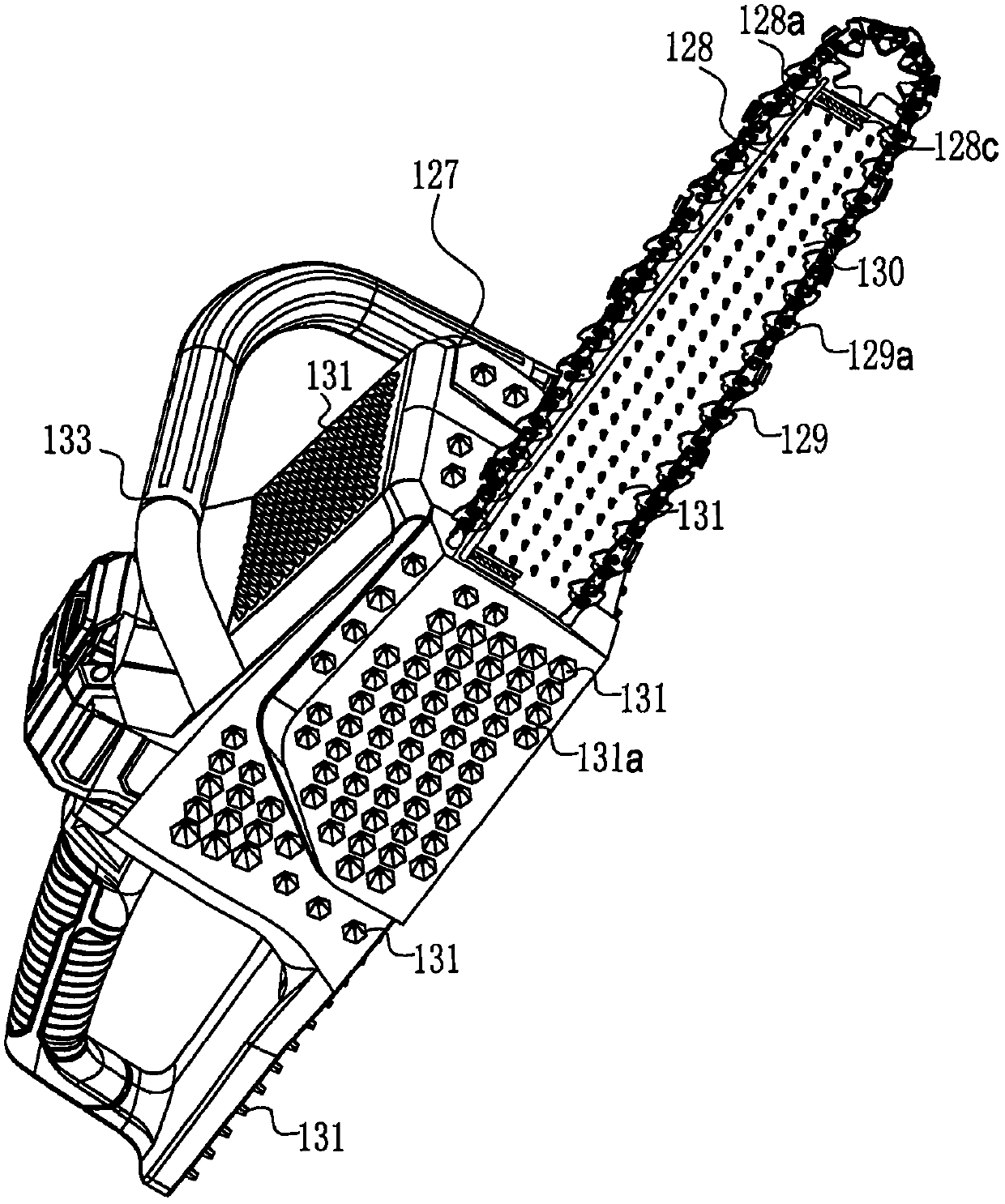

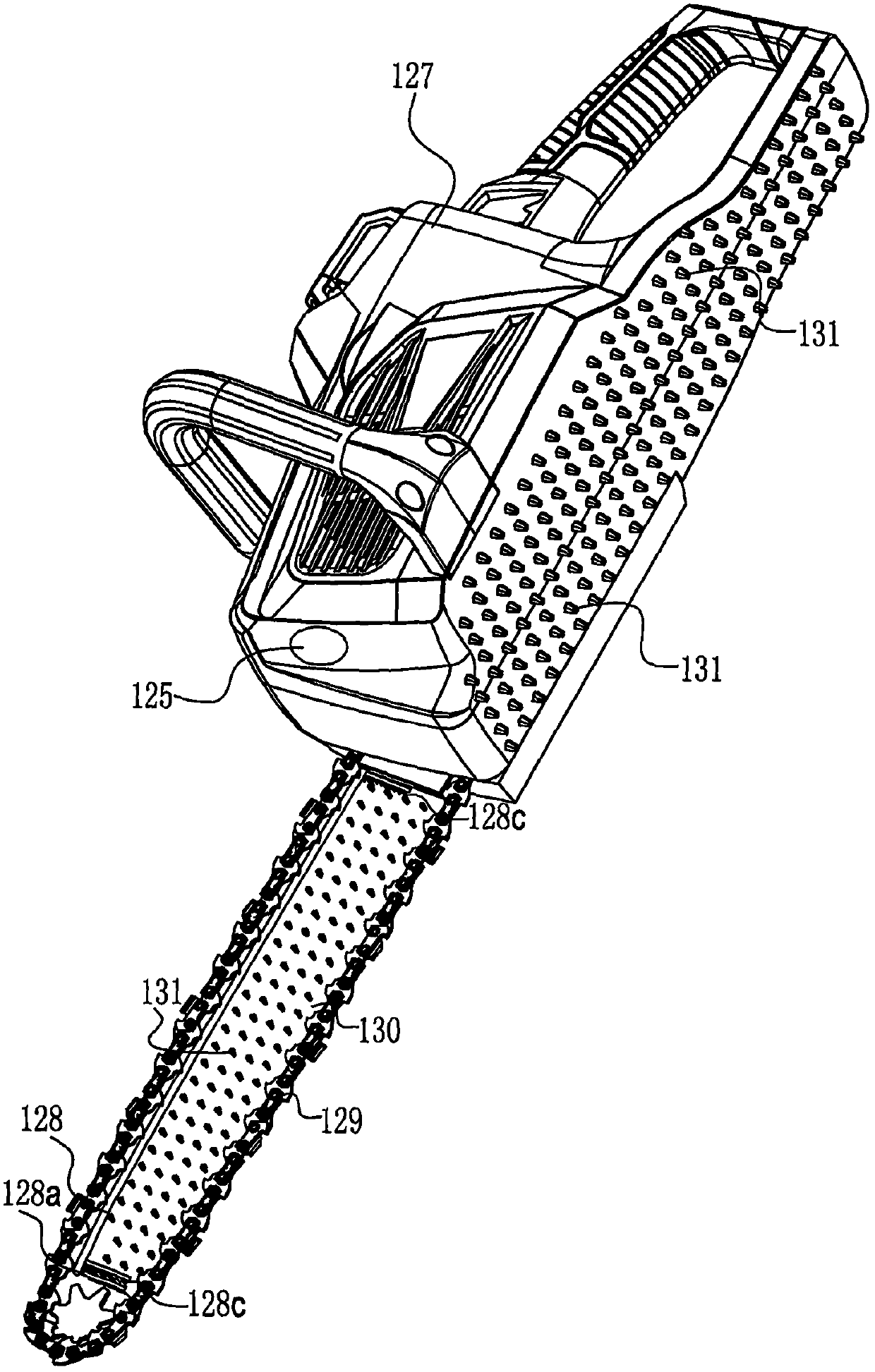

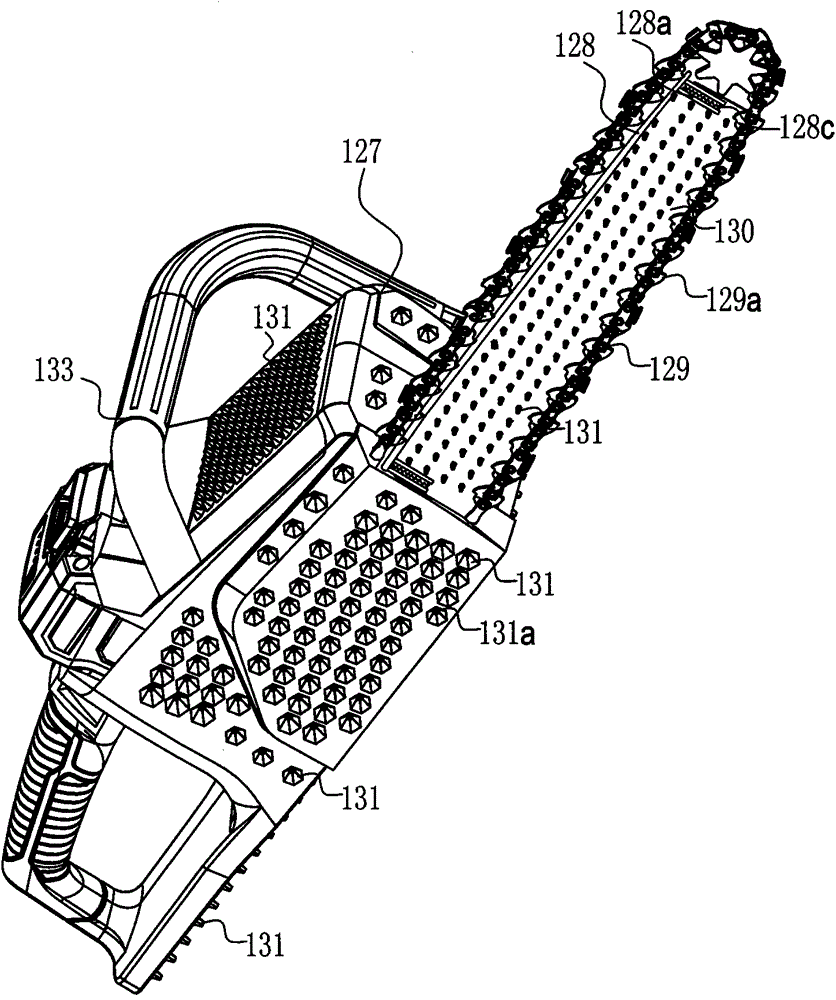

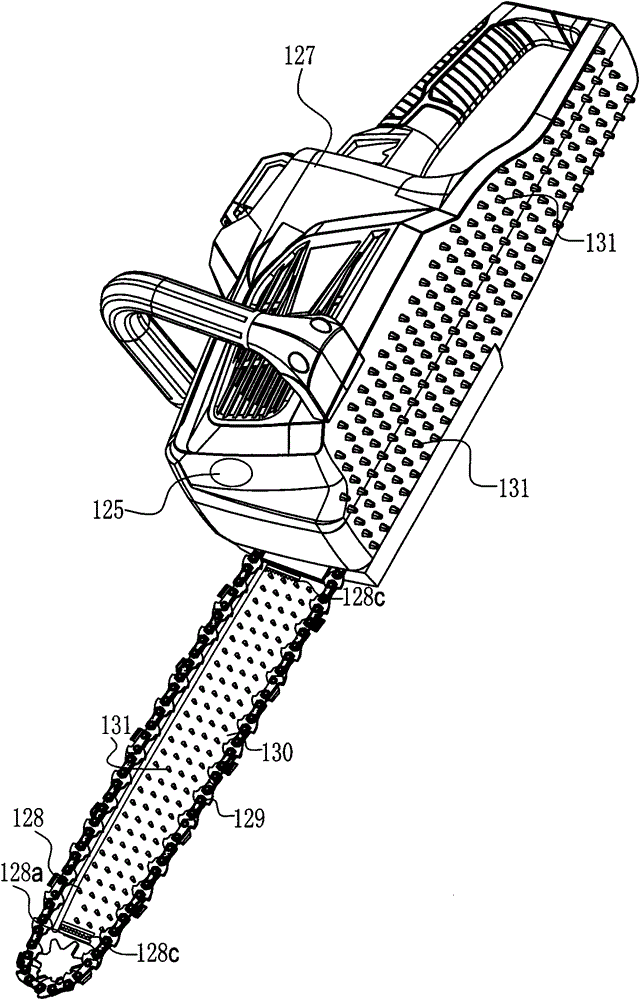

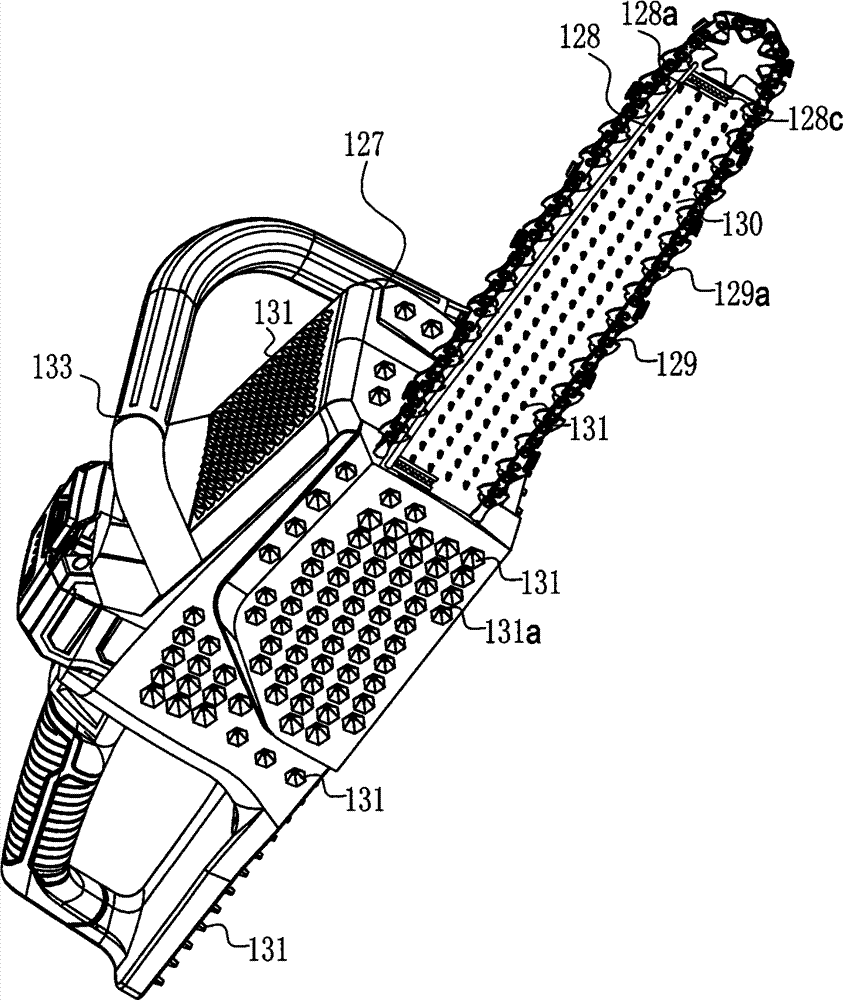

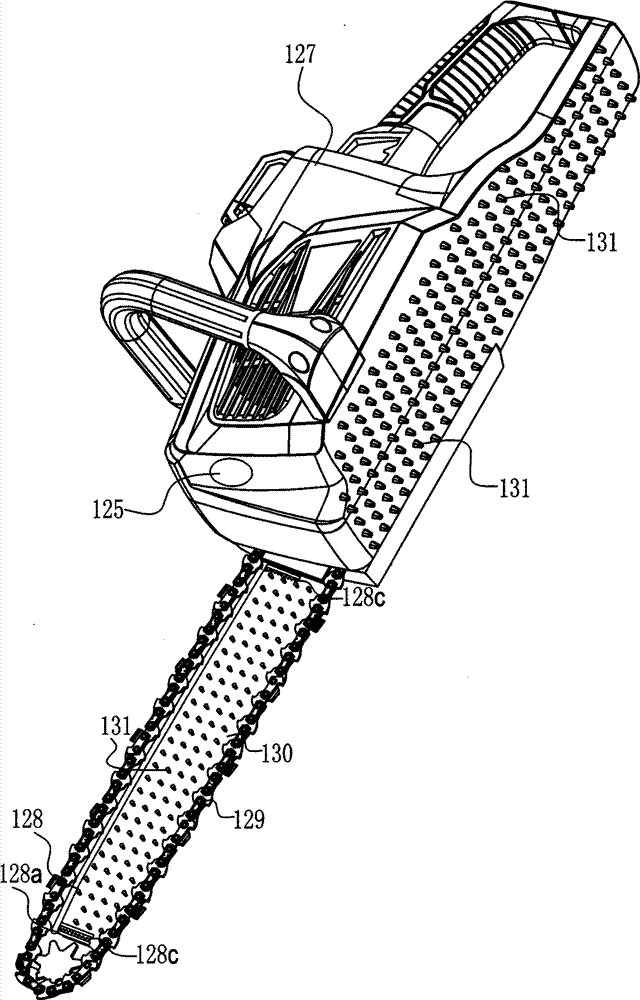

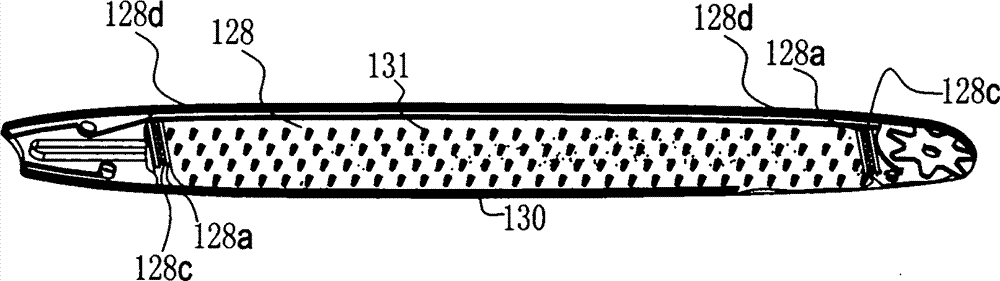

Lithium electric chain saw with conjugated arch back for autogenously grinding saw blade

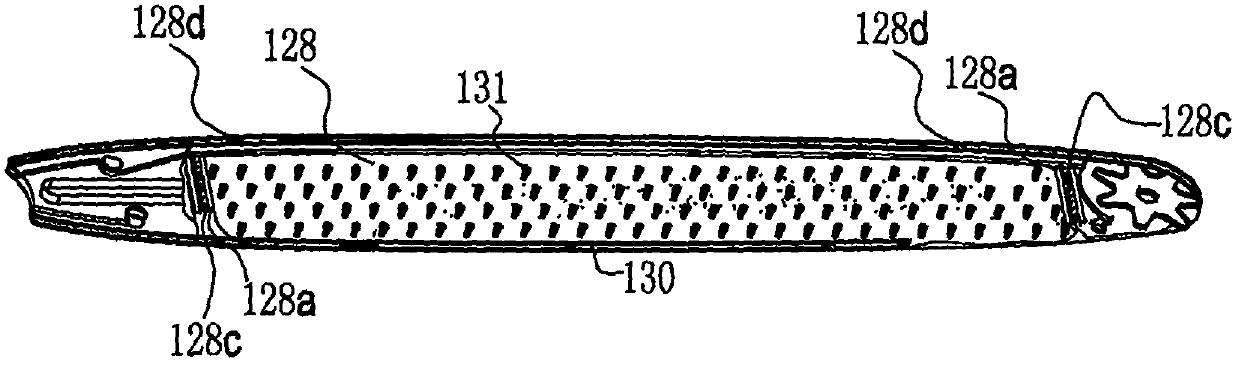

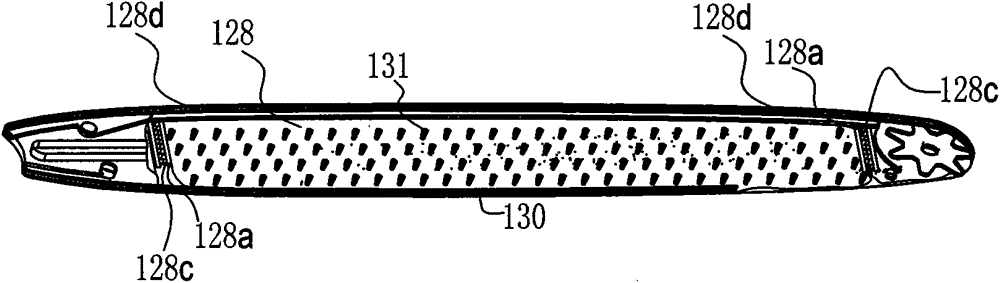

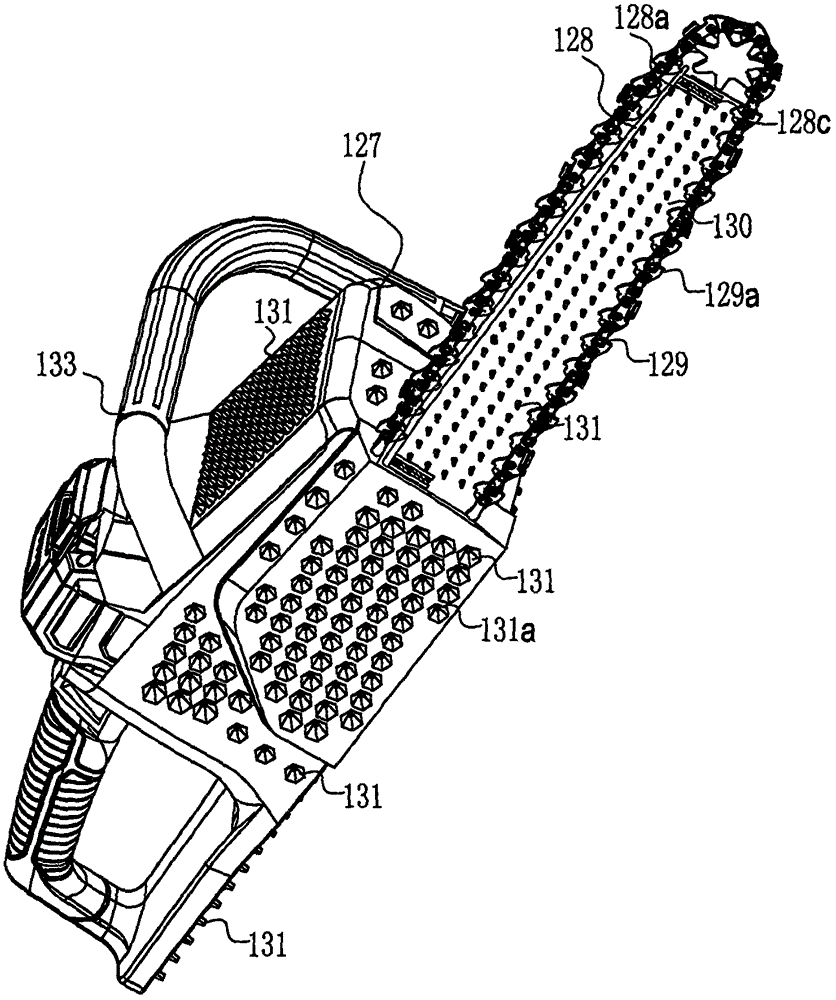

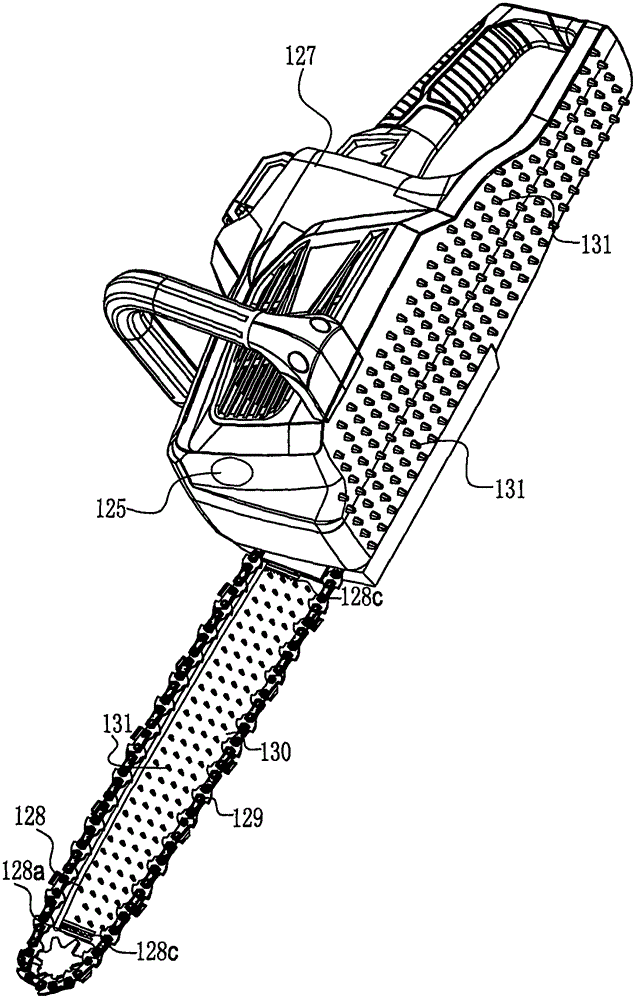

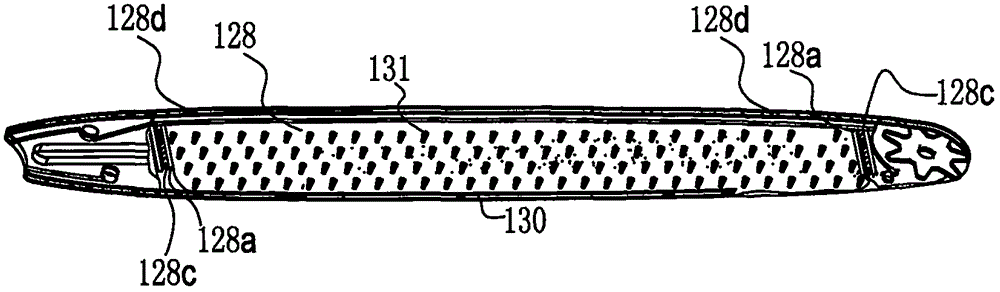

ActiveCN104206194AEasy to operate in batchesStrong penetrating powerCuttersCutting implementsLithiumSheet steel

The invention relates to a lithium electric chain saw with conjugated arch backs for autogenously grinding saw blades. The lithium electric chain saw comprises an arch back blade chain saw strip (129); the arch back blade chain saw strip (129) is provided with conjugated sharpened blade faces which are back to back and are respectively outward; each blade face of the arch back blade chain saw strip is formed by firstly stamping a steel plate into two bent faces which are at an included angle and are provided with arch backs and then sharpening the bent faces into blades; the outer profiles of both sides of each steel plate of the arch back blade chain saw strip are slightly of an equiangular spiral structure so as to form a chopping-cutting angle; each steel plate, of which the outer profiles of both sides are slightly of an equiangular spiral structure, of the arch back blade chain saw strip is blanked and is stamped and bent into two faces which are at an included angle and are provided with the arch backs and then the faces are simultaneously sharpened to form the blades so as to form a sliding-cutting angle; moreover, each two adjacent conjugated sharpened blade faces, which are formed at intervals and are back to back, of the arch back blade chain saw strip (129) are respectively sharpened outwards; the sharpened faces are in parallel to the saw-cutting faces of the chain saw strip in the rotating process, so that the lithium electric chain saw is beneficial to autogenous blade sharpening in the operation.

Owner:NINGBO DAYE GARDEN EQUIP

Ceramic matrix thermocompression impregnated honeycomb body diamond drill bit

InactiveCN107587845AImprove mechanical propertiesMake up for the defect of poor strengthDrill bitsSharpeningProtection layer

A ceramic matrix thermocompression impregnated honeycomb body diamond drill bit comprises a steel body and a working layer; a transition layer is arranged between the steel body and the working layer;and a honeycomb body serves as a framework of the working layer, the working layer contains ceramic matrix powder and diamond particles, and gate protection layers are arranged on two sides of the alloy steel honeycomb body. The alloy steel honeycomb body is put into a graphite die to serve as the drill bit matrix framework, then the evenly-mixed powder of the ceramic matrix and the diamond particles is put into the honeycomb body to serve as the working layer of the diamond drill bit, after the filling height reaches 70-80% the height of the honeycomb body, pure metal pre-alloyed powder is loaded as the transition layer, pressurization and compaction are conducted, and the steel body is erected and fixed on the transition layer; and after table pressing is finished, the product is put ona medium-frequency thermocompression sintering furnace for thermocompression and sintering, then cooling and planing of a gate slot are conducted, and the drill bit is obtained after being up to thestandards by detection. The working layer has brittleness, so that self sharpening and exposure of diamond in the drilling process are facilitated, the drilling efficiency is high, and the service life is long; and rock can be effectively incised and the problem of drilling slippage in a slipping formation is solved.

Owner:HUBEI CUG KINGROCK CEO TOOLS

Super-hard CBN grinding wheel and preparation method thereof

InactiveCN108818332AHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesGrinding wheelResin adhesive

The invention discloses a super-hard CBN grinding wheel and a preparation method thereof, and belongs to the field of super-hard abrasives. The grinding wheel comprises a steel core and an abrasive ring. The steel core and the abrasive ring are combined by a resin binder and a resin adhesive. The abrasive ring is prepared by a CBN abrasive, a metal bond and an auxiliary binder. The metal bond contains Cu60Sn40 powder and TiH<2> powder. The abrasive ring is composed of the CBN abrasive, the metal bond and pores. The preparation method comprises the steps that (1) the CBN abrasive, the Cu60Sn40powder and the TiH<2> powder are mixed to obtain a mixture A; (2) the auxiliary binder is mixed with the mixture A to obtain a mixture B; (3) the mixture B is dried; (4) the dried mixture B is sieved;(5) the sieved mixture B is subjected to cold press forming to obtain a green body of the abrasive ring; (6) the green body of the abrasive ring is sintered in an inert atmosphere and then cooled toobtain a blank of the abrasive ring; and (7) the blank of the abrasive ring is bonded to the steel core with the resin adhesive to obtain the super-hard CBN grinding wheel.

Owner:NORTHEASTERN UNIV

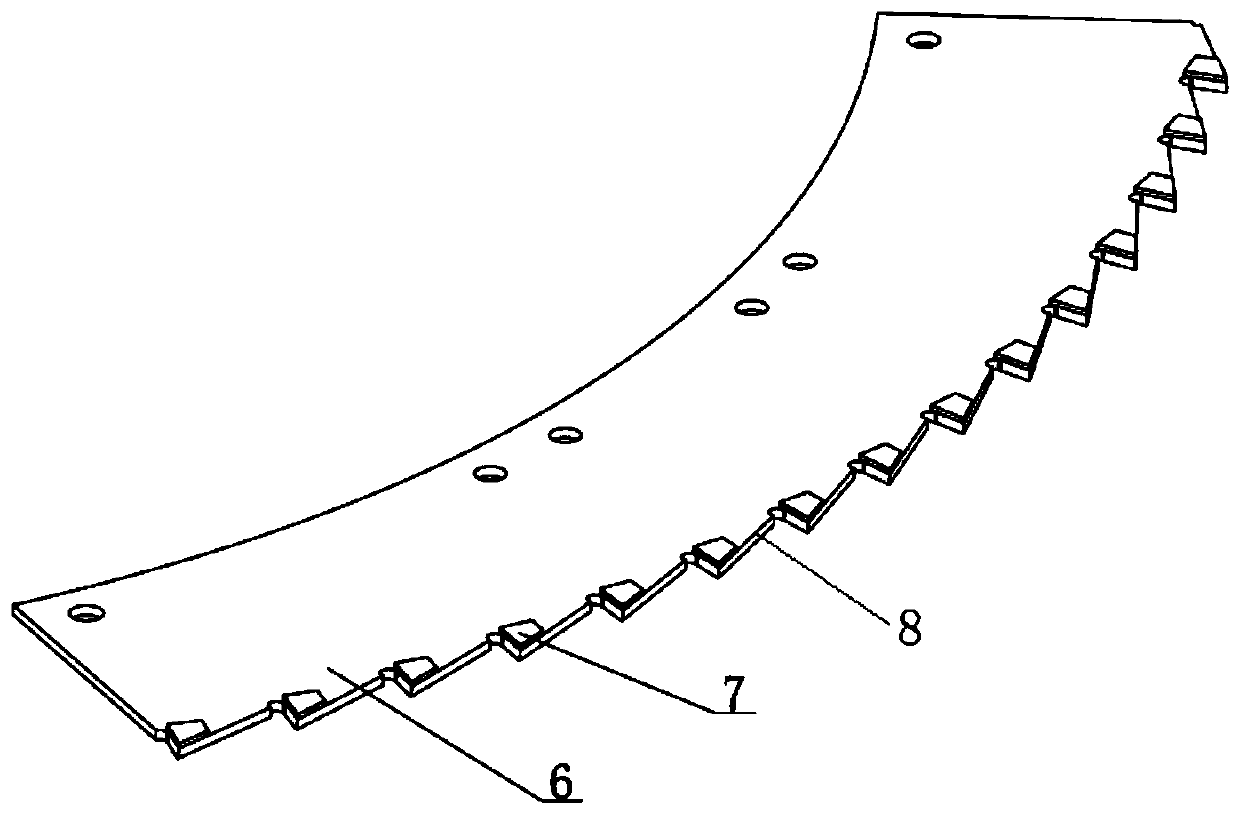

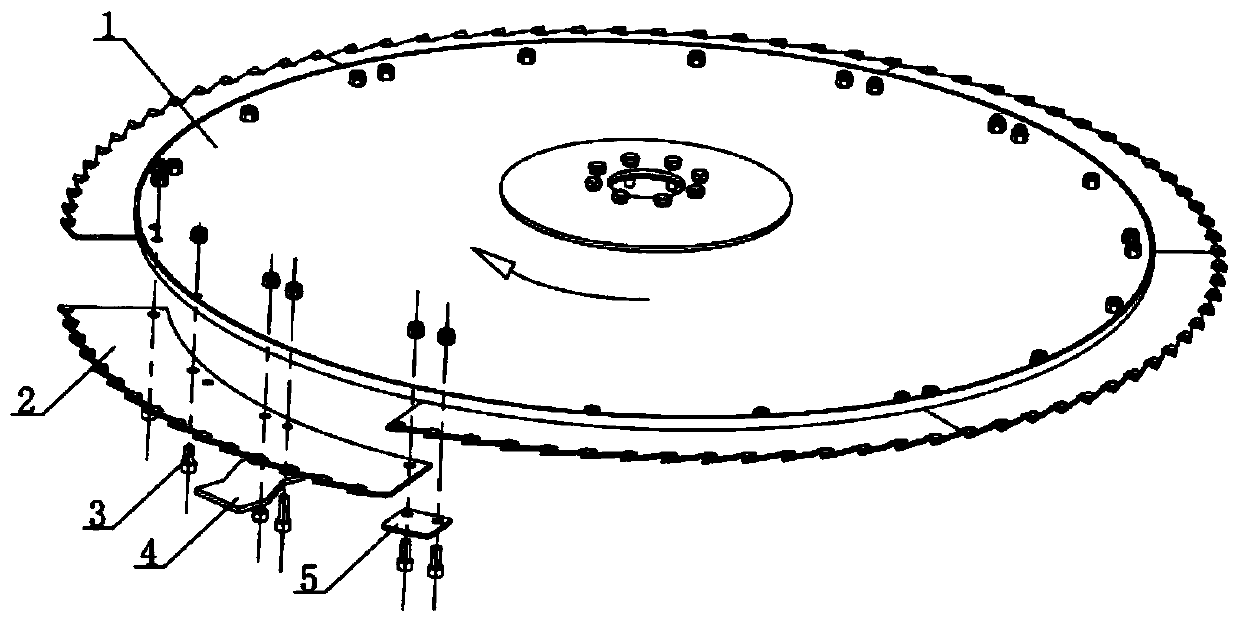

Silage maize harvester, and cutting tool and cutting cutterhead for silage maize harvester

The invention discloses a silage maize harvester, and a cutting tool and a cutting cutterhead for the silage maize harvester. The cutting tool comprises a cutting tool body in the shape of a fan ring.A toothed structure is arranged at the working end of the outer edge of the fan ring of the cutting tool body. A blocky cutting blade is arranged on the upper surface of the tip of each tooth of thetoothed structure, and the hardness of each cutting blade is greater than that of the cutting tool body to achieve automatic blade sharpening of the cutting tool during operation. During long-term operation of the cutting tool, the cutting tool body wears rapidly, the cutting blades wear slowly to naturally form cutting blades of cutting portions, and accordingly, automatic blade sharpening is achieved; the wear resistance and sharpness durability of the cutting tool are improved, and operation power consumption of the silage maize harvester is reduced.

Owner:SHANDONG ACADEMY OF AGRICULTURAL MACHINERY SCIENCES +1

Ultra-hard diamond grinding wheel and preparation method thereof

InactiveCN108789188AHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesMixed materialsResin bonding

The invention relates to an ultra-hard diamond grinding wheel and a preparation method thereof and relates to the field of super-hard abrasives. The grinding wheel comprises a steel core and an abrasive ring, and the steel core and the abrasive ring are combined through a resin bonding agent and a resin adhesive binding agent; the abrasive ring is prepared from diamond abrasives, a metal bonding agent and an auxiliary binding agent; the metal bonding agent contains Cu60Sn40 powder and Ti powder; and the abrasive ring is composed of diamond abrasives, a metal bonding agent and a pore. The preparation method includes the steps that firstly, the diamond abrasives, the Cu60Sn40 powder and the Ti powder are mixed uniformly, and a mixed material A is obtained; secondly, the auxiliary binding agent and the mixed material A are mixed, and a mixed material B is obtained; thirdly, the mixed material B is dried; fourthly, the mixed material B after being dried is subjected to sieving; fifthly, the mixed material B after being subjected to sieving is subjected to cold pressing and forming, and an abrasive ring green is obtained; sixthly, after the abrasive ring green is sintered in an inert gas atmosphere, an abrasive ring green body is obtained; and seventhly, the abrasive ring green body and the steel core are glued through the resin adhesive binding agent, and the ultra-hard diamond grinding wheel is obtained.

Owner:NORTHEASTERN UNIV

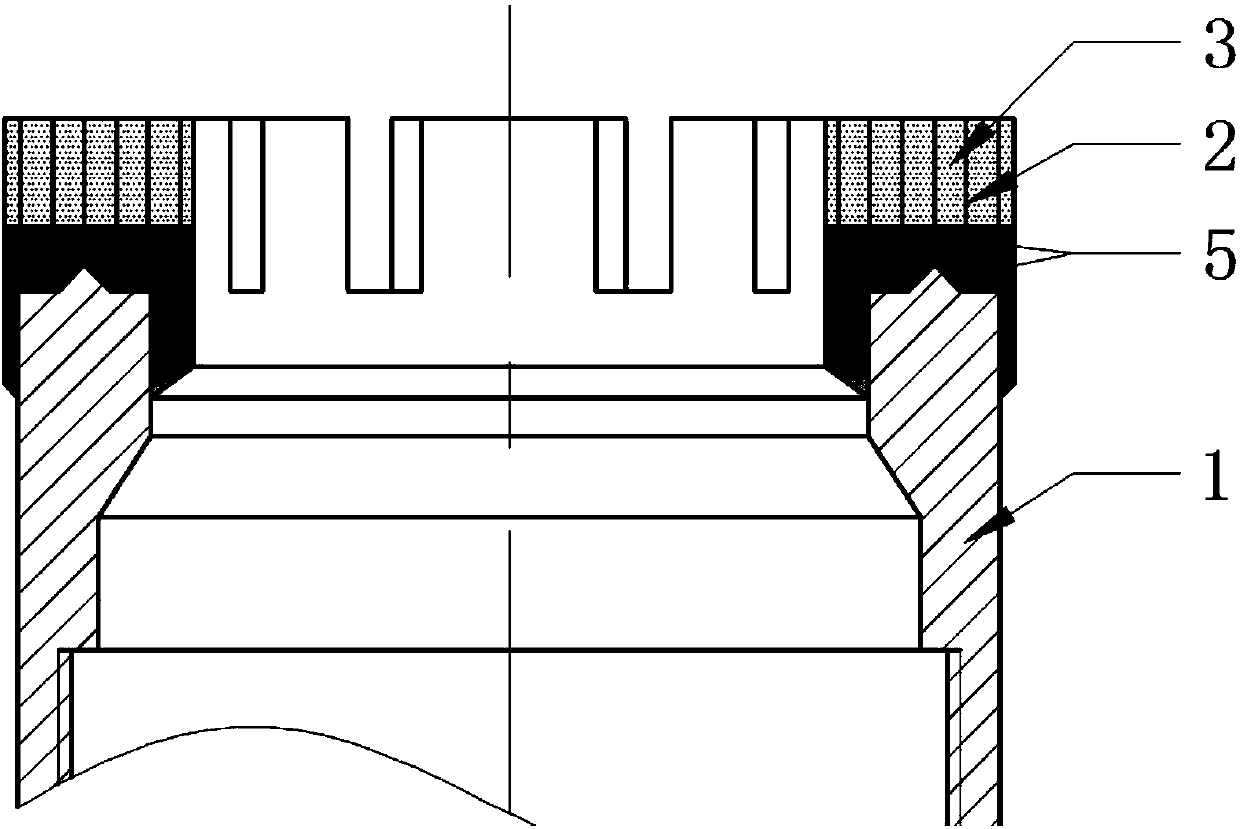

Internal connection mechanism of lithium battery box

The invention provides an internal connection mechanism of a lithium battery box. Any large-current lead wire, which easily generates heat, does not exist among twenty lithium batteries arranged in the internal connection mechanism; and six positive electrode connection plates of a lithium battery and a plurality of connection plates of an eleventh negative electrode plate of the lithium battery are connected with a lithium battery socket at the outer part of the lithium battery to form a lithium battery box which is arrayed in sequence and is durable and reliable. Pressing joint contacts of the internal connection mechanism of the lithium battery box are provided with grooves and the grooves are characterized in that one straight groove is connected with two symmetrical arc-shaped grooves to form two bulges; and two through holes are formed in each bulge so as to form the pressing joint contact. The material is an elastic plate subjected to normalization treatment or a titanium memory alloy.

Owner:NINGBO DAYE GARDEN EQUIP

Lithium Electric Chainsaw with Lithium Battery Box

ActiveCN106025124BEasy to operate in batchesSelf-sharpeningCell component detailsThermodynamicsEngineering

The internal connection mechanism of the lithium battery box, without any high-current wires that are prone to heat, is composed of the six anode connecting plates of the lithium battery and multiple connections to the eleventh negative connecting plate of the lithium battery. The connecting plate is connected with the lithium battery socket outside the lithium battery to form an orderly and durable lithium battery box. The crimping contact of the internal connection mechanism of the lithium battery box is provided with a groove, and the groove is connected with two symmetrical arc grooves by a straight groove to form two protrusions, and two protrusions are respectively arranged on the protrusions. A through hole to form a crimp contact. The material is elastic plate which has been heat treated by normalizing or titanium memory alloy.

Owner:NINGBO DAYE GARDEN EQUIP

A kind of diamond grinding wheel and preparation method thereof

ActiveCN108818329BHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesResin adhesiveMetal binding

A diamond grinding wheel and its preparation method, belonging to the field of superabrasives; the grinding wheel includes a steel core and an abrasive ring. The steel core and the abrasive ring are bonded by a resin bonding agent. The abrasive ring is composed of diamond abrasives, metal bonding agents and auxiliary agents. It is prepared from a binder; the metal binder contains Cu powder and Ti powder; the abrasive ring is composed of: diamond abrasive, metal binder and pores; preparation method: 1) Mix the diamond abrasive, Cu powder and Ti powder evenly to obtain a mixture Material A; 2) Mix the auxiliary binder and Mixture A evenly to prepare Mixture B; 3) Dry Mixture B; 4) Sieve the dried Mixture B; 5) Sieve the The final mixture B is cold-pressed and formed; 6) The green abrasive ring is sintered under an inert gas atmosphere to obtain the abrasive ring body; 7) Use a resin adhesive binder to combine the abrasive ring body with the steel core Bonding to produce a diamond grinding wheel.

Owner:NORTHEASTERN UNIV LIAONING

Re-manufacturable large tillage depth rotary tillage blade suitable for returning whole straws to field

InactiveCN102224773BCut soil sharpReduce resistanceTilling equipmentsTemperingAgricultural engineering

A remanufacturable large-plow deep-plow rotary tiller suitable for full straw returning to the field is characterized in that its turning radius R of the knife tip is not less than 280 mm, and it is manufactured by the following method: first, use 65Mn or 60Si2Mn As a raw material, a billet that meets the size and shape requirements is obtained by forging; then, the obtained billet is subjected to an overall hot-impregnation treatment, and a layer of hot-dipping hardened layer with a depth of 10-150 microns and a hardness of not less than 1000HV is formed on the billet surface as a whole. Obtain an intermediate blank with a hardened layer on the entire surface; thirdly, heat treat the intermediate blank with a hardened layer on the entire surface. The heat treatment process is overall quenching+medium temperature tempering, so that the core is tempered troostite and the surface is hot. Deep tillage rotary blade for impregnating the hardened layer. The rotary tiller of the present invention has the characteristics of high hardness on the surface, high toughness and high strength of the core, which can meet the needs of a continuous or accumulated 150 hours of rotary tillage operations with a large depth of tillage (>20cm); at the same time, the rotary tiller of the present invention can be repeated Manufacturing greatly reduces the overall cost of the rotary tiller.

Owner:JIANGSU UNIV

Punching head and manufacturing method thereof and composite small grinding head

PendingCN111152129AIncrease the cross-sectional areaHigh strengthGrinding machine componentsGrinding devicesPowder mixturePunching

The invention relates to a punching head and a manufacturing method thereof and a composite small grinding head. The manufacturing method comprises the following steps that a sintering body powder mixture is compressed through a mold and two flaky pressing heads, lateral pressing is carried out on the sintering body powder mixture; and the sintering body powder mixture is pressed into a powder metallurgy sintering body of a cuboid structure; and the upper end of the powder metallurgy sintering body is machined to be of a cylindrical structure, the lower end of the powder metallurgy sintering body is machined to be of a hemispheric structure, and the punching head is obtained. According to the punching head, the pressing strength can be greatly improved, the portion causing the insufficientdensity of the sintering body due to pressure losses caused by a mold clearance can be located at a corner and is finally cut off, and the quality of the punching head is ensued; and by means of a laser welding manner, the punching head and a grinding head base are solidified, the punching head achieving high-strength connection can be obtained, and the composite small grinding head is manufactured.

Owner:宋京新 +1

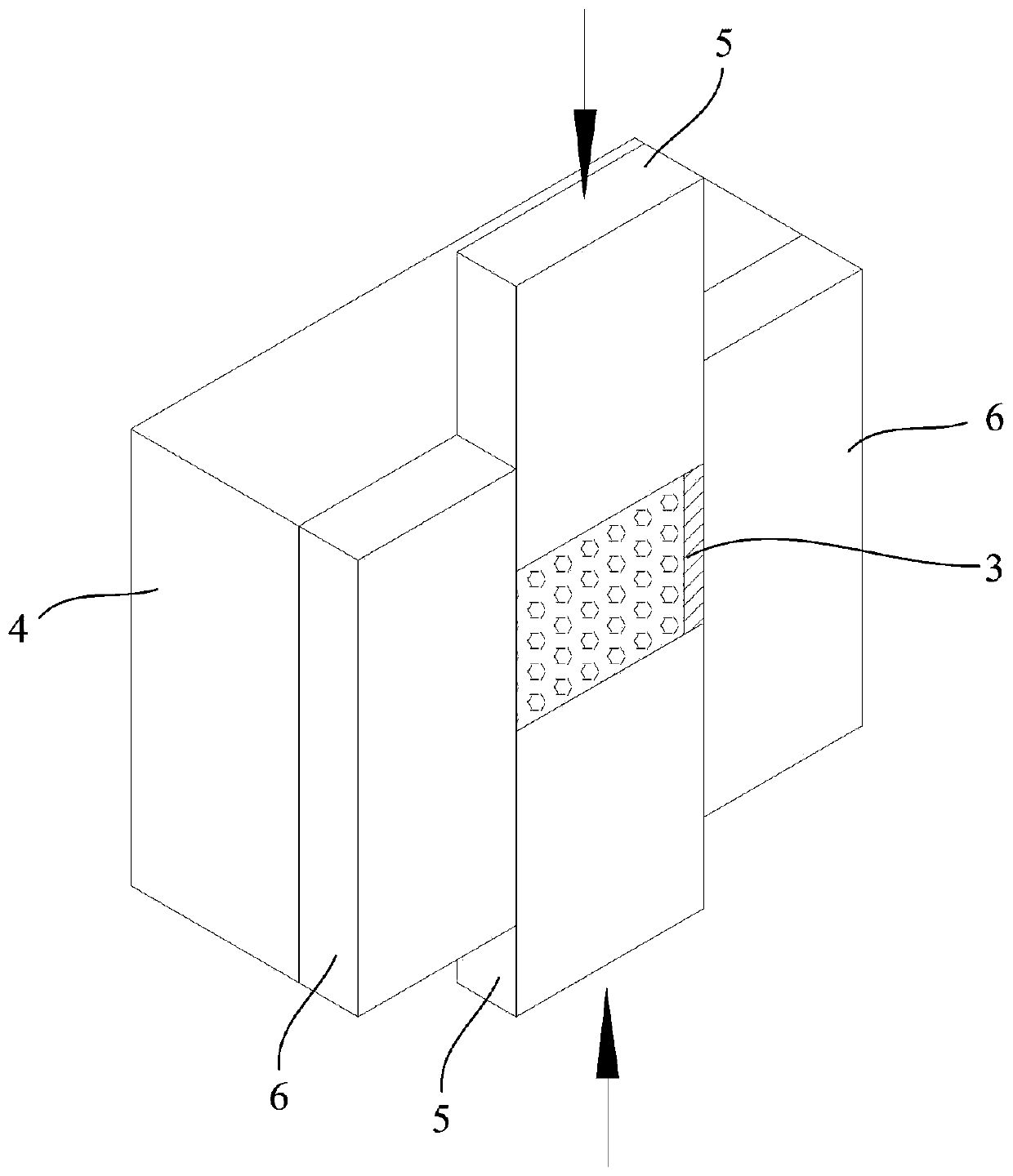

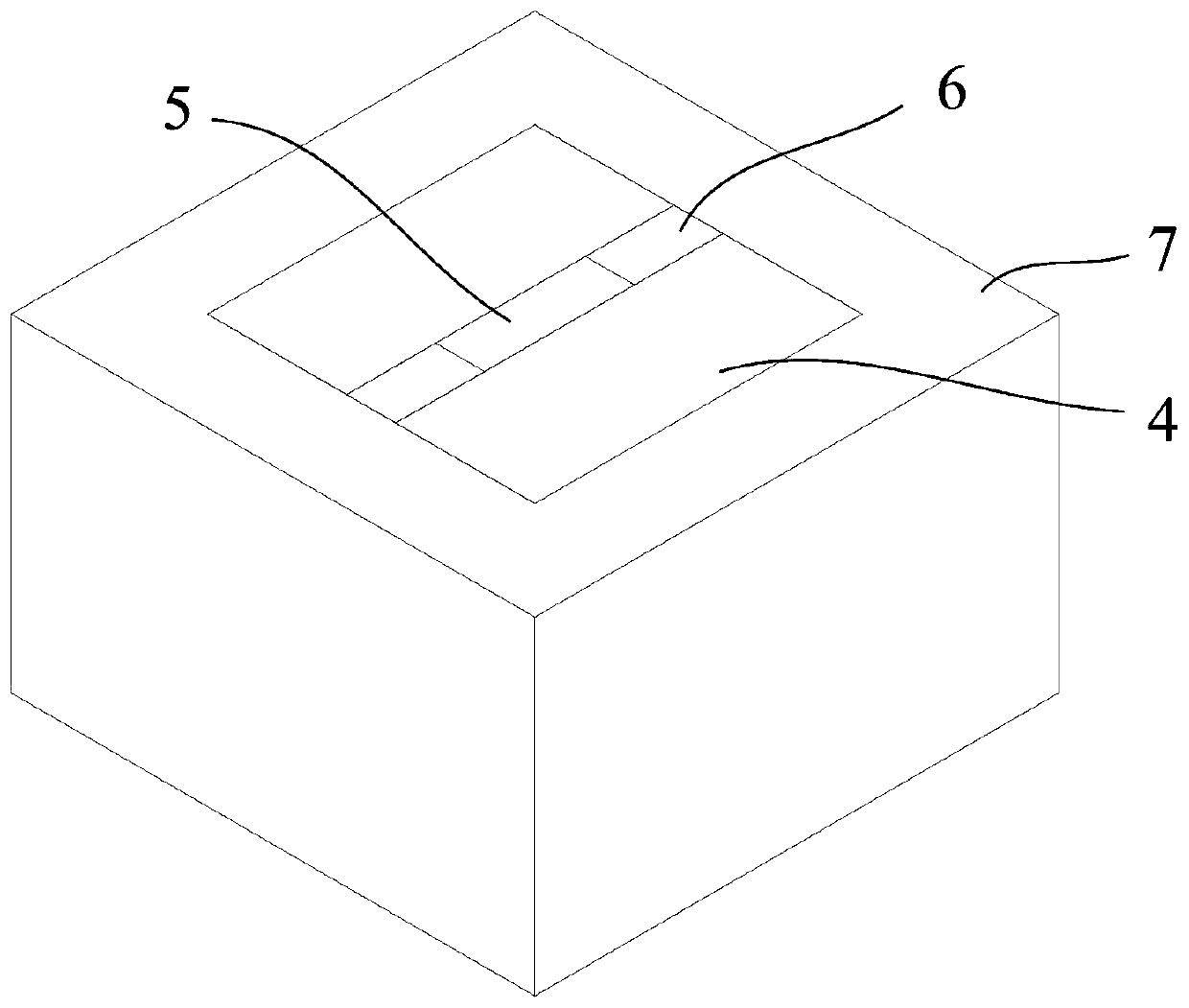

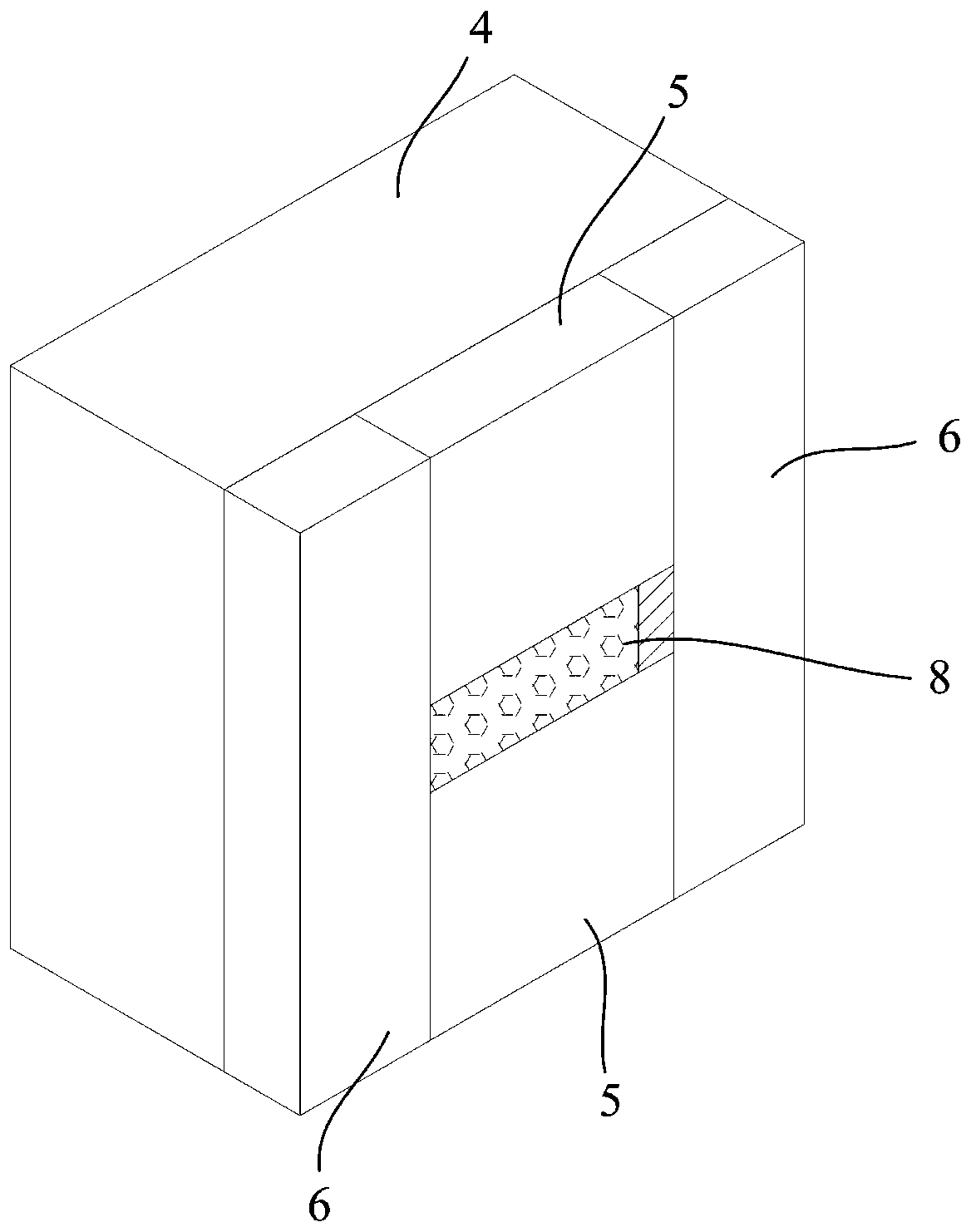

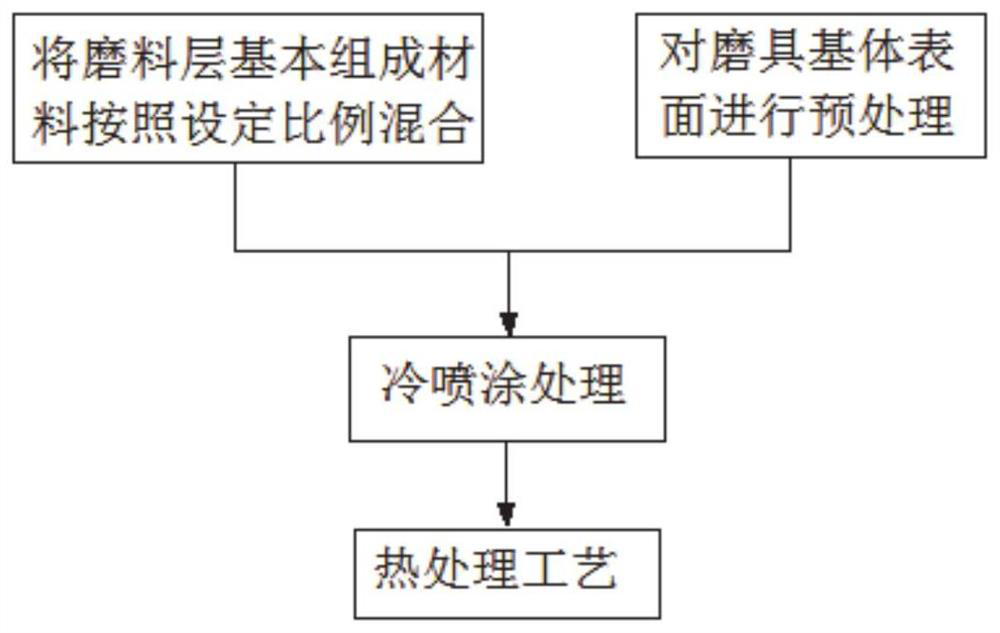

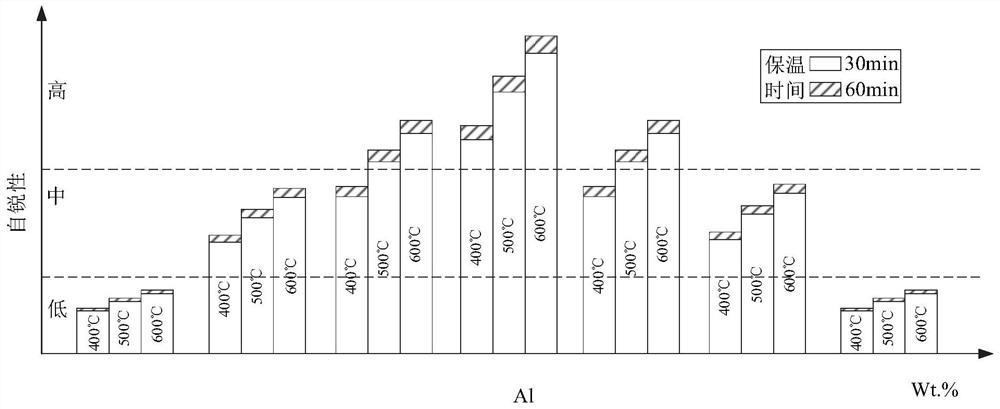

Preparation process of self-sharpening metallic bond diamond abrasive layer

ActiveCN113927495ASimple and controllable preparationEasy to operateAbrasion apparatusGrinding devicesMetal bindingAbrasive

The invention discloses a preparation process of a self-sharpening metallic bond diamond abrasive material layer, and belongs to the technical field of abrasive tool processing. According to the technical scheme, basic composition materials of the abrasive material layer are mixed according to a set proportion; the surface of an abrasive tool base body is pretreated, and the mixed materials are sprayed to the pretreated surface of the abrasive tool base body through cold spraying to form the abrasive material layer; and the gap and pore content of a hard and brittle intermetallic compound generated in the abrasive material layer is controlled through a heat treatment process, and the abrasive material layer with the controllable self-sharpening performance is obtained. The abrasive material layer has controllable self-sharpening performance, good mechanical performance and a long service life, the manufacturing process is simple, and efficiency is high.

Owner:SHANDONG UNIV

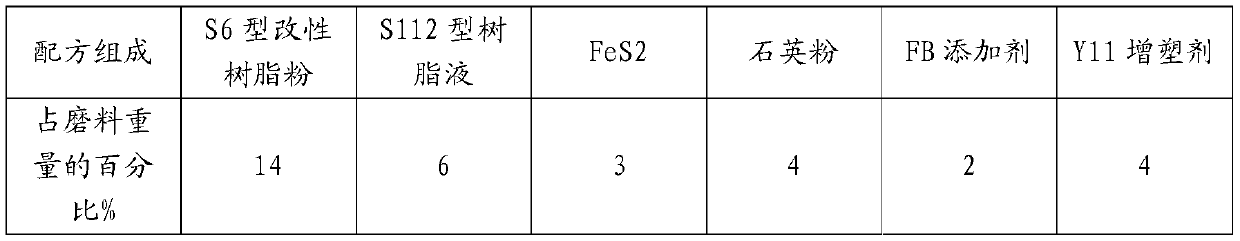

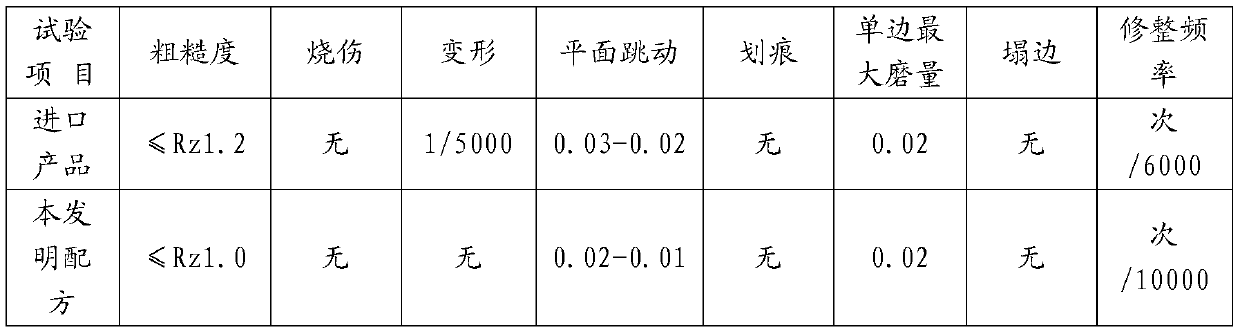

Special formula of grinding wheel for grinding automobile piston ring

The invention discloses a special formula of a grinding wheel for grinding an automobile piston ring. Adopted grinding materials comprise, 20% of 45A grinding materials of the F16 grain size, 60% of SSA grinding materials of the F16 grain size and 20% o f 31C grinding materials of the F24 grain size (the sum of the volumes of all the grinding materials is 100%). According to the further improvement, an adopted binder is composed of 12.5% of Y1 type resin powder, 4% of S6 type resin liquid, 0.5% of an M accelerant, 2% of a B enhancer, 3% of cryolite, 6% of gypsum powder and 15% of a pore forming material. By means of the special formula, the grinding yield is high, the grinding wheel dressing frequency is low, the spring surface machining quality is high, and the percent defective is low.

Owner:江苏三锐研磨科技有限公司

A kind of preparation technology of multi-layer structure 3D abrasive tool

The invention relates to the technical field of grinding tools, in particular to a preparation process of a multilayer-structured 3D grinding tool. The preparation process comprises the steps of: (1)coating of a primer on an elastic membrane; (2) pressing of a square frame; (3) scraping of an abrasive; (4) primary curing of the abrasive; (5) stamping; (6) mold shifting and curing; and (7) compounding of a sponge layer. The multilayer-structured 3D grinding tool is prepared by the preparation process of the multilayer-structured 3D grinding tool; an abrasive layer achieves self sharpness; in the grinding process, abrasive grains can fall layer by layer; and new abrasive grains are exposed constantly after falling, so that the grinding force is stable. In addition, in the prepared multilayer-structured 3D grinding tool, a groove is formed in the middle part of the abrasive layer, so that abrasive chips generated in the grinding process can be easily discharged from the groove, and the blockage problem of the abrasive chips can be prevented; and the prepared multilayer-structured 3D grinding tool is particularly suitable for a wet grinding procedure.

Owner:DONGGUAN GOLDEN SUN ABRASIVES

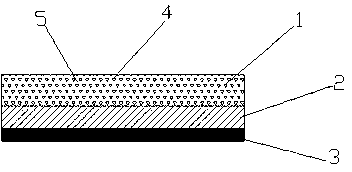

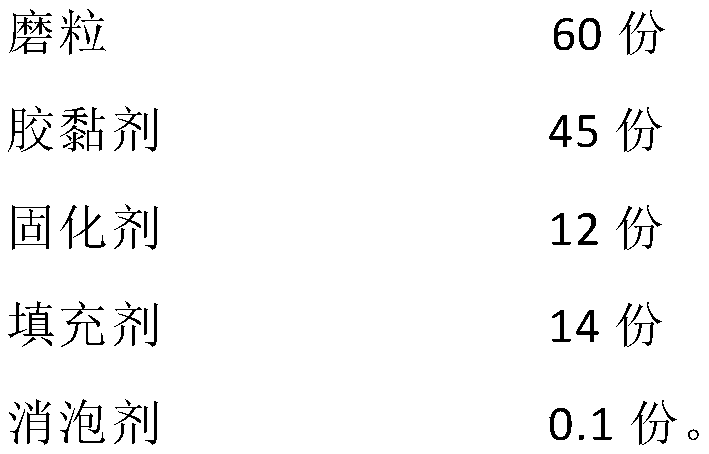

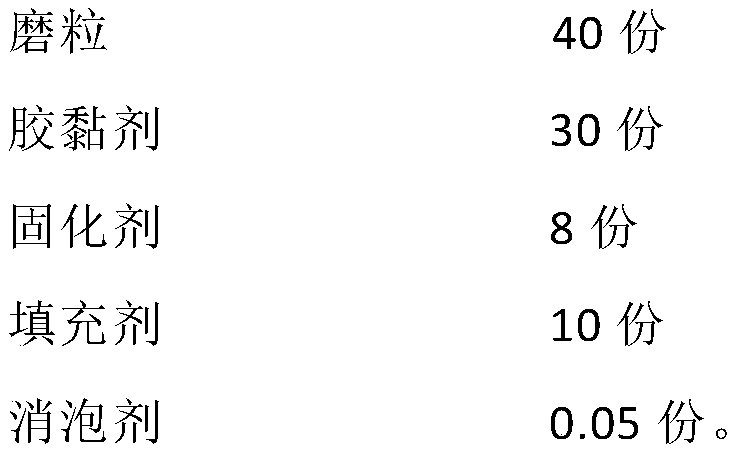

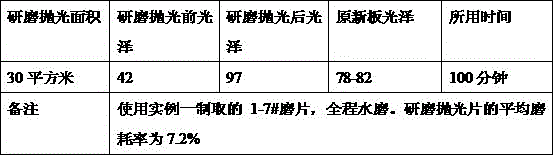

Preparation method of polyurethane matrix stone grinding and polishing sheet

ActiveCN106272125BGood self-sharpeningImprove grinding effectAbrasion apparatusGrinding devicesSilicon oxideHardness

A polyurethane matrix stone grinding and polishing pad and a preparation method thereof. The stone grinding and polishing pad relates to a novel stone grinding and polishing material made by preparing a polyurethane matrix and mixing therewith synthetic diamond powder, silicon carbide, silicon oxide, aluminum oxide, and a zinc oxide ultrafine powder as abrasive components. A density of the stone grinding and polishing material is 0.1 to 0.5 g / cm3, and a Shore A hardness thereof is 30 to 85. The polyurethane matrix has suitable foam walls and holes, and abrasive particles are mixed therein and distributed in a multi-dimensional structure of the polyurethane foam wall. The surface of a stone is ground under pressure and rotation of grinding equipment, while simultaneously, continuously and regularly releasing new sharp abrasive particles having a working face at a different layer. The abrasive particles have better self-sharpening performance, and thus have a higher grinding effect and efficiency.

Owner:王建秋

A kind of bronze-based cbn grinding wheel and preparation method thereof

ActiveCN108818331BHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesResin adhesiveGrinding wheel

Owner:NORTHEASTERN UNIV LIAONING

Novel anti-skid adhesive tape

InactiveCN107236481AHigh bonding strengthExtended service lifeFilm/foil adhesivesPolyurea/polyurethane coatingsWear resistantComposite structure

The invention discloses a novel anti-skid adhesive tape. The tape comprises an antiskid layer, a base material layer and a viscose layer, wherein the antiskid layer and the viscose layer are formed on two sides of the base material layer respectively, the base material layer is wear-resistant fiber fabric, the antiskid layer is prepared from main components in percentage as follows: 40%-50% of sand and 50%-60% of filler, raw materials of the antiskid layer are formed on the base material layer with a coating technology, and strong viscose is selected for the viscose layer. The novel anti-skid adhesive tape adopts multilayer composite structure design and has high interlayer bonding strength, the antiskid layer is a sand coating and has self-sharpening performance during usage, and the service life of the tape is effectively prolonged; meanwhile, the base material layer is made of wear-resistant fiber and has high strength and has good corrosion resistance and antibacterial performance, so that the tape has excellent use performance.

Owner:苏州沃古斯电子商务有限公司

A metal bonded diamond grinding wheel

ActiveCN106625296BHigh thermal conductivityReduce grinding temperatureAbrasion apparatusGrinding devicesSuperhard materialResin adhesive

The invention relates to the field of superhard materials, in particular to a diamond grinding wheel which is excellent in impact resistance and shape retention, can bear higher load during a high-speed grind process, and comprises a steel core and an abrasive material ring adhered together through a resin adhesive; the abrasive material ring is characterized by being prepared from the following raw materials in mass percent: 25-50% of diamond abrasive material, 44-72% of a metallic bond and 3-6% of an auxiliary adhesive. The diamond grinding wheel has excellent heat conductivity to facilitate reduction of grinding temperature so as to reduce power loss and increase grinding speed; the auxiliary adhesive in the formula facilitates formation of pores, and the characteristic of high holding force of the metallic bond is combined, so that the chip space can be effectively increased, and the utilization of the abrasive material is more sufficient; and the grinding wheel has the characteristics of high grinding efficiency, low grinding temperature and power loss, high machining precision and long service life.

Owner:磐维科技(青岛)有限公司

Non-burning decorative glaze for building exterior walls, and preparation method thereof

The invention discloses a non-burning decorative glaze for building exterior walls, and a preparation method thereof. The glaze comprises ultrafine ordinary Portland cement, emery, nano-silica, redispersible latex powder, a superplasticizer FDN, calcined gypsum, alum powder, a natural mineral pigment, lithium carbonate, calcium lignosulphonate, a film forming aid, ethylene glycol, a defoamer and water. Compared with existing real stone paints and coatings, the non-burning decorative glaze for building exterior walls has the advantages of good fireproof property, good acid and alkali resistance, non-toxicity, tastelessness, high strength, high hardness, high tensile bonding strength, richness in color, strong adhesion ability, no sand drop, low construction environment requirements, fast solidification speed, long service life, no whitening or yellowing and no soft coating layer, can replace the novel building exterior wall non-burning decoration glazes of the existing real stone paints, and has great economic and social benefits.

Owner:HENAN POLYTECHNIC UNIV

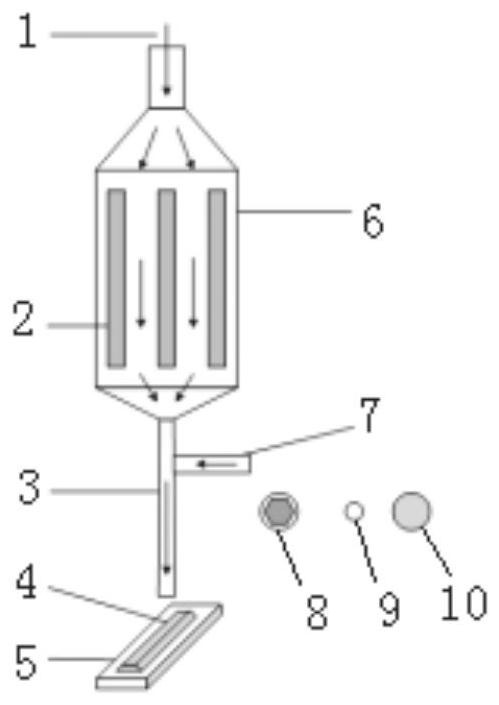

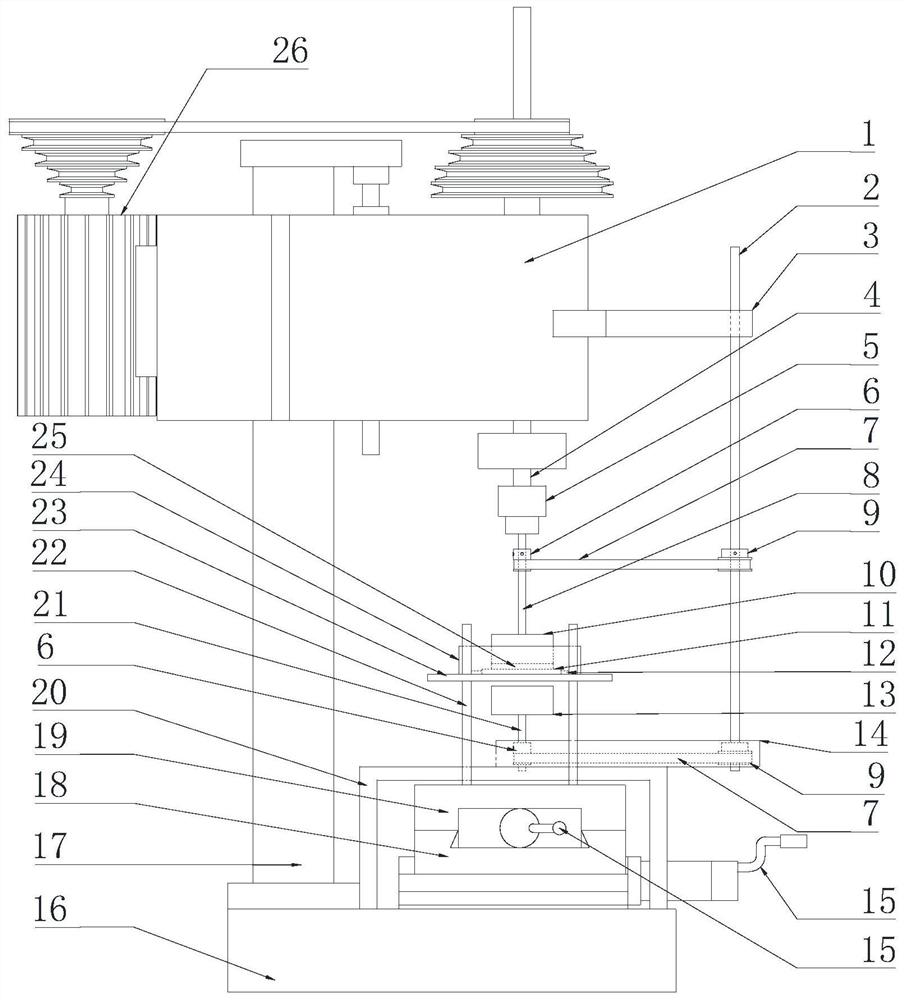

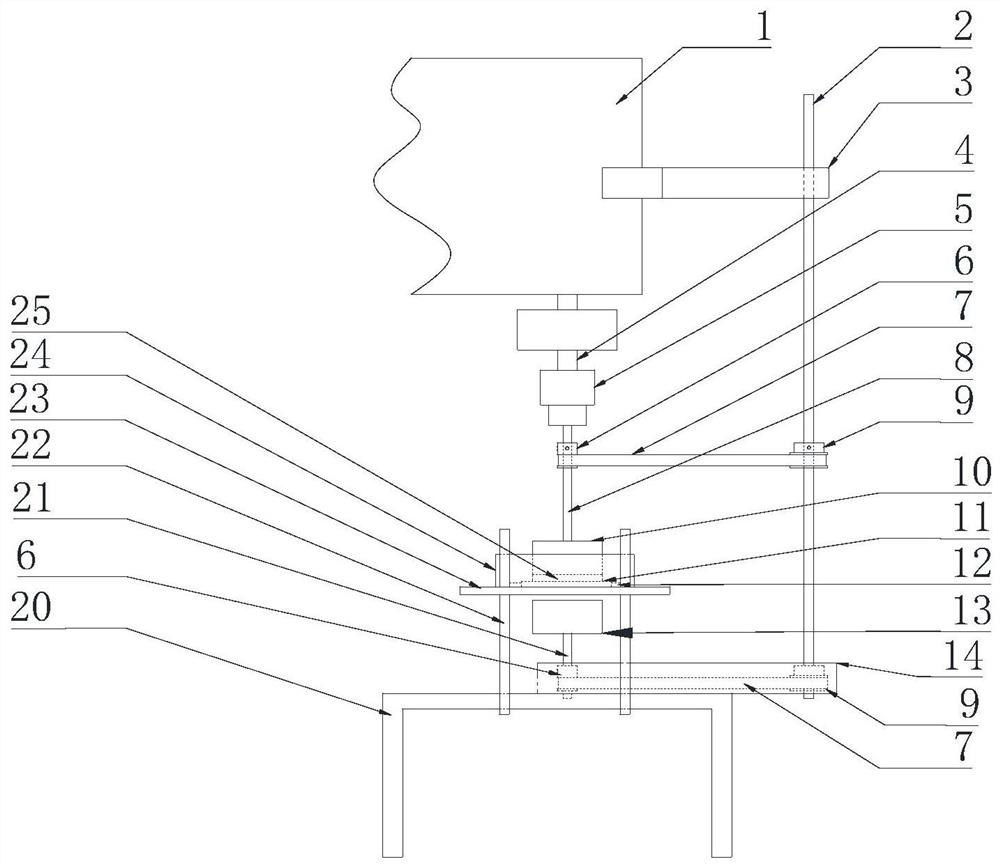

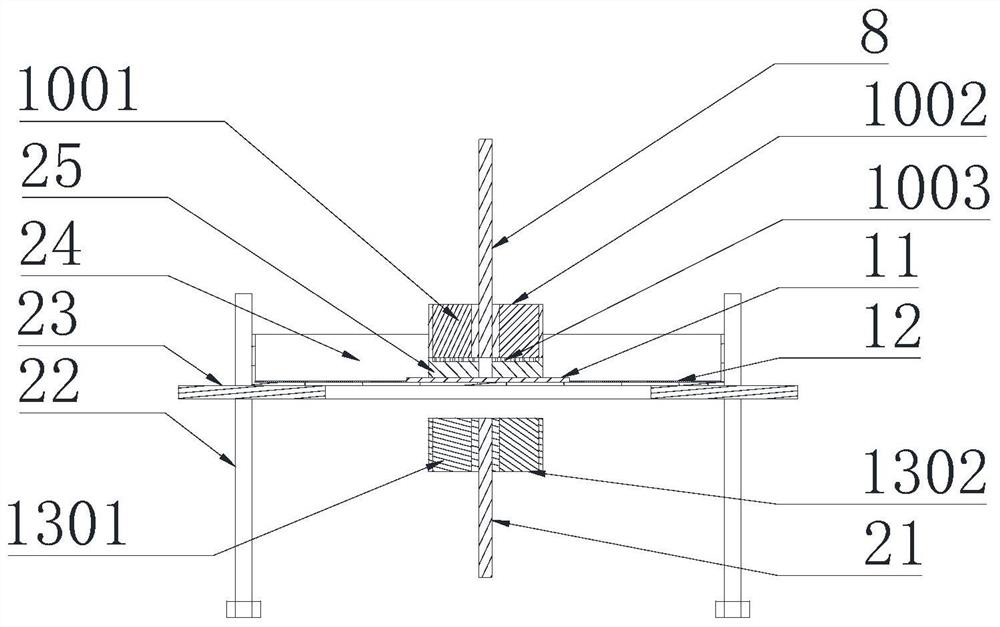

A permanent magnet type liquid magnetic abrasive surface finishing device and method

The invention discloses a permanent magnet type liquid magnetic grinding tool surface finishing machining device and method, and belongs to the field of precision finishing machining technologies andfree grinding tools. The permanent magnet type liquid magnetic grinding tool surface finishing machining device is characterized in that the device mainly comprises a liquid magnetic grinding tool, anupper magnetic pole head, a lower magnetic pole head, a mechanism, components, components for supporting and horizontal movement of a workpiece, and other auxiliary components used for achieving finishing machining, wherein the upper magnetic pole head and the lower magnetic pole head are oppositely arranged, the upper magnetic pole head and the lower magnetic pole head synchronously rotate at the high speed with the same angular speed through the mechanism and the components, and the solid-like state is formed in the liquid magnetic grinding tool under the action of the magnetic field generated by the magnetic pole heads. The permanent magnet type liquid magnetic grinding tool surface finishing machining device and method solve the problems that during metal plate workpiece polishing andgrinding through the traditional technology, workpiece deformation, edge collapsing, cutter adhering and cutter breakage happen, and meanwhile the problems that when an existing magnetorheological fluid polishing technology polishes the workpiece, the energy of the magnetic field is not sufficiently utilized, the machining performance is poor, and the machining cost is high are solved; and the advantages that the machining precision and efficiency are high, a machining affected layer does not exist, adjusting is convenient, the technology is simple, and cost is low are achieved.

Owner:TAIYUAN UNIV OF TECH

A Lithium Electric Chainsaw Containing a Conjugated Backbow for Self-Sharpening the Saw Blade

ActiveCN104206194BEasy to operate in batchesStrong penetrating powerCuttersCutting implementsLithiumEngineering

A lithium electric chainsaw with a conjugated bow back for self-sharpening saw blades, including the bow back edge chain saw blade (129), which is a bow back edge chain saw blade with back-to-back conjugate sharpening blades facing outwards, The blade surface of each piece of the curved back edge chain saw blade is first punched by the steel plate into two curved back sides with an included angle, and then sharpened to form a blade; and the curved back edge chain saw blade The outer contours of both sides of each steel plate are slightly equiangular spirals so as to make the cutting angle; the steel plates with slightly equiangular spiral outer contours of each piece of the curved back edge chain saw blade are blanked and Stamping and bending are two arched faces with an included angle, and then sharpened simultaneously to form a blade so as to make a sliding cut angle; The conjugate sharpening blades are sharpened outwards, and the sharpening surfaces are all parallel to the sawing surface when the chain saw blade rotates, so as to facilitate self-sharpening during operation.

Owner:NINGBO DAYE GARDEN EQUIP

A kind of fire-free decorative glazed surface of building exterior wall and preparation method thereof

Owner:HENAN POLYTECHNIC UNIV

Lithium battery pack

InactiveCN105826502AEasy to operate in batchesStrong penetrating powerSecondary cellsCell component detailsElectrical batteryLithium electrode

The invention provides a lithium battery pack .Twenty internally-arranged lithium ion batteries are connected with a lithium battery socket outside the lithium batteries through six cathode connecting plates of the lithium batteries and multi-connecting plates from a first anode connecting plate to an eleventh anode connecting plate of the lithium batteries to form the lithium battery pack which is arranged in order and is durable and reliable .A slot is formed in each press connecting contact of an internal connecting mechanism of the lithium battery pack, each slot is formed by connecting one straight slot with two symmetric arc-shaped slots to form two protrusions, and each protrusion is provided with two through holes to form the corresponding press connecting contact .The two protrusions of each press connecting contact of the lithium battery pack are slightly bent towards the inner side with the batteries by 1-15 degrees .Or the two protrusions of each press connecting contact are slightly bent towards the inner side with the batteries into an arc shape .Or the two protrusions are slightly bent towards the inner side with the batteries into the arc shape .Each arc is a section of a logarithmic spiral with the same pressure angle, and therefore the press connecting contacts are formed .The 20 cylindrical batteries contained in the lithium battery pack are arranged in parallel, the gap between one outer cylinder and another corresponding outer cylinder is at least 1 mm, so that heat dissipation is promoted .Copper skin of the lithium battery socket (126n) is beryllium bronze.

Owner:NINGBO DAYE GARDEN EQUIP

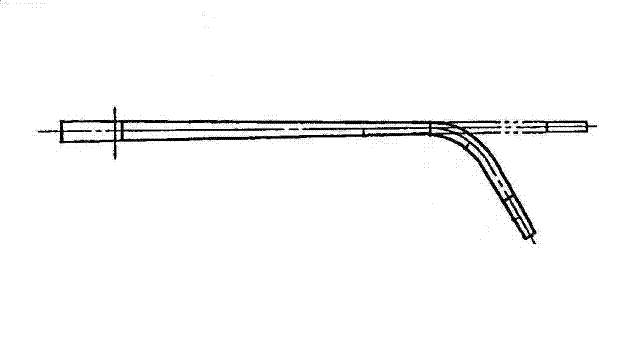

Lithium electric chain saw containing soft rope hard tube for continuation work

InactiveCN104115686AEasy to operate in batchesStrong penetrating powerCuttersCutting implementsLithiumEngineering

A lithium electric chain saw containing a soft rope hard tube for continuation work comprises a rope tube continuation rod (134a). The rope tube continuation rod comprises multiple sections of hard tubes (134) and a tensioning soft rope (134c). The multiple sections of hard tubes (134) are of a bamboo joint hollow cylinder shape and are threaded on the tensioning soft rope (134c) one by one just like a necklace in a fill-out mode so as to form a flexible rope tube continuation rod, so that the soft rope hard tube can be adopted to make continuation work to stretch further; the flexible rope tube continuation rod can be arranged in a disc which is made in a shape similar to the spiral mosquito-repellent incense, or be placed in a strip-shaped box shape, the continuation rod becomes hard when being pulled out and tightened in the distance work, the work radius is expanded, and the comprehensive characteristics of the lithium electric chain saw containing the soft rope hard tube for continuation work is self-evident.

Owner:NINGBO DAYE GARDEN EQUIP

Diamond grinding wheel for grinding and preparation method of diamond grinding wheel

InactiveCN108747853AHigh thermal conductivityReduce power lossAbrasion apparatusGrinding devicesMixed materialsMetal binding

The invention discloses a diamond grinding wheel for grinding and a preparation method of the diamond grinding wheel and relates to the field of ultra-hard abrasives. The grinding wheel comprises a steel core and an abrasive ring, and the steel core and the abrasive ring are combined through a resin binding agent and a resin glue adhesion agent; the abrasive ring is prepared from diamond abrasives, a metal binging agent and an auxiliary adhesion agent; the metal binding agent contains Cu powder and TiH2 powder; and the abrasive ring is composed of diamond abrasives, a metal binding agent and agap. The preparation method includes the steps that firstly, the diamond abrasives, the Cu powder and the TiH2 powder are mixed uniformly, and a mixed material A is obtained; secondly, the auxiliaryadhesion agent and the mixed material A are mixed uniformly, and a mixed material B is obtained; thirdly, the mixed material B is dried; fourthly, the mixed material B after being dried is subjected to sieving; fifthly, the mixed material B after being subjected to sieving is subjected to cold pressing forming; sixthly, abrasive ring green pressing is performed, and after sintering in the inert gas atmosphere, an abrasive ring green body is made; and seventhly, the resin glue adhesion agent is used for adhering the abrasive ring green body and the steel core, and the diamond grinding wheel forgrinding is obtained.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com