A permanent magnet type liquid magnetic abrasive surface finishing device and method

A liquid magnetic and finishing technology, which is applied in the field of precision finishing technology and free grinding tools, can solve the problems of workpiece deformation, sticking and chipping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

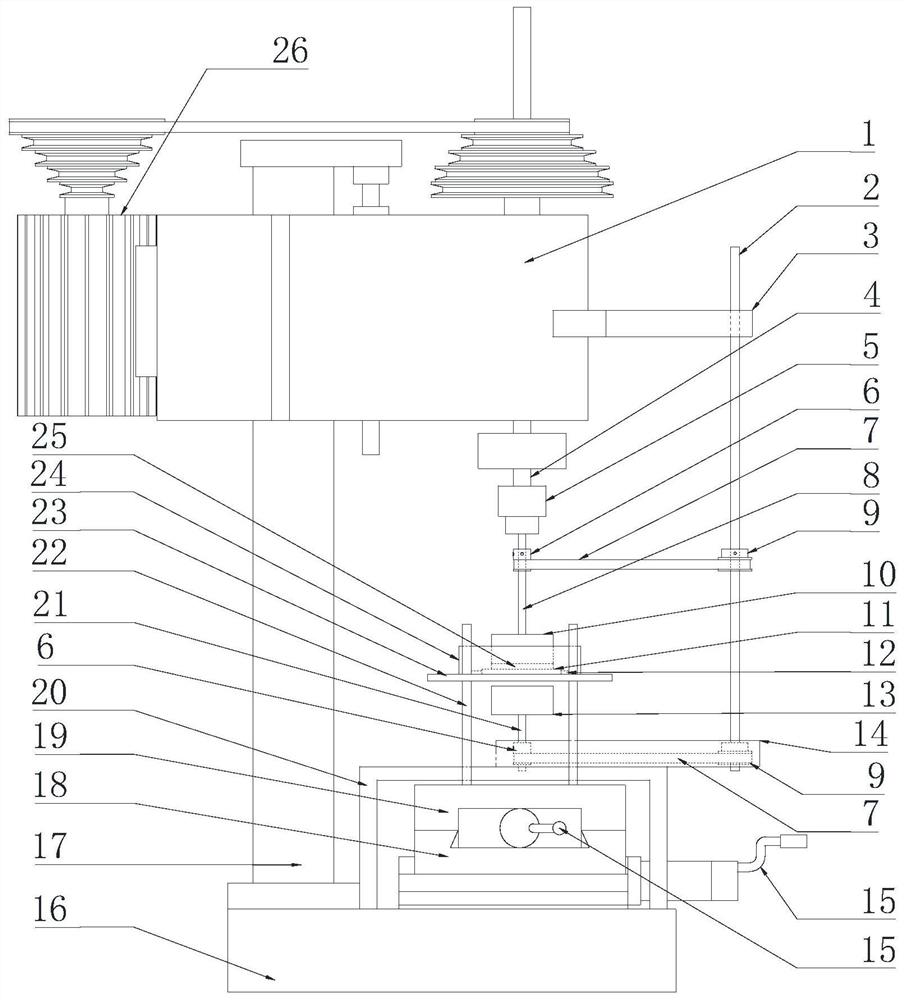

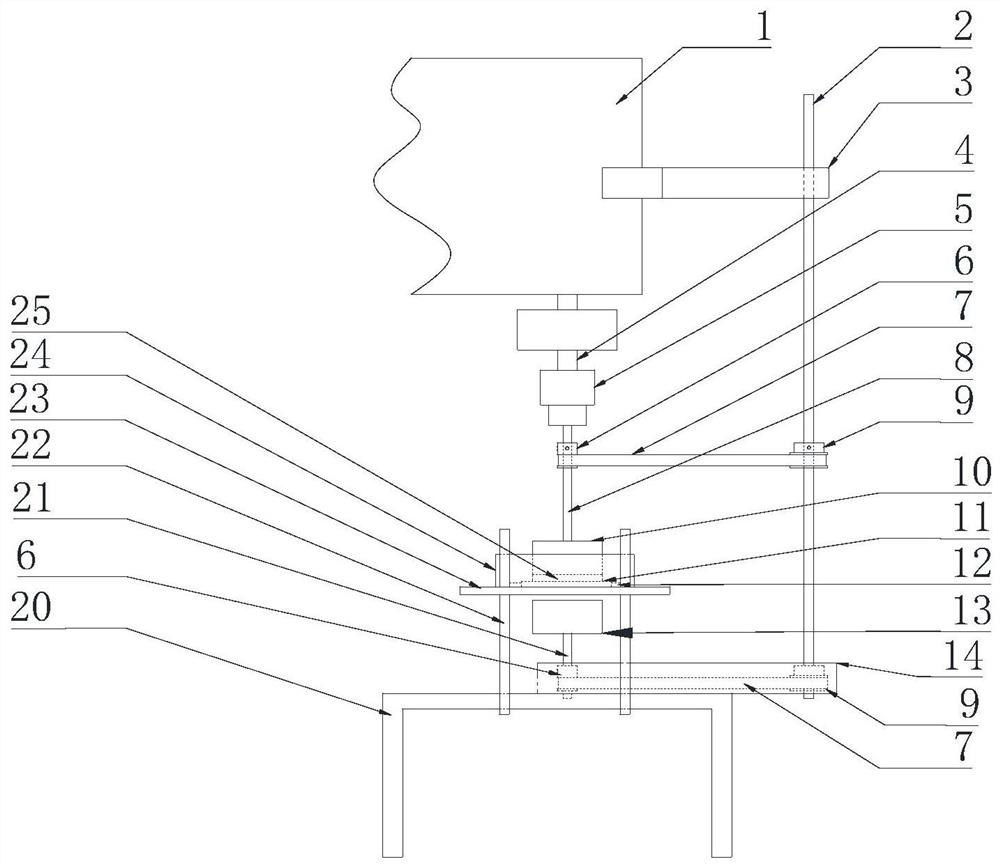

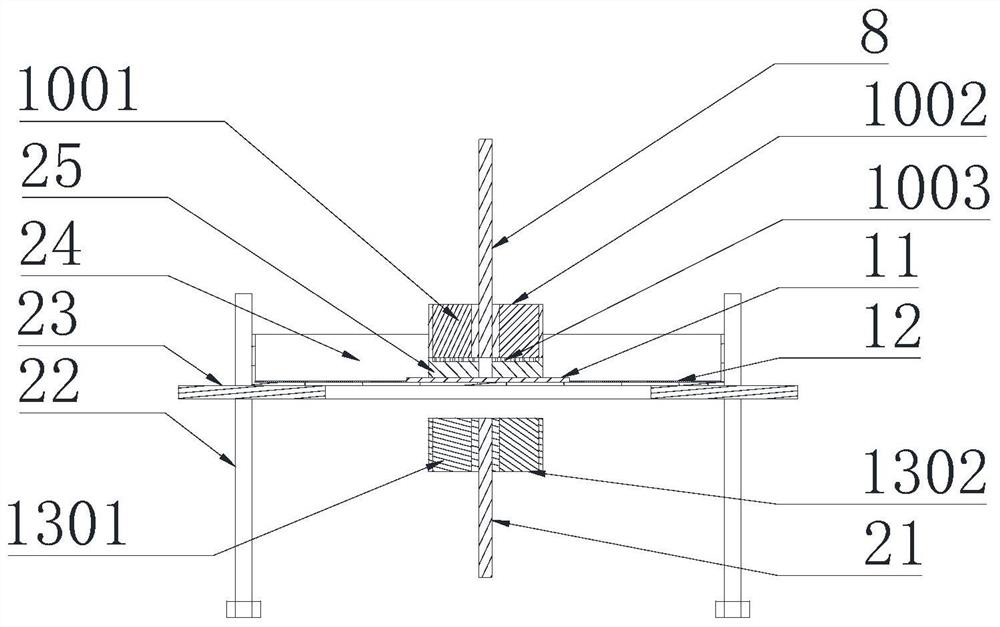

[0045] like figure 1 The present invention shown is based on the left view of the three-dimensional structure of the device of the ordinary drilling machine, including: headstock 1; moving shaft 2; transmission shaft positioning plate 3; main shaft 4; clamp 5; pulley I6; transmission belt 7; Ⅱ9; upper magnetic pole head 10; metal workpiece plate 11; workpiece fixing piece 12; lower magnetic pole head 13; rectangular aluminum alloy tube 14; sliding table handle 15; 19; fixed frame 20; magnetic pole head connecting rod II 21; supporting column 22; supporting plate 23; container 24; liquid magnetic grinding tool 25; motor 26. It is characterized in that: the front end of the machine tool spindle box 1 is fixedly connected with the rear end of the transmission shaft positioning plate 3, the upper part of the transmission shaft 2 is matched with the hole at the front end of the transmission shaft positioning plate 3 with a bearing, the middle part of the transmission shaft 2 is mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com