Preparation method of polyurethane matrix stone grinding and polishing disc

A technology of polishing sheet and polyurethane, applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems that the abrasive system is not suitable for stone grinding and polishing, the hardness and density of the matrix are not suitable for stone, and the stone grinding and polishing is not suitable , to achieve the best grinding and polishing effect, the best grinding force, and the effect of increasing the grinding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0073] This example provides a set of manufacturing methods for marble grinding and polishing sheets. According to the different particle sizes of the abrasives used, 1#, 2#, 3#, 4#, 5#, 6#, and 7# have rough grinding, fine grinding and polishing functions. Grinding combination.

[0074] (1) Prefabricated component A: polyether triol (average molecular weight 350, hydroxyl value 500) 100 grams, tertiary amine catalyst dimethylcyclohexylamine 3 grams, chain extender ethylene glycol 5 grams, foaming agent 1.5 grams of pentane and 5 grams of plasticizer fumed silica powder were mixed and stirred evenly for later use. In this example, 7 parts of the same component A are prefabricated, which are used to prepare 1-7# grinding plate sets.

[0075] (2) Prepare component B: measure 35 grams of 270-300 µm synthetic diamond abrasive grains and 15 grams of 30-35 µm silicon carbide fine powder as 1# abrasive; measure 35 grams of 125-150 µm artificial diamond abrasive grains and 30-35 µm s...

example 2

[0082] (1) Example 2 uses the same ingredients of A and B as in Example 1. The same prefabricated seven parts of components A and B respectively.

[0083] (2) Subtract the polyamide-modified high-density polyethylene wax powder and polypropylene fiber in component C of Example 1. Seven copies are also prefabricated.

[0084] (3) Use the same process and procedure as Example 1 to prepare 1-7# grinding and polishing sheet groups.

example 3

[0086] (1) Example 3 uses exactly the same ingredients of A and C components as in Example 1. A and C components are prefabricated one each.

[0087] (2) Component B of Example 3 only uses the same ingredients as the 7# abrasive in Component B of Example 1, that is, 35 grams of 1-3 μm synthetic diamond abrasive grains. Component B is prefabricated in one copy.

[0088] (3) Use the same process and procedure as Example 1 to prepare 7# polished sheet.

[0089] (4) The 7# grinding and polishing sheet prepared in Example 3 can be used as a polishing material with independent functions in the polishing process of stone grinding, so as to replace the existing commercially available polishing sheets and polishing powder.

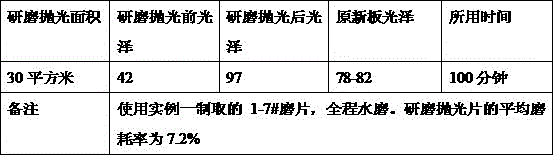

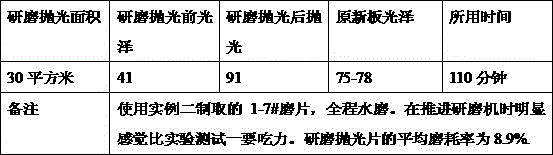

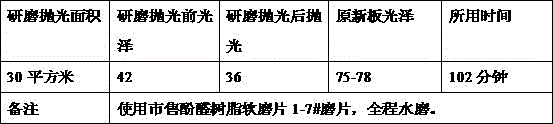

[0090] The following are the experimental test results and comparative test results of Example 1, Example 2 and Example 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com