Preparation technology of metal ceramic bonding agent diamond/ cubic boron nitride (CBN) grinding wheel

A ceramic bond and preparation technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as loss of function, long sintering time, metal oxidation, etc., and achieve simple preparation process and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

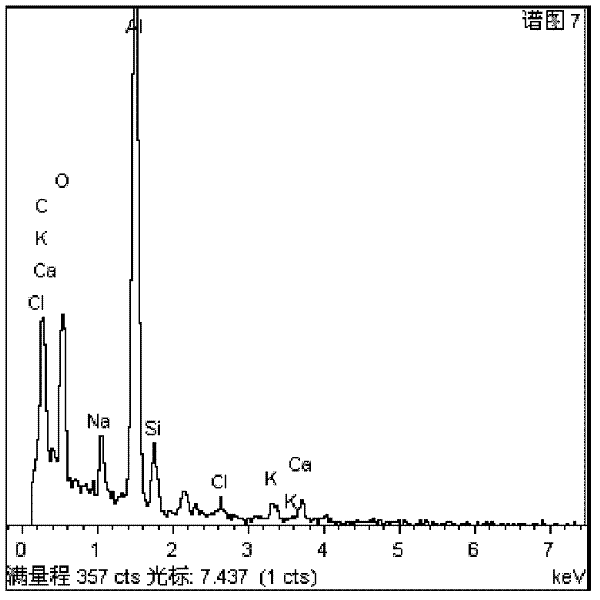

Image

Examples

Embodiment 1

[0018] The cermet bonded diamond CBN grinding wheel buried in sand was placed in a reducing atmosphere furnace. Check that the equipment is in good condition, the gas passage is unobstructed, and hydrogen gas is introduced. Set the heating curve: from room temperature to 300°C, the heating rate is 2°C / min; at 300°C for 1.5h; from 300°C to 750°C, the heating rate is 1.5°C / min; at 750°C for 2h; from 750°C Raise the temperature to 900°C with a heating rate of 1°C / min; hold at 900°C for 1.5h; then cool with the furnace.

Embodiment 2

[0020] The cermet bonded CBN grinding wheel buried in sand was placed in a reducing atmosphere furnace. Check that the equipment is in good condition, the gas passage is unobstructed, and hydrogen gas is introduced. Set the heating curve: from room temperature to 300°C, the heating rate is 2.2°C / min; at 300°C for 1.2h; from 300°C to 750°C, the heating rate is 1.8°C / min; at 750°C for 1.8h; from 750°C ℃ to 900℃, the heating rate is 1.2℃ / min; hold at 900℃ for 1.4h; cool with the furnace.

[0021] The formula of two embodiment emery wheels, mixing and cold pressing process are all the same:

[0022] Its formula and weight ratio are: CBN abrasive (100 / 120) 60%.

[0023] Metal ceramic bond 30%

[0024] Wetting agent and binder 5%

[0025] Auxiliary material (SIC or Al 2 o 3 ) 5%

[0026] The raw materials are mixed evenly, then cold-pressed, and finally sintered. After sintering, the matrix is matched, and then the product performance is tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com