Anti-blocking grinding tool and manufacturing method thereof

A manufacturing method and technology for abrasive tools, which are applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of difficulty in ensuring the shape of abrasives, complex preparation methods, and unsatisfactory effects, and achieve improved self-sharpening and reduced solvent consumption. , the effect of excellent chip removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Modification of abrasive powder: take 100g of micropowder (400# white corundum), 5g of surface modifier KH550 and 100g of pure water, add the micropowder, modifier and pure water to the glass for reaction under stirring at 65°C Still, add 10g of acetic acid, slowly stir and react at the same temperature for 6 hours, after the reaction, the solid obtained by filtering is washed twice with absolute ethanol and dried for later use;

[0041] (2) Add 40 g of the abrasive powder modified in step (1) to the adhesive, and fully disperse to eliminate air bubbles to obtain a slurry;

[0042] The components of the adhesive used are shown in Table 1:

[0043]

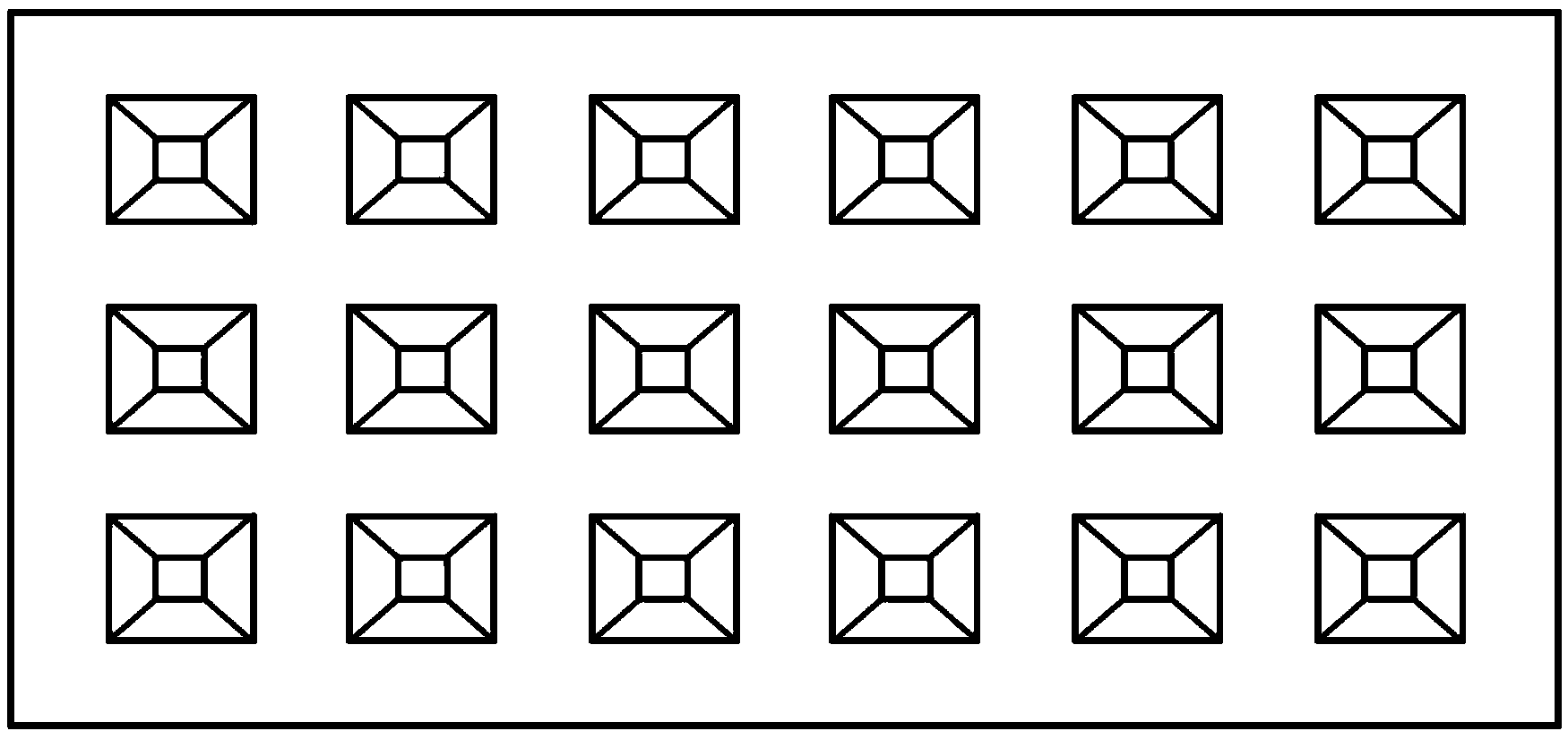

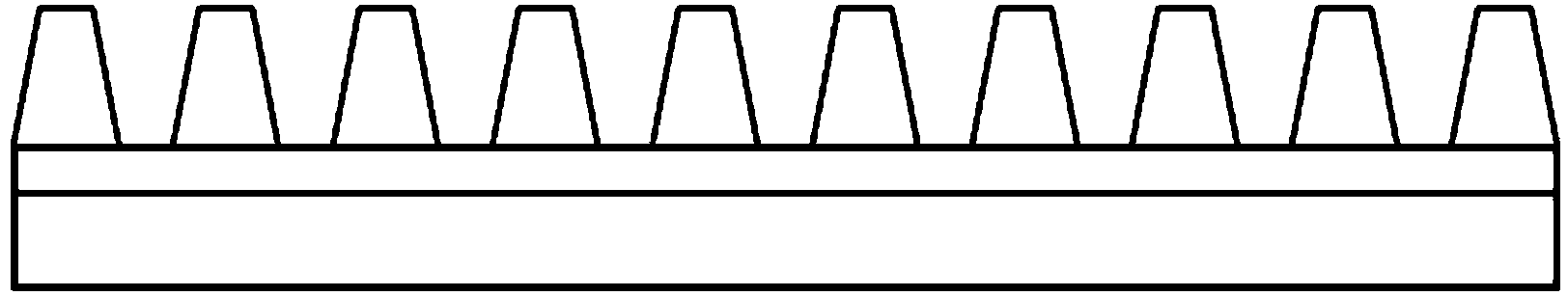

[0044] (3) The slurry that step (2) is obtained is coated on the template that has mold cavity on the surface (the shape of the mold cavity on the template: the inverted conical structure that truncated the top, size: upper surface size: 0.03mm*0.03 mm, the size of the lower surface: 0.45mm*0.45mm, the height of the ...

Embodiment 2

[0053] The used components of the adhesive of step (2) are as shown in table 3:

[0054] table 3

[0055]

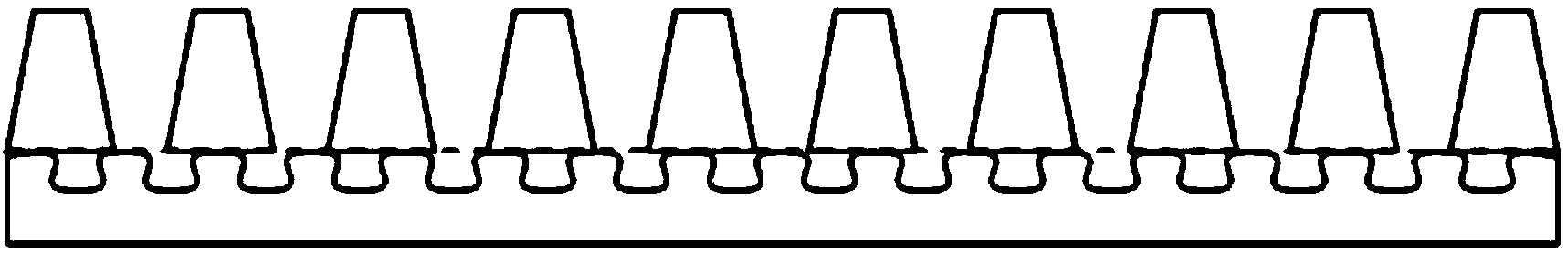

[0056] (3) Apply the slurry obtained in step (2) to a template with a cavity on the surface (template size: cube structure, upper surface size: 0.45mm*0.45mm, lower surface size: 0.45mm*0.45mm, tower 0.45mm in height and 0.45mm in spacing) to form a slurry layer, then stick and press the pretreated substrate on the surface of the slurry layer, and then use ultraviolet light to cure for 24 hours and then release the mold to obtain a semi-finished product; The operation was the same as that in Example 1 to obtain a grinding tool with a cuboid structure protrusion. The continuous cutting force comparison diagram of the product with raised cuboid structure and the stepped product of embodiment 1 is as follows Figure 5 shown by Figure 5 It can be seen that under the same formula, the cutting force of the product is slightly different, which is related to the shape of ...

Embodiment 3

[0058] The used components of the adhesive of step (2) are as shown in table 4:

[0059] Table 4

[0060]

[0061] Other operations are identical with embodiment 1, and the result that obtains is as Figure 6 As shown, the results indicate that the cutting force decreased due to the change of the composition, and the durability was also reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com